So things were going together really well for the Alpha ‘Wulf and no, I’m not going to say “and then I hit a snag.” I was impressed by all the parts so far. In the last post I talked a bit about the lower assembly and the upper parts I picked in addition to the Alexander Arms DIY upper. In this post, I’m going to share a few observations on the handguard, brake and lubrication.

The MI Combat Handguard

I don’t recall exactly when I first found out about the Midwest Industries (MI) Combat series of rails but used one this past Spring when I built a 10.5″ 5.56 AR Pistol. The biggest thing I like is the barrel nut. Now that may sound like a crazy thing to get excited about but there’s a reason. Look at the MI Combat barrel nut – it is a knurled circle with a groove in it. The reason this matters is that the handguard can rotate however it needs around the nut and is secured by a steel key and clamping onto the knurling. If you don’t have this kind of a design, you need to use shims or do some combination of filing and potentially crazy levels of torque to get the handguard’s top Picatinny rail to “time properly” (or align properly) with the rail on top of the upper receiver and also to get the gas tube to pass through into the upper receiver’s bolt carrier channel. PSA has good prices on them so click here to see what they have.

I do have a few tips for you to bear in mind. Bear in mind the Beowulf has a kick. Bring everything to a torque spec and use Blue LocTite 242 or 243. Both are “medium” formulas that can be readily disassembled with the right tools and 243 adds a bit better oil resistance. I’m moving to 243 as I use up my 242 supply but it’s up to you one which you want to use.

Install the Barrel Nut First

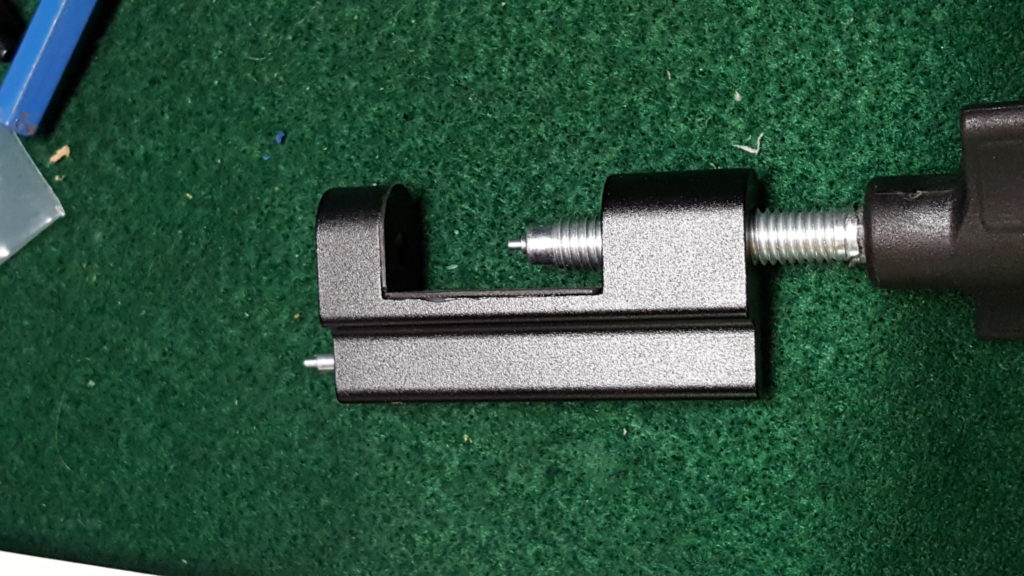

First, just back out the set screws and the low profile gas block will slide right off the barrel. You need it out of the way to install the barrel nut.

Next, secure the upper assembly in a vise. You will need to use a fixture to hold the upper when you do this. Absolutely do not use your lower to hold the upper. You will bend things. My tool of choice now is the Magpul Barrel Extension Vise (BEV) Block. It very securely holds the upper by engaging the barrel extension. It’s the best tool I’ve found and PSA carries it.

The following is the approximate process for installing a barrel nut:

- Degrease the receiver threads and the barrel nut. The Combat rail comes drenched in oil.

- Apply the AeroShell – 33MS/64 Extreme Pressure Grease, MIL-21164D to the receiver’s threads – I use an acid brush to get an even light coat.

- Torque the barrel nut down to 35 foot pounds (yes, this is foot pounds unlike the gas block) using the spcial MI torque plate they provide and your 1/2″ torque wrench

- Loosen the barrel nut – ideally not with the torque wrench to save it from wear and tear.

