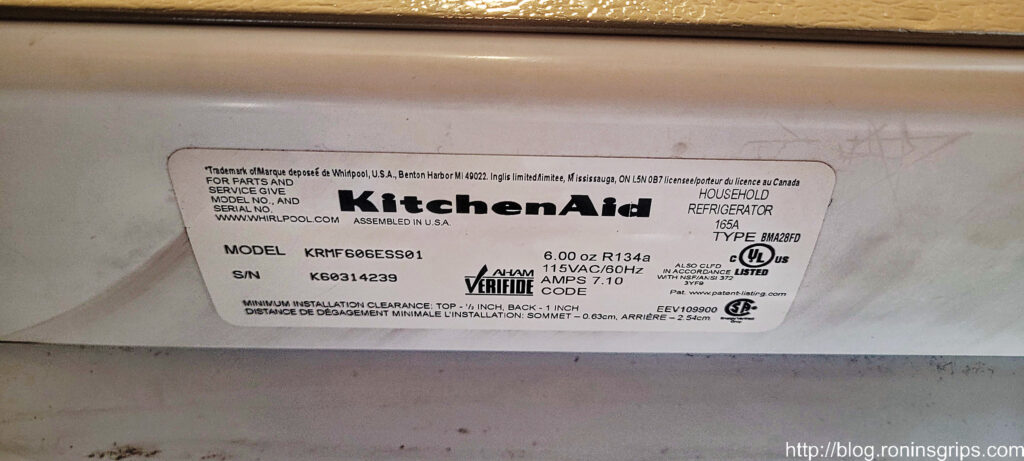

Well, when I was little it seemed like fridges (“refrigerators” for people who prefer the full word) lasted an eternity. When we bought this KitchenAid KRMF606ESS01, I thought I was buying a top of the line quality fridge, but that’s no longer the case – appliance manufacturers don’t necessarily want them to laste forever because that means no more sales to a given customer.

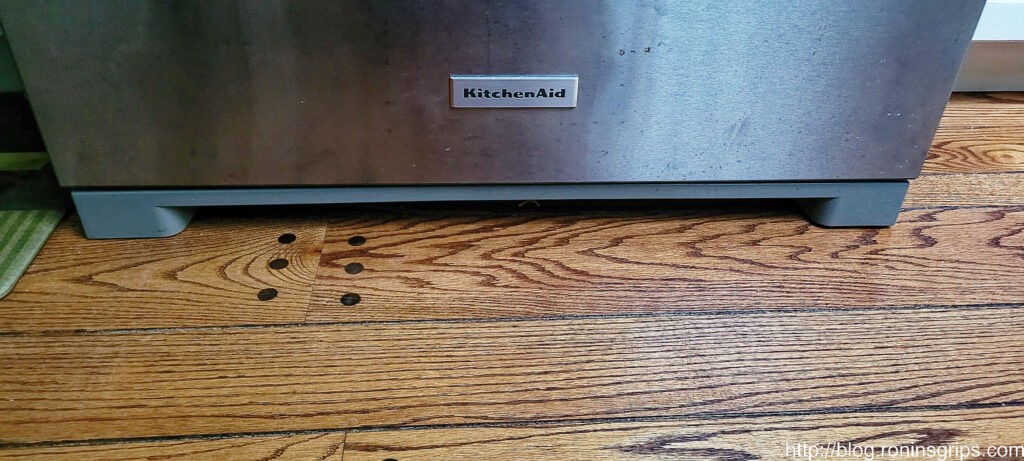

A year after the warranty the ice maker stopped working and the service person whom I trust told me it would cost a considerable amount of money to replace the circuit board. So, strike #1 against the KitchenAid. Despite being “stainless”, the shell of the fridge rusts. Strike #2. Strike #3 is the topic of today’s blog post. The water inlet valve failed and leaked water all over our wood floor.

Let me set the stage – I went through the kitchen to my shop and when I came back in I saw wet footprints – my foot prints – from the floormat in front of the fridge to my shop door. ARGH! I was hoping maybe someone spilled water and didn’t clean things up so I removed the mat, mopped up the water with a towel and watched new water slowly emerge from under the fridge. Crap. I immediately wondered about the water lines on and in the fridge. The supply line was copper tube and it had looked great the last time I pulled out the fridge so I doubted it was that but I couldn’t ignore it either or it would ruin our real wood plank floor.

