The Glock 29 Gen 4 offers a solid platform out of the box and for many, that is all they want. For me, after building a few Polymer80s and having a better idea of what I liked, I knew I wanted to upgrade some of the parts to personalize it plus run heavier loads.

Wait – Not The Trigger You Ask?

You may look at that list and be surprised that I left the trigger alone – yes, I did. I’ve used Zev, Overwatch and other aftermarket triggers along with other aftermarket parts like connectors, springs, etc. My personal choice, and this is just me, was to go with the tried and proven OEM Glock parts and let them wear in. I’m not shooting matches or precision targets – this was to be a defensive pistol so I wanted reliability and a trigger with enough pull that I wouldn’t have an accidental discharge. There are guys that will agree with me and ones that will strongly disagree – the trigger decision is totally up to you. Mine was to go with the original Glock trigger parts.

New Sights

The original Glock sights are better than nothing but I really do not care for them. Others must feel the same way because there are a ton of aftermarket sight vendors. By the way, go for a brand name – some are just total junk and not sufficiently rugged.

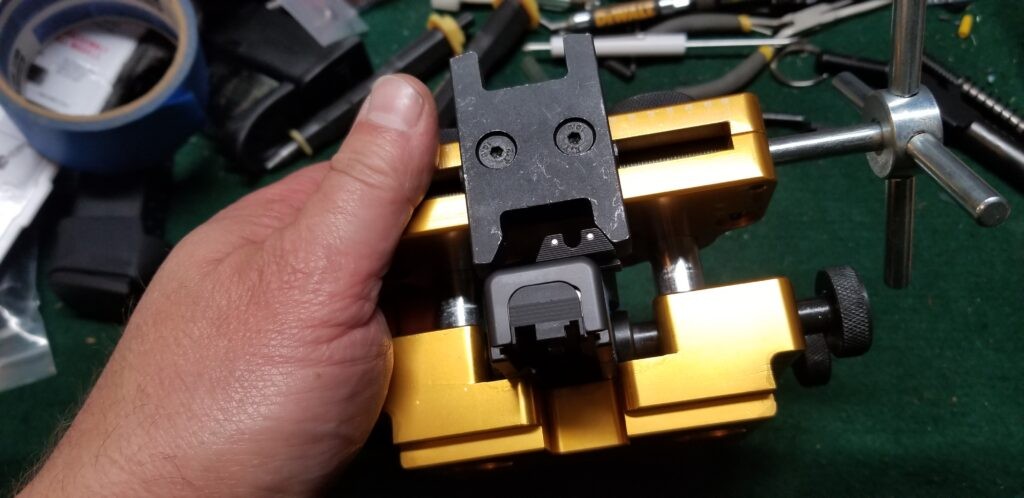

I’ve had very good luck with TruGlo and Trijicon and I tend to favor the latter more. Trijicon sights are very well designed, make aiming super easy and are incredibly rugged. I opted for the Trijicon HD Night Sights (GL1040) for large frame night sights that have an orange ball in the front and tritium illumination. I intentionally wanted a low-light sight but not to add an optic.

Changing The Controls

I like to replace the slide lock, slide release and mag catch normally. The slide stop is actually a big problem for me as I have a hard time grabbing, even feeling, the two sides to pull it down to remove the slide. This really drives me nuts and is one thing I always replace. I installed a Rival Arms extended slide release that sticks out just enough for me to get a much better grip on it. I wish I could find the packaged but I installed a no-name unit online and it had problems from the start – the Rival Arms unit is what I went to next and am still using. Point of the story – beware of cheap parts and test your stuff.

For the Slide Stop Lever, I actually am still using the Glock unit. Normally I would replace it but had a hard time finding one that would fit a Glock Gen 4 model 29. I can use the Glock lever, it’s just not my first choice.

