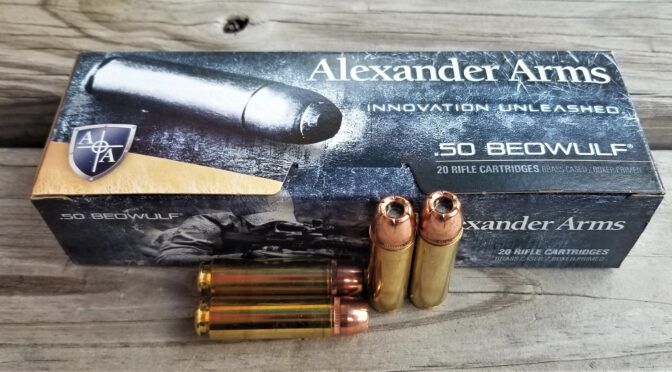

The short answer is that they are the same thing. The bullet’s diameter is 0.50″ which is 12.7mm and the case length is 1.65″ or 42mm. The reason you see some vendors say they have something to sell in 12.7x42mm is they are trying to avoid a trademark problem with Alexander Arms.

Bill Alexander, of Alexander Arms, did all the engineering to bring to life both the round and the AR components to use it. He also trademarked the term “.50 Beowulf”. As such, anybody who wants to sell something and refers to it as being for .50 Beowulf would need to get the permission and/or license the use of the term “.50 Beowulf” to avoid legal problems. So, a lot of vendors use the generic metric designation of 12.7×42 to avoid legal hassles.

With that said, bear in mind that not all engineering is equal. I have never had a problem with Alexander Arms parts but myself and others have had plenty of headaches with 12.7×42 components from budget AR vendors who haven’t done the engineering. In my case, it was poor extraction with a Radical Arms bolt and extractor. So, buyer beware and research a vendor and their offering before you buy plus make sure they are reputable in general in case you need support. For example, Satern worked great for me and I wrote a blog post about the build.

Conclusion

So, short post this time. 12.7×42 and .50 Beowulf are the same round with different descriptions but be cautious to check out vendors selling parts using the metric designation. Some of them are selling junk so search for current reviews of products before you buy them.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, we are only paid if there is an affiliate program such as Avantlink, Impact, Amazon and eBay and only if you purchase something. If you’d like to directly contribute towards our continued reporting, please visit our funding page.