I have a long history with building AK-47 rifles and a number of variants including: Hungarian, Romanians, Russian, and Yugoslavian. The problem I have these days is a total lack of time so I rarely get to indulge in building any more. In fact, this past year, I only got to build one AK and I had a lot of fun doing it. Rather than do a few giant posts, I am going to do a bunch of posts for each step I do.

The first thing I like to do is to remove the barrel and get it out of the way. Back in the golden age of AK Kit building you could get completed barreled AK kits for $89/ea and sometimes even less. Then the ATF decided to re-interpret the law and in July 2005 they told importers they would no longer approve the importation of kits with the original barrels. Now importers did have a lot of orders in the pipeline so the prices slowly went up and the supply dried up.

Today, you are only going to find kits with barrels that someone is selling from their collection usually at an astronomical price (I’ve seen them range from $600-1,200 literally for kits that used to be $99) or one of the vendors has decided to offer a service to assemble headspaced kits such as Arms of America. The other reason you may need to do this is that you have a donor rifle that you are getting parts from, which is what I was doing.

When I started, everything was done with hydraulic presses or the caveman approach of using big hammers that I never cared for. Today, you can remove a hammer super fast 99% of the time with an air hammer and that is my preferred method. I want to give you a few options to consider and some tips along the way.

What did I Just Work On?

I had an old Romanian Garda kit that I had built on an AK-Builder flat many years ago. I actually dug through my photos and it dates back to June 2007 when I built it originally. When I built it, I was tinkering with how to form the rivet heads and while it was a rock solid AK function-wise, the rivet heads always bugged me so I decided to rebuild it.

Options To Remove the Barrel Pin

There are three common ways that I can think of:

- Use a press to push out the pin – works great but it takes space and you need a jig to properly support the trunnion so nothing bends under the pressure. It also takes time to set up everything. Huge hint to the new folks who use a press – whack the side of the press that the bottle jack is pushing down – sometimes called the jack bracket – or the side of the frame supporting the bottle jack. The vibration will loosen stubborn pins and lower the risk of something breaking / bending or even shattering under extreme pressure. In short, use the hammer to introduce shock and vibration to the pin while under load – pump the jack handle to increase the load and whack, pump, whack, and so forth. I guess I should do a blog post on this some day but I hope you get the general idea – don’t just increase the pressure alone. Some pins come out super easy and some will fight you the while way out.

- Use a big hammer and beat the pin out – I have never had luck with this and only tried it a couple of times before deciding it wasn’t for me. I have a hereditary tremor in my hands and trying to hit a punch with a heavy hammer/small sledge with sufficient force just isn’t in the cards for me. Tons of guys have used the “BFH” (Big F’ing Hammer) method and driven the pin out.

- Use an air riveter or air hammer to drive the pin out. Folks, I started using this method some years back and it’s all I use now. It’s fast, easy and you don’t need to worry about things breaking/bending like you do with a press.

So option 3 is what I do. I use a Ingersoll Rand model 117 air hammer that I bought many years ago. The stroke length is 3.5″ and the hammer is .69″ diameter, or at least the bore for it is this helps the hammer hit hard at 2,000 blows per minute.

Note, I bought the 117 many years ago and may actually upgrade to one of the new 119Max air hammers. They have a .75″ bore (8% larger), still a 3.5″ stroke and is moving at 2,530 blows per minute. So it hits harder and it has an anti-vibration design as well. This makes it easier to control and less fatigue on the hands.

Regardless, the point is to get a big air hammer. I’m not sure if one of the super cheap Harbor Freight units will do the job or not. If you look to other brands on Amazon or where ever, look for units they describe as “long” – referring to the length of the hammer bore – or if they use a number, go for 4X or higher. I’ve typically seen that designation to refer to riveters and the 117 is a fine riveter for 1/4″ because of the nice variable trigger it has. The 2x, 3x, 4x, etc. all are referring to the number of times longer the barrel is compared to some original model as I understand it. The size of the rivet gun is based on the size of the rivet that needs to be set so guys may have a number of rivet guns in their tool box if they do a lot of riveting for planes, sheet metal, etc.

To push the pin out, you can use long air hammer drift pins or even start with the conical chisel and finish up with a hammer and punch.

Note – If the trunnion is not secure then not only will it want to move on you but you will also lose a ton of force due to vibrations/movement that would otherwise be directed at the pin.

Slow down as you drive the pin out or it will fly across the room. I’m speaking with first hand experience on that. You will want to save the pin so you can re-use it.

Once you have the pin out, don’t lose it! I used to use a fishing tackle organizer and now I just use a magnetic tray. It is real easy to lose track of that pin and it’s happened to me.

