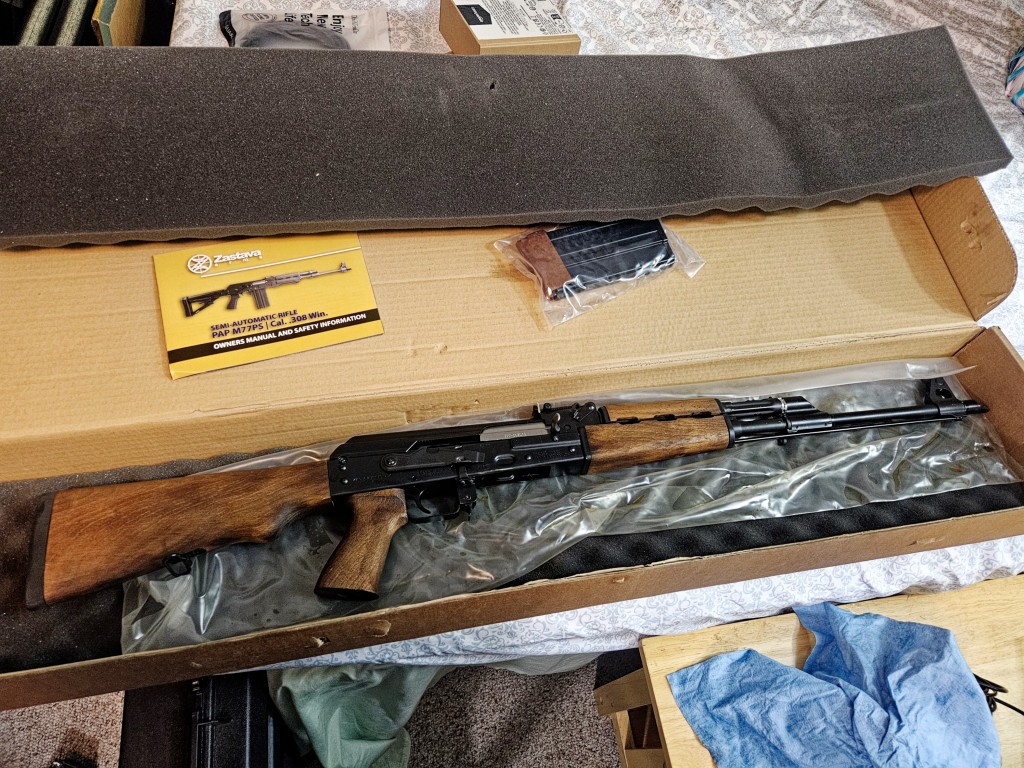

Ok, so I planned to completely redo the M77 and keep the Battleworn wood for the future just in case. The first step was to swap out the wood handguards for a RS Regulate GKR-9DY. It’s a 9″ MLOK rail for Zastava AK-type rifles – this matters because a Zastava handguard is longer and a different shape than an AKM handguard.

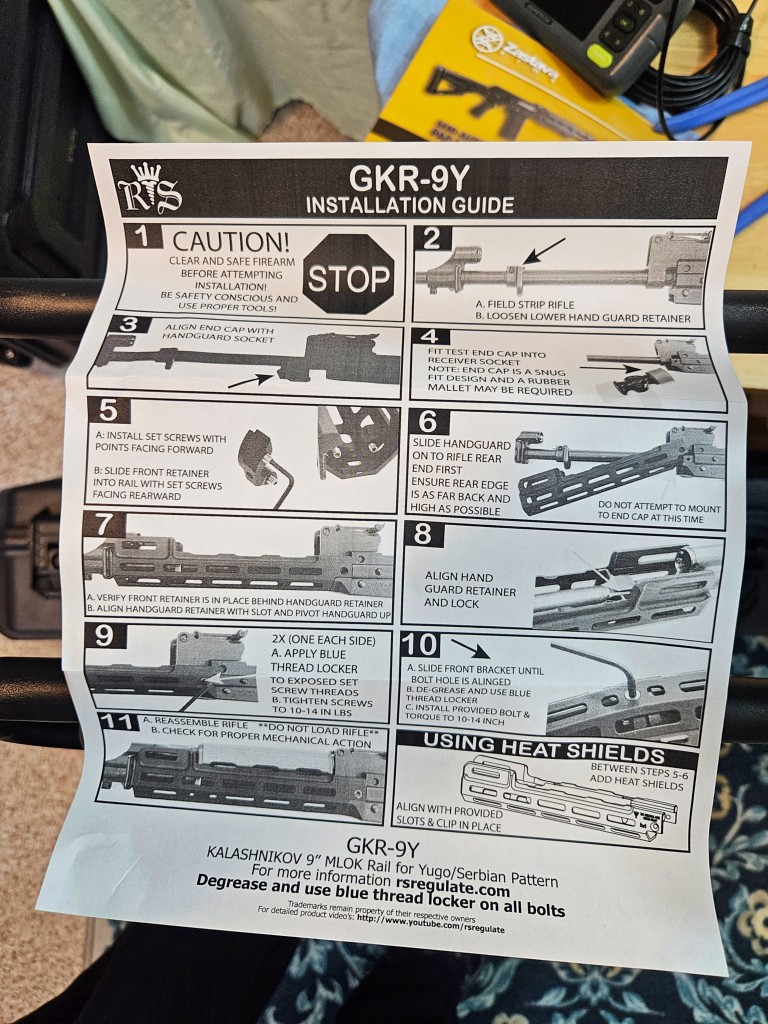

Scot Hoskinson owns RS Regulate and is a meticulous engineer. His products are top notch and one thing I would tell you is to always read the instructions. He puts a lot of effort into documenting what you need to do so find the instructions and follow them.

