In the last post, we reviewed the political climate and how the USSR did not want to share their revolutionary AK-47 design with Yugoslavia. At this point, we need to look at the ambitious 1959 launch of the project “Familija Automatskog Oružja Zastava” (FAZ), or the Zastava Family of Automatic Weapons and how the Yugoslav’s worked around the Soviets to create their own version of the AK.

Forging Their Own Path: Yugoslavia’s Independent Rifle

In the fractured landscape of post-World War II Europe, the Socijalistička Federativna Republika Jugoslavija (Socialist Federal Republic of Yugoslavia – SFRJ) charted a uniquely independent course. Initially aligned with the Soviet Union, Yugoslavia’s relationship with Moscow ruptured dramatically following the Tito-Stalin split in 1948. This political schism cast Yugoslavia adrift from the burgeoning Eastern Bloc, leading to its refusal to join the Warsaw Pact and forcing it into a precarious non-aligned position during the Cold War.1 Wary of potential aggression from both NATO and the Soviet sphere, Belgrade recognized that national survival depended on military self-sufficiency.2

This drive for independence created a significant arms dilemma. The break with Moscow severed access to the latest Soviet military technology and, crucially, the licenses to produce advanced weaponry like Mikhail Kalashnikov’s revolutionary AK-47 assault rifle.1 While Yugoslavia remained a socialist state, its ideological divergence and independent streak meant Western powers were equally hesitant to provide significant military aid or technology transfers.2 The Jugoslovenska Narodna Armija (Yugoslav People’s Army – JNA), still largely equipped with World War II-era weapons including locally produced Mauser M48 bolt-action rifles, faced the challenge of modernization alone.2

Yugoslav planners understood the changing nature of warfare. As early as 1952, the defense industry began experimenting with automatic rifle designs, initially drawing inspiration from captured German StG 44 assault rifles, large numbers of which had fallen into Yugoslav Partisan hands during the war.1 This early research underscored the awareness within the JNA of the need for an intermediate-caliber automatic rifle, but the path to acquiring or developing such a weapon remained blocked by geopolitical realities. The quest for a domestic Kalashnikov variant, therefore, was not merely a technical undertaking; it was a direct manifestation of Yugoslavia’s defiant assertion of independence and its commitment to self-reliance in a world dominated by two opposing superpowers. The rifle project became intrinsically linked to the nation’s unique political identity under Marshal Josip Broz Tito.

Glimpses of the Future: Acquiring the Kalashnikov

The first crucial breakthrough came unexpectedly in 1959. Two Albanian border guards, armed with Soviet-made AK-47 rifles, defected across the border into Yugoslavia.1 This event provided the Yugoslav military establishment with its first tangible examples of the weapon they desperately sought to understand. The captured rifles, believed to be the milled-receiver Type 3 variant which was then standard Soviet issue, were promptly handed over to engineers at the renowned Zastava arms factory (then operating as Crvena Zastava, or Red Banner) located in the city of Kragujevac, Serbia.1

While this windfall was invaluable, the two rifles presented significant limitations. Engineers at Zastava meticulously studied the weapons, even making metal castings of components using sulfur to understand their form.2 However, two samples were simply insufficient to reverse-engineer the design effectively. Critical information regarding manufacturing tolerances, precise material specifications, and the intricacies of heat treatment remained elusive.1 Reproducing the rifle reliably based solely on these examples proved impossible. A technical impasse had been reached, threatening to stall the project before it truly began.

