I was surfing around on the web one day looking at interesting builds and ran across something I had never seen before – a Pork Sword pistol. It looked like a short barreled bolt gun on a chassis with a pistol brace, scope and can. What in the heck? So it sure made me curious and I searched on “Pork Sword”. It is totally a thing and I’m surprised it hasn’t caught on yet.

Turns out there is a company called Black Collar Arms that is making the parts and also producing rifles and pistols. What I had seen was a braced pistol based on a Remington 700-foot print receiver on their minimalist Pork Sword chassis with a short barrel. At this point, I was hooked. I like bolt guns and really like building unique stuff. They’ve posted quite a few photos of firearms they have built as well as customer guns – click here.

The concept behind the Pork Sword is simple – create a compact weapon in a caliber that packs a punch without needing to go the registered shot barreled receiver (SBR) rifle route by building a pistol with brace. A Pork Sword would be ideal for hog hunting, hunting in heavy brush, survival situations or even urban engagements. Because it uses a short action Remington 700 receiver, you have tons of caliber choices plus you can decide the barrel length – you can make a firearm that is tailored to your needs.

It had been years since I last owned a Remington 700 XCR LR and all I had done was swap the trigger and stock on it so I remembered very little about how they were made. Sure most bolt guns are similar but the Devil is in the details.

I called Black Collar Arms a couple of time and they were really cool and talked me through a lot of considerations. They offered to either build one for me or sell me the parts and I told them building was really my thing and so we had a great talk. I called them two times, talked to two different guys and they were really helpful — I definitely got good vibes from them.

This build was going to be an investment so I didn’t want to screw up. On top of talking with them, I also did a lot of digging based on what the guys at Black Collar told me and what they had for sale. I then assembled a parts list and slowly started accumulating stuff for close to four agonizing months. I’m not a very patient guy so slowly getting the stuff was a new experience vs. jumping right in with both feet.

I probably researched this project more than most with lots of calls direct to vendors to better understand what they had to offer. My goal is a 1/4″ group at 100 yards and 1″ at 400. That would be about 1/4″ minute of angle (MOA) and is a mean feat. It requires that all the parts come together the right way – caliber selection, chassis, action, barrel, trigger, brake, etc.

If you plan to build a pistol start with a new receiver and not a rifle

From a NFA legality perspective, you are building a pistol so that means you must start with a receiver or pistol but absolutely not a rifle. Once a serial number is classified as a rifle it can’t be a pistol and would have to go the SBR (short barreled rifle) registration route. Again, if you plan on building a pistol and using a brace, start with an action/receiver or a barreled action but never with a rifle. If you do not understand what I am talking about then do not proceed until you understand the difference between a pistol build and what would require registration as a SBR prior to building.

