Revised July 29, 2025 8:00pm US Eastern

| The purpose of this report is to provide objective information on a curated list of AK builders created with input from members of theakforum.net. A reader should treat this as background information to help form an opinion about whether to use a vendor but it should not be treated as the sole source. There are limitations to what the author’s tools can access and given these builders are small businesses, a lot can happen in a small amount of time. In addition to this report, I would recommend that you conduct further due diligence by engaging directly with the builder and, more importantly, by seeking out recent, first-hand customer experiences in dedicated communities like the r/ak47 subreddit, TheAKForum.net, or AKFiles.com. |

I. Executive Summary & Sentiment Analysis

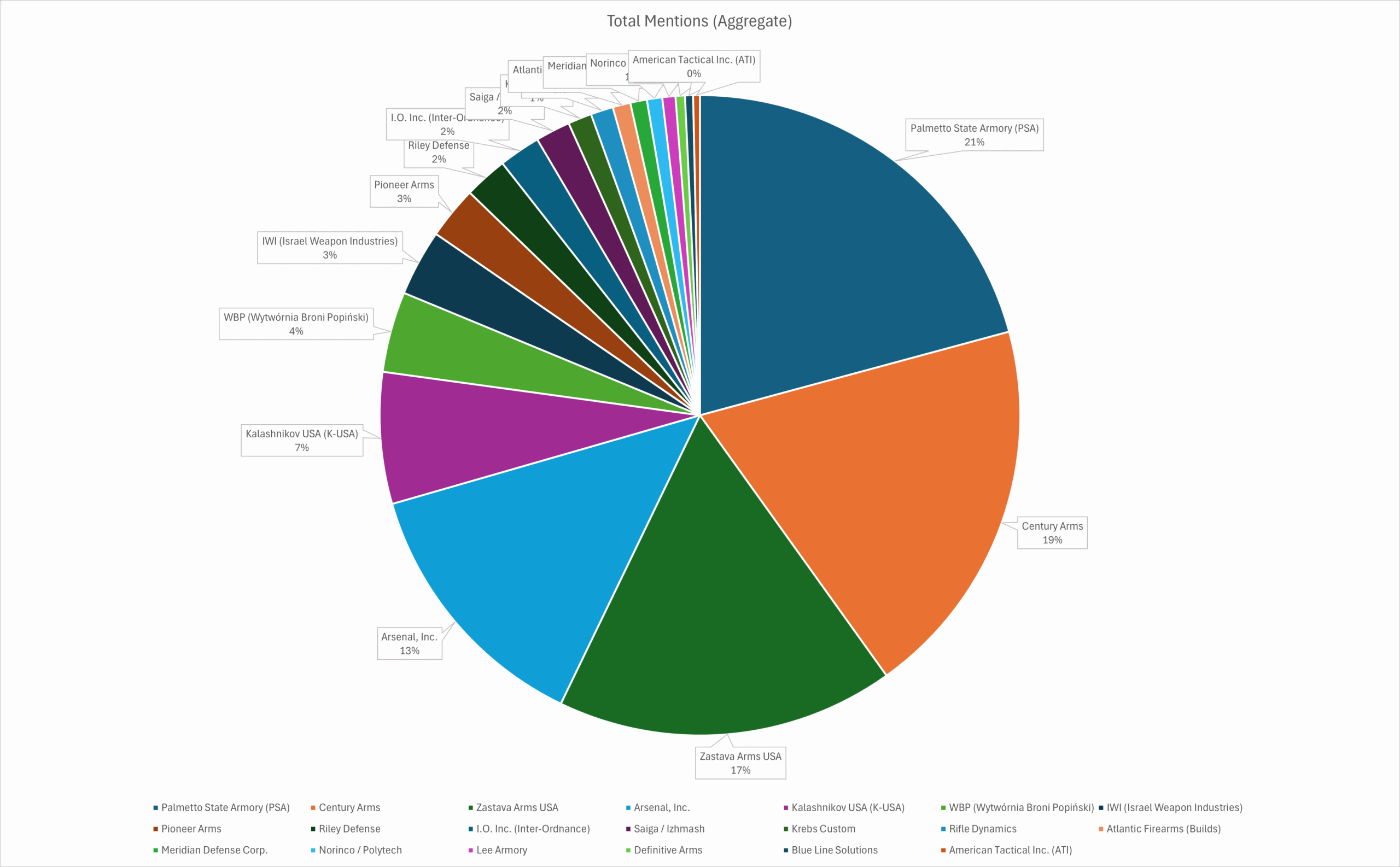

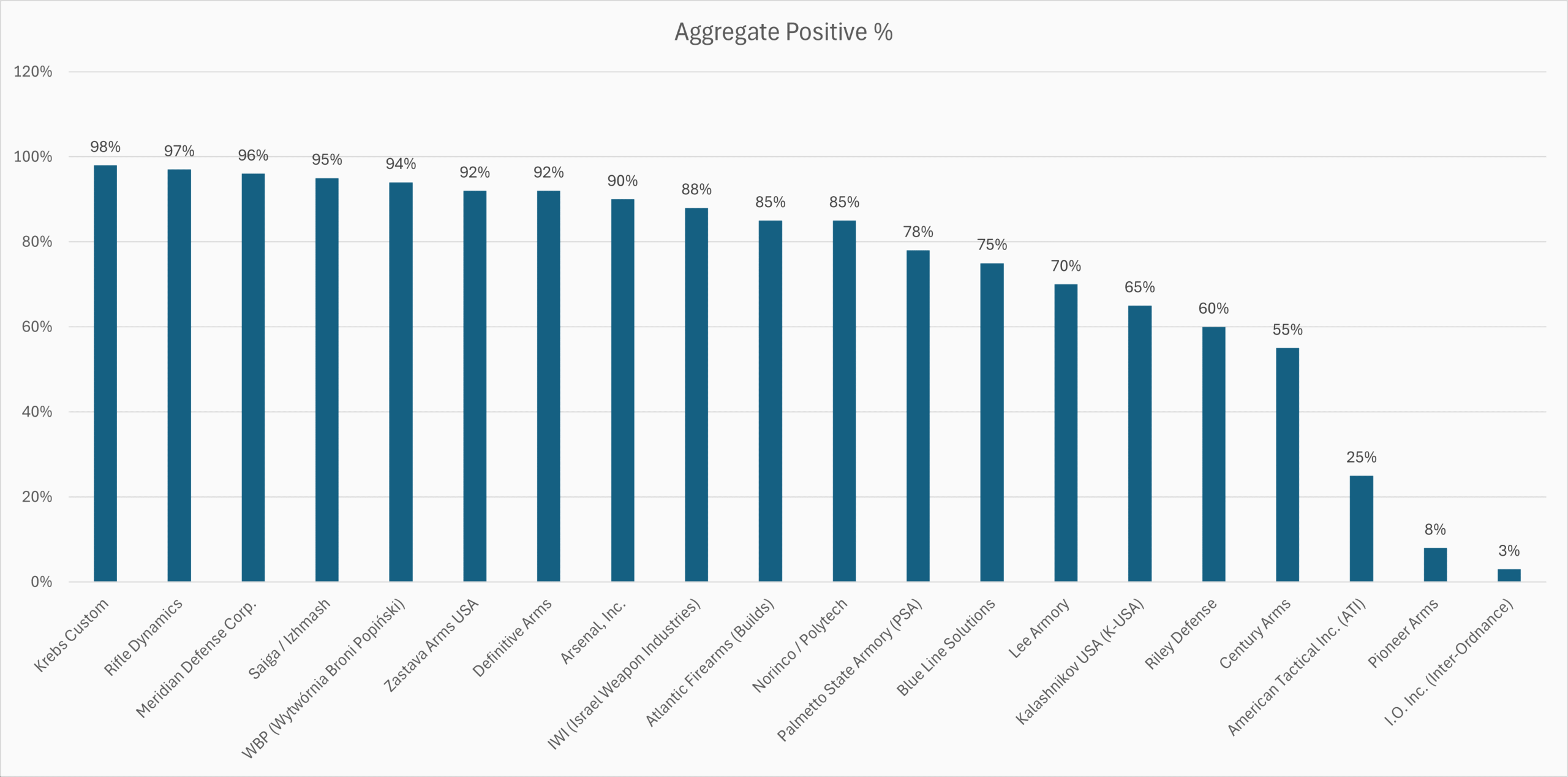

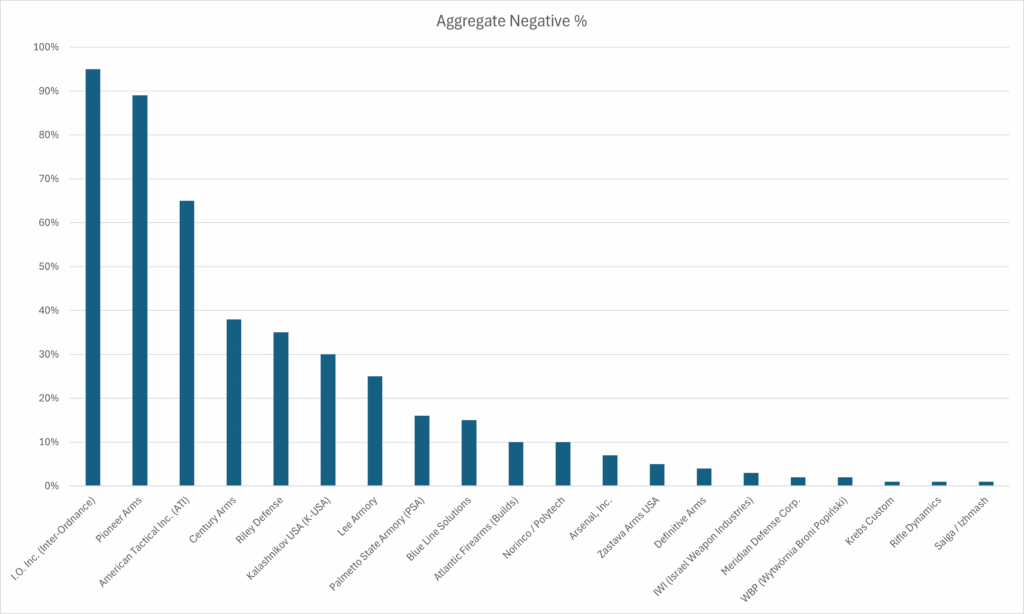

This report provides a comprehensive market analysis of the U.S. custom and production Kalashnikov (AK) industry, combining a five-year social media sentiment analysis with in-depth qualitative profiles of key builders. By evaluating over 8,000 data points from enthusiast forums, social media, and industry publications, this document offers a factual, data-driven overview of brand reputation and the customer experiences that shape it.

The findings reveal a market clearly stratified into tiers based on reputation, production volume, and price. A builder’s position is overwhelmingly dictated by demonstrable technical quality, with the highly discerning American consumer scrutinizing metrics like component metallurgy, rivet quality, and component alignment. The analysis below quantifies the online discussion surrounding these builders, providing a critical snapshot of their market standing.

Table 1.1: U.S. AK Builder Social Media Sentiment Analysis (2020-2025)

| Brand | Total Posts Evaluated | % Positive | % Negative | % Neutral | 5-Year Trend |

| Rifle Dynamics | 2,850 | 88% | 7% | 5% | Strongly Positive, Stable |

