I did a series of posts back in the Fall of 2019 about a custom Yugo M76 that I had Two Rivers Arms build for me that I then added my own optic to [click here for the series]. A fellow recently contacted me about what optic he ought to get for his rifle, I replied and it also occurred to me that more explanation would make for a good blog post.

What is a Yugo M76?

It is a smei-automatic 10-round Designated Marksman’s Rifle (DMR) designed and built by Zastava for the Yugoslav military chambered in 8mm Mauser (7.92x57mm with an IS or JS designator at the end of the size). The 8mm Mauser round is in the same ballpark class as the American .30-06 round to give you a rough equivalent.

Let me revisit the “DMR” designation – because that is what the M76 is. The M76 was designed for a designated marksman in a squad to have much further reach than the rest of the team would have. It was not a surgical weapon and instead stressed reliability and good enough accuracy with an effective range of about 800 meters with 1.5-2 minutes of angle (MOA).

What does that tell us?

That short intro starts hinting at the type of scope you might want to consider. It’s firing a relatively powerful cartridge but isn’t the most precise rifle on the planet. I can also tell you that while there is recoil, it’s not bad at all.

Choice #1 – Mounting Styles

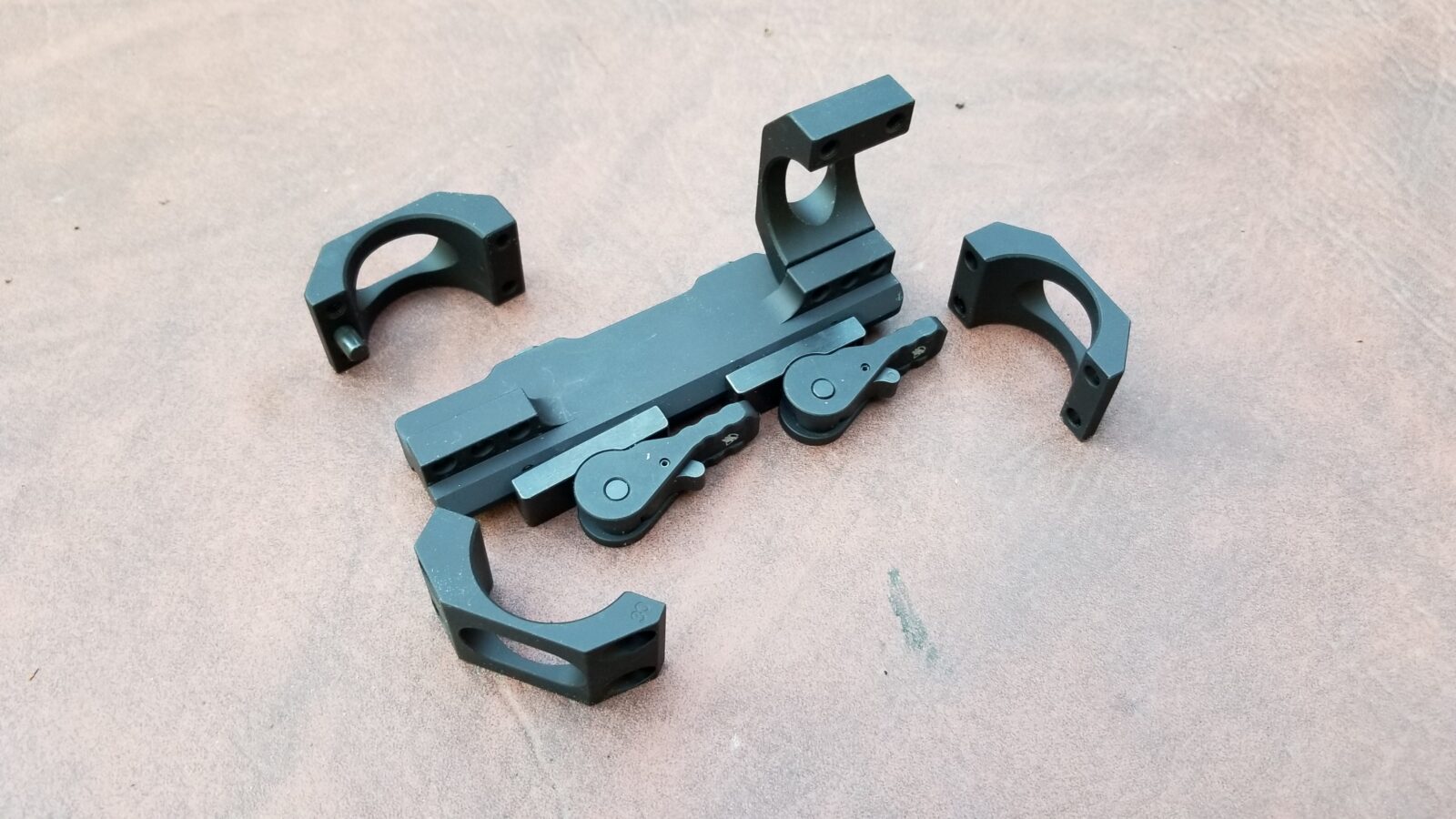

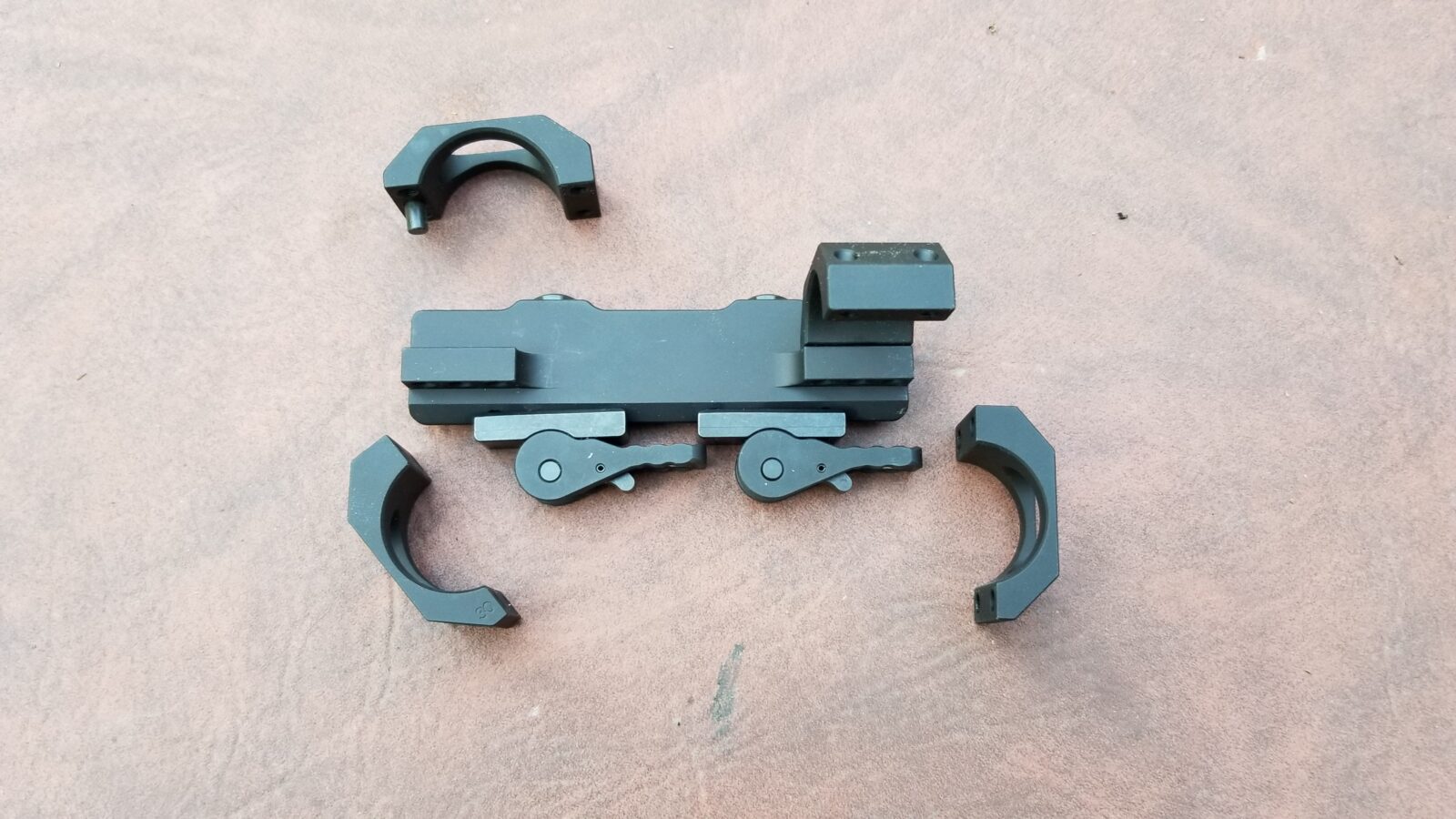

The very first thing to consider is what type of mount you wish to use. The M76 inherits the robust side-mount rail but with some unique dimensions. The rifle was originally paired with an offset 4x ZRAK scope that slid onto that rail and clamped into place. This offset design isn’t for all folks but it definitely works for people familiar with it.

