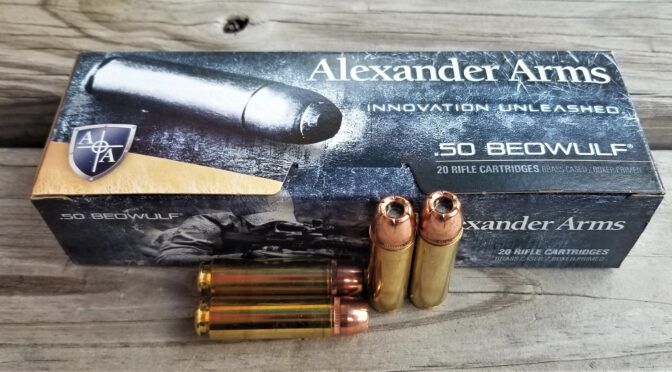

My friends know I am eccentric so I’ll point that out right up front. I design and build firearms that are very practical and some that are pushing the fringe. I’ve liked the .50 Beowulf cartridge (also known by it’s metric designation as 12.7x42mm). Bill Alexander designed the Beowulf to operate out a fairly standard AR platform which included a 16″ barrel and normal buffer. With the huge popularity of AR pistols with braces, I got to thinking – how short can I go?

Well, there are a number of pistol length uppers now that are 12″. Alexander Arms themselves both a 12″ complete upper as well as a 12″ DIY upper waiting for you to add your handguards of choice. There are cheap builders out there and I would tell you to be very careful to research the vendor before you buy. Some of them have awful track records.

Know what? I wanted to go even shorter and I had no problem buying the parts and building one myself. You see, I wanted a howitzer. To me, a howitzer is a firearm with a barrel so short that it can’t burn all the powder before the bullet exits resulting in a spectacular flare. Useful? Not really. Cool? Oh hell, yes 🙂

Satern’s Liberty Barrels & Upper Parts

If there’s one thing I have learned about the Beowulf, you need the right combination of parts or reliability will suffer. So that really meant that I needed to go with a reputable vendor. There’s a barrel company that really knows their stuff that you may not of heard about – Satern. They are located in Estherville, Iowa, and operated by Debra and Steven Satern. I talked to Deb a few times while I was planning my build. They were great to deal with and shipped fast – even with all the COVID craziness these days.

Satern has pretty much everything you will need to build a 12.7×42 upper. They have:

- different barrel lengths – 7.5, 10.5, 14.5 and 16″ – note they come with the correct headspaced bolt. This is a big deal. Not all vendors use the right bolt and that causes reliability problems. Also, the thread is unique – 3/4-24 and not the 49/64-20 that Alexander Arms uses. This means you will need to either get your brake from Satern, Timber Creek or another vendor that supports a .50 cal with 3/4-24 threads. I went with Satern’s Heliport brake in part due to this threading.

- They offer Barrel kits with brakes

- Big bore forged uppers – basically a standard AR upper with the ejection port milled open larger. They offer uppers with the dust cover already installed or just a stripped upper

- Gas tube assemblies

I went down their menu and bought the 7.5″ barrel, 3/4-24 Heliport brake, stripped upper, ejection port door, and pistol length gas tube from them. I just like doing my own thing is what it boils down to.

Other Parts

Once I had the main parts of the upper figured out, the rest was pretty easy. The lower is how-ever you want to build your lower. I planned for a pistol build using some of my favorite parts:

- SBTactical’s SBA4 brace – it has six positions and the rear end is stiffer and better formed than the SBA3.

- 12/28/2020: I am tinkering with the combination of buffer and buffer spring. Click here for a post about them.

- Midwest Industries Combat Rail – these are very well made and finished. I especially like how the handguard fits onto their locking nut allowing for a ton of flexibility.

- Vortex Strikefire II Red/Green Dot – these have a real nice wide field of view allowing for rapid target acquisition plus it can co-witness with iron sights out of the box.

- BCM’s Gunfighter Mod 3B charging handle – I’ve become very fond if these over the year’s and the enlarged latch handle just feels right to me.

Summary

That’s it for now. The next post will start to get into the actual build.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, we are only paid if there is an affiliate program such as Avantlink, Impact, Amazon and eBay and only if you purchase something. If you’d like to directly contribute towards our continued reporting, please visit our funding page.

Note, I have to buy all of my parts – nothing here was paid for by sponsors, etc. I do make a small amount if you click on an ad and buy something but that is it. You’re getting my real opinion on stuff.