I miss building AKs – I never have the time any more. At rate, some years back I wound up with two Yugo M70 front milled stubs, and then decided to convert the rifle to a stamped receiver because I liked working with AK-Builder flats. So, in the spirit of trying something new, I decided to convert a stub to a trunnion and plug weld it in place vs. trying to machine the rivet seats inside.

Yes, I’ve heard tons of people say not to weld them together and that rivets are better. Yes, rivets are better and I have done many of them. Have I ever had problems with a weld build where I filled the holes I drilled with plugs, stayed away from the locking lugs and was careful with the heat? No, I have not had any problems. I have an AMD-65 with tons of rounds through it that still runs fine. My thinking is that I am not firing full auto, not using grenades, don’t use this in combat … I’m not really stressing it. What would I use for a reliable build vs. a test like this? I’d use rivets.

| Why the big caveat in the previous paragraph – I get one or two emails a year from a purist telling me that what I did was evil, that I am a clueless half-wit, etc. Folks, innovation happens by trying new things. I have built more AKs than most – using rivets mainly because they do work best. There are a ton of reasons why rivets are best for joining forged blocks to sheet metal. In terms of welds, do I understand the risk of destroying the heat treat in the locking lug area, the risk of causing embrittlement around the plug welds, that the Soviets explored this and dropped the idea due to cracking? Yes, I do and tried it anyway because I wanted to explore how to compensate. So, don’t send me hate mail me because I will not bother responding. When I first shared this, three guys immediately sent me hate mails and unfriended me – I did not lose sleep about it. If you want to try and experiment, go for it. Should you do this with an AK build that you want to be historically accurate or plan to use heavily perhaps even under full auto, then the answer is “no – don’t do it”. |

The build I am sharing photos of was done in 2009. I found the photos and thought you might like to see them.

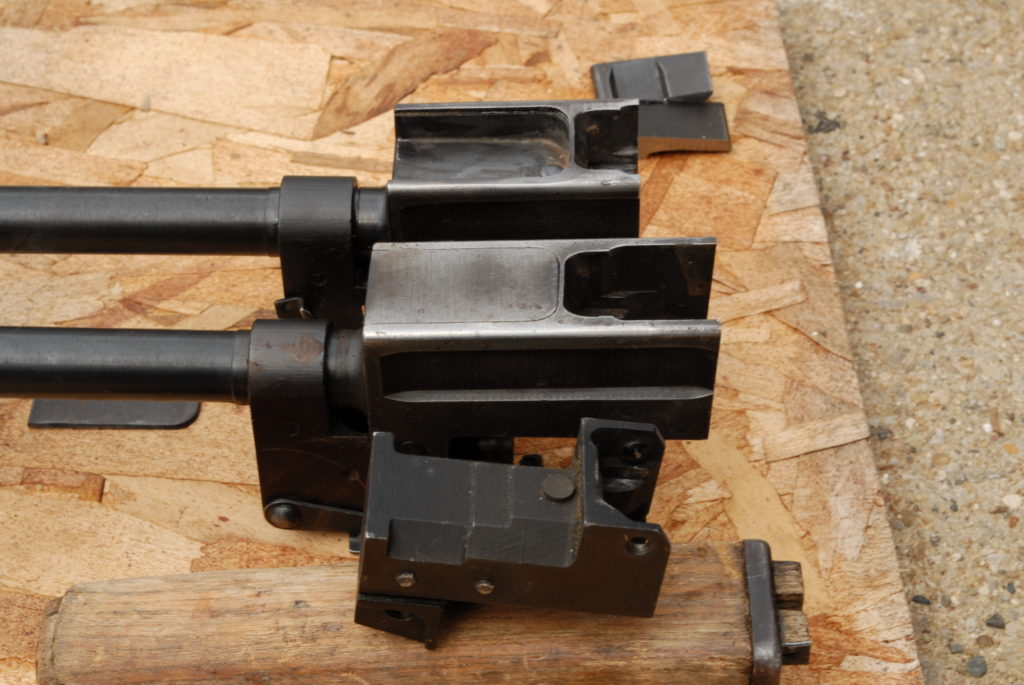

Here are the front stubs.