Overcoming this obstacle required intervention from the highest levels of the Yugoslav state. By the end of 1959, or shortly thereafter, the government managed to secure a much larger quantity of AK-47s.1 Accounts suggest that Marshal Tito himself played a direct role during a state visit to an unnamed non-aligned nation.2 This country, possibly Egypt, Indonesia, or India, was a recipient of Soviet military aid.3 Through discreet negotiations, Yugoslavia arranged the clandestine purchase of approximately 2,000 AK rifles from a batch supplied by the USSR.2 This covert acquisition, bypassing official channels and Soviet oversight, provided Zastava with the critical mass of samples needed for thorough analysis. The fact that such a significant acquisition required top-level political maneuvering underscores the project’s importance as a national priority, essential for breaking the technical deadlock and enabling the engineers to finally unlock the secrets of the Kalashnikov.

| The question of which country they bought those 2,000 AKs from has never been formally answered but I have a real strong hunch and that will be the next blog post. |

Unlocking the Kalashnikov: The Zastava Challenge

With a substantial number of Soviet AKs now available for study, the engineers at Crvena Zastava, which translates into English approximately as “Red Flag” works, in Kragujevac could finally begin the complex process of reverse engineering in earnest.1 This historic arms factory, the heart of Serbian and later Yugoslav weapons manufacturing, became the crucible for Yugoslavia’s Kalashnikov ambitions.2

In 1959, the effort was formalized under the project designation FAZ – Familija automatskog oružja Zastava (Family of Automatic Weapons Zastava).2 This name itself revealed a strategic vision extending beyond merely cloning the AK-47. The goal was to develop an integrated family of infantry weapons tailored to the JNA’s needs, encompassing not only an assault rifle but also potentially a self-loading rifle and, significantly, a light machine gun (LMG).2 This mirrored the Soviet small arms doctrine (which featured the SKS carbine alongside the AK rifle and RPD/RPK machine guns) but aimed for entirely domestic design and production. This indicated a comprehensive, long-term strategy for infantry armament, rather than a simple stopgap measure.

