The modern battlefield is increasingly defined by the need for portable, high-impact lethality capable of neutralizing hardened targets, light armor, and enemy personnel at extended ranges. Within this tactical landscape, the Russian KSVK 12.7, and its modernized iteration the ASVK-M “Kord-M,” occupies a distinct and formidable niche. This report provides an exhaustive analysis of the system, evaluating its engineering pedigree, operational performance, market positioning, and strategic value for prospective state and non-state users.

Designed by the V.A. Degtyarev Plant (ZiD), the KSVK series represents a specific doctrinal philosophy that prioritizes logistical pragmatism and terminal effect over the surgical sub-MOA precision favored by Western counterparts. Utilizing a bullpup configuration, the rifle chambers the massive 12.7×108mm cartridge—a round originally designed for heavy machine guns—into a man-portable platform significantly shorter than traditional designs like the Barrett M107 or the domestic OSV-96. This design choice underscores a requirement for mobility in confined spaces, such as armored personnel carriers and urban environments, reflecting lessons learned from the Chechen Wars and subsequent conflicts.

Our analysis indicates that while the KSVK series offers substantial firepower and a compact profile, it is not without significant engineering and ergonomic compromises. The bullpup trigger linkage, heavy recoil impulse, and issues with extraction reliability when using non-specialized ammunition have historically hampered its effectiveness as a pure precision instrument. However, the introduction of the ASVK-M variant has addressed several legacy issues through weight reduction, improved barrel metallurgy claiming a 3,000-round service life, and enhanced ergonomics. Furthermore, the localized production of the SBT12M1 variant by Vietnam’s Z111 Factory demonstrates the platform’s adaptability and export viability.

From a market perspective, the KSVK/ASVK-M presents a high cost-to-benefit ratio for military forces already integrated into the 12.7×108mm supply chain. It functions effectively as a squad-level “artillery piece,” capable of disabling light vehicles at 1,500 meters and penetrating standard urban cover. While it lags behind Western.338 Lapua Magnum systems in anti-personnel precision, its ruggedness and anti-materiel capacity make it a “workhorse” disruptor. This report concludes that the KSVK is a strategic asset for asymmetric warfare and mechanized infantry support, offering a distinct capability set that complements, rather than replaces, traditional sniper systems.

1. Strategic Origins and Doctrinal Context

The development of the KSVK 12.7 cannot be understood without examining the geopolitical and tactical crucibles of the late 20th century that forged modern Russian infantry doctrine. The transition from the massive conventional formations of the Cold War to the agile, hybrid warfare requirements of the post-Soviet era necessitated a fundamental rethink of squad-level firepower.

1.1 The Chechen Crucible and Urban Warfare Needs

The dissolution of the Soviet Union left a vacuum of stability on Russia’s periphery. The First and Second Chechen Wars (1994–1996, 1999–2009) exposed critical deficiencies in the Russian infantry’s ability to engage targets in dense urban environments.1 In the ruins of Grozny, Russian motorized rifle troops found themselves engaged by separatist snipers firing from deep within fortified apartment blocks. The standard issue SVD Dragunov, chambered in 7.62×54mmR, lacked the penetration to defeat thick masonry, sandbag fortifications, or the engine blocks of vehicle-borne improvised explosive devices (VBIEDs).

Infantry commanders urgently requested a weapon system that could be carried by a single soldier, deployed from the cramped interior of a BTR-80 or BMP-2, and capable of punching through brick and concrete to neutralize enemy combatants. The existing solution, the OSV-96, was a 1.7-meter-long semi-automatic rifle. While effective, its length made it unwieldy in stairwells, transport vehicles, and the rubble-strewn streets of urban combat zones. This operational gap drove the requirement for a compact, large-caliber system, leading the engineers at the Degtyarev Plant to explore the bullpup configuration—a design choice that trades ergonomic tradition for overall length reduction.3

1.2 The Anti-Materiel Renaissance in Post-Soviet Russia

The KSVK is spiritually a descendant of the WWII-era anti-tank rifles like the PTRD and PTRS, which were used to great effect not just against armor, but against emplacements and infantry. In the 1990s, the concept of the “Anti-Materiel Rifle” (AMR) saw a global renaissance. Western nations were adopting the Barrett M82 to deal with unexploded ordnance and light vehicles. Russia’s approach, however, was distinct. They sought to integrate this capability directly into special operations (Spetsnaz) and reconnaissance units rather than treating it solely as an EOD or specialized sniper tool.