Options To Remove the Barrel

There are four common ways to remove a barrel – I say “common” because I bet guys have figured out tons of other ways but let’s hit the trop four.

Option 1: Use A Hydraulic Shop Press

This is definitely a proven method. 12-20 ton shop presses were traditionally the go-to tools for a lot of AK work relating to barrels and rivets. For barrel work, guys use jigs from AK-Builder and others plus can make their own. The basic idea is to support the front of the trunnion and press the barrel out. Here’s a link to a post I did some years back for making your own barrel back out tool – I will tell you to make several – a long one if you need to reach through a receiver and a much shorter one if you are just pressing a barrel out of a trunnion or milled receiver stub.

If you want to get a press, the Harbor Freight 12-20 ton models do the job. You can certainly spend more money and you are paying for how true the various parts are to one another and the amount of pressure they can apply. I have a knock off import 30 ton press and it does the job but is nothing to jump up and down about. I do like the large wide H-frame presses that have a nice big work area vs. the small skinny A-frames but it is up to you. Note, a bench top press will really limit your options and probably be disappointing. Also, a 12 ton press is the smallest you should consider. I’d recommend a 20 ton unit if you can afford it. I bought mine just to do AKs but have used it for all kinds of stuff since like pressing in barrels, etc.

To be clear, I have all the tools I need to use my press and it is my fall back method for stubborn barrels but it takes me longer to do the set up than I care for because of how my shop is set up. If you go the press route and it is easy to get to your press, rock on. I can have the pin and barrel out before I even get done setting up my press to do barrel work is all I am saying.

Option 2: Use a BFH

Some guys will just take a big f’ing hammer and a punch to drive the barrel out. I have honestly never tried this approach because of the tremor in my hands but there are a few guys out there who claimed to have used this approach. If you do this, make sure the trunnion is very well supported and can’t move. Get a big heavy hammer (say 1-5 pounds) and use a barrel back out tool like I described above. Be very careful to strike just on the pin or you will beat up your trunnion. I cringe while writing this just so you know. Guys have done it so I feel I need to mention it but I can’t personally recommend it. I think the risk of the punch moving accidentally and then beating the crap out of your trunnion is just way too high to be acceptable.

Option 3: All Thread Method

This method got it’s name from the use of threaded rods that can be used to create a tool to either push out or insert a barrel. Toth Tool makes one this is very nice but I have only used it one time to insert a barrel and it did a great job. They say it will work on pushing out a barrel and I tend to believe them unless you get a kit that has an insanely tight fit. Over the years, I’ve only had a maybe 3-4 barrels out of dozens that I wonder if it could have done the job. With many people building from scratch and not demilling or they are getting headspaced kits that they don’t have to fight as bad with, I think this would be a very strong option. I literally just bought my Toth tool and will give it a try at some point.

Option 4: Use An Air Hammer (My Preference)

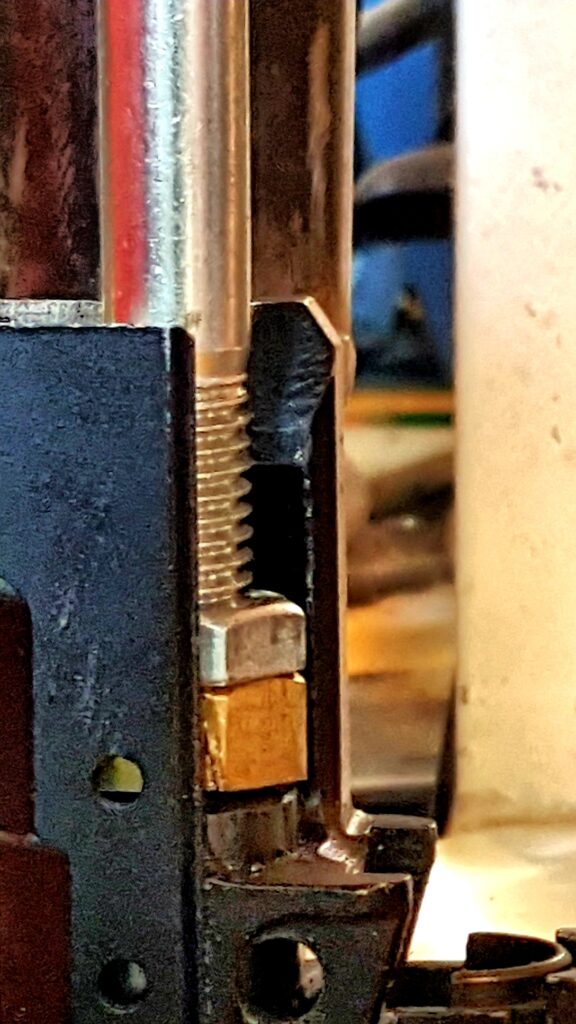

Do you notice a recurring theme? I’m not very patient so I look for quick methods. I used my big IR air hammer and drove the barrel out. I put the assembly in a solid vise, inserted a brass 1/2″ nut in to protect the barrel, an angled rivet set so I could reach in at an angle and hammer the barrel out. All said and done it took a couple of minutes.