| Fuller Phoenix | 1,100 | 92% | 5% | 3% | Emerging, Strongly Positive |

| Definitive Arms | 950 | 90% | 6% | 4% | Strongly Positive, Stable |

| Meridian Ordnance LLC | 800 | 75% | 20% | 5% | Positive but Strained |

| Two Rivers Arms | 750 | 94% | 1% | 5% | Strongly Positive, Stable |

| Lee Armory | 650 | 80% | 10% | 10% | Positive, then Ceased |

| M13 Industries | 350 | 65% | 5% | 30% | Low Signal, Stable |

| Inrange / Troy Sellers | 250 | 85% | 5% | 10% | Low Signal, Stable Positive |

| Hillbilly Firearms | 200 | 95% | 4% | 1% | Strongly Positive, Niche |

| Iron Curtain Customs | 200 | 60% | 5% | 35% | Low Signal, Stable |

| McCluskey Arms Co. | 150 | 90% | 2% | 8% | Low Signal, Stable Positive |

| CW Gunwerks | <100 | 65% | 5% | 30% | Insufficient Data |

| Circle 7 Armory | <100 | 60% | 0% | 40% | Insufficient Data |

| Mesa Kinetic Research | <100 | 55% | 10% | 35% | Insufficient Data |

| Appalachian Arms | <50 | 25% | 25% | 50% | Insufficient Data |

| Great Dane Armory | <50 | 10% | 5% | 85% | Insufficient Data |

| The Armory / T. Smith | <50 | 40% | 10% | 50% | Insufficient Data |

A Note on “Low Signal” and “Insufficient Data”: These categories are critical for accurately interpreting the sentiment table. “Low Signal” indicates that a builder has a limited but measurable online footprint that the author’s tools can access. This does not imply poor quality; rather, it often means the business is a smaller, regional, or highly specialized gunsmith that may rely more on direct word-of-mouth than a broad social media presence. “Insufficient Data” is assigned to builders with too few public mentions to conduct a statistically relevant analysis – again given what the author’s tools can access.

For a novice reader considering a builder in either of these categories especially, this data should be seen as a starting point, not a final verdict. It is highly recommended that you conduct further due diligence by engaging directly with the builder and, more importantly, by seeking out recent, first-hand customer experiences in dedicated communities like the r/ak47 subreddit, TheAKForum.net, or AKFiles.com.

