The barrel of the Avtomat Kalashnikova model 1947, or AK-47, was not conceived in an engineering vacuum. It was forged from the brutal lessons of the Second World War and shaped by the specific demands of a new Soviet military doctrine. To comprehend its design, one must first understand the strategic and tactical environment it was built to dominate.

1.1 The Lessons of the Eastern Front and the Rise of Mechanized Doctrine

The Soviet experience on the Eastern Front from 1941 to 1945 was a crucible that tested men, machines, and military theory on an unprecedented scale. The conflict starkly revealed the limitations of the Red Army’s existing small arms inventory when faced with the fluid, high-intensity combat of modern mechanized warfare. The standard-issue Mosin-Nagant bolt-action rifle, a design from the 19th century, was reliable and powerful but possessed a slow rate of fire wholly unsuited for the rapid, close-quarters engagements that characterized battles in ruined cities and forested terrain. Conversely, the widely issued PPSh-41 submachine gun offered a high volume of fire but was chambered for a pistol cartridge (7.62x25mm Tokarev) that lacked the range and penetration needed for engagements beyond 100-200 meters.

Soviet planners observed with great interest the German deployment of the Sturmgewehr 44 (StG 44), a weapon that represented a new paradigm in infantry firepower. The StG 44 fired a 7.92x33mm Kurz “intermediate” cartridge, which provided a soldier with a select-fire weapon controllable in full-automatic fire yet effective out to 300-400 meters—the vast majority of infantry engagement distances. This single weapon could fulfill the roles previously divided between the bolt-action rifle and the submachine gun.

In the post-war era, Soviet military doctrine evolved to emphasize “deep battle” principles: mobility, high rates of combat operations, concentration of main efforts, and continuous, unrelenting pressure on the enemy regardless of weather or terrain. This doctrine envisioned massive mechanized infantry formations, supported by tanks and artillery, advancing rapidly to shatter enemy defenses. The individual soldier, often a conscript with limited training, needed a weapon that was fundamentally simple, supremely reliable, and compact enough for deployment from within the confines of an armored personnel carrier like the BTR or BMP. The requirement was not for a precision marksman’s rifle but for a durable, mass-producible tool of suppressive fire that would function flawlessly in the mud of a European spring, the dust of a Central Asian summer, and the frozen depths of a Russian winter.

1.2 The Ballistic Foundation: The 7.62x39mm M43 Cartridge

Before a rifle could be designed, its ammunition had to be perfected. In 1943, Soviet engineers N.M. Elizarov and B.V. Semin finalized the 7.62x39mm M43 cartridge, the ballistic heart of the future Kalashnikov system. This intermediate cartridge was the critical enabling technology that made the assault rifle concept viable for the Soviet Union. It generated manageable recoil for controllable automatic fire while providing significantly more energy and effective range than the submachine gun rounds it was destined to replace.

A key design feature of the M43 cartridge is its pronounced case taper. The case body narrows by approximately 0.047 inches from the base to the shoulder, a much more aggressive taper than seen in many Western designs. This was a deliberate engineering choice made to ensure flawless feeding from the magazine into the chamber and positive extraction of the spent casing after firing. In a weapon designed with generous clearances between moving parts, this tapered geometry minimizes the surface area contact between the cartridge and the chamber walls, drastically reducing the likelihood of a jam caused by dirt, carbon fouling, or lacquer buildup from steel cases. This reliability-focused design choice directly dictated the iconic curved shape of the AK-47’s magazine, which is necessary to accommodate the stack of tapered cartridges.

The projectile itself was also a product of wartime pragmatism and doctrinal requirements. The original Soviet M43 bullet is a 122 to 123-grain boat-tail design. Its construction features a mild steel core, a thin layer of lead between the core and the jacket, and a copper-plated steel jacket (often referred to as a “bi-metal” jacket). This composition was not only economical for mass production but also provided excellent penetration capabilities against the types of light cover expected on the battlefield, such as dense foliage, wooden structures, and the sheet metal of vehicles. The bullet was designed for stability and penetration, with terminal ballistic effects relying on the projectile’s tendency to yaw (tumble) in tissue rather than fragmenting.

The operational demands of Soviet military doctrine were the primary force shaping the AK-47 barrel’s design. The doctrinal emphasis on continuous “combat activeness” and high rates of advance necessitated a weapon capable of delivering sustained suppressive fire under the most grueling conditions imaginable. This requirement for relentless performance translated directly into a set of engineering challenges. High volumes of fire generate extreme heat and accelerate barrel wear. The standard-issue Soviet ammunition, with its corrosive primers, would aggressively attack unprotected steel. Therefore, the barrel’s design had to prioritize longevity, corrosion resistance, and functional reliability above all else, including the potential for match-grade accuracy. This philosophy led directly to the selection of a robust barrel profile for heat management and the critical decision to implement chrome-lining for wear and corrosion resistance, creating a weapon that was guaranteed to function when needed, which was considered far more important than its ability to produce the tightest possible shot group on a firing range.

Section 2: Prototyping and Trials: From the AK-46 to the AK-47

The final design of the AK-47 was not a singular stroke of genius but the result of an iterative and intensely competitive development process. The evolution from the early AK-46 prototype to the finalized AK-47 reveals a pragmatic approach to engineering, where theoretical performance was carefully weighed against the practical needs of the soldier and the realities of mass production. The barrel, in particular, underwent a critical design change during this period.

2.1 The AK-46 Prototype Barrel

Mikhail Kalashnikov’s initial design, the AK-46, shared a visual resemblance to the later AK-47 and was chambered in the same 7.62x39mm cartridge. However, it featured several key differences, including a separate safety and fire selector on the left side of the receiver and a non-reciprocating charging handle, also on the left. Critically, at least one of the AK-46 prototypes was built with a 450 mm barrel. This longer barrel, compared to the final production model, would have been an attempt to maximize the ballistic potential of the new M43 cartridge, likely providing a marginal increase in muzzle velocity and a slightly flatter trajectory, which could translate to a modest improvement in effective range.