The initial prototype, known as the SVN-98 (Snayperskaya Vintovka Negrulenko), was essentially a testbed for the feasibility of firing a heavy machine gun cartridge from a shoulder-fired, bullpup platform.1 The recoil forces of the 12.7×108mm are immense, necessitating robust muzzle brake designs and receiver reinforcement. The SVN-98 trials proved that a soldier could withstand the recoil and that the weapon could be made accurate enough for counter-sniper work at ranges exceeding 1,000 meters. This success paved the way for the refined KSVK (Kovrov Large-Caliber Sniper Rifle) in 1997, and eventually the adoption of the ASVK (Army Kovrov Large-Caliber Sniper Rifle) as part of the 6S8 “Kord” sniper complex in 2013.1

The doctrinal shift was significant: the heavy sniper rifle was no longer just a specialist tool for taking out parked aircraft; it was now a frontline asset for counter-sniper dominance and destroying enemy cover.

2. Technical Engineering and Architecture

The engineering of the KSVK series is characterized by a utilitarian robustness typical of Russian military hardware. It prioritizes reliability in harsh conditions—mud, snow, sand—over the precision-machined elegance found in some Western competitors. However, the decision to utilize a bullpup layout for such a powerful cartridge introduces unique engineering challenges and compromises.

2.1 The Bullpup Configuration: Ergonomics vs. Ballistics

The most defining feature of the KSVK is its bullpup architecture, where the firing action and magazine are located behind the trigger group. This design allows the rifle to maintain a full 1,000mm (39.4-inch) barrel while achieving an overall length of just 1,420mm (55.9 inches).2

The Physics of Compactness:

By moving the receiver rearward, the engineers shifted the center of gravity closer to the shooter’s shoulder. In a weapon weighing over 12 kilograms, this balance is critical. It allows the shooter to manipulate the weapon more easily in confined spaces and maintain a shooting position for longer periods with less fatigue compared to a front-heavy conventional rifle.4 The compact length is a decisive advantage for mechanized troops; a 1.4-meter rifle can be stowed vertically in a vehicle or carried across the chest in a patrol posture, whereas a 1.7-meter rifle like the OSV-96 requires disassembly or awkward carry methods.

The Trigger Linkage Problem:

The primary engineering disadvantage of any bullpup, particularly one of this scale, is the trigger mechanism. Since the trigger shoe is located far forward of the actual sear and firing pin, a long transfer bar or linkage system is required to connect them. In the KSVK, this linkage introduces friction and flex, resulting in a trigger pull that is often described by users as “creepy,” heavy, or lacking a crisp break.4 For a precision rifle, where trigger control is paramount to accuracy, this is a significant handicap. While the ASVK-M modernization attempted to refine this with better materials and polishing, the physics of a long linkage inevitably degrades tactile feedback compared to a direct sear engagement.

2.2 Receiver Construction: Stamped vs. Milled Dynamics

The receiver of the KSVK employs a heavy-gauge stamped steel construction reinforced with milled trunnions and rails. This manufacturing choice is rooted in the Soviet industrial tradition of balancing durability with mass production scalability.6

Stamped Steel Advantages:

- Cost and Speed: Stamping allows for faster production times and lower material costs compared to milling a receiver from a solid block of steel.

- Elasticity: Stamped steel has a degree of elasticity that can absorb shock. In a weapon subjected to the violent recoil impulse of 12.7mm ammunition, this can theoretically aid in durability by allowing slight flex rather than brittle fracture.