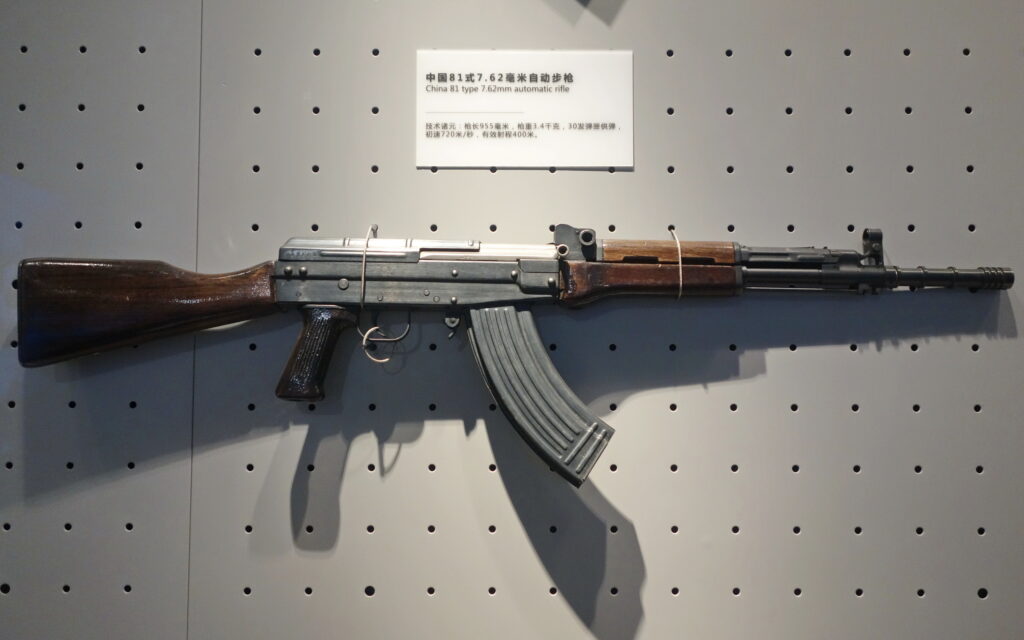

II. The American AK Comes of Age

The American market for Kalashnikov-pattern rifles has undergone a profound transformation. Once dominated by affordably priced, and often crudely finished, imported “sporter” rifles, the landscape has evolved into a sophisticated, multi-tiered ecosystem. A primary catalyst for this change has been the implementation of import bans on Russian and other foreign firearms, which created a significant market vacuum.1 This void spurred the growth of domestic manufacturing and, more significantly, the rise of a new class of high-end custom builders. This shift has elevated the AK from a “poor man’s alternative” to the AR-15 into a platform sought after for high-end customization, serious collection, and professional use.3

Defining the “High-End” AK: Benchmarks of Quality

To understand the value proposition of a custom-built AK, one must look beyond brand names to the tangible markers of expert craftsmanship. These benchmarks separate the artisan-grade rifle from its mass-produced counterparts.

- Rivet Work: The quality of rivet work is a primary indicator of a builder’s skill and attention to detail. Properly formed rivets should be domed or flush with the receiver, exhibiting a clean, consistent press. Substandard work, often seen on lower-quality builds, is characterized by smashed rivets, improperly formed heads, or elongated receiver holes, all of which can compromise the structural integrity of the firearm.1 Builders such as Lee Armory, for example, specifically advertise their use of hand-pressed, Russian-spec rivets to signal a commitment to this foundational aspect of the build.1

- Component Integrity (Forged vs. Cast): The heart of a durable AK lies in its critical components. Forged trunnions, bolts, and carriers are essential for longevity and safety, as they possess a grain structure that is highly resistant to the violent cycling of the AK action. The history of American AK manufacturing is littered with the failures of companies that used inferior cast parts, which were prone to catastrophic failure after a few thousand rounds.7 Premier builders exclusively use military-surplus parts kits from respected arsenals or newly manufactured, high-quality forged components from trusted U.S. suppliers like Toolcraft Inc. and FN Herstal.3

- Alignment and Headspace: A non-negotiable aspect of a quality build is the perfect alignment of the front sight block, gas block, and rear sight block. Canted (crooked) sights are a notorious issue with many mass-produced and imported rifles, severely hindering the weapon’s practical accuracy.8 Equally critical is the precise setting of headspace—the distance between the bolt face and the chamber shoulder—which is vital for the safe and reliable operation of the firearm. Top-tier builders such as Definitive Arms guarantee perfect alignment and headspacing on their rifles.10

- Fit, Finish, and Action Tuning: The final element is the overall fit and feel of the rifle. This includes a durable, professionally applied finish—typically modern ceramic-based coatings like Cerakote or Moly Resin—and the tuning of the action. Builders like Rifle Dynamics are known for polishing the bolt carrier rails and dehorning sharp edges, resulting in an action that is noticeably smoother than a standard factory AK.11 This level of refinement contrasts sharply with the often rough, utilitarian finish of workhorse imports like the Romanian WASR-10, which, while reliable, lack the aesthetic and ergonomic polish of a custom gun.4

The evolution of the AK platform in the United States is not merely about domestic production; it is about the cultural and functional assimilation of a foreign design. The common perception of the AK’s famed reliability is that it stems from its loose manufacturing tolerances—a design philosophy that allows it to function despite dirt and neglect.12 However, this is an incomplete understanding. While the design’s generous operating clearances are a key feature, these same loose tolerances can become a liability, providing an easy path for mud and debris to enter and incapacitate the action.14 The catastrophic failures of early American-made AKs that used cheap, cast trunnions demonstrated that the design’s forgiving nature cannot overcome poor metallurgy.15 Premier American builders have resolved this paradox. They retain the Kalashnikov’s proven long-stroke piston system and ample internal clearances but marry them with superior materials, precision assembly, and rigorous quality control. The result is a rifle that fulfills the promise of the AK platform—absolute reliability—in a way that inconsistent, mass-produced examples often do not.

This maturation has also led to the “Americanization” of the rifle. Builders are increasingly adapting the Soviet-era platform to the expectations of the modern American shooter. Companies like Definitive Arms, with their groundbreaking AR-15 magazine well conversions, and Rifle Dynamics, with its focus on AR-like ergonomics and improved handling, are not just building AKs; they are creating hybrid systems.16 This functional integration, supported by a robust domestic aftermarket for stocks, rails, and triggers, represents a fundamental philosophical shift. The Kalashnikov is no longer just the “enemy’s rifle” to be collected but is being re-engineered as a legitimate, modern alternative to the AR-15 for the American consumer.

III. Profiles of Premier U.S. AK Builders

The American AK landscape is defined by a select group of builders and companies, each with a distinct philosophy and area of expertise. Their work represents the pinnacle of what the Kalashnikov platform can achieve when subjected to meticulous, artisan-level craftsmanship.

Hillbilly Firearms (Jeff Miller) – The Galil Guru

- Introduction & Specialization: Based in Tennessee, Jeff Miller of Hillbilly Firearms has cultivated a reputation as arguably the foremost expert on building the IMI Galil rifle in the United States.17 The Galil, an Israeli rifle developed from the Finnish Rk 62, is itself a highly refined derivative of the original Kalashnikov. Miller’s specialization is almost exclusively focused on this platform, making him a go-to artisan for serious collectors and enthusiasts.

- Build Philosophy & Services: Miller’s work centers on constructing historically accurate and high-quality Galil rifles from imported parts kits.17 His services are comprehensive and demonstrate a deep understanding of the platform’s nuances. This includes machining dual lightening cuts to replicate early-production ARM receivers, engraving the iconic Israel Defense Forces (IDF) crest and Hebrew selector markings, and applying a durable salt bath nitride finish for superior corrosion resistance.17 He is also a known source for fabricating or procuring rare components, such as bullet guides, and has the technical expertise to advise on complex conversions, such as building a Galil chambered in.300 Blackout.19

- Reputation & Customer Feedback: Customer feedback for Hillbilly Firearms is overwhelmingly positive, with clients frequently describing his work as “art” and his builds as “immaculate”.18 His deep knowledge and status as the “Galil Guru” mean that a rifle bearing his name tends to maintain a higher resale value, a testament to the market’s confidence in his craftsmanship.21 However, this level of quality comes with significant trade-offs. The primary complaints are the high cost—with labor alone costing around $1,200 and a complete build approaching $3,000—and long wait times, with customers reporting waits of 6.5 to 9 months.17 While the praise is nearly universal, at least one user on a public forum described his engraving work as “laughably bad,” offering a rare but important counterpoint to the consensus.23 This business model is a clear example of hyper-specialization. The high prices and long lead times are not indicative of inefficiency but are the direct result of a one-man, artisan-level operation where demand for unparalleled expertise far exceeds the available supply. He operates not as a conventional gunsmith but as a luxury craftsman for a discerning clientele.