2.2 Rationale for the 415 mm Final Barrel Length

During the 1947 trials, Kalashnikov’s team radically redesigned the weapon, leading to the AK-47 prototype. One of the most significant changes was the decision to shorten the barrel from 450 mm to the now-standard 415 mm (16.3 inches). This was not an arbitrary reduction but a calculated engineering compromise that optimized the rifle for its intended role.

- Ballistic Sufficiency: Extensive testing of the 7.62x39mm cartridge revealed that a 415 mm barrel was more than adequate to achieve the doctrinally required performance. It produced a muzzle velocity of approximately 715 m/s (2,350 ft/s), which provided a practical effective range of 300 to 400 meters. Ballistic data shows that intermediate cartridges like the 7.62x39mm gain progressively less velocity with each additional inch of barrel past a certain point. The small velocity increase offered by the extra 35 mm of the AK-46 barrel was deemed tactically insignificant, as the M43 projectile’s trajectory becomes quite pronounced beyond 300 meters anyway, making precise long-range shots difficult regardless of a minor velocity boost.

- Maneuverability and Handling: The primary user of the new rifle was envisioned as a mechanized infantryman who would need to fight in and around vehicles. A shorter, more compact weapon is vastly superior in such environments. The 35 mm reduction in barrel length, combined with other design changes, resulted in a handier, more maneuverable rifle that was less likely to snag on equipment or the confines of a vehicle hatch.

- Weight, Balance, and Material Economy: Shortening the barrel reduced the overall weight of the rifle, an important consideration for a soldier carrying their weapon and ammunition for extended periods. It also shifted the rifle’s center of balance rearward, making it feel less “front-heavy” and quicker to point. From a production standpoint, a shorter barrel requires less steel and less machining time, a non-trivial consideration when planning to manufacture millions of units.

- Gas System Optimization: The function of the AK-47’s famously reliable long-stroke gas piston system is critically dependent on the barrel length. The distance the bullet travels past the gas port before exiting the muzzle is known as “dwell time.” This period determines how long and with what pressure curve the expanding propellant gases act upon the piston to cycle the action. The 415 mm length, with the gas port located at its specific position, was carefully tuned to provide the perfect amount of gas impulse—enough to cycle the heavy bolt carrier assembly with authority under all conditions, but not so much as to cause violent, premature unlocking or excessive wear on the components.

The choice to shorten the barrel from the AK-46 prototype to the final AK-47 design is a clear illustration of the Soviet philosophy of “sufficient optimization.” The designers recognized the point of diminishing returns where a marginal gain in one area (ballistics) came at the cost of significant penalties in others (handling, weight, cost). Instead of chasing the highest possible muzzle velocity, they engineered a barrel that delivered perfectly adequate performance for its intended combat role while maximizing the weapon’s practicality for the soldier who had to carry and fight with it. This pragmatic, system-level approach to design, prioritizing the user’s real-world needs over abstract performance metrics, is a hallmark of the Kalashnikov’s enduring success.

Section 3: Forging an Icon: Manufacturing the AK-47 Barrel (Type 1 to Type 3)

The production of the AK-47 barrel was a monumental industrial undertaking that leveraged state-of-the-art manufacturing techniques available to the Soviet Union in the post-war period. The combination of carefully selected materials and highly efficient production processes was key to creating a barrel that was not only effective but could be produced in the millions.

3.1 Materials Science: Soviet Ordnance Steel

While the exact GOST (Государственный стандарт, or State Standard) designation for the steel used in original AK-47 barrels is a closely guarded detail, analysis and comparison with contemporary standards allow for a well-supported characterization. The material was a high-quality chrome-molybdenum alloy steel, similar in its properties to the Western AISI 4140 and 4150 grades, which are still referred to as “ordnance steel” today. Modern American manufacturers of high-quality AK barrels frequently use 4150 Chrome-Moly Vanadium (CMV) steel, which offers excellent heat resistance and durability.

The Soviet GOST system for steel designation, such as GOST 1050-41, used a combination of numbers to indicate carbon content and Cyrillic letters to denote alloying elements like ‘X’ (Хром – Chromium) and ‘M’ (Молибден – Molybdenum). The alloy chosen for the AK-47 barrel would have been specified under a standard for high-quality structural steels, selected for its ability to provide a precise balance of properties. It needed sufficient hardness to resist the erosive wear of hot gases and bullet friction, but also crucial toughness and ductility to withstand the immense chamber pressures of the 7.62x39mm cartridge (up to 355.0 MPa or over 51,000 psi) without fracturing.

Following the primary manufacturing steps, the barrels underwent a critical heat treatment regimen. This process, likely involving heating the barrel to a specific austenitizing temperature followed by a controlled quench (rapid cooling in oil or water) and subsequent tempering (reheating to a lower temperature), was essential to refine the steel’s grain structure. This treatment relieved internal stresses induced by forging and machining, and achieved the final desired Rockwell hardness, ensuring the barrel was both wear-resistant and resilient.

3.2 The Manufacturing Process: A Revolution in Efficiency

The Soviet Union’s goal was to equip its massive army, necessitating a barrel production method that prioritized speed and consistency.

- Barrel Blank and Early Rifling Methods: Production began with a solid bar of ordnance steel, which was deep-hole drilled to form the initial bore. For the earliest prototypes, it is likely that traditional rifling methods were used. These could have included cut rifling, a slow process where a single hook-cutter scrapes out one groove at a time in multiple passes, or the slightly faster button rifling, where a super-hard tungsten carbide “button” is pushed or pulled through the bore to displace the steel and form the grooves in a single pass. While capable of producing accurate barrels, these methods were too slow and labor-intensive for the scale of production required.

- Adoption of Cold Hammer Forging (CHF): To meet production quotas, the Soviets adopted the highly efficient cold hammer forging process. This technology, first commercialized in Germany in the late 1930s, revolutionized barrel manufacturing. The process begins with a short, thick barrel blank with a smooth, oversized bore. A hardened steel mandrel, which is a precise reverse image of the desired rifling and chamber, is inserted into the bore. The blank and mandrel are then fed into a forging machine where multiple, powerful hammers (often four) strike the outside of the barrel thousands of times per minute. This intense hammering compresses the barrel steel down onto the mandrel, simultaneously forming the rifling, chamber, and final external contour, while also elongating the barrel to its final length.