Turning off the water

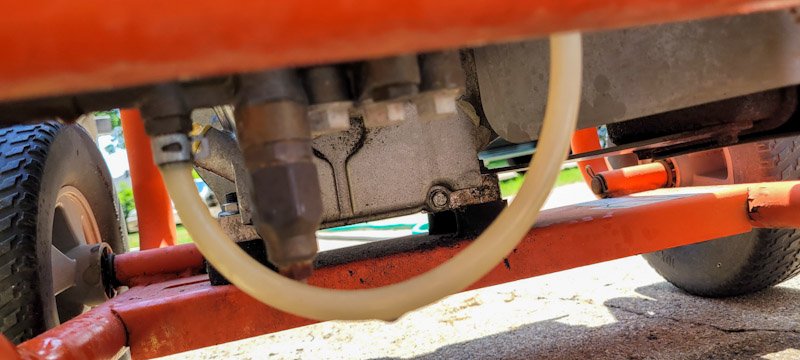

Most fridge installers put a vampire tap on a water line to get the supply needed. In my case, I knew there was a tap under the house. We have a crawl space that isn’t bad compared to some that look like they are a scene from a horror movie but being a pretty big guy with a sore back I have to fold myself in half and do a crab shuffle over to where it is about 50-60 feet from the entrance. Short translation – it’s doable but I swore the whole way over to it.

