Okay, so I built my first .50 Beowulf rifle in 2018, spent a lot of time planning out the recoil mitigation and documented the adventure – click here for the post. At any rate, I sold it to move on to fund other projects but ran into a problem – I missed the ‘Wulf. There are some bragging rights when you say you have a .50 caliber rifle even when you explain it’s not the .50 BMG round. So, I decided to build another one and make it pretty unique. It’s the Alpha, or the dominant Wulf in my mind.

The first thing I want to point out to folks is that the 12.7x42mm is the generic designation of the .50 Beowulf round and is mainly used by firms who don’t want to get into intellectual property issues with Alexander Arms (AA). If you look on Gun Broker and do some searching with Google you will turn up tons of listings for complete 12.7x42mm uppers starting just over $300. … Let me put this delicately – I would recommend that you avoid them. You will get what you pay for either in terms of performance out of the box or over time. If you do some searching you will read that I wasn’t the only buyer who had issues with Radical Arms uppers for example because of the wrong bolt being used.

If you do buy a cheap 12.7×42 upper, I’d recommend you test it right away before the warranty expires. I’m sorry – I just don’t have much faith in them.

Started With an AA .50 Beowulf DIY Upper

This time around, I decided to use an actual Alexander Arms (AA) upper and not screw around with cheap stuff. The only problem was that I wasn’t really sold on the handguards of their complete units. That and the prices were a turn off the last time. As I looked down the AA page, I saw they now sell a “.50 Beowulf Upper Kit DIY” that had everything except for the barrel nut, handguard and brake of your choice. They have both 12″ and 16″ barrel versions of the kit. As much fun as a 12″ howitzer would be, that didn’t interest me as much as building a new rifle using a 16″ barrel.

To sum up the AA upper, they make this build real easy. For me, building an AR is like building with Lego parts from different kits to make something unique, which was exactly my plan with this new ‘Wulf. Next, I am going to skip the upper for a minute and tell you what I in terms of the lower receiver. Why? Well, I’m a creature of habit and always build the lower first and then the upper.

An Overview of The Lower and Parts Used

I thought about using an existing AR lower from another rifle but I decided to build one from scratch. In case you didn’t know it, a Beowulf upper is actually designed to work with any 5.56 AR lower without any modifications being needed to the lower itself – same trigger, buffer, etc. The magazines are slightly modified but we’ll return to that later. So here are the parts details for the lower assembly:

- I bought a stripped Spike’s Tactical lower with a cool Crusader cross logo on it from my FFL and friend, Scott Igert at Michigan Gun Exchange / Modern Antique Firearms. It’s a quality 7075 T6 forging, has a Mil-spec hard coat and a cool enlarged trigger guard is integral with the design – no need to add one like you do with many stripped lowers.

- CMC Triggers AR-15 Lower Assembly Kit without Fire Control Group or Grip. Definitely solid mil-spec parts. Beware of cheap stuff that isn’t dimensionally correct or doesn’t last. I used to get the extended bolt release and takedown pins and ambidextrous safeties but I just didn’t find them necessary as I was so used to the originals.