The advantages of CHF for the AK-47 were immense:

- Speed and Throughput: CHF is the fastest known method for rifling a barrel, capable of producing a finished barrel in a matter of minutes, making it ideal for mass production.

- Enhanced Durability: The forging process is a form of cold working that realigns and densifies the grain structure of the steel. This work-hardening results in an extremely smooth and durable bore surface that is more resistant to heat erosion and mechanical wear, leading to a longer service life.

- Cost-Effectiveness and Consistency: Although the initial investment in a CHF machine is extremely high, the per-unit cost for large production runs is very low. The process yields barrels with highly consistent dimensions, which simplifies quality control and subsequent assembly steps.

3.3 The Chrome-Lining Imperative

Beginning with the introduction of the Type 2 AK-47 in 1951, all subsequent Soviet-produced AK barrels had their bore and chamber chrome-lined. This feature was not an enhancement for accuracy—in fact, imperfect application can degrade it—but a non-negotiable requirement for reliability and longevity in the field.

- Corrosion Resistance: The primary driver for chrome-lining was the universal use of Berdan-primed, corrosively-charged ammunition in the Warsaw Pact. The residue from these primers contains potassium chloride salts, which are hygroscopic (they attract water from the atmosphere) and cause extremely rapid and destructive rusting (pitting) of bare steel. For a conscript soldier in harsh field conditions, who might not have the opportunity or supplies to clean their rifle for days, this corrosion could quickly render a weapon inoperable. The hard, inert, non-porous layer of electroplated chromium provided a robust barrier, protecting the steel from these corrosive salts and ensuring the rifle would function. This feature was a literal life-saver, a lesson the U.S. military would later learn the hard way with early M16s in Vietnam.

- Extended Barrel Life: Hard chrome is significantly harder than the barrel steel itself, with a hardness of around 67 on the Rockwell C scale compared to the 20-30 HRC of the underlying steel. This incredibly hard surface drastically reduces friction and wear from the thousands of bullets passing through the bore, especially under the intense heat and pressure of sustained automatic fire. The result is a barrel that maintains its integrity and acceptable accuracy for a much higher round count, extending its service life by thousands of rounds.

The combination of cold hammer forging and chrome-lining was a masterstroke of industrial military engineering. The CHF process produced a barrel with a very smooth, uniform, and work-hardened surface. This consistency was the ideal foundation for the electroplating process, allowing for a uniform and well-adhered layer of chrome. A bore with imperfections from a lesser manufacturing process would result in uneven plating, which could easily flake off under fire and ruin the barrel. Thus, one advanced technology enabled and perfected the other, creating a barrel that was perfectly suited to Soviet needs: cheap to make in the millions, virtually impervious to neglect and corrosive ammunition, and durable enough to withstand the rigors of mechanized warfare.

3.4 Barrel Assembly (Type 2/3)

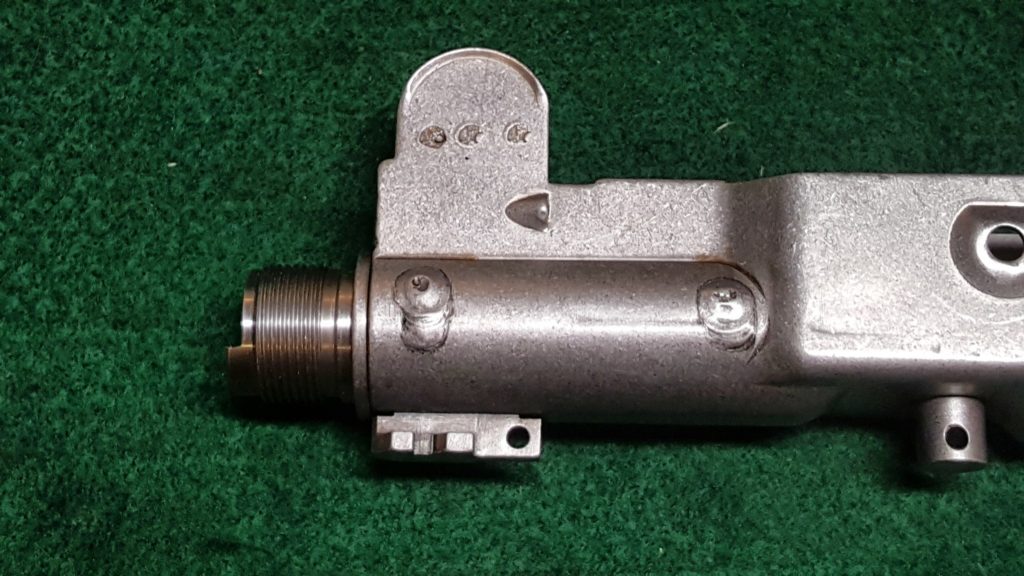

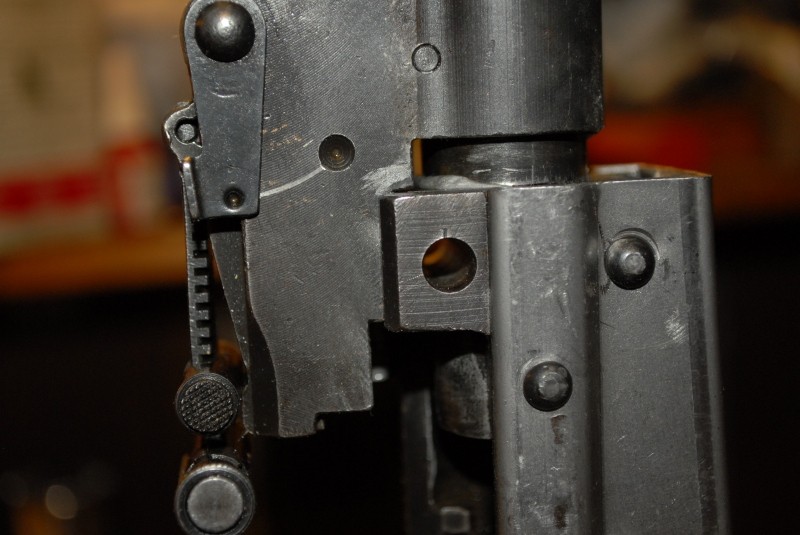

The early production challenges with the stamped-receiver Type 1 AK led to a temporary but important shift in manufacturing philosophy. For the Type 2 (1951-1954) and Type 3 (1954-1959) models, the Soviets reverted to a more traditional, robust, and much heavier milled receiver, which was machined from a solid forging of steel.