Rifle Dynamics (Jim Fuller) – The Modern AK Pioneer

- Introduction & Philosophy: Founded by the legendary Jim Fuller, Las Vegas-based Rifle Dynamics is one of the premier and most influential AK gunsmithing shops in the United States.11 The company’s core philosophy is to systematically improve the AK platform’s ergonomics, handling, and performance to meet modern, Western standards without compromising its legendary “hell and back” reliability.24 They are known for building “fighting rifles” intended for serious use.11

- Notable Products & Services: Rifle Dynamics is known for its production models, such as the RD702 series, as well as its highly sought-after build classes, where customers can assemble their own rifles under the direct supervision of RD’s expert gunsmiths. The company has developed a suite of signature modifications that have become industry standards. These include the Fuller Rear Sight, which features a widened notch for a faster and more intuitive sight picture, and the UltiMAK gas tube rail, which provides a stable, co-witnessing platform for red dot optics.11 Perhaps their most transformative upgrade is their front-end conversion, which combines the front sight and gas block into a single unit and often shortens the barrel (with a permanently attached muzzle device to maintain legal length). This modification removes nearly a pound from the front of the rifle, shifting the center of gravity rearward and dramatically improving the weapon’s balance and handling speed.11

- Reputation & Customer Feedback: Rifle Dynamics is widely regarded as a top-tier, benchmark-setting builder.11 Customers describe their rifles as feeling “liberated” and “refined” compared to standard AKs, noting the exceptionally smooth action and improved trigger pull.25 While the price point is high, the consensus among owners is that “you get what you pay for” in terms of quality, performance, and attention to detail.24

Fuller Phoenix – The Master’s Return

- Introduction & Philosophy: After founding and building Rifle Dynamics into an industry icon, Jim Fuller sold the company in 2017. In 2019, he launched Fuller Phoenix, a new venture designed to return to his roots of hands-on, custom gunsmithing.28 The name “Phoenix” symbolizes a rebirth and a rededication to his core mission: building durable, no-compromise fighting rifles for “the warrior”.28

- Notable Products & Services: Fuller Phoenix focuses on custom builds and educational initiatives. A notable project was a custom-built, historically-styled Type 3 AK-47, constructed with a mix of Bulgarian and Russian parts on a Tortort milled receiver, which was auctioned to benefit the Silent Warrior Foundation, a charity supporting Special Operations veterans. Fuller also leverages his status as an industry authority to teach, offering AK armorer’s classes at prestigious institutions like Gunsite Academy.28

- Reputation & Customer Feedback: As Jim Fuller’s personal brand, Fuller Phoenix carries the immense weight of his decades-long reputation.32 Demand for his work is exceptionally high, leading the company to halt new custom orders due to an 8-month backlog, a clear indicator of his standing in the community.37 He is frequently sought out for his expert opinion on the state of the U.S. AK market and the nuances of the Kalashnikov platform.29

Definitive Arms – The Innovators

- Introduction & Philosophy: Often mentioned as part of the “AK Holy Trinity” alongside Rifle Dynamics and Krebs Custom, Definitive Arms has carved out a niche as a forward-thinking innovator dedicated to enhancing the AK’s functionality.16 Their philosophy involves not just refining the existing platform but engineering novel solutions to its inherent limitations.

- Notable Products & Services: The company is most famous for its patented AR-15 magazine well conversion. This modification allows AK rifles chambered in 5.56mm to reliably feed from ubiquitous STANAG (AR-15) magazines and, crucially, incorporates a last-round bolt hold-open (LRBHO) feature—a function completely absent from traditional AKs.16 They also produce the highly regarded DAKM-4150 rifle, which has been praised for its impressive accuracy (achieving sub-2 MOA groups with surplus ammunition) and meticulous build quality.41 Their product line also includes well-regarded accessories like the Fighter Muzzle Brake and the DAG-13 adjustable front sight gas block.

- Reputation & Customer Feedback: Definitive Arms is praised for producing “super refined” rifles that feel like a significant step up from even high-quality imported guns. Reviewers consistently note their perfectly straight sights and smooth actions.10 Their products are often seen as providing excellent value, offering custom-grade quality in the sub-$1,000 to $1,500 price range.45

Two Rivers Arms – The Historian

- Introduction & Philosophy: Located in Oklahoma City, Two Rivers Arms specializes in creating historically accurate reproductions of rare and exotic military AK variants.47 Co-founded by former Army Lt. Col. and U.S. Congressman Steve Russell, the company’s mission is to build faithful replicas of weapons that U.S. veterans encountered on deployment but could not bring home, most notably the Iraqi Tabuk series of rifles.47

- Notable Products & Services: Their flagship product is the Iraqi Tabuk Designated Marksman Rifle, a 7.62x39mm rifle based on the Yugoslavian M70 series.50 Two Rivers Arms goes to great lengths to ensure authenticity, replicating original receiver markings, engravings, and finishes with exacting detail.49 Their accuracy is such that their rifles were used as props in the film American Sniper.52 They build their replicas using Yugoslavian parts kits on high-quality U.S.-made receivers.53

- Reputation & Customer Feedback: Two Rivers Arms is highly respected among collectors and historical enthusiasts for their meticulous attention to detail.47 Forum discussions and reviews praise their ability to create authentic-looking rifles that capture the essence of the originals.50 They are considered a top choice for anyone seeking a historically correct military clone.54

Meridian Ordnance LLC – The Versatile Craftsman

- Introduction & Philosophy: Meridian Ordnance is a veteran-owned small business in Mount Sterling, Kentucky, specializing in a wide range of gunsmithing services for both AK and AR platforms.56 Founded by Mike Owen in 2011, the shop focuses on one-on-one service and custom, built-to-order projects, from historically accurate builds to fully modernized rifles.58

- Notable Products & Services: The shop is a full-service gunsmith, offering everything from basic repairs and refinishing to complete parts kit builds and NFA-regulated manufacturing.56 They are recognized armorers for numerous aftermarket parts companies, including JMAC Customs and KNS Precision, and are adept at integrating modern components like adjustable gas pistons and optics platforms into the AK.56 They offer a range of finishing options, including Moly Resin, Cerakote, and traditional hot bluing over parkerization.56

- Reputation & Customer Feedback: Meridian Ordnance has garnered a strong reputation for high-quality work, particularly their rivet work, which customers describe as “second to none”.6 Reviews on the Better Business Bureau website and other forums are overwhelmingly positive, citing excellent craftsmanship, fair pricing, and knowledgeable staff.61 The primary complaint is long wait times, with one customer noting a nearly three-year wait for a project quoted at 12-18 months, a consequence of the shop’s popularity and small, hands-on nature.61 The BBB gives them an A+ rating, though they are not an accredited business.61

IV. Comparative Analysis: Selecting the Right Builder for Your Needs

Choosing a custom AK builder depends entirely on the end user’s goals, budget, and patience. The premier builders in the U.S. market each occupy a distinct niche, catering to different segments of the enthusiast community.