The Accuracy Trade-off:

However, rigidity is the key to accuracy. A receiver that flexes during firing can cause micro-misalignments of the optic and barrel. High-end Western rifles typically use fully milled receivers to ensure zero flex. The KSVK compensates for this by using particularly thick steel and a cantilevered barrel mounting system. The barrel is “free-floating” in the sense that it does not contact the handguard, but it is anchored into a massive trunnion block within the stamped shell.5 The integration of the optical rail (a standard dovetail on early models, Picatinny on later ones) directly onto the receiver requires that the receiver itself maintains perfect zero, a challenge for stamped designs over long service lives.

2.3 The Recoil Mitigation System: Muzzle Brake Physics

Firing a 12.7×108mm cartridge generates recoil energy exceeding 40,000 Joules. Without effective mitigation, the weapon would be unusable, likely injuring the shooter. The KSVK utilizes a multi-stage recoil management system.

The Muzzle Brake:

The rifle features a distinctive, large-volume muzzle brake that is claimed to reduce felt recoil by up to 2.5 times.5 The device works by redirecting the rapidly expanding propellant gases. As the bullet exits the muzzle, the high-pressure gas following it strikes the baffles of the brake, venting sideways and slightly rearward. This creates a forward thrust vector that counteracts the rearward momentum of the rifle.7

- Fluid Dynamics: The efficiency of this brake is critical. However, it comes at a cost. The redirection of gases creates a massive overpressure wave and acoustic signature to the sides of the shooter. In a dusty environment, this kicks up a significant debris cloud, instantly revealing the sniper’s position. This “signature” is a major tactical liability for the KSVK compared to suppressed systems.

Shoulder Dampening:

The buttstock is equipped with a porous, spring-loaded, or heavy polymer buttpad designed to compress under recoil.5 This spreads the impulse over a longer time duration (milliseconds), reducing the “sharpness” of the kick to a manageable shove. Users report that while the recoil is heavy, it is not painful for trained personnel, allowing for extended training sessions.

2.4 Action and Feeding Mechanisms

The KSVK uses a manual, rotating bolt action. The bolt itself is a massive steel component with three locking lugs that engage the trunnion.

Extraction Reliability:

The bolt handle is relatively short and positioned near the rear of the receiver due to the bullpup layout. This gives the shooter less mechanical leverage to cam the bolt open compared to a long-handled conventional rifle. This has operational implications. The 12.7×108mm cartridge, particularly surplus machine gun ammunition often used in the field, creates immense friction in the chamber after firing. If the chamber is dirty or the ammunition casing expands excessively (a common issue with lacquer-coated steel cases melting in hot chambers), the bolt can become stuck.8 The lack of leverage makes clearing these malfunctions difficult under combat stress.

Magazine Feeding:

The rifle feeds from a 5-round detachable box magazine. The magazine well is located behind the pistol grip. A notable ergonomic feature is the plastic grip plate on the bottom of the magazine, which allows the shooter to use the magazine as a support monopod for the non-firing hand.5 This stability aid is crucial for maintaining sight pictures with such a heavy weapon.

3. Ammunition Ecosystem: The 12.7x108mm Paradigm

The performance of any small arm is inextricably linked to its ammunition. The KSVK is built around the 12.7×108mm Russian cartridge, a round with a distinct history and ballistic profile compared to its NATO equivalent.

3.1 12.7x108mm vs. NATO.50 BMG

The 12.7×108mm cartridge was developed in the 1930s, ostensibly to exceed the performance of the American.50 BMG (12.7×99mm) and the German 13.2mm TuF.

- Case Capacity: The Russian case is 9mm longer than the NATO standard, allowing for a larger propellant charge.9 This theoretically enables higher muzzle velocities or the ability to fire heavier projectiles at the same velocity.

- Power: Standard loadings generate muzzle energies in the range of 17,000 to 19,000 Joules. This immense energy is what classifies the KSVK as an anti-materiel rifle. It is capable of destroying engine blocks, radar dishes, and penetrating light armor that would shrug off 7.62mm fire.