The air hammer works almost all of the time and is my go to method but note that I do have a big press in the event I run into something really stubborn that can’t be air hammered out.

Avoiding Galling

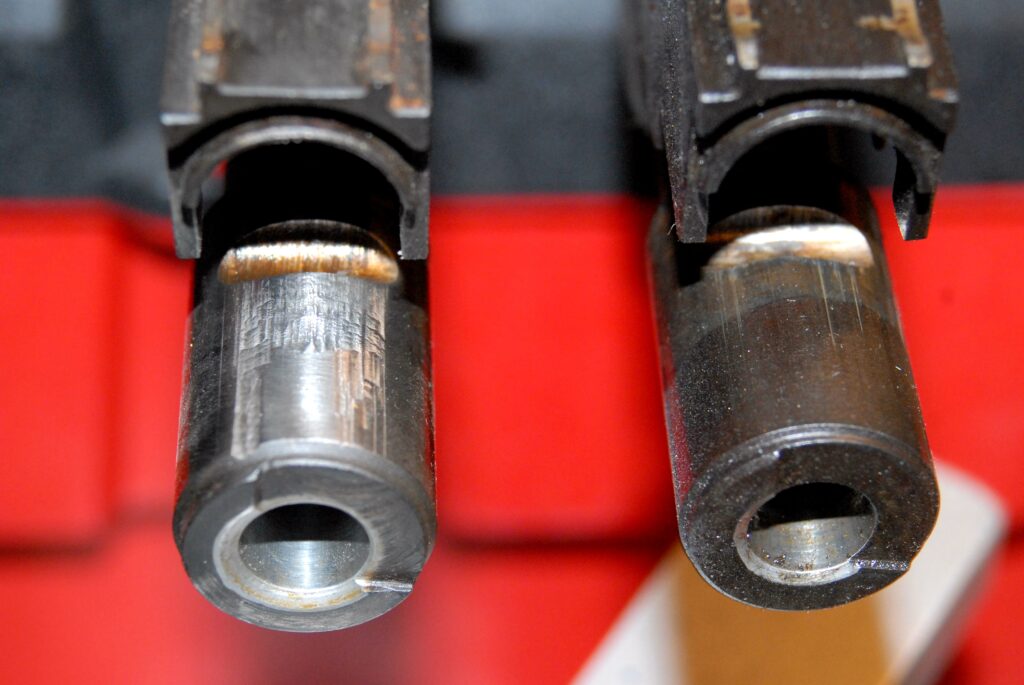

There is an ugly cosmetic issue that can happen when pushing out an extremely tight fitting AK barrel or one where the originating country maybe didn’t have the best metallurgy and that is a problem known as “galling”.

When an AK is assembled at the factory, the barrel is inserted into the trunnion, the hole for the barrel pin is drilled and then the pin is inserted. When the hole is drilled, a potentially sharp surface is created at the top front portion of the hole in the trunnion. If the barrel is pressed very tightly or the metallurgy is off, when pushing the barrel back out, this surface shaves the metal off the barrel creating an unsightly blemish on the shank of the barrel. It’s just cosmetic and does not hurt the functioning of the barrel but it sure is ugly.