For these milled-receiver rifles, the barrel was manufactured with threads on the breech end. It was then screwed into the receiver’s integral front trunnion and carefully torqued to set the correct headspace—the critical distance between the bolt face and the chamber shoulder. This method created an extremely strong and rigid barrel-to-receiver lockup but was also slow, required skilled labor, and consumed a great deal of steel and machine time, making it less than ideal for the ultimate goal of mass-producing the rifle as cheaply and quickly as possible.

Section 4: Anatomy of the Finalized Barrel: A Technical Deep Dive

The final design of the AK-47 barrel is a study in purposeful engineering, where every dimension and feature was selected to contribute to the weapon system’s overall performance goals of reliability and effectiveness within its intended combat envelope.

4.1 Rifling Twist Rate (1:240mm or 1:9.45″)

The bore of the AK-47 barrel is characterized by four grooves with a right-hand twist. The rate of this twist is standardized at 1 turn in 240 mm, which is equivalent to 1 turn in 9.45 inches. This specific rate was not an arbitrary choice; it was carefully calculated to impart the optimal rotational velocity, or gyroscopic stability, to the standard 123-grain, 26.8 mm-long M43 projectile.

The primary purpose of this spin is to stabilize the bullet in flight, preventing it from tumbling end over end and allowing it to fly point-forward towards the target, which is essential for achieving any degree of accuracy. The 1:240mm rate provides sufficient stability for the M43 bullet to remain accurate out to the rifle’s effective range of 300-400 meters. Some ballistic analyses suggest that this twist rate is just enough to stabilize the bullet in air but not so fast as to “over-stabilize” it upon impact with a soft medium. This marginal stability is thought to contribute to the M43 bullet’s well-documented tendency to yaw (tumble) relatively early after entering soft tissue, thereby creating a more severe wound channel despite its non-fragmenting, steel-core construction.

4.2 Barrel Profile and Thickness

The external contour of the AK-47 barrel is a critical design feature that balances three competing requirements: heat management, rigidity, and weight. The resulting profile is a relatively straight, medium-weight contour—noticeably thicker than a lightweight “pencil” barrel but not as cumbersome as a heavy machine gun barrel.

- Heat Absorption and Dissipation: Sustained automatic fire generates an immense amount of heat, with propellant gases reaching temperatures over 2,200°F (1,200°C). The steel mass of the barrel acts as a heat sink, absorbing this thermal energy. A barrel that is too thin will heat up very quickly, which can lead to several problems: a “walking” point of impact as the steel expands unevenly, accelerated throat erosion, and in extreme cases, the danger of a “cook-off,” where a chambered round detonates from the ambient heat without the trigger being pulled. The AK-47’s medium profile provides enough thermal mass to absorb the heat from several magazines fired in quick succession without reaching a critical failure temperature, a crucial attribute for a weapon designed for suppressive fire.

- Rigidity and Barrel Harmonics: When a rifle is fired, the barrel vibrates in a complex, whip-like motion known as barrel harmonics. For consistent accuracy, these vibrations must be as repeatable as possible from shot to shot. A thicker, more rigid barrel vibrates with a smaller amplitude and is less affected by external pressures (such as from a sling or resting on cover) than a thinner, more flexible barrel. The AK-47’s robust profile contributes to its “combat accuracy” by ensuring the barrel is stiff enough to resist excessive whip, particularly during the violent cycling of automatic fire.

- Weight Management: While a heavier barrel is generally better for heat absorption and rigidity, it comes with a significant weight penalty. The designers had to adhere to the overall weight requirements for an individual infantry weapon. The final loaded weight of a Type 3 AK-47 is approximately 4.8 kg (10.6 lbs). The chosen barrel profile represents a carefully calculated compromise, providing the necessary thermal and mechanical robustness while keeping the rifle’s total weight and balance within acceptable limits for the average soldier.

The final barrel design was not a collection of independent features but a highly integrated component of the complete weapon system. The twist rate was specifically matched to the M43 projectile’s size, weight, and velocity. The barrel’s external profile was engineered to manage the thermal loads generated by that cartridge when fired in automatic mode, while also providing the rigidity needed for acceptable accuracy and meeting the overall weight constraints of the rifle platform. It is a testament to a design process that prioritized a holistic balance of competing factors to create a tool perfectly suited for its intended purpose.

Section 5: The AKM Evolution: Optimizing the Barrel for Mass Production

The adoption of the Avtomat Kalashnikova Modernizirovanny (AKM) in 1959 marked the final and most significant evolution of the original Kalashnikov design. The AKM was not a radical departure but a thorough refinement focused on simplifying manufacturing, reducing weight, and improving performance, all with the goal of making the rifle even easier and cheaper to produce on a massive scale. While the core ballistics of the barrel remained untouched, its method of construction and integration into the rifle were fundamentally changed.