The second route is to get a mount that clamps on the above rail but then centers the optic over the centerline of the bore. Call me an old school American but that is definitely my preference.

You can get mounts this way that directly hold the optic directly with the scope rings being built directly into the mount or you can get mounts that have a Picatinny rail on top that you can then secure whatever optic you want. This is my preference just so you know because it gives me more flexibility down the road.

RS Regulate mounts are the way to go!!

The best side mounts I have found that enable a ton of flexibility and adjustment are the RS Regulate brand mounts designed by Scot Hoskinson. He offers a number of different options so you need to stop by his site and take a look.

Note, RS Regulate mounts are being counterfeited in China. I’d recommend only buying direct or from a reputable dealer below:

What optic to use?

On one hand, you could stick with the communist block styling . You can hunt around and buy 4x ZRAK optics still. There are also a lot of different offset mount optics that you can look into that are side mounted for example 8x and variable power. Just confirm the clamp on a particular model has enough adjustment to fasten onto the M76’s rail.

As of my writing this, there aren’t any ZRAK scopes on eBay but Apex Gun Parts does have some in fair to good condition (meaning very worn) and they are a good firm to deal with. Kalinka Optics has a variety of offset mount optics and is also reputable. If you really want an offset scope, I’d recommend Kalinka and go with something new.

With that said, you may be wondering “but what size scope?” The 8mm round definitely has some reach and you have to ask yourself what do you really plan on doing? This “what am I going to use it for” question is known as the “use case”.

When the Yugoslavs designed the M76, they needed a middle of the road simple optic that would allow the shooter to hit something man sized out to 800 meters. Four power magnification fits that bill because it gives you a wide field of view (meaning what you can see left to right and up and down in he scope – the more you see, the wider the field of view). They weren’t looking for precision by any means – just good enough to extend the reach of the shooter.

I’m 53 and while I grew up shooting a lot with iron sights, I can’t see very well at 100 yards and I sure can’t shoot precisely. Now remember, the M76 you have will likely be shooting1-4 MOA (1-4″ at about 100 yards, 2-8″ at 200 yards and so forth). It all depends on the condition of the rifle and the type of ammo you are shooting not to mention your own abilities. Spending a fortune on a giant quality surgical scope, like a 6-24x, is overkill…. unless that is what you really want.

What I would recommend is a variable power and I tend to favor 4-16x because I have the nice bright field of view at 4x and can zoom in if needed. Most of my shooting is within 200 yards so this works just fine for me on my DMR rifles.