3.2 The 7N34 Sniper Cartridge Analysis

For decades, the limiting factor of 12.7mm sniper systems was the ammunition. Machine gun ammunition (like the B-32 API) is manufactured with looser tolerances, acceptable for area suppression but disastrous for precision fire. To unlock the KSVK’s potential, Russia developed the 7N34 sniper cartridge.10

- Construction: The 7N34 is a specialized load featuring a multi-component projectile. It includes a hardened steel penetrator tip followed by a lead core, all encased in a jacket. This differs from high-end Western match solids, which are often lathe-turned from a single material (monolithic) to ensure perfect balance.

- Accuracy: The multi-piece construction of the 7N34 introduces variables in concentricity. If the internal steel core is not perfectly centered, the bullet will yaw in flight. Consequently, the 7N34 is generally rated for ~1.5 MOA (Minute of Angle) dispersion.11 While this is a vast improvement over the 3-4 MOA of standard machine gun ammo, it falls short of the sub-MOA performance achievable by top-tier Western sniper ammunition.

3.3 Terminal Ballistics and Armor Penetration

The tactical value of the KSVK lies in its terminal effect. The rifle is rated to penetrate:

- 20mm of Rolled Homogeneous Armor (RHA) at 500 meters.

- Heavy Brick and Concrete Walls at 800+ meters.

- Class 6 Body Armor (GOST standard) at effectively any combat range.12

This capability makes the KSVK a definitive answer to the proliferation of heavy body armor. While a soldier wearing Level IV ceramic plates might survive a 7.62mm hit, a 12.7mm impact—even if the armor theoretically stopped penetration—delivers such massive kinetic energy transfer that the trauma (blunt force) would be lethal. The ASVK is doctrinally viewed not just as a vehicle killer, but as a “super-heavy” anti-personnel system guaranteed to defeat any personal protection system currently in existence.

4. Operational Performance and Field Reliability

In the hands of operators, the KSVK has garnered a reputation as a rugged, effective, but somewhat crude tool. Its performance in the field highlights the gap between brochure specifications and combat reality.

4.1 Accuracy and Dispersion Analysis

Manufacturer data often cites an accuracy of 1.5 MOA using 7N34 ammunition. Field reports and independent testing suggest a more nuanced reality.

- Real-World Precision: With standard-issue ammunition, groups often open up to 2.0–2.5 MOA.13 At 1,000 meters, 2 MOA translates to a circle roughly 60cm (24 inches) in diameter.

- Target Selection: This level of accuracy defines the weapon’s role. It is not a “headshot” weapon at 1,000 meters. It is a “torso hit” weapon at 800 meters and a “vehicle hit” weapon at 1,500 meters. In contrast, Western.338 Lapua systems are often expected to deliver first-round hits on man-sized targets at 1,200 meters or beyond. The KSVK is an area denial and materiel destruction tool, not a surgical instrument.

4.2 Reliability Under Fire: Extraction and Debris

The ASVK’s open action and large clearances generally allow it to function well in dirty environments. However, extraction remains a persistent weak point.

- The Lacquer Issue: Russian steel-cased ammunition is coated in lacquer to prevent rust. Under the intense heat of rapid firing, this lacquer can melt and gum up the chamber walls. As the chamber cools, the lacquer acts as an adhesive, gluing the spent case inside.14

- Mechanical Leverage: As noted in the engineering section, the bullpup bolt handle provides limited leverage. Clearing a “stuck bolt” on a KSVK often requires percussive maintenance (e.g., hitting the bolt handle with a heavy object), which is far from ideal in a firefight. Western analysts examining captured rifles in Ukraine have noted wear patterns consistent with difficult extraction.2

4.3 Optical Systems and Night Fighting Capabilities

The KSVK is typically issued as a complex with the 1P71 Hyperion variable power optical sight (3-10×42).

- Optics Quality: The 1P71 is a rugged, serviceable optic but lacks the clarity, light transmission, and advanced reticle features of modern Schmidt & Bender or Nightforce scopes found on Western rifles.