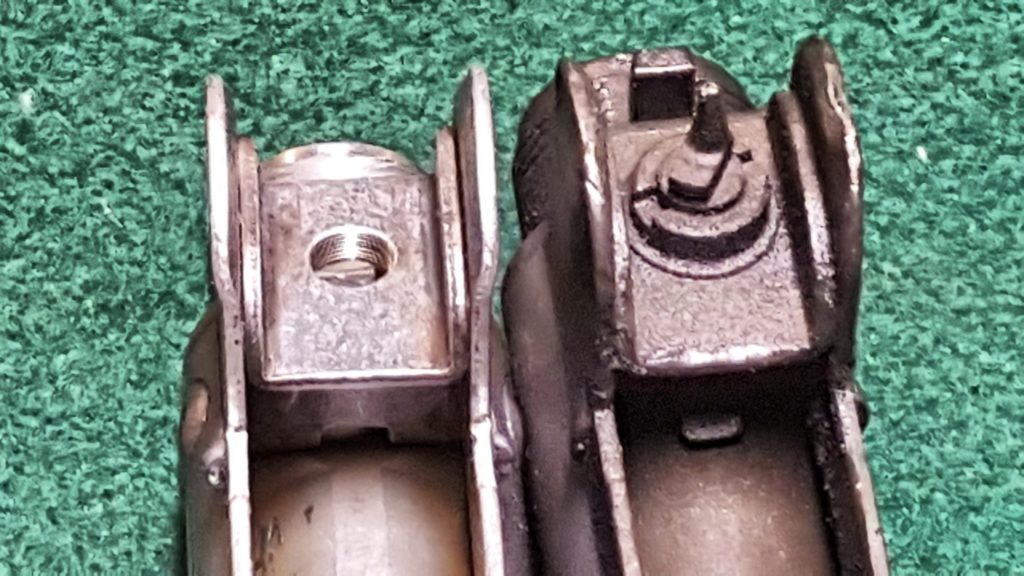

5.1 Return to Stamped Receiver and New Barrel Mounting

The single most important innovation of the AKM was the successful implementation of a stamped sheet steel receiver, replacing the heavy, costly, and labor-intensive milled receiver of the Type 2 and Type 3 AK-47s. By the late 1950s, Soviet industrial technology had overcome the quality control issues—primarily warping during heat treatment—that had plagued the early Type 1 stamped receivers. The new 1.0 mm thick stamped receiver was significantly lighter and could be produced in a fraction of the time required to machine a solid block of steel.

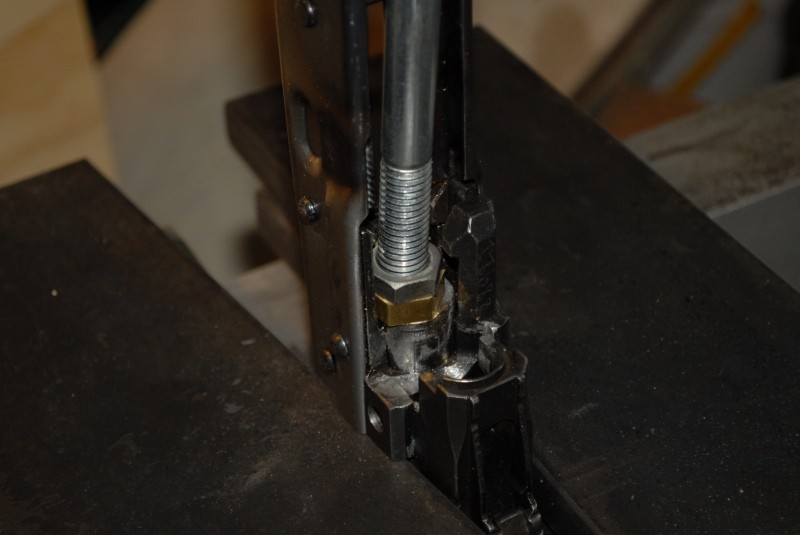

This shift in receiver construction necessitated a corresponding change in how the barrel was attached. The complex and time-consuming process of threading the barrel and screwing it into a milled receiver was abandoned. Instead, the AKM barrel was designed with a smooth, unthreaded journal at the breech end. This journal was pressed into a separate, hardened steel front trunnion using a hydraulic press. Once the correct headspace was achieved, the barrel was permanently fixed in place by drilling through the trunnion and barrel journal and pressing a solid steel transverse pin through the assembly. This press-and-pin method was dramatically faster, required less skilled labor, and was perfectly suited for an assembly-line environment, representing a pivotal step in optimizing the Kalashnikov for truly massive global production.

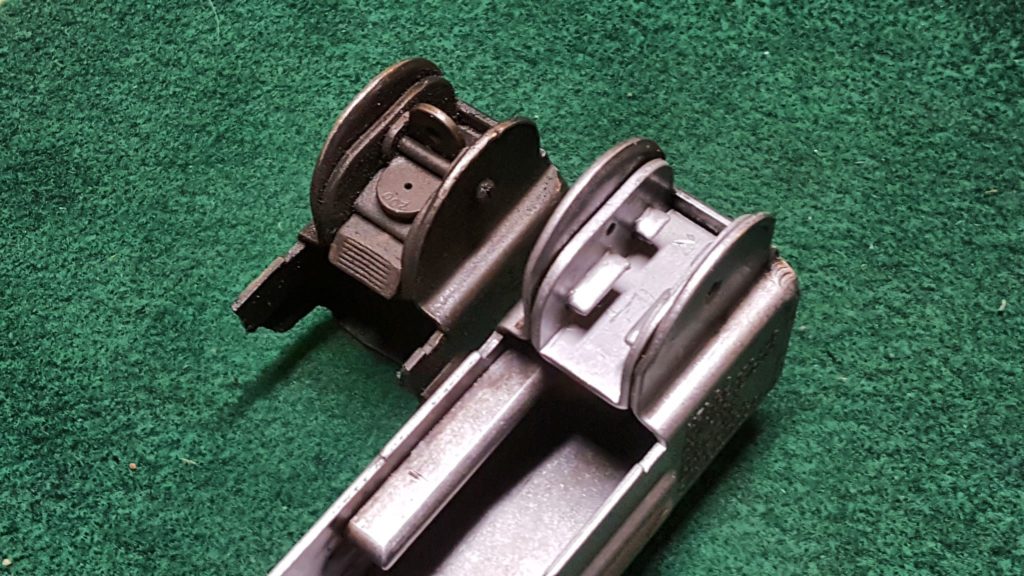

5.2 Muzzle Device: The Slant Compensator

While the muzzle of the AK-47 barrel was threaded, it was typically fitted with only a simple thread-protecting nut. The AKM introduced the now-iconic slant compensator. This simple yet ingenious device is a short steel brake with an angled face. When the rifle is fired, a portion of the high-pressure propellant gas exiting the muzzle strikes this slanted surface, creating a vector of force that pushes the muzzle down and to the left. This action directly counteracts the natural tendency of the rifle to climb and move to the right during the recoil of automatic fire (for a right-handed shooter). The result was a noticeable improvement in controllability during full-auto bursts, allowing the soldier to keep more rounds on target.

