When you buy a scope/optic and mount it on your rifle or pistol, it may relatively be close to where the actual bullet will hit the target or it may be a mile off. This applies just as much to dot optics as well as scopes with magnification. First off, this is why you need to sight in any type of optic before you use it. Second, unless you want to waste a ton of ammo, this is why you want to bore sight an optic before you do the final adjustments.

“Bore Sighting” refers to looking down the bore, seeing the target and roughly dialing on the elevation and windage of the optic. This was never perfect but it at least got you on the paper at 25-50 yards you could then start dialing in the scope and backing up to whatever range you wanted to dial the scope in for. This method worked fine if you could actually remove the bolt and look down the scope, such as a bolt action rifle. It doesn’t work for semi-autos where you typically have a closed rear receiver and can’t look down the bore. It also doesn’t work for folks like me who can’t see the broad side of a bright red barn when trying to look down a bore.

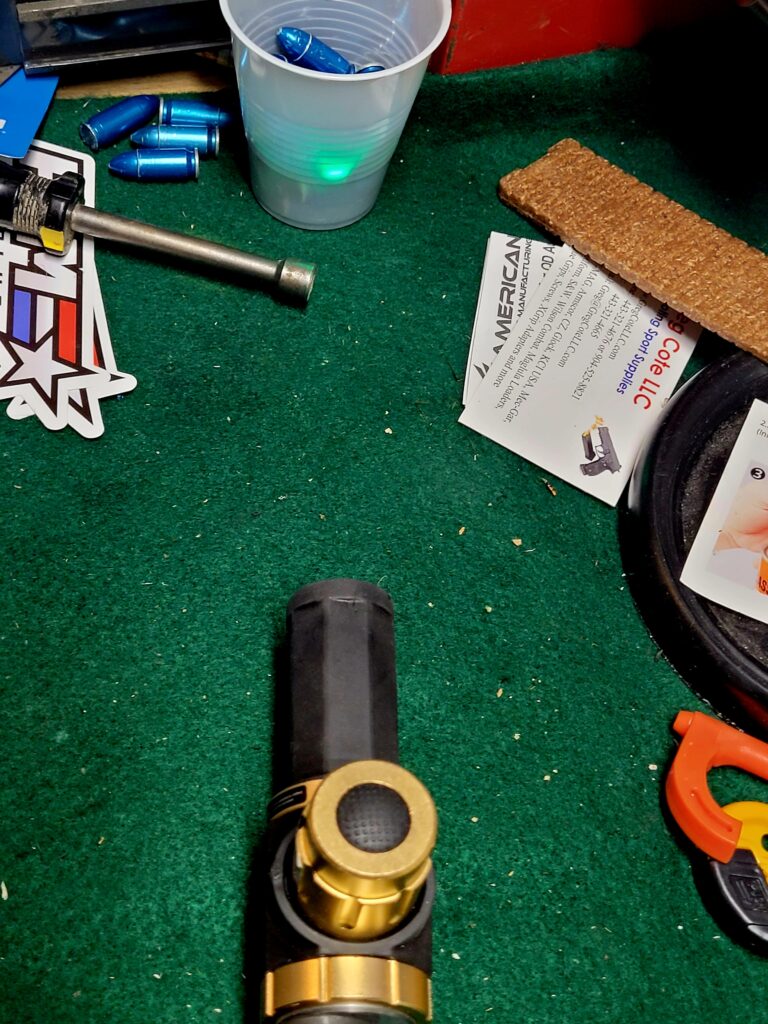

The industry responded with all kinds of gizmos to help improve the process ranging from calibrated collimeters that let you roughly sight in by pointing at some target held up from the end of the barrel. That lasted for a few years until lasers started getting affordable and then models started popping up that either went in the muzzle with some form of collet to help center the shaft in the barrel or there were ones that approximated the shape of a given round and went in the chamber. The accuracy of either one greatly depended on the quality control of the manufacturer. In general, they worked and were really simple – put the laser in, turn it on and then dial in your scope to where the red dot was showing.

Pros: Simple, cheap, did the job Cons: acccuracy was highly dependent on how well the manufacturer made the unit, they are impacted by how well the inside of the muzzle device aligns with the barrel and the red laser faded out quickly in bright light and because they all use button cells of varying sizes the battery life might be short – especially the fake cartridge units. Note, a number of the muzzle end manufacturers do offer green lasers and that helps. Bottom line, they do the job and I do favor the muzzle end devices more provided they are from a quality manufacturer.

Then along came Wheeler Engineering with relatively large green laser unit with a strong magnet that sticks on the face of the muzzle (the end of the barrel). This got away from issues with the muzzle end units not centering and the frequent poor quality of the imported fake cartridge units. The green laser is powered by a relatively large CR123A battery that is the same used in many tactical lights. I should point out that they make a red laser version too but if I had to pick I would go with the green laser as your eye can see it easier and it reflects from further away.

I’ve used it for a few years now (I bought it in 2019) and have found two issues that affect it. First, the end of the barrel or your muzzle device (flash hider, muzzle brake, and so forth must be steel for the magnet to stick to it. By the way, I am not impressed by how aluminum muzzle devices hold up over time and just buy steel whenever I can.

The second shortcoming is that the manufacturer of the muzzle device and/or the barrel must have created a true end meaning the end of the barrel, the thread, the muzzle device – they must all result in an end of the barrel/muzzle device that is perpendicular to the barrel. The worst offenders in my experience are the muzzle devices because their positioning depends both on how well the threads were but on the barrel plus how well the device was made. Some combinations are better than others. If I were to make a generalization, unthreaded barrel muzzle faces from a quality manufacturer tend to be pretty true.

As with the other bore sighting devices, this unit will get you in the ballpark. Because of the factors above, you might be on the paper at 100 yards but you are better starting off at 50 and working things out from there.

By the way, one tip of any of them is to do your boresighting early in the morning or at dusk but not in the bright light of day. You can reach out 25-50+ yards and see the dot enough to do the initial sighting.

As a closing comment – none of them are perfect because they were all designed to be approximations. The final sighting must be done by you with the rounds you expect to use because a ton of variable will affect where you bullet actuall hits – your cheek weld, your trigger pull, factors with the bolt and barrel, how consistent the ammo is, the weight of the bullets, etc. My goal is to save some ammo and at least hit the target so I don’t have to shoot so many rounds to dial in the final settings and then begin working out firing solutions for different ranges.

In Conclusion

There actually isn’t a perfect solution – I mainly use the Wheeler Pro Green Laser Boresighter when I can but I still have a couple of good muzzle end units that I use when the muzzle device is aluminum. I know one unit is from LaserLyte and I really do not recall who the other is from. I do not use the dummy cartridge units after a few disappointing tries.

So, if you haven’t tried a Wheeler Pro boresighter and are in the market, I like mine.

Note, I have to buy all of my parts – nothing here was paid for by sponsors, etc. I do make a small amount if you click on an ad and buy something but that is it. You’re getting my real opinion on stuff.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, I may be paid via an affiliate program such as Avantlink, Impact, Amazon and eBay.