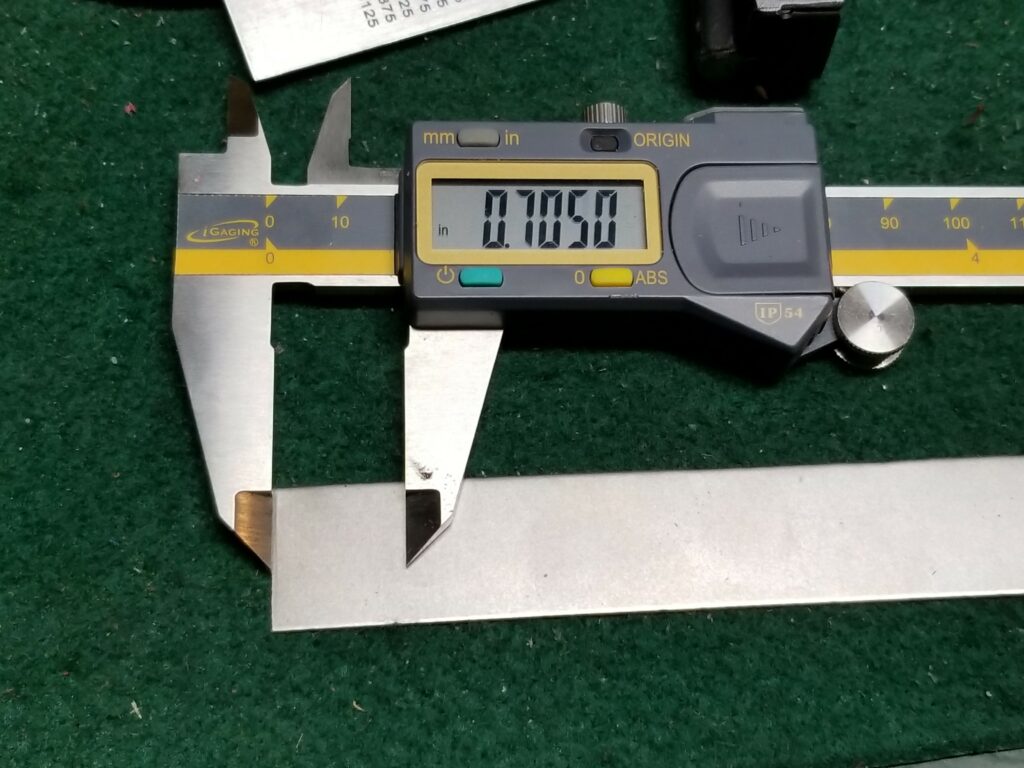

The FAZ project was a collaborative effort, spearheaded by a team of talented Zastava engineers and designers. Key figures included Božidar Blagojević (who would later design the CZ99 pistol), Major Miloš Ostojić, Miodrag Lukovac, Milutin Milivojević, Stevan Tomašević, Predrag Mirčić, and Mika Mudrić, with engineer Milan Čirić leading the project.2 Their task was immense: to meticulously disassemble, measure, analyze materials, and create complete technical drawings for a weapon system they had no license or official documentation for.1 Every dimension, tolerance, and material property had to be painstakingly deduced through careful examination of the acquired Soviet rifles.

The First Yugoslavian AK: Enter the M64

By 1964 and 1965, the intensive work at Zastava bore fruit. The first prototypes of a distinctly Yugoslavian Kalashnikov emerged, designated the M64A (featuring a fixed wooden stock) and M64B (equipped with an underfolding metal stock).1 Alongside these rifles, prototypes for a companion light machine gun, the M65A and M65B (featuring a quick-detach barrel), were also developed, though these LMGs would ultimately not see mass production.2

While based on the Soviet Type 3 AK-47, the M64 prototypes incorporated several unique features and modifications, reflecting both Yugoslav ingenuity and specific JNA requirements. This early design demonstrated that Zastava‘s engineers were not content with mere replication; they sought to adapt and potentially improve upon the Kalashnikov design. Key differences included:

- Milled Receiver: Like its Soviet progenitor, the M64 utilized a robust milled steel receiver. However, the Yugoslav receiver had distinct geometry: the characteristic lightning cut above the magazine well was present only on the right side, while the left side featured a unique profile incorporating a visible pin intended to retain the bolt hold-open mechanism.5