5.3 Continuity of Core Features

Despite the revolutionary changes to the receiver and barrel mounting, the internal and ballistic specifications of the AKM barrel were a direct continuation of the successful formula established by the AK-47. The Soviets recognized that they had already optimized the core of the system and wisely chose not to alter it. The AKM barrel retained the following critical features:

- Length: 415 mm

- Bore Treatment: Chrome-Lined

- Rifling Method: Cold Hammer Forged

- Rifling Specification: 4-groove, right-hand twist at 1 turn in 240 mm

The continuity of these features demonstrates that by the mid-1950s, Soviet engineers were confident they had perfected the internal design of the barrel for its intended purpose. The focus of the AKM project was not on reinventing the barrel’s ballistics, but on reinventing the rifle around it to achieve unprecedented levels of manufacturing efficiency.

| Feature | AK-46 (Prototype) | AK-47 (Type 2/3 Milled) | AKM (Stamped) |

|---|---|---|---|

| Barrel Length | 450 mm | 415 mm | 415 mm |

| Rifling | 4-groove, RH 1:240mm (Assumed) | 4-groove, RH 1:240mm | 4-groove, RH 1:240mm |

| Bore Treatment | Unlined | Chrome-Lined | Chrome-Lined |

| Rifling Method | Cut or Button (Inferred) | Cold Hammer Forged | Cold Hammer Forged |

| Receiver Attachment | N/A (Prototype) | Threaded / Screwed-in | Pressed & Pinned |

| Muzzle Device | Simple Muzzle Nut (Inferred) | Threaded for Muzzle Nut | Threaded for Slant Compensator |

Section 6: Conclusion: The Enduring Legacy of the Kalashnikov Barrel Design

The evolution of the AK-47 barrel, from the early prototypes to the mass-produced AKM, is a definitive case study in pragmatic, doctrine-driven military engineering. The final design was not the result of a quest for perfection in any single metric, but a masterclass in achieving an optimal balance of characteristics essential for the realities of modern warfare as envisioned by the Soviet Union. Its legacy is not defined by match-grade accuracy but by its unparalleled reliability and manufacturability.

The analysis reveals several key conclusions:

- Doctrine Dictated Design: The barrel’s core attributes—its 415 mm length, medium-weight profile, and extreme durability—were direct engineering responses to the post-WWII Soviet military doctrine of high-tempo, mechanized warfare. The requirement was for a weapon that could be wielded effectively by conscripts from within armored vehicles and could sustain high volumes of fire in the most unforgiving environments on earth. Every major design choice prioritized this functional reliability over theoretical precision.

- Manufacturing as a Strategic Weapon: The Soviet adoption of cutting-edge industrial processes was as crucial as the design itself. The combination of cold hammer forging for speed and durability, and chrome-lining for corrosion resistance and extended service life, created a synergistic system. This pairing allowed for the rapid and economical production of millions of barrels that were uniquely suited to the harsh realities of military service and the use of corrosive ammunition. The evolution to the AKM’s pressed-and-pinned barrel assembly was the final step in perfecting the rifle as an instrument of global strategic proliferation.

- A System of Calculated Compromises: The final specifications of the barrel represent a series of intelligent trade-offs. The 415 mm length was chosen because it provided sufficient ballistic performance for the 7.62x39mm cartridge within its intended 300-400 meter engagement envelope, while maximizing soldier mobility and handling. The 1:240mm twist rate was perfectly matched to stabilize the standard M43 projectile. The barrel profile provided enough mass to manage heat during automatic fire without making the rifle excessively heavy.

In conclusion, the barrel of the AK-47 and its successor, the AKM, is the physical embodiment of the Kalashnikov design philosophy: absolute reliability, simplicity of maintenance, and suitability for mass production. It is not the most accurate barrel ever designed, nor the lightest, nor the most ballistically efficient. It is, however, arguably the most successful rifle barrel in history, having been produced in greater numbers than any other and having proven its effectiveness in every climate and conflict for over seven decades. Its design is a testament to the principle that in warfare, the weapon that functions every time is superior to the one that functions perfectly only some of the time.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, we are only paid if there is an affiliate program such as Avantlink, Impact, Amazon and eBay and only if you purchase something. If you’d like to directly contribute towards our continued reporting, please visit our funding page.

Works cited

- The Lesser Known Origins of the AK-47: How the Legendary Rifle Came to Be, accessed July 28, 2025, https://akoptionsllc.com/blogthe-lesser-known-origins-of-the-ak47-how-the-legendary-rifle-came-to-be/

- Seven Principles of Soviet Tactical Doctrine – Marine Corps Association, accessed July 28, 2025, https://www.mca-marines.org/gazette/seven-principles-of-soviet-tactical-doctrine/

- The first appearance of the AK-47 as described by the CIA. : r/guns – Reddit, accessed July 28, 2025, https://www.reddit.com/r/guns/comments/84nx6f/the_first_appearance_of_the_ak47_as_described_by/

- AK-47 | Definition, History, Operation, & Facts – Britannica, accessed July 28, 2025, https://www.britannica.com/technology/AK-47

- History Of The AK-47 – Wideners Shooting, Hunting & Gun Blog, accessed July 28, 2025, https://www.wideners.com/blog/history-of-the-ak-47/