- Torque it again to 35 foot pounds again and loosen it again.

- Now, this is the final torque – take the MI nut down to 35-80 foot pounds. I took mine down to 40 foot pounds and called it even. Why the huge range? Well, if you have an old school barrel nut, you may need to torque it quite a bit to get things to align but in our case we just need to apply enough torque to call it even.

Installing the Gas Block

The gas block set screws do have a torque spec if you hunt long enough. Alexander Arms (AA) does not provide it in their general purpose Beowulf manual or instruction sheet that comes with the DIY upper. People cite 25 inch pounds (not foot pounds) with one drop of 242 Loctite per “echnical Repair Standard (TRS) SOFWEP-07-G12P-00032-00 Rev 1 Appx H” that I have yet to locate a copy of that manual. With that said, that is exactly what I did but I used the 243 formulation of Loctite.

Also, AA has done all the machining and used centering set screws to go into the divots in the barrel. You do not need to worry about needing to measure a set back from the barrel’s step lip – just slide the gas block on, put a drop of Loctite on each screw, carefully align the tube and then torque down the screws.

Timber Creek Heart Breaker Brake

Based on my first Beowulf, it’s very critical to get a good muzzle brake. If you want to reduce felt recoil, the best things you can do in order are: 1) install a good brake. 2) have a good recoil pad 3) make the rifle heavier. Now, I do all three plus I use a hydraulic buffer that helps a tad but a good brake is absolutely critical. For me, it is absolutely my first priority and I knew I wanted to use the Timber Creek Heart Breaker again.

The AA barrel uses a unique 49/64-20 RH thread. If you are not using an AA barrel, confirm the thread before you order a brake.

To install the brake, I run the lock nut to the bottom of the thread and then thread the brake on as far as it will go, rotate it into final position and then tighten down the lock nut to 20 foot pounds using a crowsfoot head on my torque wrench. I’ve not used Loctite but you can if you want extra protection – I would still go with the medium strength 242 or 243 formula.

Lubrication

To lubricate the whole rifle, I use SuperLube grease and oil. I know it sounds like an infomercial name but it actually works really good. The base is a synthetic lubricant with “micronized PTFE” (think tiny Teflon particles) added in.

If it slides, I apply a light brushed on film of Superlube grease. If something rotates, I use drops of the Superlube oil. Now some folks will disagree with me and go with all CLP or LSA or some secret blend they like – fine. This is just what I do.

After lubricating it, everything was nice and smooth plus I did function testing to make sure everything was working properly in terms of the selector, disconnector, trigger, etc. In fact, Brownells has a nice page on attaching the upper to the lower, lubrication and function testing.

Vortex Strike Eagle 1-6×24 Optic

Before I pick an optic, I think about how the firearms it is going on will be used. For the Beowulf, it will be hunting and target shooting typically within 100 yards and maybe out to 200 max plus low light situations might well occur.

Armed with that, I decided to use a Vortex Optics Strike Eagle with a 1-6 power magnification, a 24mm objective and a lit reticle. My eyes aren’t so red hot any more so I knew I would need some basic magnification while still having a wide field of view at 1x. Also, I am a huge fan of Vortex due to their quality and no BS warranty. If anything goes wrong with a Vortex optic, they will repair or replace the unit and not run you ragged.

I also opted for a quality offset Vortex mount. You need a solid mount and not something that is going to constantly shoot loose or break under strain.

How Does It Look?

I haven’t had time to take it to the range yet, but am definitely liking how it turned out. The Alexander Arms DIY upper was great to work with as were the Geiselle trigger and MICombat handguard. The PRS stock helps balance out the rifle and adds weight plus the great recoil pad that comes with it. Now, If I can just find some time to go to the range 🙂

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, we are only paid if there is an affiliate program such as Avantlink, Impact, Amazon and eBay and only if you purchase something. If you’d like to directly contribute towards our continued reporting, please visit our funding page.

My apologies but I have no way to filter out items that the vendors have sold out such as ammo. For example, most places sell out of the ammo fast but you should keep an eye on both Midway USA and going to Underwood Ammo directly – Underwood makes very good ammo by the way. I usually run Alexander Arms ammo but they are sold out most places and while you can place an order directly, you will need to wait quite a while for it to be made and shipped.