I don’t have photos of every step Scot lists, but I do want to mention step 5 – the front retainer set screws are backed out towards the receiver with the allen heads facing the rear. Once you have the front retainer in place and screwed to the handguard in step 10, you then tighten down the set screws to make everything nice and tight.

| In all of his steps, be sure to follow the torque specifications and use blue loc-tite or your favorite medium strength thread locker. If you don’t, then the screws will risk coming loose and potentially falling out. |

The Gas Tube Cover

The RS Regulate handguards are the lower-half only. It’s up to you to decide if you want to run the wood or just what. In my case, I am using one of our Yugo/Zastava gas tube covers that is made from glass-fiber reinforced high-temp urethane. A Yugo gas tube cover is significantly longer than that of an AKM and are not interchangeable.

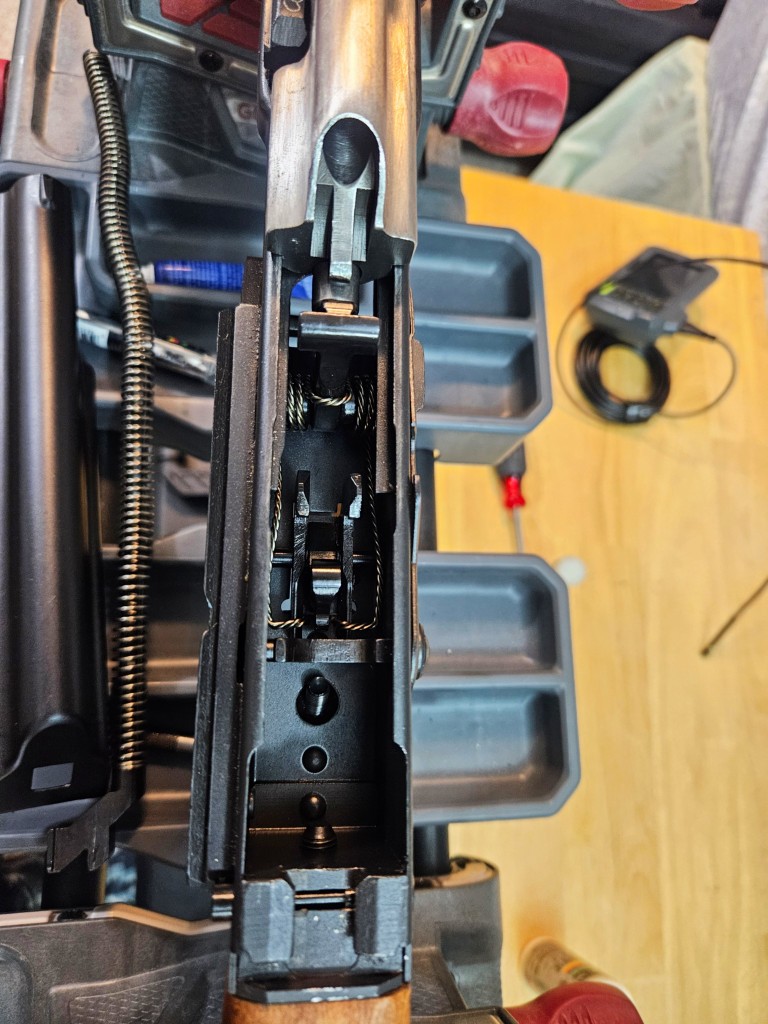

To remove it, rotate the locking lever on the rear sight base. Zastava is one of the makers that make that lever really tight. I use a large adjustable wrench’s jaws to hold the lever while I rotate it up. You can also use a hammer with plastic heads to tap the lever up. Once it is rotated, the rear of the tube closer to the receiver can be lifted up and the unit brought back just a tad to clear the front gas block. By the way, the bolt carrier must be removed or the long gas piston will be in the tube and block removal.

Years ago, I did do a blog post with more instructions and links to videos. Please click here if you want to read it.

End Result

Summary

RS Regulate makes some great lower handguards for a variety of AKs including for the Yugo/Zastava M70 and M77s. It takes a little bit of effort to install and is very much worth it. You can optionally use your wood gas tube cover or buy one of our polymer units.

Note, I have to buy all of my parts – nothing here was paid for by sponsors, etc. I do make a small amount if you click on an ad and buy something but that is it. You’re getting my real opinion on stuff.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, we are only paid if there is an affiliate program such as Avantlink, Impact, Amazon and eBay and only if you purchase something. If you’d like to directly contribute towards our continued reporting, please visit our funding page.