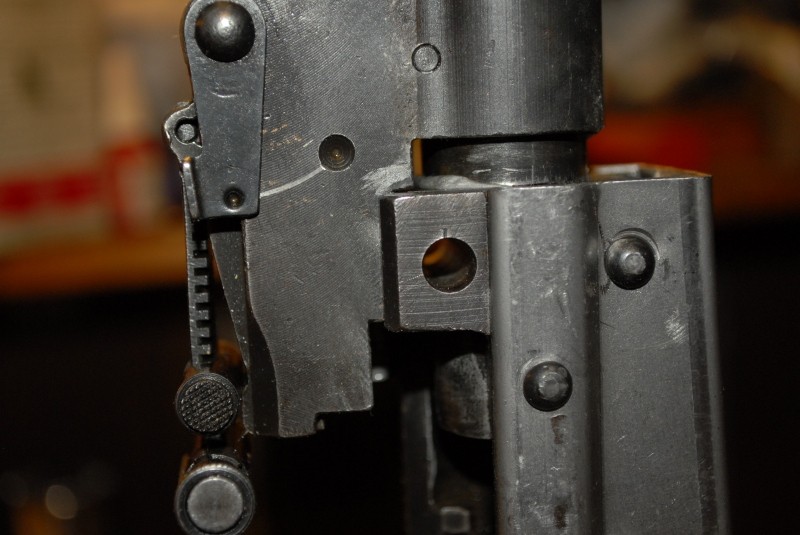

When you look at the front stub, you can see readily hiw it could become a trunnion.

Here’s a Hungarian AMD trunnion next to it.

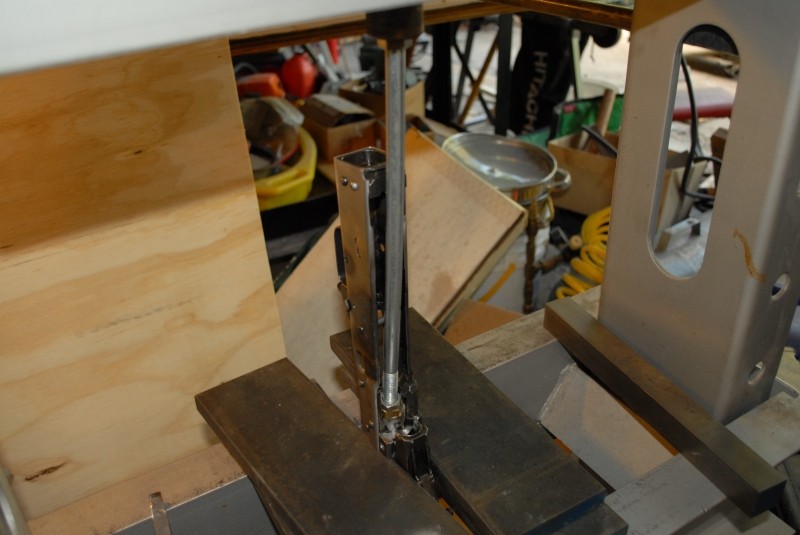

Here are the stubs from a couple of angles. I already used my bandsaw to cut the top one

