Well, I bought SCT17 frames to move my Polymer80 builds over to so they could have serial numbers and be tracked. The SCT 17 frames are nicely designed and molded so kudos there. I bought assembled/populated frames and wished I hadn’t. I have always changed the mag lock, slide stop and slide lock controls on a Glock because they are too small for me. The SCT triggers were pretty crude too – I did not like the feel of the shoe or the pull so I did some reading and changed the components out.

Now, my original plan was to simply move the internals of my Polymer80s to the SCT frames. The problem I was running into was that none of my triggers just moved over – the slide was hanging up big time. I’m not a Glock guru and I read some about bending the cruciform at the back and finally decided screw it – I’d just buy new triggers.

I did some digging and guys reported the Overwatch Drop-In Poly-DAT triggers did just that – they went right in with no tweaking. Huh? Basically they designed an affordable trigger that should fit most Glocks based on their experience. It cuts pre-travel by about 20%, had their NP3 treated their Minus connector, and their exra power return spring but with an OEM trigger housing.

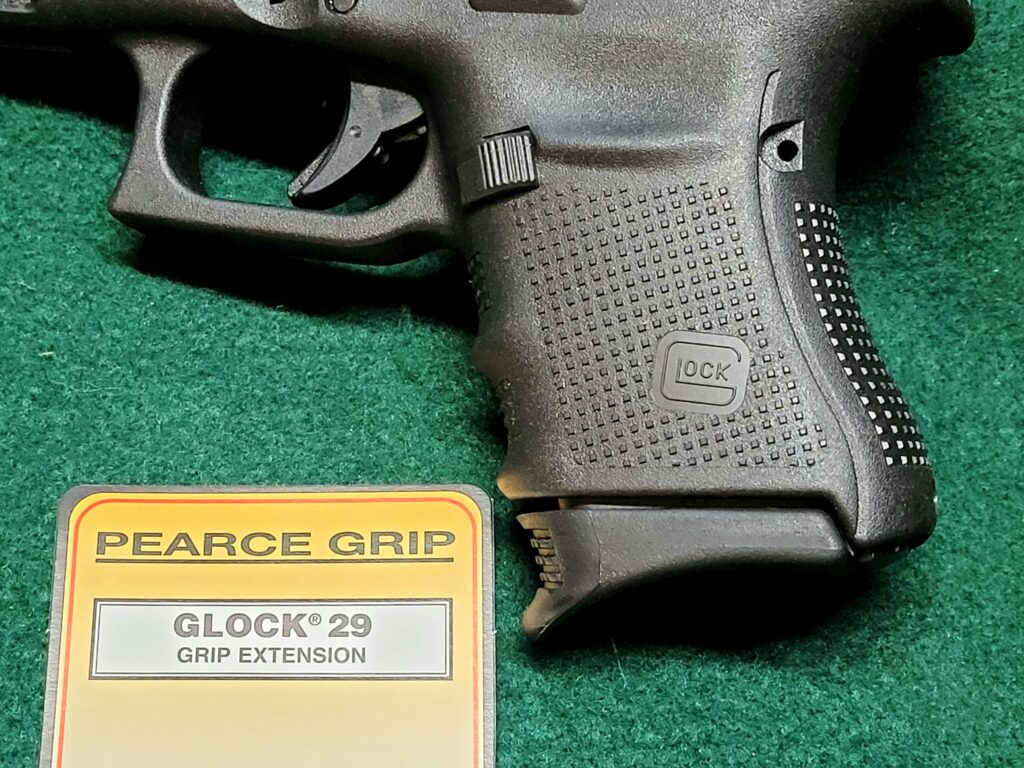

Okay, it was just before Christmas and I scored three of the Overwatch Precision Drop In PolyDAT triggers for $79.99/ea. I also picked up new Vickers Tactical Slide Stops for $21.56 and decided to also get new Strike Industries pins for $9.99 fom Primary Arms. My slide stops and pins were pretty beat up and I figured I’d go with new ones.

For the extended mag catches, I did just move the Vickers units over from the Polymer80s to the SCT17s.

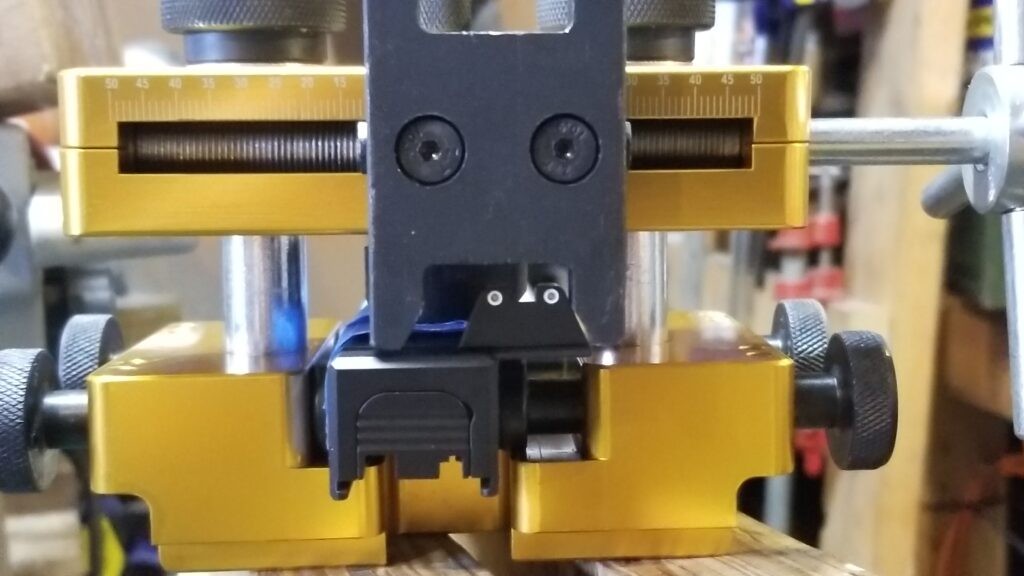

Pics or it didn’t happen

Trigger Results

Average trigger pull weights for each pistol were 3# 11.7 oz, 3# 13.7oz and 4# 8.5oz. The triggers were lubricated and tested maybe 10-20 times each max. Pull testing was done using five sample pulls from each with care taken to postion the Wheeler digital gauge in the same place each time. The pistols were on a bench also to try and aid consistency.

Overall, the they feel much, much better with the Overwatch triggers – less travel and not gritty. I’d give them a 7 out of 10 and have no hesitation recommending them to someone looking for a very cost effective trigger improvement. If you have an SCT17 and want something that literally drops in – try this. I had to do zero tuning and would do it again.

Summary

I’m happy with the results. I need to get them to the range but they all function test fine.

I hope this helps you out.

Note, I have to buy all of my parts – nothing here was paid for by sponsors, etc. I do make a small amount if you click on an ad and buy something but that is it. You’re getting my real opinion on stuff.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, I may be paid via an affiliate program such as Avantlink, Impact, Amazon and eBay.