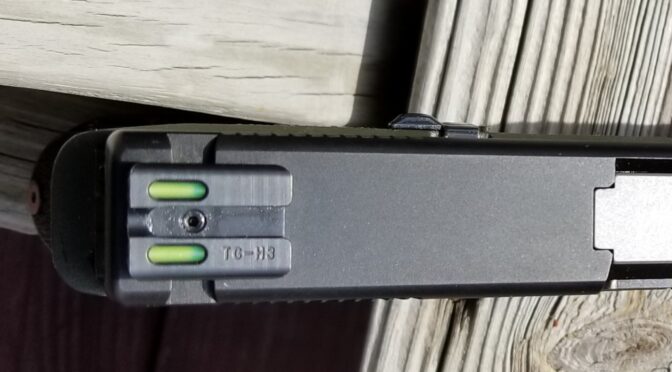

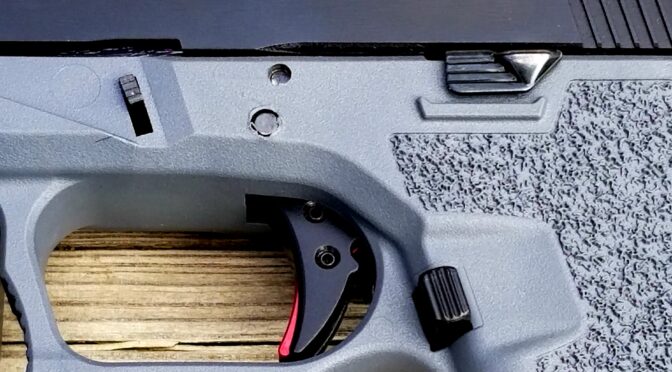

- Geissele SSA-E trigger – these triggers and the CMC trigger modules are my favorites. I used the Geissele because it probably just nudges out CMC just a bit to be my #1 favorite AR trigger plus I had one on hand. These triggers can be hard to find as they are popular. Check out the sources listed at the bottom of the post.

- Brownell’s rifle length buffer tube – these are solid and I’ve never had a problem with them. Note, they do sell a kit with the tube, spring and buffer but I had the tube in stock.

- Anderson rifle length buffer spring – just a good generic spring that I picked up from Primary Arms.

- Rifle length buffer for fixed stock 5.56 rifles

- Magpul PRS Gen 3 stock – this new version of the PRS stock is stunningly cool. I’ve used every generation now and this is definitely the best. I’ll write up more later but this is the reason I went with the rifle length buffer system – the interesting thing is that the PRS III can work with a carbine buffer system as well! That was news to me. PSA tends to have them in stock.

- Ergo Tactical Deluxe Grip With Palm Shelf – While it may have a hokey product name this is my favorite grip for precision rifles. I couldn’t decide whether to install this or a Magpul grip but since I am running with a precision theme, I decided to use this Ergo model.

Building the Lower

A Beowulf uses a standard lower so there really isn’t anything special that you must do. Thus, I’m not going to do a complete part by part instruction just for this rifle. Here’s a write up I did a while ago while building an AR pistol, which is pretty similar other than the use of a brace with a pistol vs. a stock with a rifle:

- Magazine Catch Assembly

- Trigger Guard Assembly

- Bolt Catch Assembly

- Pivot Pin Assembly

- Trigger Assembly

- Hammer Assembly

- Selector Assembly

- Pistol Grip, Selector Spring and Detent

- Buffer Tube and Arm Brace — An AR rifle will have either a carbine buffer tube, carbine buffer and M4-style stock or a rifle buffer tube, buffer and fixed stock. A pistol is similar but can differ depending on the brace you use. The new SBA3 and SBA4 come with Mil-Spec carbine receiver extensions (buffer tubes) so they are just like a carbine right up until either the brace or stock is installed.

I always found having multiple perspectives to draw on can help. Here are two excellent written resources for you if you are new to building lowers:

- The first is the one curated by the folks over at AR15.com. Click here to open that page in a new tab.

- The second is a USMC TM 05538/10012-IN Which is the repair manual for the M16A2, M16A4, M4 and M4A1 that was published in 2008. Click here to load a PDF copy we host in a new tab.

If you would like to see videos of the AR build process, Brownells also has a ton of training videos online that cover building the AR-15 overall. If you click here, you can then select whatever videos you want to watch.

Closing This First Post

Okay, so you have an idea of the Alexander Arms DIY .50 Beowulf Upper upper I bought and the lower parts plus assembly. In the next post, I’m going to give you some tips/observations that I had when assembling my lower. I’ll add a link to the new post here as soon as it is complete.

Note, I have to buy all of my parts – nothing here was paid for by sponsors, etc. I do make a small amount if you click on an ad and buy something but that is it. You’re getting my real opinion on stuff.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, we are only paid if there is an affiliate program such as Avantlink, Impact, Amazon and eBay and only if you purchase something. If you’d like to directly contribute towards our continued reporting, please visit our funding page.