- The AK-46 Nearly Beat the AK-47 – The National Interest, accessed July 28, 2025, https://nationalinterest.org/blog/buzz/ak-46-nearly-beat-ak-47-157331

- Comparison of the AK-47 and M16 – Wikipedia, accessed July 28, 2025, https://en.wikipedia.org/wiki/Comparison_of_the_AK-47_and_M16

- SOVIET MILITARY ORGANIZATION AND DOCTRINE – CIA, accessed July 28, 2025, https://www.cia.gov/readingroom/docs/CIA-RDP80T00246A046100150001-3.pdf

- The Soviet Battalion, Its Commander, and Combined-Arms Warfare – DTIC, accessed July 28, 2025, https://apps.dtic.mil/sti/tr/pdf/ADA211005.pdf

- SOVIET INFANTRY TACTICS – CIA, accessed July 28, 2025, https://www.cia.gov/readingroom/docs/CIA-RDP80-00809A000600020174-3.pdf

- An Overview of the AK-47 Assault Rifle – Boot Camp & Military Fitness Institute, accessed July 28, 2025, https://bootcampmilitaryfitnessinstitute.com/2023/08/28/an-overview-of-the-ak-47-assault-rifle/

- AK-47 – Wikipedia, accessed July 28, 2025, https://en.wikipedia.org/wiki/AK-47

- The Great Debate AK47 vs AR15, accessed July 28, 2025, https://gtitraining.org/news-AK47-vs-AR15.htm

- Kalashnikov AKM: One of the most produced versions of the AK – Combat Operators, accessed July 28, 2025, https://combatoperators.com/firearms/rifles/kalashnikov-akm/

- 7.62×39mm – Wikipedia, accessed July 28, 2025, https://en.wikipedia.org/wiki/7.62%C3%9739mm

- 7.62×39mm – Ammunition Store, accessed July 28, 2025, https://ammunitionstore.com/content/7.62%C3%9739mm.pdf

- Handloading The 7.62×39 mm (M43) | An Official Journal Of The NRA – American Rifleman, accessed July 28, 2025, https://www.americanrifleman.org/content/handloading-the-7-62×39-mm-m43/

- Building the AK-47: Why It’s One of the Most Chosen Weapons – YouTube, accessed July 28, 2025, https://www.youtube.com/watch?v=0gI7-PKPLYg

- AK 47 Variants You Might Not Have Heard of – GunSkins, accessed July 28, 2025, https://www.gunskins.com/blogs/the-wrap/ak-47-variants

- AK-47 – Wikipedia, accessed July 28, 2025, https://sco.wikipedia.org/wiki/AK-47

- AKM – Wikipedia, accessed July 28, 2025, https://en.wikipedia.org/wiki/AKM

- Navigating AK Caliber Variants: A Comprehensive Guide – The Primary Source On PrimaryArms.com, accessed July 28, 2025, https://blog.primaryarms.com/guide/ak-47-calibers-explained/

- KS47 in 10.5″ or 16″? – KS-47 – Palmetto State Armory | Forum, accessed July 28, 2025, https://palmettostatearmory.com/forum/t/ks47-in-10-5-or-16/11968

- Difference in AK’s : r/EscapefromTarkov – Reddit, accessed July 28, 2025, https://www.reddit.com/r/EscapefromTarkov/comments/asjmtj/difference_in_aks/

- What kind of steel is used in gun barrels? – Quora, accessed July 28, 2025, https://www.quora.com/What-kind-of-steel-is-used-in-gun-barrels

- AR15 Barrel Types and Materials – 80 Percent Arms, accessed July 28, 2025, https://www.80percentarms.com/blog/ar15-barrel-types-and-materials/

- Evocatus AKM (Custom Pistol) 7.62x39mm (AK-47), accessed July 28, 2025, https://evocatusllc.com/evocatus-akm-custom-pistol-7-62x39mm/

- PSA AK-5.56 – Palmetto State Armory, accessed July 28, 2025, https://palmettostatearmory.com/ak-47/ak-5-56.html

- SOVIET STANDARDS FOR METALLURGICAL PRODUCTION – CIA, accessed July 28, 2025, https://www.cia.gov/readingroom/docs/CIA-RDP80-00809A000700230073-4.pdf

- Soup To Nuts 2 | PDF | Heat Treating | Annealing (Metallurgy) – Scribd, accessed July 28, 2025, https://pt.scribd.com/document/86810452/Soup-to-Nuts-2

- Heat Treating Gun Parts – L&L Special Furnace, accessed July 28, 2025, https://llfurnace.com/blog/heat-treating-gun-parts/

- Cryogenic Treatments for Sniper Rifle Barrels – DSIAC, accessed July 28, 2025, https://dsiac.dtic.mil/wp-content/uploads/2019/04/2174784_STI_Document.pdf

- What are the advantages of cut rifling versus button or hammer forged rifle barrels? – Quora, accessed July 28, 2025, https://www.quora.com/What-are-the-advantages-of-cut-rifling-versus-button-or-hammer-forged-rifle-barrels

- Cut rifling vs button? | AfricaHunting.com, accessed July 28, 2025, https://www.africahunting.com/threads/cut-rifling-vs-button.65246/

- Rifling Types 101 – Vortakt Barrel Works, accessed July 28, 2025, https://vortakt.com/learn/rifling-types-101/

- Inside Cold Hammer Forged Barrels | #CZFORTHOSEWHOKNOW, accessed July 28, 2025, https://www.czforthosewhoknow.com/blog/2023/05/24/inside-cold-hammer-forged-barrels/

- Cold Hammer Forged – Sig Sauer, accessed July 28, 2025, https://www.sigsauer.com/glossary/cold-hammer-forged/

- Cold Hammer Forged Barrel vs. Button Rifled: A Deep Dive into Barrel Manufacturing, accessed July 28, 2025, https://store.iconisagency.com/cold-hammer-forged-barrel-vs-button-rifled-a-deep-dive-into-barrel-manufacturing/

- Firearms Examiner Training | Hammer Forged – National Institute of Justice, accessed July 28, 2025, https://nij.ojp.gov/nij-hosted-online-training-courses/firearms-examiner-training/module-04/hammer-forged