Confirming it was the inlet valve

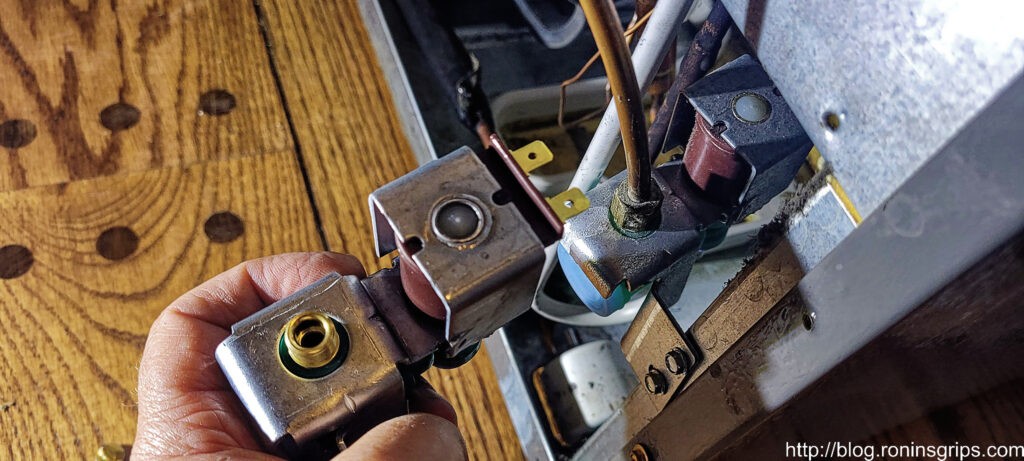

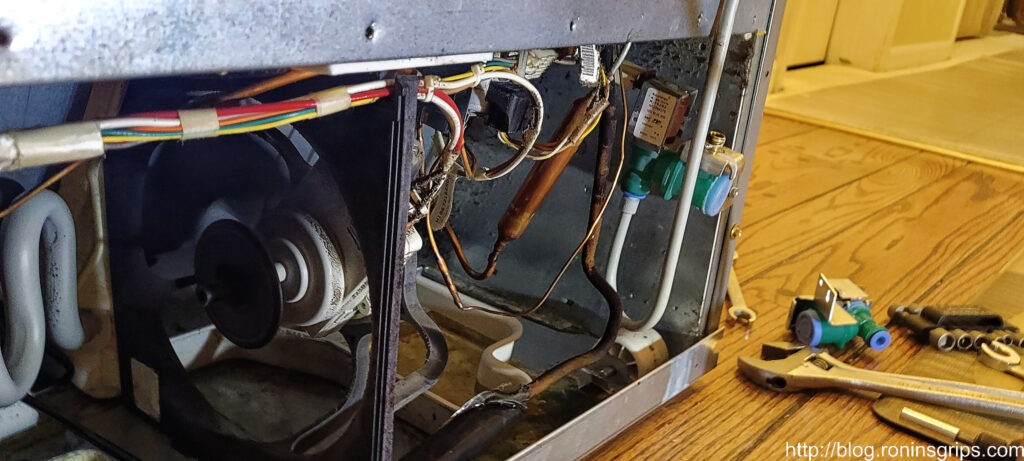

In reading, there are a few ways these inlet valves fail – they can leak water on the floor but still work and dispense water, not leak but dispense water very slowly, or don’t work at all. I was 90% sure it was the valve given past experience with other fridges so the first thing I did was to pull out the unit.

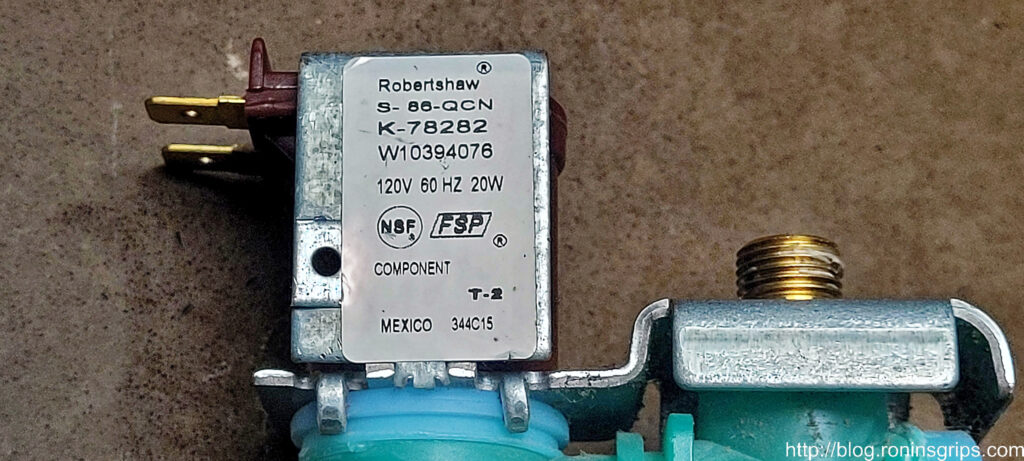

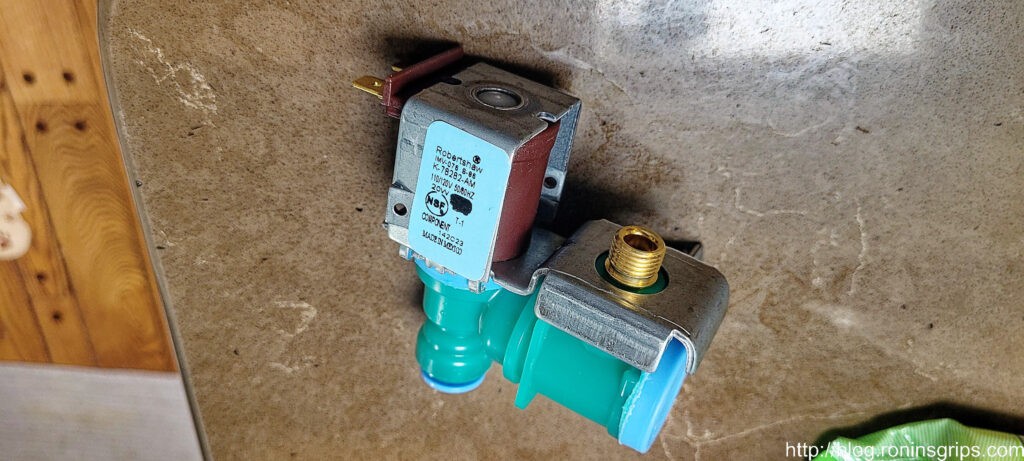

Okay, the water inlet valve is a small electricslly controlled valve that is turned on and off by either the ice maker (that no longer works) or a person wanting cold water from the dispenser pushing their cup against the on-off switch. The valve body is made of plastic and that is what failed. The only saving grace is that the engineers put it at the back of the fridge and it is very easy to access and change – literally a 5-10 minute job. You can easily buy one online without spending a fortune.