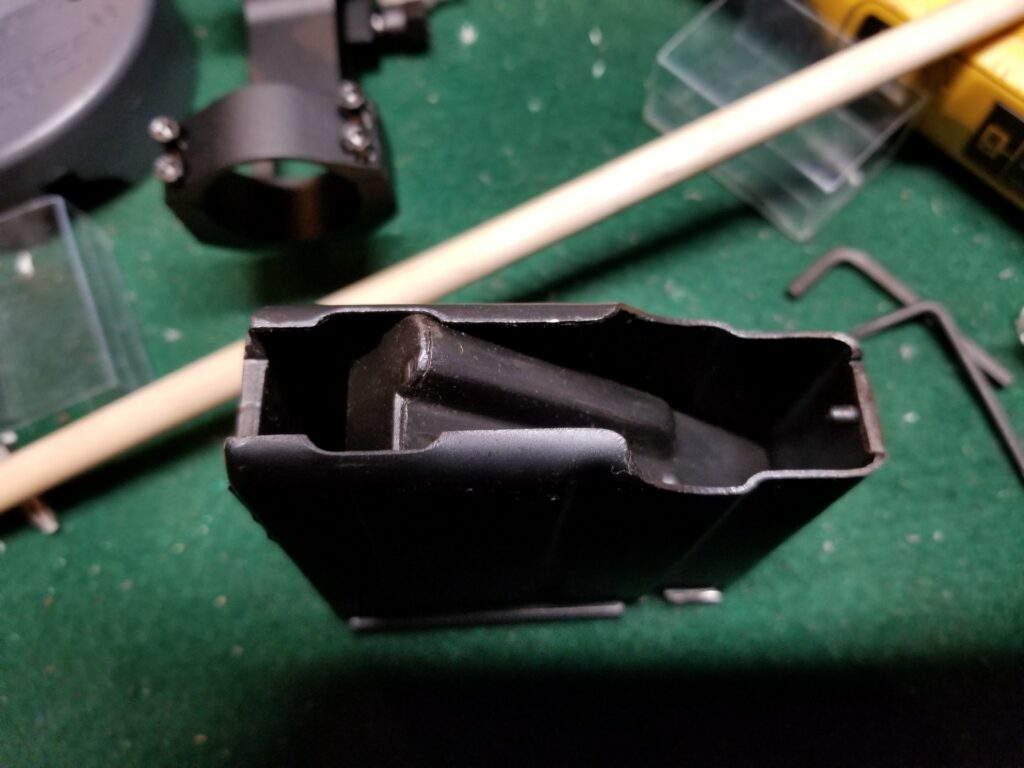

- Bolt Hold-Open (BHO): Perhaps the most significant innovation was a fully functional bolt catch mechanism. This device locked the bolt to the rear after the last round was fired from the magazine, offering a potential tactical advantage by speeding up reloads and providing immediate visual confirmation of an empty weapon. However, this system required specially modified magazines featuring a unique cutout on the follower or feed lip.1

- Integrated Grenade Launching Capability: Reflecting a strong emphasis in JNA doctrine, the M64 was designed from the outset to launch rifle grenades. It featured a built-in, flip-up grenade sight mounted on the gas block and incorporated a gas cut-off mechanism, allowing the rifle’s gas system to be shut off to safely propel grenades.2 This was a notable difference from standard Soviet AKs, where grenade launching often required separate attachments.

- Distinct Furniture: The M64 sported longer wooden handguards compared to the Soviet AK, giving it a different profile. These handguards were not interchangeable with standard AK parts.1 The M64B underfolding stock was borrowed directly from the existing Yugoslav M56 submachine gun, showcasing resourcefulness in utilizing existing production lines.2

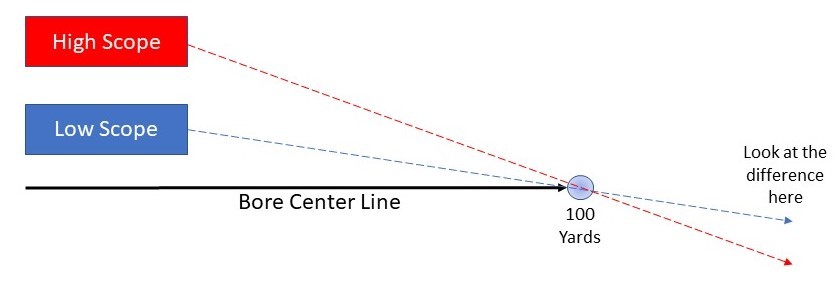

- Modified Sights and Charging Handle: The rear sight was positioned further back on the receiver compared to the standard AK placement on the rear sight block (though some very early prototypes experimented with receiver cover mounting), providing a longer sight radius for potentially improved aiming accuracy.1 Additionally, engineers pragmatically adopted the hollow cylindrical charging handle design from the domestically produced M59 rifle (Yugoslavia’s licensed SKS variant, known colloquially as the Papovka), again leveraging existing manufacturing capabilities.2

These modifications highlight a design philosophy that blended adaptation to specific military needs (grenade launching), innovation (BHO), and practical resource management (reusing existing parts). The M64 was clearly shaping up to be more than just a copy; it was becoming a uniquely Yugoslavian interpretation of the Kalashnikov system.

Feature Comparison: Soviet AK-47 Type 3 vs. Zastava M64 Prototype

| Feature | Soviet AK-47 (Type 3) | Zastava M64A/B Prototype | Snippet Reference(s) |

| Receiver Type | Milled | Milled (Yugoslav pattern) | 6 |

| Bolt Hold-Open | No | Yes (requires modified magazine) | 1 |

| Grenade Sight/Gas Cut-off | No (added later/separate) | Yes (integrated) | 2 |

| Handguards | Standard length | Longer, unique design | 1 |

| Rear Sight Location | Standard (rear sight block) | Further rearward on receiver | 1 |

| Charging Handle | Standard AK | Hollow cylindrical (from M59 SKS) | 2 |

| Folding Stock (M64B) | N/A (AKS was different) | Underfolder (from M56 SMG) | 2 |