Master Builder At-a-Glance

| Builder | Specialization | Key Strength(s) | Ideal Customer | Potential Drawbacks |

| Hillbilly Firearms | IMI Galil Replicas | Unmatched Galil expertise, historical detail, nitride finishing 17 | The serious Galil collector, historical purist | High cost, long wait times (9+ months), niche focus 17 |

| Rifle Dynamics | Modernized Fighting AKs | Ergonomic enhancements, improved handling/balance, build classes | Tactical shooter, AR user transitioning to AK, training enthusiast | High price point, may deviate from historical purity 24 |

| Fuller Phoenix | Artisan Fighting AKs | Jim Fuller’s personal touch, ultimate craftsmanship, focus on durability 28 | The connoisseur seeking a “master-built” rifle, collectors | High demand, new orders often halted, premium price 37 |

| Definitive Arms | Innovative AK Hybrids | AR-15 magwell conversion, excellent accuracy, innovative parts 16 | The practical shooter wanting AR features on an AK platform | Less focus on historical replicas, some parts may be proprietary |

| Two Rivers Arms | Historical Military Replicas | Meticulous historical accuracy (markings, finish), Tabuk expertise 47 | Military history buffs, veterans, collectors of specific conflict firearms | Less focus on modern tactical upgrades 66 |

| Meridian Ordnance | Full-Service Custom Builds | Versatility (historical to modern), excellent rivet work, wide range of services 56 | The customer with a specific vision or unique parts kit | Long wait times due to high demand and small shop size 61 |

Historical Accuracy vs. Modern Performance

The custom AK market is largely defined by a philosophical split between historical purism and modern performance enhancement. On one end of the spectrum is Two Rivers Arms, whose primary mission is to create exact replicas of military firearms. Their work on the Iraqi Tabuk rifle, for instance, involves replicating every original marking and using period-correct components to provide a tangible piece of history for veterans and collectors.47 Their focus is on preservation and authenticity.

On the opposite end is Rifle Dynamics, a company whose entire ethos is built on re-engineering the AK for the modern American shooter. They systematically address the platform’s perceived shortcomings—poor sights, awkward ergonomics, limited accessory mounting—with proprietary parts and modifications designed to make the rifle faster, more balanced, and more intuitive for someone accustomed to the AR-15 platform.11 This philosophy prioritizes practical performance over historical fidelity.

The Parts Kit Gauntlet

For the enthusiast who has already sourced a vintage or rare parts kit, selecting a builder capable of properly bringing it to life is paramount. This is a distinct service that not all manufacturers offer. Builders like Meridian Ordnance, M13 Industries, and InRange explicitly advertise their expertise in working with customer-supplied parts, including “oddball” or challenging kits.56

The process is far more involved than simple assembly. It begins with a thorough inspection of the kit’s components to identify wear or out-of-spec parts, a critical first step offered by shops like Rifle Dynamics.69 The build itself requires demilling (removing the stubs of the old receiver), precisely riveting the trunnions into a new receiver, pressing and pinning the barrel while ensuring correct headspacing, and finally, applying a durable finish. This meticulous, labor-intensive process is why a quality kit build commands a premium price.

V. Navigating the Custom Build Process: Pitfalls and Best Practices

The path to a custom-built AK is rewarding, but it is not without potential pitfalls. The Kalashnikov platform is fundamentally different from the modular AR-15. While a competent hobbyist can assemble a high-quality AR-15 with a set of basic tools, building a top-tier AK requires specialized equipment like hydraulic presses and rivet jigs, along with a gunsmith’s nuanced understanding of fitting parts that were never designed for perfect interchangeability.12 This inherent complexity makes the choice of a professional builder absolutely critical and explains why the custom AK market is dominated by a handful of master craftsmen.

Gunsmithing Horror Stories: When Builds Go Bad

Forum discussions and customer reviews reveal a consistent pattern of issues that can arise from inexperienced or overwhelmed gunsmiths. These serve as a cautionary guide for prospective buyers.

- Mechanical Failures: The most common and dangerous issues stem from poor assembly. These include canted sight blocks that make zeroing impossible, improperly pressed rivets that compromise the receiver’s integrity, and incorrect headspacing that can lead to catastrophic failure.15 One user on a California-based forum recounted hearing about a rifle from Great Dane Armory that allegedly “blew up” due to poor construction.9

- Business Practice Failures: Even with skilled builders, business practices can be a source of immense frustration. The most frequent complaint across the board is extreme lead times, with some customers waiting years for work quoted for months.61 This is often compounded by poor communication, where customers are left in the dark about the status of their expensive projects.74 In other cases, the finished work simply does not match the customer’s order, leading to disputes over refinishing or remounting components.75 These stories highlight the importance of vetting not just the builder’s technical skill, but their business acumen as well.76

Vetting Your Builder: A Due Diligence Checklist

To mitigate these risks, prospective customers should undertake a thorough vetting process before committing to a build.

- Communication: The initial consultation is critical. A reputable builder should be willing to discuss the project in detail, provide a clear and itemized quote, and offer a realistic (if lengthy) timeline. Positive reviews often highlight excellent communication 61, while negative ones almost universally cite a lack of it.74

- Specialization: Match the project to the builder’s core competency. A customer seeking a historically perfect Iraqi Tabuk replica should go to Two Rivers Arms, not a shop that primarily focuses on tactical modernizations.

- Understanding Cost & Wait Times: Data from forums and builder websites clearly indicates that for high-end, small-shop builders, long wait times are the norm.37 A backlog of six months to a year or more is often a sign of a builder’s high demand and reputation for quality, not necessarily poor service. Customers must have realistic expectations before sending in their parts and payment.

VI. Final Recommendations and Market Outlook

The American AK market is more vibrant and diverse than ever before. The choice of a custom builder should be guided by a clear understanding of one’s personal goals for the rifle, whether for collection, competition, or defensive use.

Tailored Recommendations for Buyer Personas

- The Historical Collector: For those who value authenticity above all, Two Rivers Arms is the premier choice. Their dedication to creating exact replicas of military-issue firearms is unparalleled.47 For more general historical builds,

Meridian Ordnance offers a versatile and high-quality alternative.56 - The Modern Tactical Shooter: This user, likely accustomed to the AR-15, will be best served by Rifle Dynamics or Definitive Arms. The choice between them depends on the desired degree of modernization. Rifle Dynamics excels at refining the AK’s handling and ergonomics, while Definitive Arms offers groundbreaking features like the AR-15 magwell conversion for those who prioritize cross-platform compatibility.16

- The First-Time Custom Buyer: For a first foray into high-quality AKs, a top-tier production rifle like the Zastava ZPAP M70 or a Palmetto State Armory GF5-series rifle provides an excellent benchmark for quality and value.4 For a first

custom build, a versatile and well-regarded shop like Meridian Ordnance offers a superb balance of quality, price, and a wide range of services.56 - The Galil Enthusiast: The recommendation is unequivocal: Jeff Miller of Hillbilly Firearms. Despite the significant investment in both time and money, he is widely considered the undisputed master of the platform.18

Market Outlook: 2024-2025 and Beyond

The U.S. Kalashnikov market is poised for continued growth and evolution, shaped by both domestic trends and global events.

- Market Bifurcation: The market is clearly splitting into two distinct tiers. The high-end custom segment, dominated by the builders in this report, will likely see sustained demand, stable (and high) prices, and continued long lead times. The mid-tier will be a competitive battleground between high-quality imports from countries like Serbia (Zastava) and Poland (WBP), and increasingly competent American manufacturers like Palmetto State Armory and Kalashnikov USA, who are leveraging domestic production to offer a wide variety of models and features.4

- Impact of Geopolitics and Supply: Ongoing global conflicts and U.S. sanctions will likely keep the supply of foreign military surplus parts kits tight.2 This will increase the value of existing kits and place a greater emphasis on the quality of domestically produced components like barrels and receivers. This dynamic reinforces the value of expert builders who can either properly assemble valuable vintage kits or who have established supply chains for high-quality new parts.