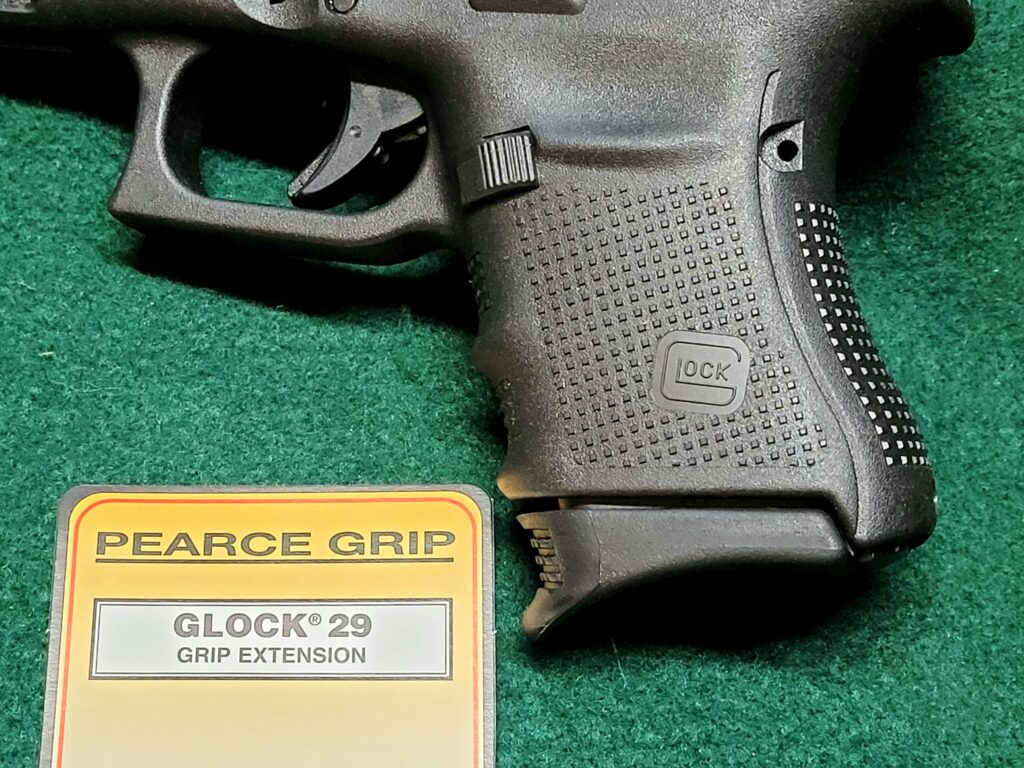

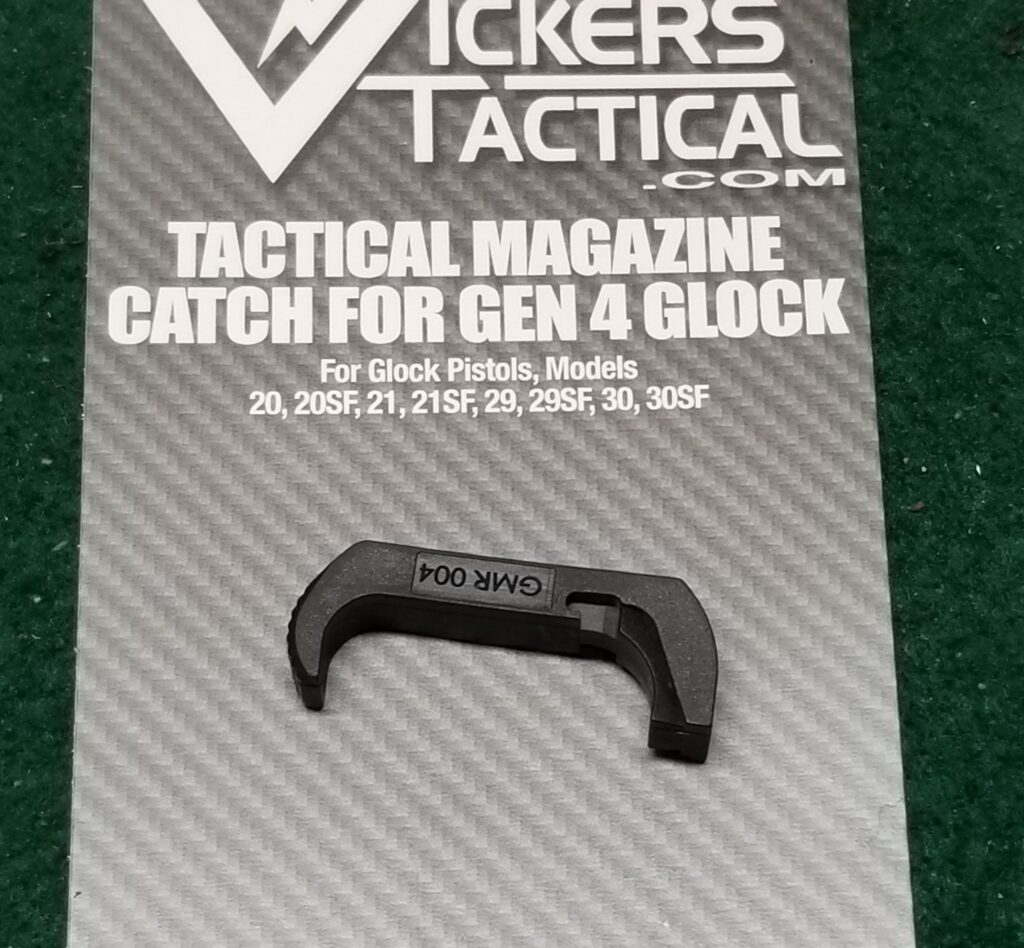

For the Magazine Catch, I went with a Tango Down Vickers Tactical model. I’ve used these a number of time of times now because I like how it sticks out just a bit more than the original but not too much. I’ve tried ones that stick out so far that if you even lay the pistol on its side, the catch is depressed enough to release the magazine and then the next round fails to feed because the mag isn’t properly seated.

Recoil Spring Upgrade

The stock Glock 29 spring is rated for 17 pounds as I understand it. To better run the hotter loads from Buffalo Bore and Underwood, I wanted to put in a stiffer spring but I wasn’t exactly sure what to go with. This helps with obtaining both higher and more consistent velocities with these loads. Yes, the OEM recoil spring will still work – this is an improvement is all. However, if you run too stiff of a spring, your pistol may not cycle reliably with other loads you want to run.

Wolff Gun Springs makes this decision super easy for you. They sell what they call a “Recoil Calibration Pak” with springs at 17, 19 and 21 pounds. They have a variety of these assortments for different Glock models as well.

To install the spring, you need to get a two piece guide rod assembly and Wolff sells them as well. The native Glock springs are in a captured assembly that really isn’t designed to come apart. The Wolff guide rods make it super easy for you to try different springs and do not affect accuracy or reliability in terms of the rods themselves.

I installed a 19 pound spring and found it functioned just fine with all of my Buffalo Bore, Ammo Inc, S&B, and Underwood loads. That’s what I am running at this point and haven’t had any reliability issues so far.

In Conclusion

The pistol is configured the way I want it and as reliable as ever. The end of the day, what you do is your choice but just be sure to test your combinations (the new parts, magazine and ammo) before you rely on them.

Note, I have to buy all of my parts – nothing here was paid for by sponsors, etc. I do make a small amount if you click on an ad and buy something but that is it. You’re getting my real opinion on stuff.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, we are only paid if there is an affiliate program such as Avantlink, Impact, Amazon and eBay and only if you purchase something. If you’d like to directly contribute towards our continued reporting, please visit our funding page.