Towards a Standard: Trials, Tribulations, and Transition

Despite the successful development of the M64 prototypes and reportedly satisfactory performance during initial field trials 1, the path to mass adoption by the JNA was not immediate. A degree of conservatism existed within the military leadership; some senior officers remained skeptical about the utility and cost-effectiveness of equipping every infantry soldier with a fully automatic rifle, fearing it would lead to excessive ammunition expenditure.2 Yugoslavia had, after all, only recently standardized its licensed version of the semi-automatic SKS, the Zastava M59.8

This institutional hesitation was significantly challenged by external events. The Warsaw Pact invasion of Czechoslovakia in August 1968 served as a stark demonstration of modern Soviet military doctrine, where entire infantry units were equipped with Kalashnikov assault rifles. Witnessing the effectiveness of massed automatic fire likely swayed opinions within the JNA command structure, highlighting the urgent need for a comparable domestic capability.2 The geopolitical situation acted as a catalyst, pushing the JNA to overcome its previous reservations and accelerate the process of adopting a modern assault rifle. Interestingly, around this period, warming relations with Moscow led Yugoslavia to briefly enter negotiations to purchase Soviet AKs directly, primarily for special forces units.2 This development undoubtedly put pressure on Zastava and proponents of the domestic FAZ program to prove their rifle was ready.2

However, the M64 faced a critical technical hurdle on the path to standardization: its innovative bolt hold-open mechanism. While potentially useful, the BHO necessitated the use of proprietary magazines, incompatible with the standard AK magazines that were becoming increasingly common worldwide.6 From a logistical perspective, introducing a non-standard magazine for the army’s main service rifle presented significant challenges. The JNA leadership ultimately prioritized interoperability and logistical simplicity, deciding that the new standard rifle must be compatible with commonly available AK-pattern magazines.6 This pragmatic decision, favoring ease of supply and potential use of captured magazines over a unique but non-standard feature, sealed the fate of the M64’s BHO system.

As the design moved towards finalization for mass production, the Vojnotehnički institut Beograd (Military Technical Institute Belgrade – VTI) likely played an increasingly important role.10 While Zastava engineers had driven the initial design and prototyping of the M64 2, the VTI, as the JNA’s central research and development body, would have been involved in refining the technical requirements based on trial results, overseeing final testing protocols, and preparing the definitive technical documentation for the production rifle.2 This included incorporating the mandated changes, most notably the removal of the bolt hold-open feature, paving the way for the weapon that would become Yugoslavia’s standard assault rifle.

Conclusion: On the Brink of the M70

The journey from Yugoslavia’s post-war isolation to the verge of mass-producing its own Kalashnikov variant was a testament to national determination, engineering skill, and political will. Blocked from acquiring licensed Soviet technology due to the Tito-Stalin split, Yugoslavia embarked on a challenging path of independent development.1 The opportunistic acquisition of initial AK-47 samples via Albanian defectors in 1959 provided the crucial spark.1 Overcoming the limitations of these few examples required high-level political intervention to secure a larger batch of rifles through clandestine channels, enabling Zastava engineers to undertake a comprehensive, unlicensed reverse-engineering effort under the ambitious FAZ program.1

The resulting M64 prototypes were far more than simple copies. They represented an innovative adaptation of the Kalashnikov design, incorporating features tailored to JNA doctrine, such as integrated grenade-launching capabilities, alongside novel additions like the bolt hold-open mechanism and resourceful use of existing domestic components.1 However, trials, evolving military thought spurred by events like the 1968 Czechoslovakia invasion, and pragmatic logistical considerations—specifically the need for standard magazine compatibility—led to crucial design revisions.2

By 1970, the culmination of over a decade of effort was at hand. The lessons learned from the M64 program, the strategic decisions made by the JNA leadership, and the collaborative work between Zastava and the VTI had refined the design into a production-ready rifle. In that year, the Yugoslav government formally approved this modified design for serial production, designating it the Automatska Puška Model 1970 (Automatic Rifle Model 1970), or AP M70.1 The stage was set for the introduction of Yugoslavia’s first mass-produced Kalashnikov, a rifle born from political necessity and forged through ingenuity and perseverance. The detailed story of the M70 itself would be a new chapter, but its foundations were now firmly laid in the experiences chronicled here.