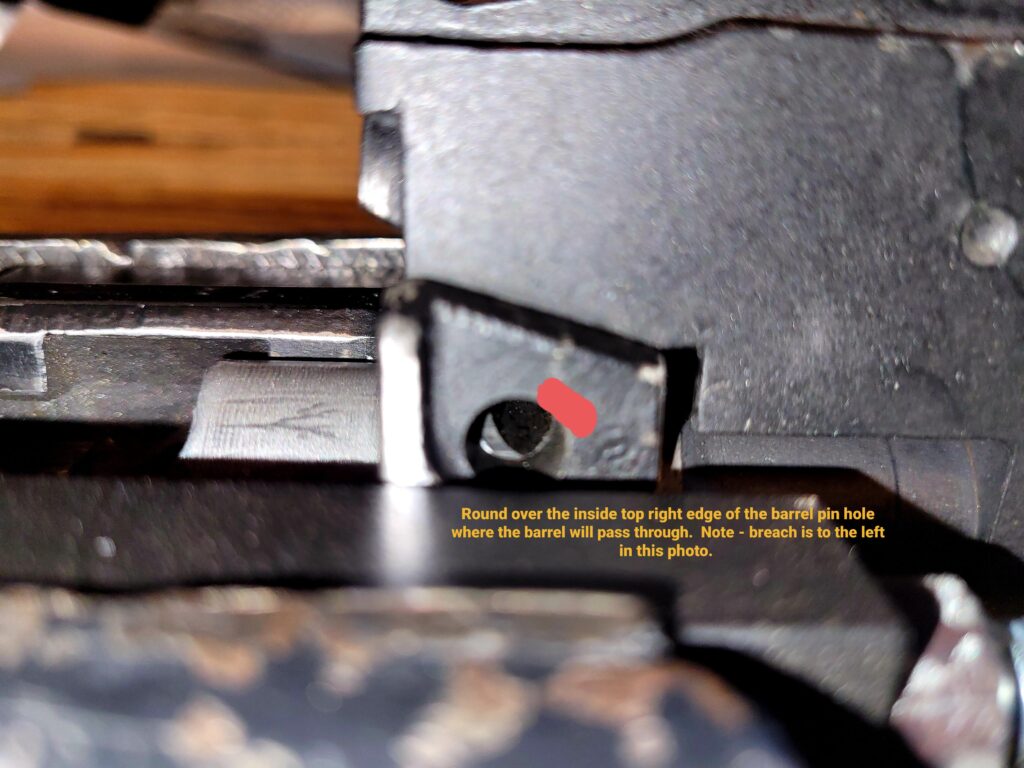

There is a trick that can help reduce the chance of galling. You push the barrel pin out as normal and just start to press the barrel out so you expose part of the front top edge of barrel channel inside the trunnion in the pin hole and dress it, meanin slightly dull or bevel it so it does not dig into the part of the barrel shank (the breach end) that will still need to push past that sharp surface.

Small circular files, like chainsaw sharpening files make quick work of this. I have a few circular files and just grab whatever one gives me enough room to maneuver inside the 7mm (0.276″) barrel pin hole.

You can then press a bit more and see if there is galling taking place. If so, push the barrel back out a bit, get rid of the steel that is shearing off and try breaking the edge of the front barrel channel lip a bit more.

Again, this is purely cosmetic and not something that will reduce the safety or reliability of the weapon. Do I always do this? No, just on expensive kits where I don’t want the barrel to look bad.

Some Quick Tips

Let me briefly summarize some lessons I’ve learned over the years:

- If there’s any sign of rust around the barrel, trunnion or pin then either soak the assembly in Ed’s Red or spray it down with PB Blaster and let it sit at least overnight. I have a 5 gallon bucket about half full of Ed’s Red and I will literally put the whole trunnion assembly right in the bucket with the barrel sticking out and leave it there.

- If you are not familiar with your air hammer, practice with it and get a feel for the trigger and how to control it. Otherwise you might beat some parts up that you did not want to.

- If you use a press to push out the barrel pin, remember that tons (literally) of additional pressure is not always the best bet. Press pins can shatter, trunnions can tear and so forth. Whack the press with a metal hammer to introduce vibrations to the part. It can make things way easier.

- Keep track of your barrel pin both when it comes out of the hole as well as later.

- Make sure everything is properly supported and you have clearances all the way around your part. I bent a barrel once years ago because I didn’t notice it was resting on something that shouldn’t have been there.

- If you are going to clamp a barreled receiver in a vise, clamp on the trunnion and not on the far softer sheet metal.

- When pressing out the barrel, protect the steel on the chamber end and do not press or beat on it directly. Insert a brass or copper buffer in there to avoid steel to steel contact.

- When pressing or hammering out the barrel, make sure your tool is pushing directly on the barrel and hasn’t somehow lodged against the trunnion.

- When the barrel comes out of the trunnion have something soft for it to land on or hold on to it so the barrel isn’t damaged during the fall.

Conclusion

You can absolutely get a barrel pin and barrel out of an AK with a press fit barrel in 10-15 minutes with an air hammer. The only catch is if you are stuck with one of those kits with unholy tight interference fit and then you’ll need a press.

Note, I have to buy all of my parts – nothing here was paid for by sponsors, etc. I do make a small amount if you click on an ad and buy something but that is it. You’re getting my real opinion on stuff.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, I may be paid via an affiliate program such as Avantlink, Impact, Amazon and eBay.