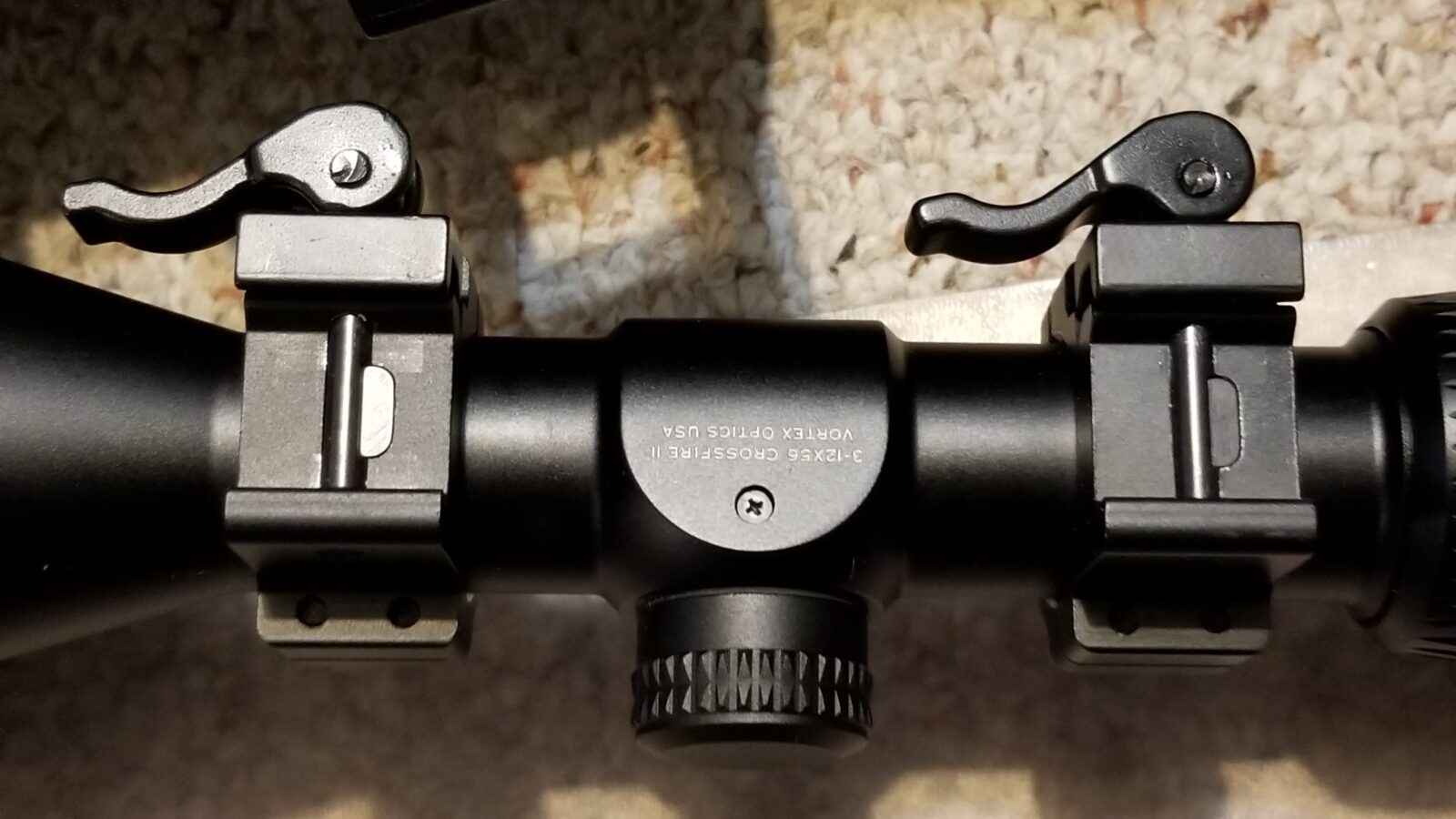

Now you may be wondering “But I saw the photo of that giant scope you are running – what’s up with that?” Good question and let me explain.

My “use case” when I was planning for the optics was for hog hunting. I wanted a really big objective to suck in light for shooting at dusk and an illuminated recticle. I also happened to already have it left over from another project. It is quite affordable by the way.

So, the Hog Hunter seemed like a great match – 3-12x for fast shooting in close to having a 12x for distance shots. The big 56mm objective does pull in a lot of light. The lit recticle is only bright enough to make a difference at night and isn’t as bright as what you would see on a tactical scope.