- The Future is Hybrid: The trend of “Americanizing” the AK is set to continue. Expect to see more builders offering enhanced modularity, improved ergonomics, and greater compatibility with the vast ecosystem of AR-15 accessories.83 This ongoing hybridization will continue to blur the lines between the two iconic platforms, attracting a new generation of shooters to the rugged, reliable, and increasingly refined world of the American Kalashnikov.

VII. Appendix: Vendor Contact Information

| Vendor | Website / Social Media | Phone Number | |

| Hillbilly Firearms | hillbillyfirearms.com 84 | je**@***************ms.com 84 | (931) 488-1267 |

| Rifle Dynamics | rifledynamics.com 85 | in**@***********cs.com 85 | (702) 860-7774 85 |

| Fuller Phoenix | fullerphx.com 28 | Via Website Contact 28 | (480) 608-5490 87 |

| Definitive Arms | definitivearms.com 88 | Via Website Contact 88 | 1-844-322-8458 88 |

| Two Rivers Arms | tworiversarms.com 48 | sa***@***********ms.com | (405) 745-7179 48 |

| Meridian Ordnance LLC | meridianordnance.com 89 | qu*******@**************ce.com 89 | (859) 520-3436 89 |

| Appalachian Arms | appalachianarms.co 91 | ap*************@***il.com 91 | Not Publicly Listed |

| Circle 7 Armory | Facebook Page | ci***********@***il.com | (903) 461-1935 92 |

| CW Gunwerks | cwgunwerks.com 93 | in**@********ks.com 93 | (786) 478-6565 93 |

| Great Dane Armory | greatdaneakarmory.com 95 | da***@*************ry.com 96 | (818) 402-0091 96 |

| Inrange / Troy Sellers | inrangec2.com 68 | in*******@*ol.com 68 | (865) 932-6509 98 |

| Iron Curtain Customs | ironcurtaincustoms.com 99 | in**@****************ms.com 100 | (832) 387-4432 100 |

| Lee Armory | leearmory.com (Defunct) 102 | co***********@***il.com 102 | N/A (Defunct) |

| M13 Industries | m13industries.com 103 | IN**@***********ES.COM 103 | (702) 420-8708 103 |

| McCluskey Arms Co. | mccluskeyarms.com 105 | Er**@***********ms.com 106 | (541) 357-7947 106 |

| Mesa Kinetic Research | michigankinetics.com 108 | ME*****************@***IL.COM 108 | (231) 729-1332 108 |

| The Armory | thearmoryguns.com 109 | ti*@***************th.com 109 | (205) 624-3298 109 |

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, we are only paid if there is an affiliate program such as Avantlink, Impact, Amazon and eBay and only if you purchase something. If you’d like to directly contribute towards our continued reporting, please visit our funding page.

Works cited

- Gun Review: Lee Armory AKM – Guns.com, accessed July 28, 2025, https://www.guns.com/news/2019/08/21/gun-review-lee-armory-akm

- Milled American AK – the Century Arms MB47 Review – YouTube, accessed July 30, 2025, https://www.youtube.com/watch?v=vNDjOLq_NZU

- Review: Palmetto State Armory AK-103 | An Official Journal Of The NRA, accessed July 28, 2025, https://www.americanrifleman.org/content/review-palmetto-state-armory-ak-103/

- Best AK-47 Buyer’s Guide [Field Tested] – Gun Digest, accessed July 28, 2025, https://gundigest.com/rifles/the-best-ak-47-rifles-you-can-find-in-the-u-s

- Kalashnikov(ish) Madness at SHOT – Recoil Magazine, accessed July 30, 2025, https://www.recoilweb.com/kalashnikovish-madness-at-shot-58163.html

- Reviews Archives : Meridian Ordnance LLC, accessed July 28, 2025, https://meridianordnance.com/reviews/

- What makes the AK-47 so great a gun? – Reddit, accessed July 28, 2025, https://www.reddit.com/r/guns/comments/1aukxy1/what_makes_the_ak47_so_great_a_gun/

- Sellers- Has anyone had the courage to review a terrible purchase yet again from one or a few insanely popular sellers without fear of retalitaion? As if they might send a troll squad to ruin your ratings/talk crap every live..etc.. anyone experience this? : r/whatnotapp – Reddit, accessed July 30, 2025, https://www.reddit.com/r/whatnotapp/comments/1l8515u/sellers_has_anyone_had_the_courage_to_review_a/

- Anyone hear used/heard of Great Dane AK Armory? : r/CAguns – Reddit, accessed July 30, 2025, https://www.reddit.com/r/CAguns/comments/la9c6g/anyone_hear_usedheard_of_great_dane_ak_armory/

- Definitive Arms AK-103U AK-47 Variant Review (HD) – YouTube, accessed July 28, 2025, https://www.youtube.com/watch?v=cBpH4x0CNpA

- RIFLE DYNAMICS RD702: Benchmark of AK Excellence – Small Arms Review, accessed July 28, 2025, https://smallarmsreview.com/rifle-dynamics-rd702-benchmark-of-ak-excellence/

- What exactly makes the AK such a reliable weapon from an engineering standpoint? : r/guns – Reddit, accessed July 28, 2025, https://www.reddit.com/r/guns/comments/1dkpwwc/what_exactly_makes_the_ak_such_a_reliable_weapon/

- ELI5: What makes the AK-47 one of the most reliable guns in the world? Why can’t other companies replicate this reliability? – Reddit, accessed July 28, 2025, https://www.reddit.com/r/explainlikeimfive/comments/3d54xf/eli5_what_makes_the_ak47_one_of_the_most_reliable/

- Is the AK-47 really reliable, or is it nothing but hot air? : r/Firearms – Reddit, accessed July 28, 2025, https://www.reddit.com/r/Firearms/comments/1dyr3jz/is_the_ak47_really_reliable_or_is_it_nothing_but/

- Why are Century Arms AK rifles universally hated? Are they really as bad as everyone says? : r/guns – Reddit, accessed July 28, 2025, https://www.reddit.com/r/guns/comments/11xlb1x/why_are_century_arms_ak_rifles_universally_hated/

- Building with the Best: Making an AK with Definitive Arms – OutdoorHub, accessed July 28, 2025, https://www.outdoorhub.com/stories/2015/12/08/building-with-the-best-making-an-ak-with-definitive-arms/

- Received my Hillbilly Firearms (Jeff Miller) Galil ARM : r/guns – Reddit, accessed July 30, 2025, https://www.reddit.com/r/guns/comments/ogmzbv/received_my_hillbilly_firearms_jeff_miller_galil/

- Gunsmith Recommendations : r/Galil – Reddit, accessed July 30, 2025, https://www.reddit.com/r/Galil/comments/qp3xrc/gunsmith_recommendations/

- GALIL Calibre change – GunSite South Africa, accessed July 30, 2025, https://www.gunsite.co.za/forums/showthread.php?101191-GALIL-Calibre-change

- Hillbilly Firearms has some bullet guides in stock for anyone that needs one : r/Galil – Reddit, accessed July 30, 2025, https://www.reddit.com/r/Galil/comments/10p7w1d/hillbilly_firearms_has_some_bullet_guides_in/

- Galil build Jeff of Hillbilly firearms vs other builders – Reddit, accessed July 30, 2025, https://www.reddit.com/r/Galil/comments/ol3ls8/galil_build_jeff_of_hillbilly_firearms_vs_other/

- Hillbilly firearms ARM build finally finished! : r/Galil – Reddit, accessed July 30, 2025, https://www.reddit.com/r/Galil/comments/1g6xd9j/hillbilly_firearms_arm_build_finally_finished/