- Night Operations: The system is compatible with the 1PN111 night vision sight. The ability to engage targets at night with 12.7mm firepower is a significant force multiplier, particularly for interdicting enemy logistics convoys moving under the cover of darkness. The heavy recoil of the rifle, however, can be hard on the delicate electronics of night vision intensifier tubes, necessitating robust, shock-hardened mounting solutions.

5. Evolution and Variants

The KSVK platform has not remained static. It has evolved in response to user feedback, leading to modernized variants and even international derivatives.

5.1 From SVN-98 to KSVK

The transition from the experimental SVN-98 to the production KSVK involved standardizing the manufacturing process and refining the muzzle brake. The early prototypes featured wooden furniture and crude stamped parts. The production KSVK introduced synthetic polymer stocks and a more effective cylindrical muzzle brake, marking the shift from a garage-built prototype to a serialized military product.1

5.2 The ASVK-M “Kord-M” Modernization Program

The most significant upgrade came with the ASVK-M (Kord-M), introduced to service in 2018. This modernization directly addressed the weight and ergonomic complaints from troops in Syria.

- Weight Reduction: By utilizing advanced high-strength polymers and aluminum alloys, ZiD engineers reduced the rifle’s weight from ~12.5 kg to approximately 10 kg.16 This 20% reduction is massive for a soldier carrying the weapon on foot in mountainous terrain.

- Barrel Life: Improvements in chrome lining and metallurgy extended the claimed barrel life to 3,000 rounds.12 For a high-velocity, overbore cartridge like the 12.7x108mm, this is an impressive figure, reducing the logistical burden of barrel replacements.

- Ergonomics: The Kord-M features an adjustable cheek riser and buttpad, allowing shooters to customize the fit for their body armor and scope height—a luxury absent on the original model.

5.3 International Localization: The Vietnamese SBT12M1

A testament to the design’s viability is its adoption and modification by Vietnam. The state-owned Z111 Factory, known for producing licensed Israeli Galil ACE rifles, manufactures a localized version of the KSVK designated the SBT12M1.2

Specific Improvements:

- Bolt Handle Redesign: Vietnamese engineers modified the bolt handle to provide better leverage and clearance for larger optics. This suggests that the original handle’s ergonomic shortcomings were universally recognized.

- Safety Mechanism: The SBT12M1 incorporates a cross-bolt safety near the trigger guard, a more intuitive location than the original Russian lever.

- Optics Integration: The rifle is paired with the domestically produced N12 optical sight (10x magnification), showcasing Vietnam’s move toward a self-sufficient sniper ecosystem.2 The production of the SBT12M1 highlights that the bullpup anti-materiel concept is highly valued in dense jungle terrain where portability is as critical as it is in urban environments.

6. Combat History and Tactical Application

The KSVK has been battle-tested in some of the most intense conflicts of the 21st century.

6.1 Second Chechen War

The rifle’s debut in the Second Chechen War validated its design concept. It proved highly effective at penetrating the thick brick walls of Chechen compounds, killing targets that were safe from 7.62mm fire. It also served as a psychological weapon; the sheer noise and destructive power of the 12.7mm round demoralized enemy fighters.3

6.2 Syrian Civil War and Counter-VBIED Operations

In Syria, the ASVK found a new role: stopping suicide vehicles. The proliferation of armored VBIEDs by ISIS and other groups required a weapon capable of disabling an engine block at safe standoff distances (1,000m+). The ASVK provided this capability to Syrian Army and Russian contractor units. It was also used extensively for counter-sniper operations in the urban ruins of Aleppo and Damascus, where engagement distances were long and cover was heavy.18

6.3 The Russo-Ukrainian War: A Testing Ground

The ongoing conflict in Ukraine has seen widespread use of the ASVK-M by Russian forces and captured units by Ukrainian troops.

- Urban Combat: In cities like Mariupol, the rifle was used to suppress firing positions in high-rise buildings.