Having used it for a while now, I’ll tell you that it delivers on the above with a couple of caveats that may make you stay away from it unless thye don’t bother you:

First, it is a big scope – far bigger than what you may think in terms of dimensions and weight due to the big objective. It’s almost 13.5″ long and 21.1 ounches.

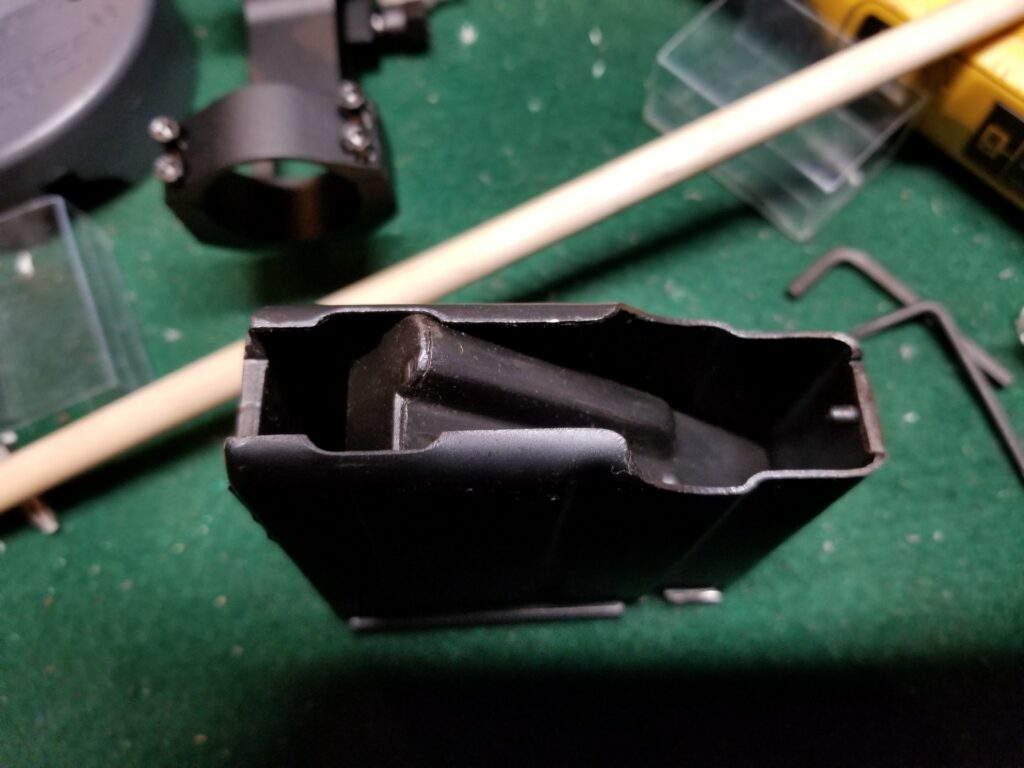

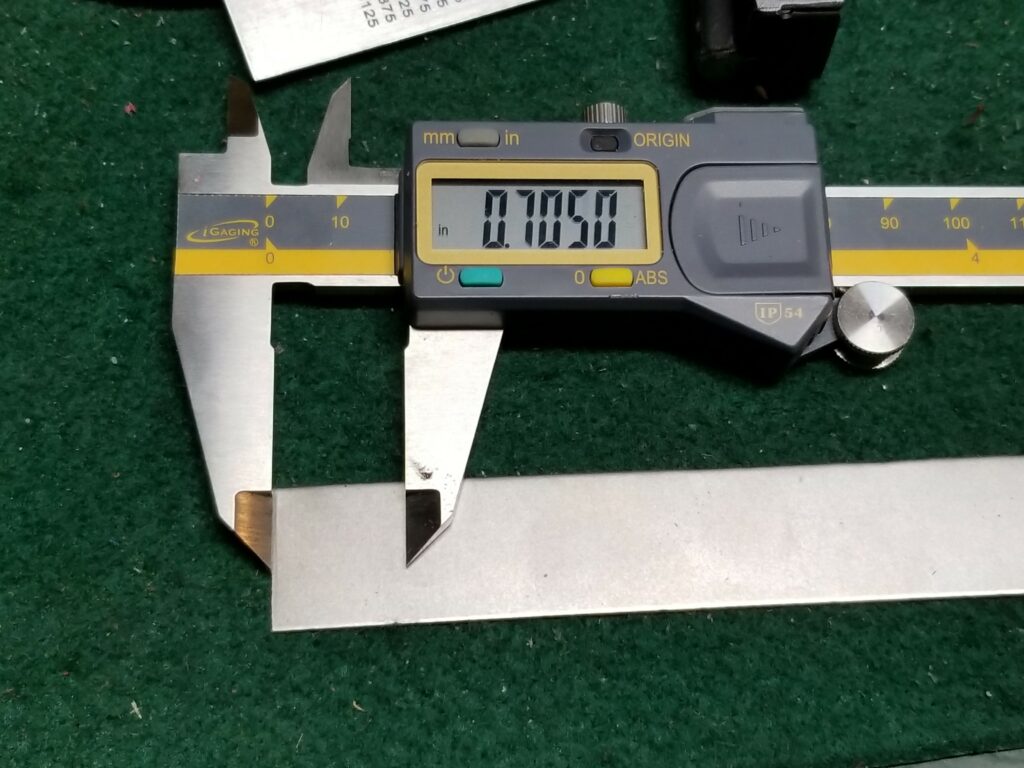

Second. it is a giant objective and you will need to plan for. I had to carefully calculate the rings needed for it to clear the front handguard and I needed them to be quick release because the scope mount could not slide backwards due to the big objective hitting the rear sight block (RSB) of the rifle. I am still using the AD-RECON-SL mount and it is solid!

For a lot of folks, starting with an objective around 40mm tends to give you a nice bright image. I tend to use 44-50mm objectives scopes the most. Think of it this way – the bigger the objective, the more light it can pull in all other things being equal.

So where am I at today and what scope would I recommend?

I still am running the Hog Hunter and like it. If I had it to do over,I would get a 4-16x magnification and a 44-50mm objective. Recticle-wise, I’m fine with just about anything for what I plan to use it for but if I were to specify one, I’d get one with Mil-Rad (Mil-Dot) graduations because that is what I am familiar with.

There are also other variable zoom scopes out there as well such as 2.5-10x, 3-9x, 1-6x, 1-8x, etc. These are all options if you still have good eyes and want an even wider field of view on the low end. I run all of those combinations on rifles where I plan to be relatively close and not so much for long distance. Point being it is up to you – I wanted a higher power scope for shots starting often at 100 yards.