I spent some time searching on Kitchen aid KRMF606ES01 water valve and found out that my fridge has two – one at the inlet (that I needed) and one inside that I did not so make sure you order the right part. The valve part number I needed was W10394076.

Direct from KitchenAid I could get the part for over $95.49. No, Whirlpool, I didn’t feel like spending a fortune by ordering it direct. I kept on searching and found it in the $70s then the $50s and then hopped over to Amazon and found it for $27.99 with free Prime shipping. It got great reviews and I ordered it on Saturday with delivery on Monday. Guess what – it was the exact same valve. Strike #4 for KitchenAid by the way.

Replacing the valve

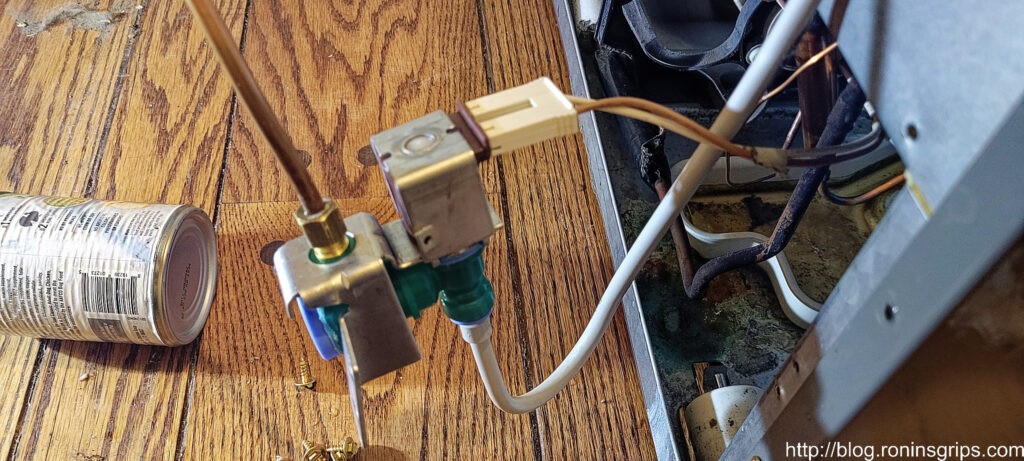

First, make sure the water supply is turned off and have a container you can set the supply line in just in case it drops. I’ll step through this with photos:

And with the new valve unit installed and my wife watching everything, I headed back down into the crawl space and turned the water on. No leaks. She tried the water dispenser and it was actually putting out a larger volume of water also – our jet had always been on the anemic side.

So, I waited while she filled a few big cups of water and threw them out to purge the lines. She also didn’t see any leaks so I headed back up after a few minutes hoping my crawl space work was done … and it was.

With the fridge back in place, use the levelers if you need to – I don’t actually.

I didn’t get photos but the last thing I did was to use a long brush made for cleaning condenser coils to do just that. As lint and dust build up on the condenser it becomes less efficient, the fridge runs more and your electric bill is higher. The lint and dust there by the way because of an electric fan that is running underneath to help cool things off.

The last step is to open the lower freezer door and push the plastic cover back on the bottom. Done.

Summary

A week later and it is still running great. I hoped that the ice maker might start working again but no luck there. We bought am Aglucky counter top ice maker a few years ago that we’ve been very happy with.

I paid a premium for a supposed top-of-the line KitchenAid fridge and I don’t think the same level of quality is there. We have a Samsung fridge downstairs that has been flawless for us. When we replace this main fridge in the kitchen it may very well be a Samsung but it will not be a KitchenAid.

In the mean time, if you are having problems with your water inlet valve, I hope this helps you solve your problems and save some money.

3/2/24 Update: The new valve is still working great. We noticed we have more flow also – glasses fill faster. So, if you want to save some money, it’s an easy DIY repair that valve is still only $27.99 off Amazon.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, we are only paid if there is an affiliate program such as Avantlink, Impact, Amazon and eBay and only if you purchase something. If you’d like to directly contribute towards our continued reporting, please visit our funding page.