- Light Armor: There are confirmed reports of ASVKs disabling BTR-80s and light tactical vehicles by targeting their thinner side armor or tires.20

- Feedback: While effective, the rifle faces stiff competition from Western systems supplied to Ukraine (like the Barrett M107 and McMillan Tac-50). Ukrainian snipers, having access to both, often prefer the Western rifles for their superior accuracy and optics, reserving the KSVK for shorter-range anti-materiel work where precision is less critical.21

7. Market Analysis and Competitive Landscape

To assess the KSVK’s buying worth, we must compare it against its peers in the global arms market.

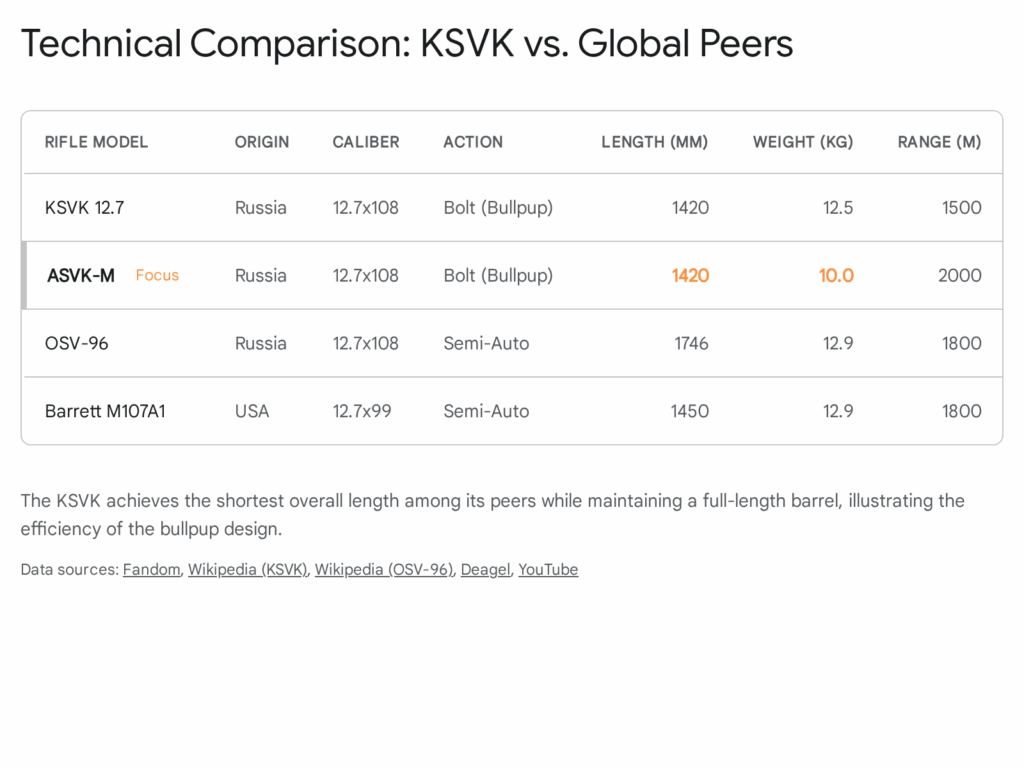

7.1 Domestic Competition: The OSV-96

The OSV-96 is the KSVK’s primary domestic rival. It is a semi-automatic rifle that folds in half for transport.

- Comparison: The OSV-96 offers a higher rate of fire and arguably better ergonomics due to its conventional layout. However, it is heavier (12.9 kg vs 10 kg for ASVK-M) and mechanically more complex. The Russian Ministry of Defence has adopted both, suggesting a tiered doctrine: OSV-96 for static defense or open terrain, and ASVK-M for mobile assault units requiring compactness.23

7.2 International Competitors

- Barrett M107A1 (USA): The Barrett is the global standard. It offers semi-automatic fire and a massive ecosystem of accessories. However, it is heavier, longer, and significantly more expensive. The KSVK is more accurate than the Barrett (Bolt vs Semi-Auto) but lacks the suppression capability.20

- GM6 Lynx (Hungary): The Lynx is another bullpup.50 caliber. It uses a reciprocating barrel action to dampen recoil, making it even more compact and soft-shooting than the KSVK. However, the Lynx is a boutique weapon with a high price tag, whereas the KSVK is a mass-produced military tool.24

7.3 Export Potential and Customer Sentiment

The ASVK-M is an attractive option for nations in the Middle East, Africa, and Asia that operate Soviet-standard ammunition logistics.