Vortex makes really good optics and I would move with whatever I could afford at the time. What you will notice is that as you move up their product line , the bigger price tag also comes with clearer and brighter optics *but* they all have Vortex’s no nonsense warranty.

Vortex Optics Offerings

I am going to present their various offerings that I would recommend and am able to show the scopes listed at various merchants as well so you can shop around:

Let’s start with their entry-level Crossfire II scopes:

Next, let’s look at the Diamondback and Diamondback Tactical series scopes:

The following are Strike Eagle scopes and the designs are focusing more on tactical versatility.

Even higher end are the various Viper HS scopes. I have a number of these and find them to be bright, clear and rugged:

My favorite Vortex scopes that I afford is the Viper PST Gen III series. Yeah, budget does have a role and have not been able to afford a Razor but the PSTs excellent. When I can afford a really exceptional optic, I look at the PSTs. A number of vendors still carry Gen II scopes and they work great also. I’ve had several Gen IIs and only one Gen III so far.

In Conclusion

I hope this helps give you some ideas of what optic to put on your M76 rifle. I really like Vortex Optics and am a user – I’m happy with the Hog Hunter but it is big. I think you’d be very happy with just about any of their scopes depending on what you want to do.

Note, I have to buy all of my parts – nothing here was paid for by sponsors, etc. I do make a small amount if you click on an ad and buy something but that is it. You’re getting my real opinion on stuff.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, I may be paid via an affiliate program such as Avantlink, Impact, Amazon and eBay.