- Cold Hammer Forging of Barrels — How The Process Works – Accurate Shooter Bulletin, accessed July 28, 2025, https://bulletin.accurateshooter.com/2022/12/cold-hammer-forging-of-barrels-how-the-process-works/

- How important is cold hammer forging to you? : r/ar15 – Reddit, accessed July 28, 2025, https://www.reddit.com/r/ar15/comments/i63ea0/how_important_is_cold_hammer_forging_to_you/

- File:AK-47 Type 1 Receiver.jpg – Wikimedia Commons, accessed July 28, 2025, https://commons.wikimedia.org/wiki/File:AK-47_Type_1_Receiver.jpg

- What’s the deal with chrome-lining and chrome-plating? – GunTweaks.com, accessed July 28, 2025, https://www.guntweaks.com/whats-the-deal-with-chrome-lining-and-chrome-plating.html

- Behind The Shine Of Chrome-Lined Barrels – Gun Digest, accessed July 28, 2025, https://gundigest.com/rifles/chrome-lined-barrels

- SKS – Wikipedia, accessed July 28, 2025, https://en.wikipedia.org/wiki/SKS

- How AK-47 Guns Work – Kalashnikov Weaponry Timeline – Popular Mechanics, accessed July 28, 2025, https://www.popularmechanics.com/military/weapons/a6301/anatomy-of-an-ak-47/

- RPD machine gun – Wikipedia, accessed July 28, 2025, https://en.wikipedia.org/wiki/RPD_machine_gun

- Quick Tip: The Difference Between Nitrided & Chrome-Lined Barrels – YouTube, accessed July 28, 2025, https://www.youtube.com/watch?v=Y2cv2MclByM

- File:AK-47 type II noBG.png – Wikipedia, the free encyclopedia, accessed July 28, 2025, https://en.m.wikipedia.org/wiki/File:AK-47_type_II_noBG.png

- File:AK-47 type II noBG.png – Wikimedia Commons, accessed July 28, 2025, https://commons.wikimedia.org/wiki/File:AK-47_type_II_noBG.png

- File:AK 47.JPG – Wikimedia Commons, accessed July 28, 2025, https://commons.wikimedia.org/wiki/File:AK_47.JPG

- Kalashnikov AK-47 – Weaponsystems.net, accessed July 28, 2025, https://weaponsystems.net/system/605-Kalashnikov+AK-47

- AK-47 – Weapon Systems, accessed July 28, 2025, https://old.weaponsystems.net/weaponsystem/AA04%20-%20AK-47.html

- AK-47 16″ Barrel 7.62X39 US Made AKM Non-Chrome – Nitride – Centerfire Systems, accessed July 28, 2025, https://centerfiresystems.com/16-762×39-us-cold-hammer-forged-akm-non-chrome-barrel/

- Can someone explain the twist rate of a barrel like I’m biden/harris. : r/Firearms – Reddit, accessed July 28, 2025, https://www.reddit.com/r/Firearms/comments/1fgmc0x/can_someone_explain_the_twist_rate_of_a_barrel/

- File:Cartridge 7.62x39mm M43 Steel CC BY-SA 4.0 by Grasyl.jpg …, accessed July 28, 2025, https://commons.wikimedia.org/wiki/File:Cartridge_7.62x39mm_M43_Steel_CC_BY-SA_4.0_by_Grasyl.jpg

- Heat vs thickness of barrel | Shooters’ Forum, accessed July 28, 2025, https://forum.accurateshooter.com/threads/heat-vs-thickness-of-barrel.4122038/

- Barrel heating affecting POI? : r/longrange – Reddit, accessed July 28, 2025, https://www.reddit.com/r/longrange/comments/u3nkt0/barrel_heating_affecting_poi/

- Barrel Contour vs Accuracy – Shooters’ Forum, accessed July 28, 2025, https://forum.accurateshooter.com/threads/barrel-contour-vs-accuracy.3969136/

- The Different Types of Barrel Contours and What You’re Left With – Athlon Outdoors, accessed July 28, 2025, https://athlonoutdoors.com/article/different-barrel-contours-types/

- Understanding AR-15 Barrel Profiles: From Lightweight to Bull Barrels – Dirty Bird Industries, accessed July 28, 2025, https://dirtybirdusa.com/understanding-ar-15-barrel-profiles/

- Analysis of heat transfer coefficient inside gun barrel – Inpressco, accessed July 28, 2025, https://inpressco.com/wp-content/uploads/2016/07/Paper86460-463.pdf

- Modernized AKM & AKMS – AK History Part II – YouTube, accessed July 28, 2025, https://www.youtube.com/watch?v=4xkws8j6WGc

- AKM Russian 7.62mm Automatic Assault Rifle – ODIN – OE Data Integration Network, accessed July 28, 2025, https://odin.tradoc.army.mil/WEG/Asset/81938b91ee77ceadcef64a66bf7c3f23

- Type 1 Russian AK: The First Production Stamped AK (Updated) – YouTube, accessed July 28, 2025, https://www.youtube.com/watch?v=zFagaHLuekQ

- AK Variants: A Closer Look – The Primary Source On PrimaryArms.com, accessed July 28, 2025, https://blog.primaryarms.com/guide/ak-variants-explored/

- AK-47 – How this rifle works! (Animation) – YouTube, accessed July 28, 2025, https://www.youtube.com/watch?v=ZyajvvsuGcU

- File:AKM (rifle).jpg – Wikimedia Commons, accessed July 28, 2025, https://commons.wikimedia.org/wiki/File:AKM_(rifle).jpg

- IZHMASH SGL31-68 5.45x39mm Semi-Automatic Rifle – K-Var, accessed July 28, 2025, https://www.k-var.com/saiga-rifle-russian-made-stamped-receiver-545×395-caliber-hammer-forged-chrome-lined-barrel-fr

Back in the AK game with an Izhmash (Saiga) – Milsurps, accessed July 28, 2025, https://www.milsurps.com/showthread.php?t=25873