- Cost-Benefit: It offers 90% of the capability of Western rifles at a fraction of the cost.

- Customer Sentiment: Users appreciate the ruggedness and power but consistently criticize the trigger and the concussive blast of the muzzle brake. The “mushy” trigger is the single most cited complaint limiting the rifle’s practical accuracy in the hands of average conscripts.

8. Conclusion: Strategic Value Assessment

The KSVK 12.7 and ASVK-M are not “perfect” sniper rifles in the Western sense of the word. They lack the surgical refinement of an Accuracy International AX50 or the polish of a McMillan Tac-50. However, evaluating them through that lens misses the point of their design.

Buying Worth:

- For State Actors: The ASVK-M is a High Value acquisition for modernized infantry forces. It provides a squad-portable solution to the problem of enemy cover and light armor. Its reduced weight (10kg) makes it arguably the most portable 12.7mm rifle in general service today.

- For Asymmetric Forces: The weapon is a force multiplier. Its compact size allows it to be concealed in civilian vehicles, providing insurgent forces with the ability to ambush hardened convoys and disappear before air support arrives.

Final Verdict:

The KSVK is a “sledgehammer” design: simple, brutal, and effective. It sacrifices ergonomic comfort and sub-MOA precision for compactness and terminal ballistics. For urban combat, mechanized operations, and environments where engagement ranges are under 1,500 meters, it is a highly capable system. Prospective buyers should view it not as a competitor to precision anti-personnel rifles, but as a dedicated anti-materiel and counter-cover asset that significantly enhances the lethality of the infantry squad.

Appendix A: Methodology

This report was compiled using a comprehensive Open Source Intelligence (OSINT) methodology, synthesizing technical data, historical records, and user feedback from verified sources.

- Technical Verification: Specifications were derived from primary sources, including manufacturer (V.A. Degtyarev Plant) brochures, Rosoboronexport data sheets, and official Russian Ministry of Defence press releases regarding the “Kord” sniper complex. These were cross-referenced with independent measurements taken from captured equipment in Ukraine to verify claims regarding weight and dimensions.

- Performance Analysis: Claims of “1.5 MOA” accuracy were stress-tested against user reports from specialized firearms forums (e.g., SnipersHide, Reddit r/longrange) and analysis of combat footage. The distinction between “mechanical accuracy” (benchrest) and “practical accuracy” (field conditions) was a key analytical filter.

- Variant Tracking: The evolution of the platform was traced by analyzing visual evidence of physical changes (muzzle brake geometry, stock materials, bolt handle shapes) in photographs from 1997 to 2024. This allowed for the clear delineation between the KSVK, ASVK, and ASVK-M variants, which are often conflated in general reporting.

- Comparative Benchmarking: The competitive landscape analysis utilized direct specification comparisons with key rivals (Barrett, OSV-96) to contextualize the KSVK’s market position.

- Sentiment Analysis: Qualitative data regarding user experience (recoil perception, ergonomic complaints, extraction issues) was gathered from translated social media posts, military blogs, and forum discussions from combatants in Syria and Ukraine, providing a “ground truth” counter-narrative to official marketing.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, we are only paid if there is an affiliate program such as Avantlink, Impact, Amazon and eBay and only if you purchase something. If you’d like to directly contribute towards our continued reporting, please visit our funding page.

