In the last post, I told you I bought an HK SP5K. It’s relatively heavy and begging for a brace. I don’t really feel the need to spend the money and wait to register it to be a Short Barreled Rifle (SBR) and there are actually a ton of arm brace options out there.

Option 1: The SBT5KA Brace

I have a SB Tactical SBT5A Brace on my POF-5 and really like it. I knew they made a version for the SP5K known as the SBT5KA but I was hoping for something different. Please note they are two different models of braces reflecting the different receiver end caps.

Option 2: The SOB Brace

Every time I write this product name – the “SOB” – down, I smile. SB Tactical has a ton of braces for the AR/M4 weapons family and they have evolved a ton away from the ugly original. The SOB has clean lines and I run one on my PTR PDWR. I think it looks good and has handled the .308 rounds from the PDWR just fine and feels solid too.

Option 3: The SBPDW

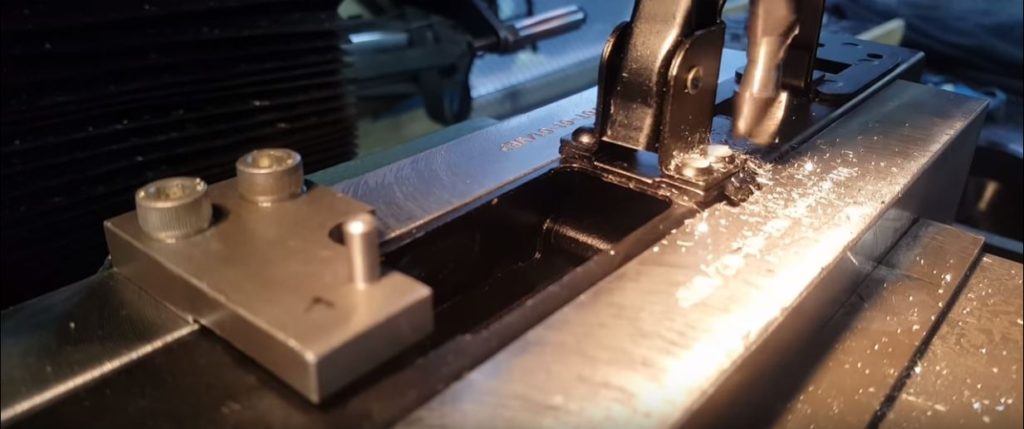

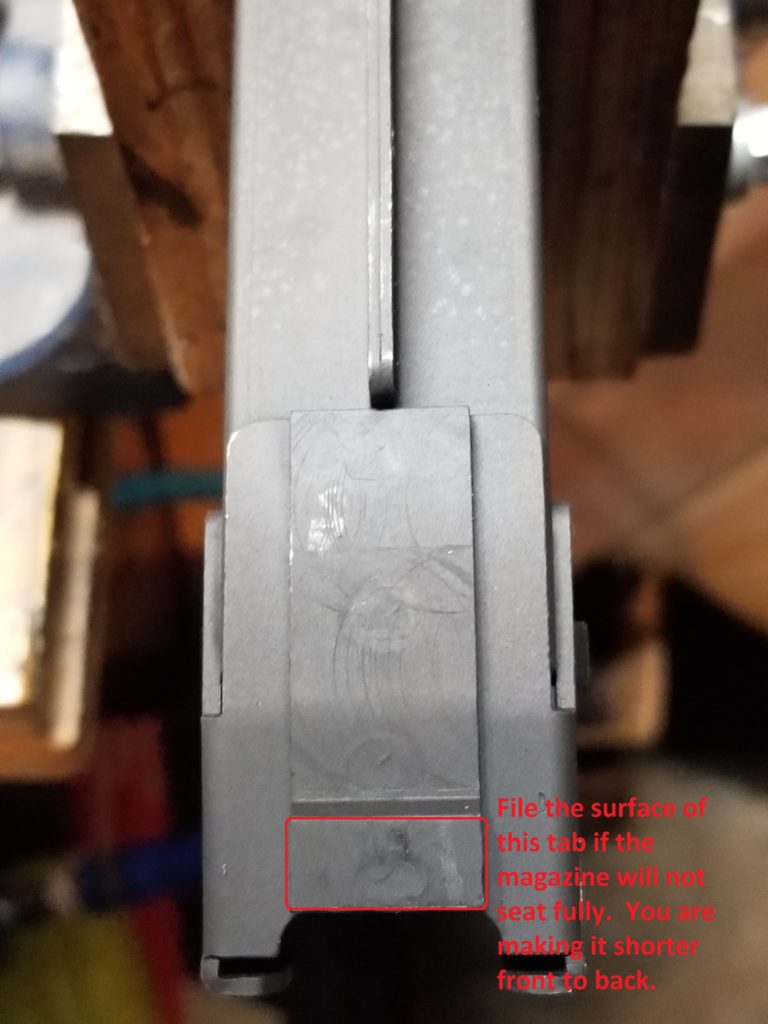

I thought I had found just what I wanted with the SBPDW – a collapsing stock that looked really slick and it would be easy enough to add an M4 adapter to the SP5K. So, I ordered a very well made adapter and the expensive SBPDW stock and guess what? It would not fit.

Needless to say, I was bummed. I had it completely installed only to find out that the guide rods on the SBPDW run right into the sides of the SP5K. Crud. I didn’t feel like figuring out all the changes that would be needed.

The Winner? The SBT5KA

Installation was a breeze. Pull out the two small pins at the back, swap the old end-cap for the brace, push them together and reinsert the pins. I did make sure the recoil rod lined up and nothing was binding as I reassembled the unit.