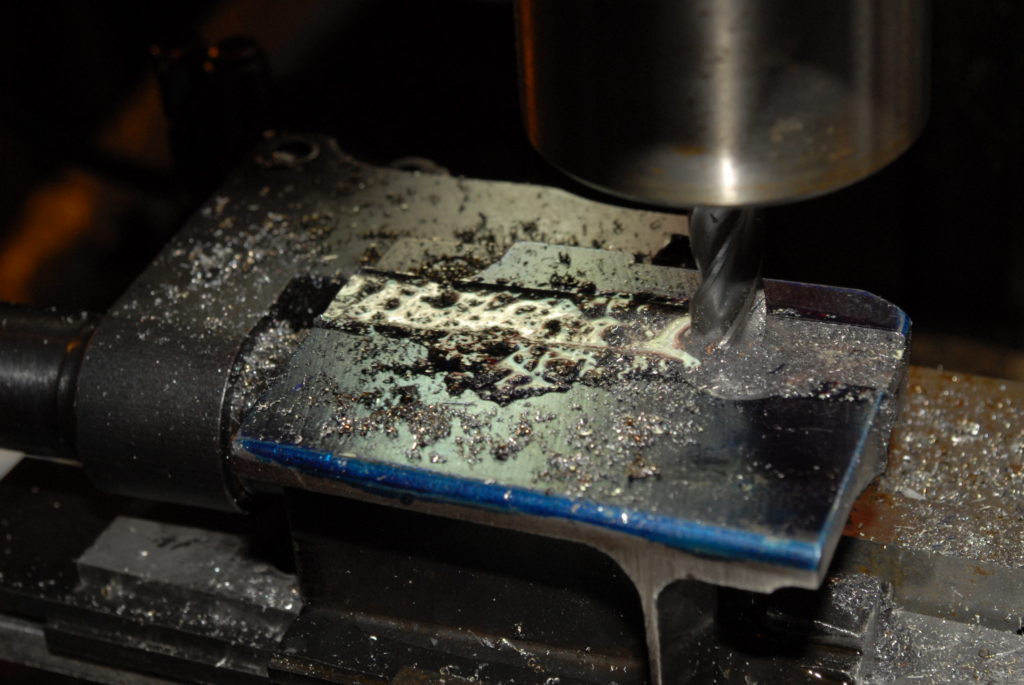

Ok, time to make some chips. It’s secured an I’m milling the OD under the top shelf of the trunnion that sticks out over the receiver:

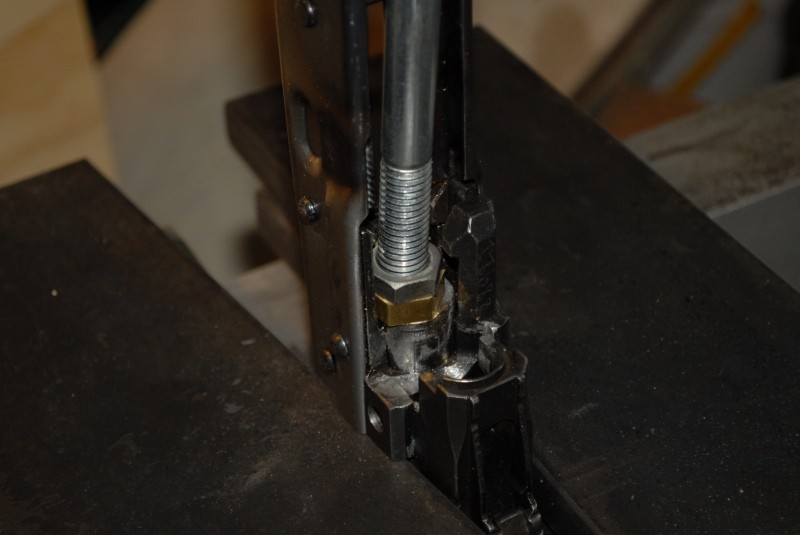

I didn’t have anything to cut the slot with for my mill so I clamped a straight edge and then ran a Dremel wheel down it over and over until I got the depth and width needed for the stamped receiver to to slide into:

My theory was that by drilling holes and filling them via plug welds that I could lock the receiver into place. Thus, I drilled holes for the plug welds both in the stamped receiver and into the newly made trunnion:

The plug welds were done with a Harbor Freight 220V MIG running ArCo2 gas and .030 wire. I let it cool down after each weld and was careful not to pour on a ton of heat. Notice the relatively big weld area to distribute the load.

I then sanded it all down with a flap sander. The back was just a regular M72 rear trunnion that I found at R-Guns. I never had problems with cracking, etc. The experiment seemed to work for a casual use semi-automatic rifle.

That’s all I have as far as photos go. I hope maybe it gives you some ideas.

Writing this makes me wish I had time to build another AK but it’s back to our grips and handguards 🙂

Note, I have to buy all of my parts – nothing here was paid for by sponsors, etc. I do make a small amount if you click on an ad and buy something but that is it. You’re getting my real opinion on stuff.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, I may be paid via an affiliate program such as Avantlink, Impact, Amazon and eBay.