Action/Receiver Comment

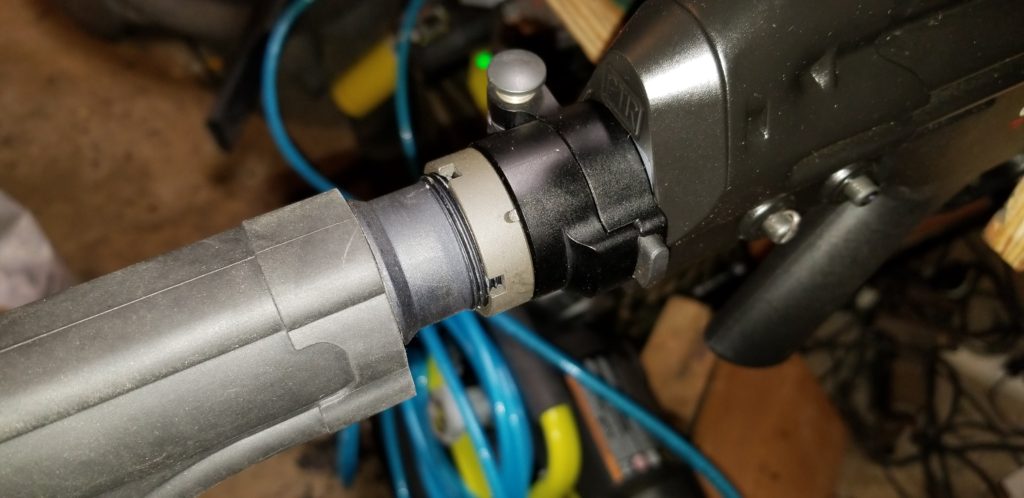

By the way, the chassis can use Remington 700 receivers as well as others that fit. That sounds odd but not all third party receivers that say they are “Remington 700 compatible” necessarily have the exact same footprint plus you are going to need a recoil lug. I went with a Big Horn Origin that has a Remmage type of barrel mount meaning you thread the barrel into the receiver and set the headspace and you then tighten down the barrel nut to lock it in place. It’s a slick method. Here are other potential action vendors to consider: Defiance, Alamo Precision Rifles, Surgeon, Impact Precision, Accuracy International, Gunwerks, Bighorn Arms, Pacific Tool and Gauge, Thompson Leh, BAT Machine, Impact Precision, GA Precision, Stiller, Kelbly’s, American Rifle Company, Badger Ordnance, Viper Actions, and Bergara. Again, confirm it will fit before you buy anything.

The Parts List

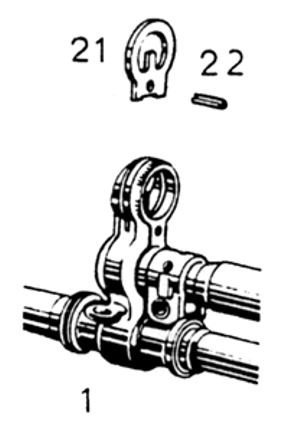

- Pork Sword Chassis and 12″ Tri-LOK FARend – the chassis is very nicely machined and finished and will use a short-action Remington 700 footprint action with a recoil lug. I bought the chassis and FARend from Black Collar arms directly.

- Big Horn Origin Short Action – This includes the scope rail and I bought this from Northland Shooter Supply (NSUS). Note, Big Horn’s name is changing to Zermatt Arms. I talked to Big Horn directly but bought it from NSUS in the hopes of getting it sooner. NSUS often has them in stock but I had about a 4-6 week wait until mine came in because they had run out of inventory and the owner was very up front with me that I might need to wait a while before I ordered.

- X-Caliber Pre Fit Big Horn 12.5″ .308 MTU-profile Barrel with 5/8-24 threads – I bought this direct from X-Caliber when they were having a sale. I needed to talk to them because they have a ton of options and most of them I had no idea what to get so they were a huge help. Their lead times vary but I think it took about 3-4 weeks for them to send me the barrel.

- TriggerTech Primary Trigger – These things are so sweet!! They drop right in and are very easy to adjust from 1.5 to 4 pounds of pull and are very crisp. I went with a black straight blade trigger purely out of preference. They offer flat/straight and curved triggers as well as colored black or stainless.

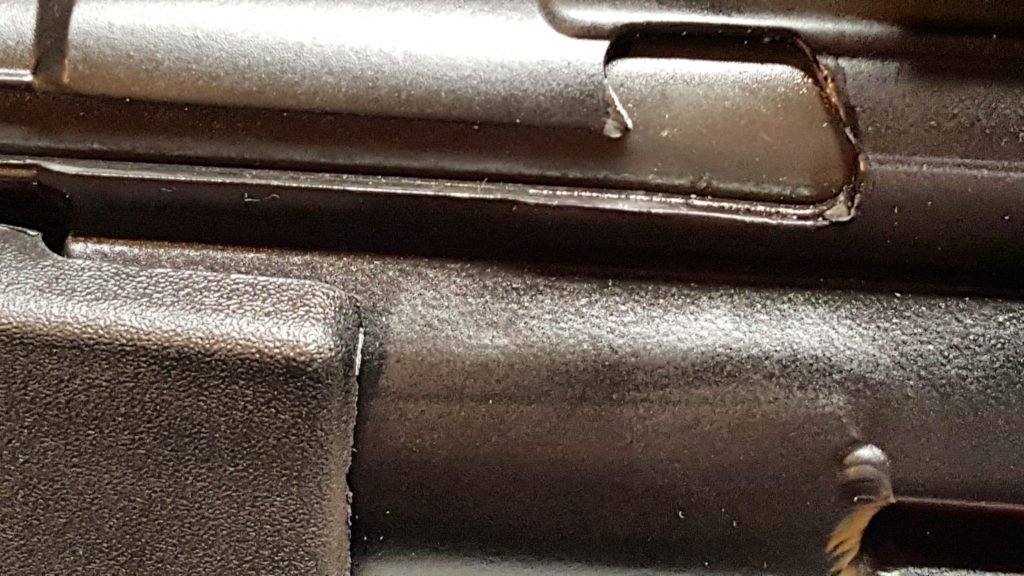

- SB Tactical FS1913A Brace – These are relatively new braces from SB Tactical with a long strut, a folding mechanism and fairly stout arm brace assembly at the end. Please note the “A” in the model number I bought. The first version of this brace (FS1913 without the “A”) has a polymer strut that can flex. The FS1913A has an aluminum strut and is stiffer. Given my plans to shoot a .308, I definitely wanted stiffer. You may need to shop a bit – I bought mine from Natchez. If the price is under $199, it’s probably the polymer unit. If you are going with a lighter recoiling round, the polymer ought to be fine.