I Did Clean and Lube The Internals

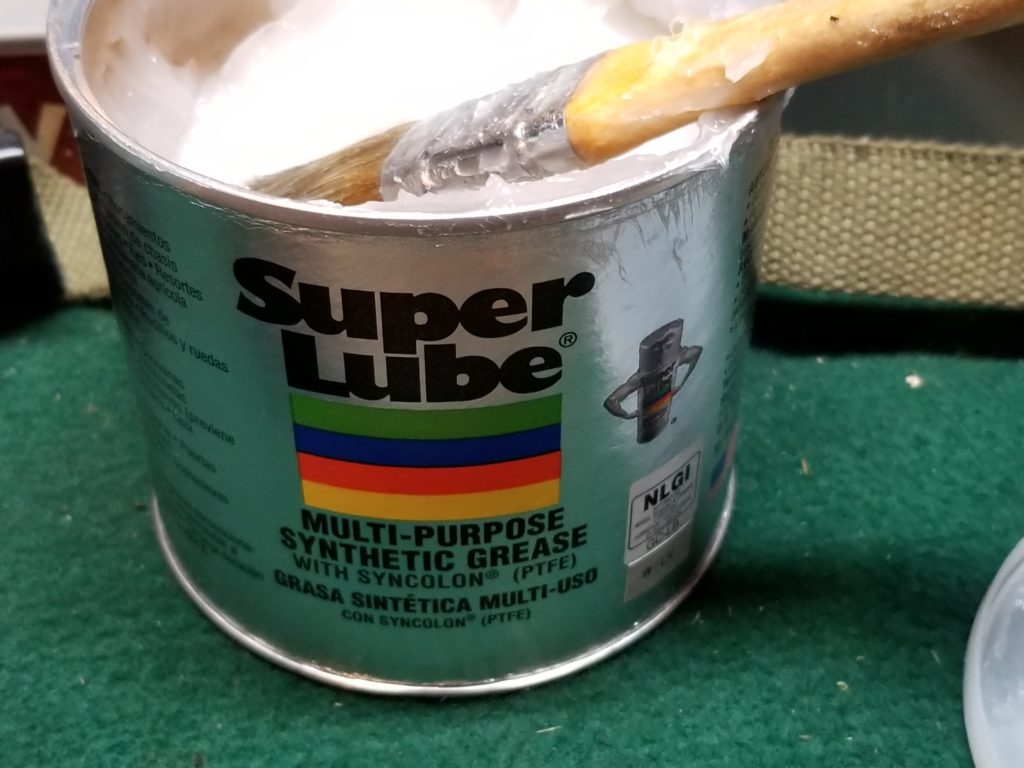

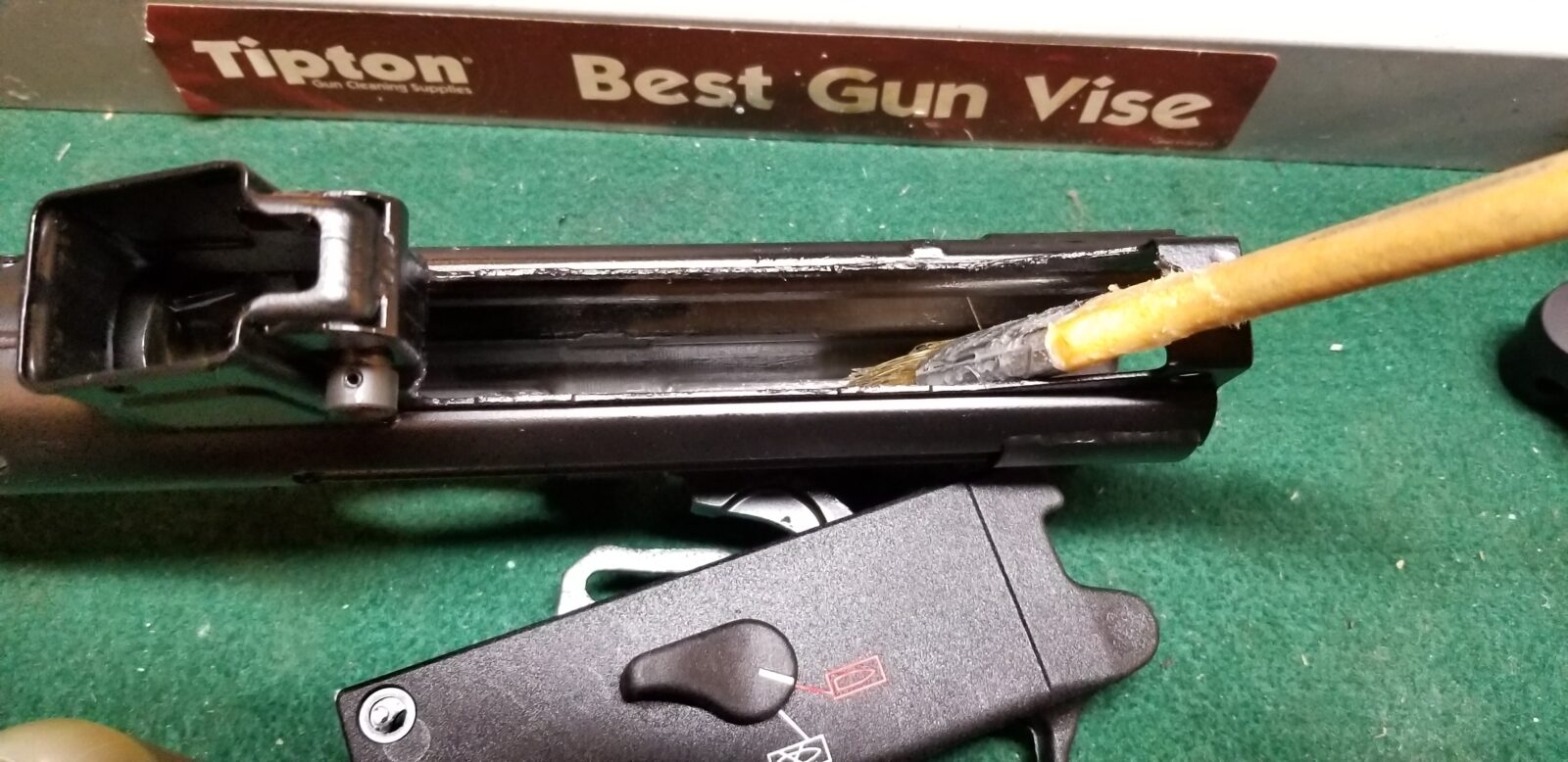

I should point out that when I removed the end cap, I went ahead and slid out the bolt group and lubricated everything. I applied Super Lube grease to the bolt body and Mobil 1 Synthetic 10w30 via a precision oiler to the rollers of the bolt and rotating surfaces. I also oiled the pins on the trigger pack while greasing the hammer face with Super Lube.

Summary

So you see I went with the SBT5KA brace. In the next post I will discuss handguards.

Note, I have to buy all of my parts – nothing here was paid for by sponsors, etc. I do make a small amount if you click on an ad and buy something but that is it. You’re getting my real opinion on stuff.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, we are only paid if there is an affiliate program such as Avantlink, Impact, Amazon and eBay and only if you purchase something. If you’d like to directly contribute towards our continued reporting, please visit our funding page.