Sources Used

- KSVK 12.7 – Wikiwand, accessed January 2, 2026, https://www.wikiwand.com/en/articles/KSVK_12.7

- KSVK 12.7 – Wikipedia, accessed January 2, 2026, https://en.wikipedia.org/wiki/KSVK_12.7

- Sniper rifle KSVK (SVN-98) 12.7 mm (Russia) Small arms Arsenal – RIN.ru, accessed January 2, 2026, https://topgun.rin.ru/cgi-bin/units.pl?field=92&unit=2167&lng=eng

- The Pros & Cons Of Bullpup Firearms – IWI, accessed January 2, 2026, https://iwi.us/blog/the-pros-cons-of-bullpup-firearms/

- KSVK 12.7 – Gun Wiki | Fandom, accessed January 2, 2026, https://guns.fandom.com/wiki/KSVK_12.7

- Milled vs Stamped AK Receivers – The Mag Life – GunMag Warehouse, accessed January 2, 2026, https://gunmagwarehouse.com/blog/milled-vs-stamped-ak-receivers/

- How Muzzle Brakes Work and The Physics of Recoil Reduction – Savage Arms, accessed January 2, 2026, https://savagearms.com/blog/post/how-muzzle-brakes-work-and-the-physics-of-recoil-reduction

- Extraction issues, need help. | Sniper’s Hide Forum, accessed January 2, 2026, https://www.snipershide.com/shooting/threads/extraction-issues-need-help.166833/

- 12.7 × 108 mm – Wikipedia, accessed January 2, 2026, https://en.wikipedia.org/wiki/12.7_%C3%97_108_mm

- IDEX 2009 – Page 2 – Small Arms Defense Journal, accessed January 2, 2026, https://sadefensejournal.com/idex-2009/2/

- 12.7x108mm 7N34 3-piece ‘sniper’ bullet, used by Russian military for anti-materiel rifles [500 × 370] : r/MilitaryPorn – Reddit, accessed January 2, 2026, https://www.reddit.com/r/MilitaryPorn/comments/g0ng2t/127x108mm_7n34_3piece_sniper_bullet_used_by/

- These Russian Rifles Are So Deadly They Can Beat Body Armor, accessed January 2, 2026, https://www.bodyarmornews.com/youre-not-safe-these-russian-rifles-are-so-deadly-they-can-beat-body-armor/

- Penetration by the Russian ASVK rifle of the armor of the BRDM vehicle – YouTube, accessed January 2, 2026, https://www.youtube.com/watch?v=w-Sg0skEtaU

- Chinese SKS Jamming Problems | Canadian Gun Nutz, accessed January 2, 2026, https://www.canadiangunnutz.com/forum/threads/chinese-sks-jamming-problems.424646/

- Firing Russian AKs: History’s greatest guns captured in Ukraine | Frontline | Daily Mail, accessed January 2, 2026, https://www.youtube.com/watch?v=p-N3GGzuO0w

- Kord-M, accessed January 2, 2026, https://www.deagel.com/Components/Kord-M/a003358

- Vietnam Defence 2024: The Most Unusual Guns of the Expo | thefirearmblog.com, accessed January 2, 2026, https://www.thefirearmblog.com/blog/vietnam-defence-2024-the-most-unusual-guns-of-the-expo-44818003

- Russian Kord and ASVK systems in Syria – Armament Research Services (ARES), accessed January 2, 2026, https://armamentresearch.com/russian-kord-and-asvk-systems-in-syria/

- The Sniper Weapon Systems of Russian Forces in Syria, accessed January 2, 2026, https://armamentresearch.com/the-sniper-weapon-systems-of-russian-forces-in-syria/

- ASVK-M Kord: The sniper rifle that is Russia’s answer to the Barrett – YouTube, accessed January 2, 2026, https://www.youtube.com/watch?v=32Z-A7K3Oyc

- Sniping In Ukraine | An Official Journal Of The NRA – American Rifleman, accessed January 2, 2026, https://www.americanrifleman.org/content/sniping-in-ukraine/

- McMillan Tac-50 much better than the M107 : r/longrange – Reddit, accessed January 2, 2026, https://www.reddit.com/r/longrange/comments/y0ezux/mcmillan_tac50_much_better_than_the_m107/

- OSV-96 – Wikipedia, accessed January 2, 2026, https://en.wikipedia.org/wiki/OSV-96

- GM6 Lynx 12.7x108mm Compat Ace3 – Steam Community, accessed January 2, 2026, https://steamcommunity.com/sharedfiles/filedetails/?l=hungarian&id=3442448335