Image Source

The rifles were uploaded to Wikimedia by TheLokov. And the Yugoslavian map is also from Wikimedia and was shared by the UN. The author created the combined image.

https://commons.wikimedia.org/wiki/File:Zastava_M-64_prototypes.png

https://commons.wikimedia.org/wiki/File:Former_Yugoslavia_Map.png

The M64B image is from Wikimedia also and was shared by AZ2001.

https://commons.wikimedia.org/wiki/File:ZastavaM64B.jpg

Works cited

- Zastava M70 assault rifle – Wikipedia, accessed May 12, 2025, https://en.wikipedia.org/wiki/Zastava_M70_assault_rifle

- Zastava M64. Part 1. The Unusual History of Yugoslavian AKs …, accessed May 12, 2025, https://www.thefirearmblog.com/blog/2024/05/07/zastava-m64-part-1-unusual-history-yugoslavian-aks/

- Zastava M70 (автомат) — Википедия, accessed May 12, 2025, https://ru.wikipedia.org/wiki/Zastava_M70_(%D0%B0%D0%B2%D1%82%D0%BE%D0%BC%D0%B0%D1%82)

- Is the Yugoslav, Zastava M-70, the best licensed built Ak-47 and maybe the best Ak-47 variant to this day? : r/ak47 – Reddit, accessed May 12, 2025, https://www.reddit.com/r/ak47/comments/10r4iq9/is_the_yugoslav_zastava_m70_the_best_licensed/

- Guns in Movies, TV and Video Games – Zastava M70 – Internet Movie Firearms Database, accessed May 12, 2025, https://www.imfdb.org/wiki/Zastava_M70

- Zastava AKs, Part 2. M70 – The First Mass-Produced Yugoslavian …, accessed May 12, 2025, https://www.thefirearmblog.com/blog/2024/05/14/zastava-aks-part-2-m70-first-mass-produced-yugoslavian-kalashnikov/

- How Does The Yugoslavian Zastava M70 Compare To Other Ak-47 Variants? – GunCreed, accessed May 12, 2025, https://guncreed.com/2024/08/17/how-does-the-yugoslavian-zastava-m70-compare-to-other-ak47-variants/

- My Complete Yugoslavian Smallarms Collection History (Zastava Trek VIII: Communist First Contact) – YouTube, accessed May 12, 2025, https://www.youtube.com/watch?v=kzJ5v_HREt0

- A country’s weapons can be a good indication of whether they wanted to be a Soviet puppet state : r/NonCredibleDefense – Reddit, accessed May 12, 2025, https://www.reddit.com/r/NonCredibleDefense/comments/17jukc7/a_countrys_weapons_can_be_a_good_indication_of/

- PROCEEDINGS, accessed May 12, 2025, https://scindeks-clanci.ceon.rs/data/pdf/proc-0018/OTEH_2024.pdf

- Војнотехнички институт — Википедија, accessed May 12, 2025, https://sr.wikipedia.org/wiki/%D0%92%D0%BE%D1%98%D0%BD%D0%BE%D1%82%D0%B5%D1%85%D0%BD%D0%B8%D1%87%D0%BA%D0%B8_%D0%B8%D0%BD%D1%81%D1%82%D0%B8%D1%82%D1%83%D1%82

- ПОЛИТИКА ОДБРАНЕ ЈУГОСЛАВИЈЕ (1945–1958): ИДЕЈЕ И ПРАКСА, accessed May 12, 2025, https://nardus.mpn.gov.rs/bitstream/id/143356/Disertacija_12293.pdf

- Zakon o Opasnim Materijama | PDF – Scribd, accessed May 12, 2025, https://www.scribd.com/document/395551284/Zakon-o-Opasnim-Materijama

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, we are only paid if there is an affiliate program such as Avantlink, Impact, Amazon and eBay and only if you purchase something. If you’d like to directly contribute towards our continued reporting, please visit our funding page.