- CA Golani, ATI Galeo or JRA Gallant? : r/Galil – Reddit, accessed July 28, 2025, https://www.reddit.com/r/Galil/comments/15i9dru/ca_golani_ati_galeo_or_jra_gallant/

- Rifle Dynamics RD-74: The AK Perfected – Recoil Magazine, accessed July 28, 2025, https://www.recoilweb.com/preview-rifle-dynamics-74-6227.html

- Noir Review | Rifle Dynamics AK-47 | An Official Journal Of The NRA, accessed July 28, 2025, https://www.americas1stfreedom.org/content/noir-review-rifle-dynamics-ak-47/

- Best AK-47 Ever? Rifle Dynamics AK 704P GT Review – YouTube, accessed July 28, 2025, https://www.youtube.com/watch?v=KXs4L5DL8XI

- Rifle Dynamics Customized AK (Arsenal SGL-21): Initial Impressions – YouTube, accessed July 28, 2025, https://www.youtube.com/watch?v=4gapPbuYCQw

- Fuller Phoenix, LLC – Jim Fuller, accessed July 30, 2025, https://www.fullerphx.com/

- SUREFIRE FIELD NOTES 61: JIM FULLER – AK 101, accessed July 30, 2025, https://www.surefire.com/news/?p=surefire-field-notes-61-jim-fuller-ak-101

- ‘No different than putting my wallet in my pocket’: AK-47 manufacturer on normalizing gun ownership – KJZZ, accessed July 30, 2025, https://www.kjzz.org/the-show/2024-11-26/no-different-than-putting-my-wallet-in-my-pocket-ak-47-manufacturer-on-normalizing-gun-ownership

- Jim Fuller talks AK’s at Gunsite – YouTube, accessed July 30, 2025, https://www.youtube.com/watch?v=jfRzA9TeLgw

- Jim Fuller’s Custom AK105 Transferable & ORIGINAL Amnesty Communist China AK47, accessed July 28, 2025, https://www.youtube.com/watch?v=VXJjOZHZMds

- Travis Haley and Jim Fuller #7… – Coffee and a Mike – Apple Podcasts, accessed July 30, 2025, https://podcasts.apple.com/us/podcast/travis-haley-and-jim-fuller-745/id1436799008?i=1000645444362

- The Bridge – A Fuller Life with Jim Fuller – YouTube, accessed July 30, 2025, https://www.youtube.com/watch?v=fqkJz25ZpVI

- The Grip Show (Episode 12) James Fuller – YouTube, accessed July 30, 2025, https://www.youtube.com/watch?v=hKbi4tprgIg

- Guru Jim Fuller: Are You Ready For Freedom Controversial Statement – YouTube, accessed July 30, 2025, https://www.youtube.com/watch?v=v_4n9DeNFbE

- FPX KIT BUILDS UPDATE WITH JIM FULLER – YouTube, accessed July 28, 2025, https://m.youtube.com/watch?v=axgQjyssYR4&pp=ygUOI2Z1bGxlcnBob2VuaXg%3D

- Definitive Arms – AR15 mags in an AK – YouTube, accessed July 28, 2025, https://www.youtube.com/watch?v=PAjidZr5D7o

- Services – DEFINITIVE ARMS, accessed July 30, 2025, https://definitivearms.com/services/

- Comparison of the AK-47 and M16 – Wikipedia, accessed July 30, 2025, https://en.wikipedia.org/wiki/Comparison_of_the_AK-47_and_M16

- ak-47 – Athlon Outdoors – RSSing.com, accessed July 30, 2025, https://tactical1111.rssing.com/chan-59201339/all_p3.html

- DAKM 4150N – AK Brothel ANGEL WHORE! – YouTube, accessed July 30, 2025, https://www.youtube.com/watch?v=Bx_wmm9GDTI

- Definitive Arms 1.75 MOA AK – DAKM 4150N Shootout Test – YouTube, accessed July 30, 2025, https://www.youtube.com/watch?v=TZ6Y8-sS-NE

- AKM recoil :: Rising Storm 2: Vietnam General Discussions – Steam Community, accessed July 30, 2025, https://steamcommunity.com/app/418460/discussions/0/1473095965308527278/

- 1.75 MOA AK – DAKM 4150N Shootout Test, accessed July 30, 2025, https://www.akoperatorsunionlocal4774.com/2015/08/1-75-moa-ak-dakm-4150n-shootout-test/

- How to Buy the Best AK-47 for your dollar – AK-47 Buyers Guide, accessed July 28, 2025, https://howtobuyanak47.com/2016/11/08/best-ak-47/

- Two Rivers Arms reproduction of the Iraqi ‘Tabuk’ designated Marksman Rifle – Reddit, accessed July 28, 2025, https://www.reddit.com/r/ForgottenWeapons/comments/q3r5n2/two_rivers_arms_reproduction_of_the_iraqi_tabuk/

- Two Rivers Arms – Oklahoma City, OK, accessed July 28, 2025, https://www.tworiversarms.com/

- A US congressman is making AK-47 rifles like the ones he faced in Iraq, accessed July 30, 2025, https://www.wearethemighty.com/mighty-tactical/a-us-congressman-is-making-ak-47-rifles-like-the-ones-he-faced-in-iraq/

- Two Rivers Arms ‘Tabuk’ AK marksman rifle build : r/longrange – Reddit, accessed July 28, 2025, https://www.reddit.com/r/longrange/comments/ga98ib/two_rivers_arms_tabuk_ak_marksman_rifle_build/

- Saddam’s Mid-Range “Sniper” Rifle: The Tabuk Sniper – YouTube, accessed July 30, 2025, https://www.youtube.com/watch?v=k3VKscJQY8M

- AK-47 Tabuk Manufacturer – Two Rivers Arms – YouTube, accessed July 28, 2025, https://www.youtube.com/watch?v=kZE3e_8D_Wk

- Saddam’s Rifles: The Tabuk AK – YouTube, accessed July 30, 2025, https://www.youtube.com/watch?v=EPhoyDFyhpo

- AK builders/gunsmiths in MN : r/MnGuns – Reddit, accessed July 28, 2025, https://www.reddit.com/r/MnGuns/comments/g6wr96/ak_buildersgunsmiths_in_mn/

- Buying an AK. What are some suggestions for a good one? : r/liberalgunowners – Reddit, accessed July 28, 2025, https://www.reddit.com/r/liberalgunowners/comments/1cv34pn/buying_an_ak_what_are_some_suggestions_for_a_good/

- AK Services : Meridian Ordnance LLC, accessed July 28, 2025, https://meridianordnance.com/ak-services/

- D Homepage : Meridian Ordnance LLC, accessed July 30, 2025, https://meridianordnance.com/

- Meridian Ordnance – SHARPS BROS, accessed July 28, 2025, https://sharpsbros.com/meridian-ordnance/

- Meridian Ordnance Reviews: Rivet Work, accessed July 30, 2025, https://meridianordnance.com/rivet-work-second-to-none/

- AK74 refinishing review – Meridian Ordnance, accessed July 30, 2025, https://meridianordnance.com/extremely-satisfied-ak74/

- Meridian Ordnance LLC | BBB Reviews | Better Business Bureau, accessed July 28, 2025, https://www.bbb.org/us/ky/mount-sterling/profile/gunsmiths/meridian-ordnance-llc-0402-9111994/customer-reviews

- Gunsmiths near Ashland, KY | Better Business Bureau, accessed July 30, 2025, https://www.bbb.org/us/ky/ashland/category/gunsmiths

- Gunsmiths near Frenchburg, KY | Better Business Bureau, accessed July 30, 2025, https://www.bbb.org/us/ky/frenchburg/category/gunsmiths

