I’m sure there are a lot of shooters like me who buy and install back up iron sites on their weapons just in case the optic fails. Except for pure range toys that will never see use beyond having fun, I do think BUIS are a really good idea – optics fail for any number of reasons with batteries being dead quite possibly being the #1 issue – especially given how folks love their red dot, green dot and holographic sights. You need a backup for aiming your firearm.

A quick comment about “BUIS” – it stands for Back Up Iron Sights. I’m a creature of habit and that’s how they were first introduced to me but not everyone uses that term. For example, Magpul calls their units MBUS – Magpul Back-Up Sights. Other’s just say “back up sights” or even just “attachable” or “folding” sights. So, if you are wanting to search and see what your options are, it will take some searching.

Four Camps of BUIS Users

In talking with shooters, regardless of their firearm platform (AR, AK, Stribog, HK, etc.) about their BUIS, I usually find they fit in one of four camps:

- Installed the BUIS and run them full time with their optic in a co-witness manner

- Installed the BUIS and periodically use them in a co-witness model but fold them down when not in use

- Installed the BUIS and only use them when needed but did sight them in. For example, if they need to remove the optic to deploy the sights or are using offset sights and tilt the weapon 45 degrees to use them.

- Attached the units to the Picatinny rail, did not sight them in and have never actually practiced using them to hit targets at the range … “but have them just in case”.

With scenario #1, you know those sights will work – it doesn’t matter if the scope is powered off as long as you can see through the glass.

With #2 & #3 – the sights will probably work as long as you can see through the glass or otherwise see them. Hopefully the shooter has practiced enough how to use the units.

The last one is the most concerning – camp #4 – to be honest, a person in this camp doesn’t really have a backup. Yeah, they have the sights but they aren’t dialed in and lack experience with them. This is a gamble you do not want to take. If this describes you – please don’t take it personally and read the next section – I want to help.

If You Are In Camp #4…

First off, I am glad you invested in BUIS – if you are reading this and you haven’t yet, then do so. With that said, do you have quality units or did you buy something dirt cheap off Amazon or eBay. I’d recommend going with a brand name and not cheap airsoft import stuff – I like Magpul (they have a ton of models so click here to see them) plus, in all fairness, there are other quality BUIS sets from the likes of ARMS, Bobro, DiamondHead, Troy and others. Cheap stuff may not hold their zero or break easily. Buy quality to have true BUIS that you can count on.

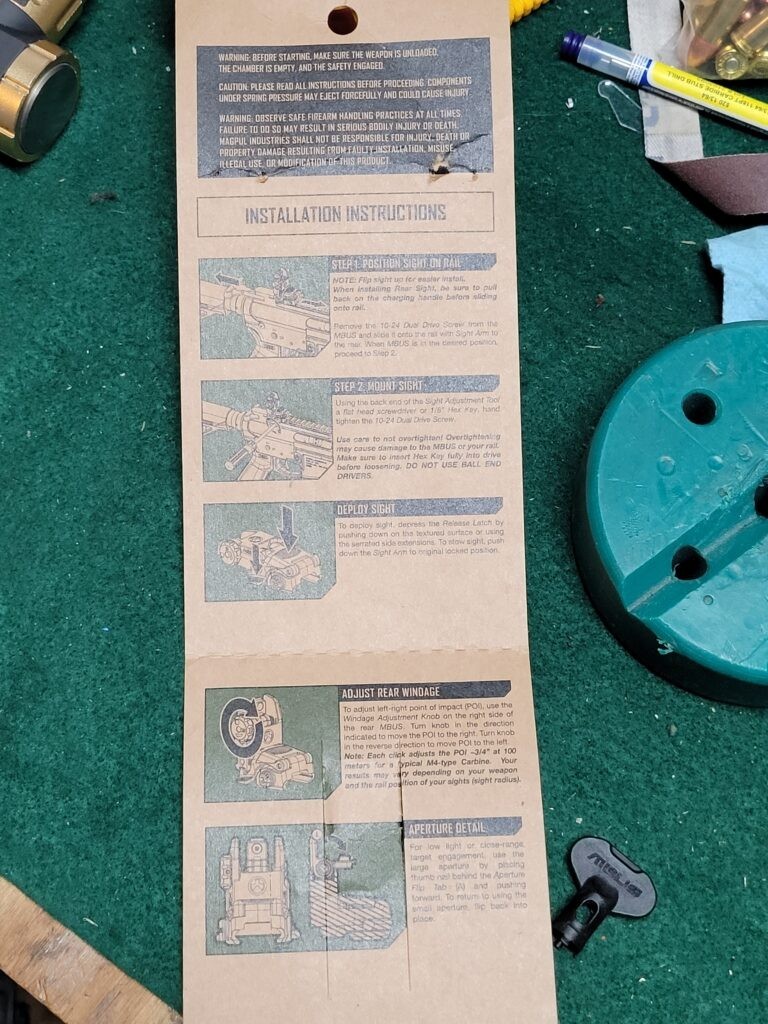

Second, make sure they are mounted properly. Did you follow the instructions from the vendor who made them? Sometimes there is more to do than slap them on the Picatinny Rail.

Second, you need to sight in the BUIS. I use a laser to help get in the ballpark in the shop and then I do the final tuning at the range. Read up on the recommended range for your firearm and type of optic. For rifles, I go for 50 yards because then you are then zeroed for 50 yards and at 200. The BUIS are just that – emergency backups. I look to be in the ballpark with them and am not looking for perfection but some guys are amazingly proficient with them.

Third, absolutely take them to the range and practice with them!!! Buying, installing and zeroing the BUIS are only part of the game – you must also know how to use them. If they fold, practice on opening and closing them while shooting. If they are offset, practice transitioning to them. Bottom line, you need to practice hitting targets with them and adjust the sights and what you are doing accordingly. The more you practice the greater the odds that things will work when you need them. If you don’t practice then you are taking a huge gamble both on the BUIS and your ability to use them – so don’t gamble.

Summary

The whole reason I wrote this is that it seems like I have encountered a lot of shooters this past year that had BUIS and fell square in camp 4 – they had never sighted them in or practiced with them. This is very concerning to me – they are gambling on something that shouldn’t be left to chance. So, yes, I think BUIS are a great idea but you need to sight them in and regularly practice using them also. If you don’t, then your backup probably isn’t a backup.

I hope this gives you some food for thought.

Note, I have to buy all of my parts – nothing here was paid for by sponsors, etc. I do make a small amount if you click on an ad and buy something but that is it. You’re getting my real opinion on stuff.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, we are only paid if there is an affiliate program such as Avantlink, Impact, Amazon and eBay and only if you purchase something. If you’d like to directly contribute towards our continued reporting, please visit our funding page.