- Ergo Tactical Deluxe Zero Angle Grip – I’ve always liked target stocks with near vertical grips so I opted for this model.

- APA Little Bastard brake – this is a tunable brake for precision rifles. I will get a suppressor down the road but for now, I’ll run this brake.

- Magpul AFG – Normally I am not a huge fan of angled fore grips but think I may want something to hold on to. I’m really not sure if I will keep it on the rifle long-term but we’ll see.

- Magpul bipod – I dismissed this bipod when I first heard about it but guys reported liking it so I figured I better check it out. I bought the Picatinny rail version so I could remove it readily. In hindsight I should have bought the one that was ARMS lever ready but that is a topic for another post. There are a ton of color and options combinations you can consider. As you can see in the photo at the top of the page, I went with black and I did use a small section of Magpul M-Lok aluminum rail to mount it.

- AD Recon SL 30mm Scope mount – I like quality quick detach scope mounts. There are two big differences between a quality mount like an ADM and a cheap one. First, when you remove the optic and mount from the rifle and then re-attach them, the zero holds true for a good mount and not a cheap one. Second, the cheap ones tend to wear and bend on the throw lever cams and plates over time and then the accuracy gets worse.

- Vortex 4-16×44 HST MRAD scope – I am a huge fan of Vortex scopes and thing you get a lot of quality glass at a reasonable price. I opted for a medium physical size scope. My first choice would have been a PST Gen 2 5-25×50 but I couldn’t quite swing it right now. I may well change to this scope down the road.

- Magpul PMAG 7.62×51 AC Magazines – the Pork Sword chassis uses the AC short action series of PMAG 7.62×51 magazines. I bought a couple of 5-round magazines and a couple of 10-round magazines.

Tools Needed

- Wheeler Remington 700 Action Wrench – this holds the bolt action while you do the barrel work. I didn’t have one and it was definitely a worthwhile purchase.

- Clymer .308 GO and NO-GO Headspace Gages – normally I use Manson out of habit. Clymer has a good reputation and one tip I was told long ago is to go with the same brand of gage for a given caliber. So I went with Clymer for both the GO and NO-GO gages because they were in stock.

- Wheeler Professional Laser Bore Sighter – I’ve been using a green laser model for about a year now and really like it. The green is very visible further away but they also have a red laser model at a lower price if you aren’t interested in paying extra for the green laser.

The following tools aren’t firearm specific but will help with the build:

- 1-1/4″ Crowfoot Wrench – you’ll need this to torque the barrel nut to spec. Confirm the size you need with the barrel maker. I didn’t have one this size and needed to buy it.

- 1/2″ Torque Wrench – Get one that starts at 10 foot/lbs and goes at 100. That gives you a really versatile range. The action wrench bolts are 10 foot/pounds each and then we you bring the barrel nut down, it’s 50-55 foot/pounds.

- 1/4″ Torquing Screwdriver – Get a good one. I highly recommend the Vortex Optics unit because it is a precision tool for the optics work but it does max out at 50 inch-pounds and the action screws need 55-65 inch/pounds (note that is inch/pounds and not foot/pounds).

- 1/4″ Torque Wrench – I used a clicker-style torque wrench for the action screws that I installed at 60-in-pounds.

- Vise – have a good enough one bolted to a surface that can hold the action wrench and your life will be way easier.

- Blue Loctite – Firearms can shake just about any fastener loose so use Blue Loctite, or your favorite medium strength thread locker, to keep them from rattling loose.

- SAE Allen Wrench Bits – If I recall right, all of the hex head screws were SAE and you’ll want the bits so you can torque them down to spec with the torquing screw driver.

Conclusion

That’s it for now. In the next post, I’ve go over installing the barrel. Thank you for reading and I hope you found this interesting.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, I may be paid via an affiliate program such as Avantlink, Impact, Amazon and eBay.