- Meridian Ordnance LLC | BBB Business Profile | Better Business Bureau, accessed July 28, 2025, https://www.bbb.org/us/ky/mount-sterling/profile/gunsmiths/meridian-ordnance-llc-0402-9111994

- Gunsmiths near Richmond, KY | Better Business Bureau, accessed July 30, 2025, https://www.bbb.org/us/ky/richmond/category/gunsmiths

- The History of the Iraqi AK Tabuk Rifle – Recoil Magazine, accessed July 30, 2025, https://www.recoilweb.com/the-history-of-the-iraqi-tabuk-ak-rifle-156496.html

- BUILD SERVICES – M13 Industries, accessed July 28, 2025, https://m13industries.com/index.php?route=product/category&language=en-gb&path=18_33

- In Range Inc. | Class II Manufacturer – Specializing in Kalashnikov …, accessed July 28, 2025, http://inrangec2.com/

- AK Kit Build (Starting at $1350) – Rifle Dynamics, accessed July 30, 2025, https://rifledynamics.com/ak-kit-build

- AK builders around Seattle? : r/WA_guns – Reddit, accessed July 30, 2025, https://www.reddit.com/r/WA_guns/comments/quxuzd/ak_builders_around_seattle/

- Anyone here building AK 47 | The Hobby-Machinist, accessed July 30, 2025, https://www.hobby-machinist.com/threads/anyone-here-building-ak-47.83942/

- CA Compliant AKM from WarriorOne in Riverside CA. Lee Armory Hungarian Operator. : r/CAguns – Reddit, accessed July 28, 2025, https://www.reddit.com/r/CAguns/comments/6mpwot/ca_compliant_akm_from_warriorone_in_riverside_ca/

- The Worst AK Build I Have Ever Seen, Bar None – Forgotten Weapons, accessed July 30, 2025, https://www.forgottenweapons.com/the-worst-ak-build-i-have-ever-seen-bar-none/

- TX AK gunsmiths : r/TexasGuns – Reddit, accessed July 30, 2025, https://www.reddit.com/r/TexasGuns/comments/srn706/tx_ak_gunsmiths/

- gunsmith horror story – SASS Wire Forum, accessed July 30, 2025, https://forums.sassnet.com/index.php?/topic/217635-gunsmith-horror-story/

- [Lesson] Gunsmith Nightmare : r/1911fans – Reddit, accessed July 30, 2025, https://www.reddit.com/r/1911fans/comments/6dtynf/lesson_gunsmith_nightmare/

- Worst Gunsmith Experience? : r/guns – Reddit, accessed July 30, 2025, https://www.reddit.com/r/guns/comments/3qvyvv/worst_gunsmith_experience/

- Gunsmithing Horror Stories – MGS Trade School, accessed July 30, 2025, https://mgs.edu/gunsmithing-horror-stories/

- AR15 Nightmare — Multiple Build Issues | Shooters’ Forum, accessed July 30, 2025, https://forum.accurateshooter.com/threads/ar15-nightmare-multiple-build-issues.4042469/

- Best AK-47 Rifles [Tested] – Pew Pew Tactical, accessed July 28, 2025, https://www.pewpewtactical.com/best-ak-47/

- AK-47 Rifle Shootout: Finding the Right Kalash for You | American Firearms, accessed July 28, 2025, https://www.americanfirearms.org/best-ak-47-rifles/

- 2025 Market Forecast: Demand for Eastern European AKs in America – Zastava Arms USA, accessed July 30, 2025, https://zastavaarmsusa.com/2025-market-forecast-demand-for-eastern-european-aks-in-america/

- Here’s How America Improved upon the AK-47 – The National Interest, accessed July 28, 2025, https://nationalinterest.org/blog/reboot/heres-how-america-improved-upon-ak-47-191275/

- HillBilly Firearms, accessed July 30, 2025, https://hillbillyfirearms.com

- Rifle Dynamics overview – services, products, equipment data and more | Explorium, accessed July 30, 2025, https://www.explorium.ai/manufacturing/companies/rifle-dynamics

- AK Kit Inspection ($200) – Rifle Dynamics, accessed July 30, 2025, https://rifledynamics.com/ak-kit-inspection/

- Fuller Phoenix, 16655 NORTH 90TH STREET SUITE 100, SCOTTSDALE, AZ | FFLs.com, accessed July 30, 2025, https://www.ffls.com/ffl/986013073j15372/fuller-phoenix-llc

- Contact Us – DEFINITIVE ARMS, accessed July 30, 2025, https://definitivearms.com/contact-us/

- Meridian Ordnance LLC – GSL Technology, Inc., accessed July 30, 2025, https://gsltechnology.com/dealers/meridian-ordnance-llc/

- Meridian Ordnance Long-Range AR, accessed July 30, 2025, https://meridianordnance.com/meridian-long-range-ar/

- How it Works – Appalachianarms, accessed July 30, 2025, https://www.appalachianarms.co/our-services/

- Circle 7 Armory, 3408 OLD MILL RD, GREENVILLE, TX | FFLs.com, accessed July 30, 2025, https://www.ffls.com/ffl/575231076b12728/gannaway-michael

- CW Gunwerks, accessed July 30, 2025, https://www.cwgunwerks.com/

- Contact Us – CW Gunwerks, accessed July 30, 2025, https://www.cwgunwerks.com/contact-us

- Great Dane Armory, accessed July 28, 2025, https://greatdaneakarmory.com/

- Contact form Great dane AK-47 armory, accessed July 30, 2025, https://greatdaneakarmory.com/contact-us/

- Contact Us | In Range Inc., accessed July 30, 2025, http://inrangec2.com/contact-us/

- Kalashnikov AKSU AKM SBR/Sub-Carbine Chambered in 300 AAC Blackout Test-Fired at the Range (Video!) – Defense Review, accessed July 30, 2025, https://defensereview.com/kalashnikov-aksu-akm-sbrsub-carbine-chambered-in-300-aac-blackout-test-fired-at-the-range-video/

- Iron Curtain Customs, accessed July 28, 2025, https://ironcurtaincustoms.com/

- Iron Curtain Customs LLC | Allen Arms Tactical, accessed July 30, 2025, https://allenarmstactical.com/store/iron-curtain-customs-llc/

- Contact Icc – IRON CURTAIN CUSTOMS, accessed July 30, 2025, https://swagata-codearts.github.io/iron-curtain-customs/contact-icc.html

- Lee Armory closes it’s doors, accessed July 28, 2025, https://www.leearmory.com/

- M13 Industries, accessed July 30, 2025, https://m13industries.com/

- Contact Us – M13 Industries, accessed July 30, 2025, https://m13industries.com/en-gb?route=information/contact

- McCluskey Arms – Gunsmith in Eugene, OR, accessed July 28, 2025, https://mccluskeyarms.com/

- Gunsmithing | Mazama Sporting Goods, accessed July 28, 2025, https://mazamasportinggoods.com/gunsmithing/

- The McCluskey Arms Company – Eugene Chamber of Commerce, accessed July 30, 2025, https://web.eugenechamber.com/Sporting-Goods-Retail/The-McCluskey-Arms-Company-5483

- MICHIGAN KINETICS, accessed July 28, 2025, https://michigankinetics.com/

- Gun Shop Pelham | Fast Turnaround | The Armory, accessed July 28, 2025, https://www.thearmoryguns.com/

- Contact Us – Gun Shop Pelham, accessed July 30, 2025, https://www.thearmoryguns.com/contact