It’s interesting that we hold the AK-47 in near mythic regard when it comes to reliability. It took almost 12 years from 1947 to the release of the AKM (Avtomát Kaláshnikova modernizírovanny or “Modernized Kalashnikov Automatic Rifle”) in 1959. The journey the design team made over the years is quite interesting.

I did a post on the Type 1 previously (click here to open it) and that first iteration had problems with the stamped sheet metal receiver that affected reliability. In response, Valeriy Kharkov lead a design team who created a milled receiver from a forging to address the reliability problems and it was ready by 1949.

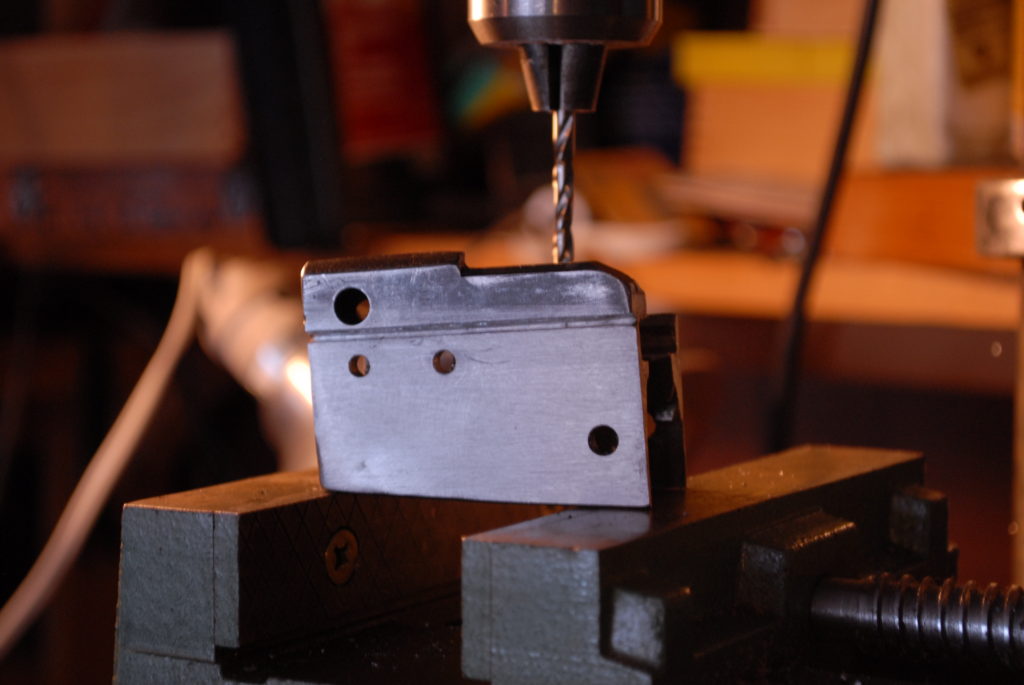

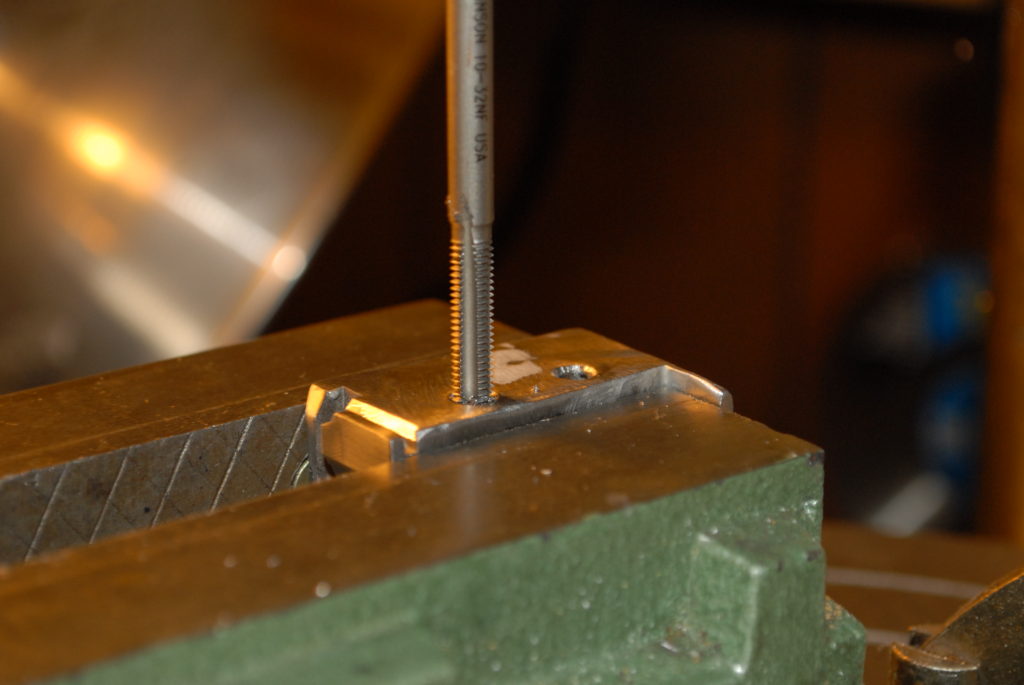

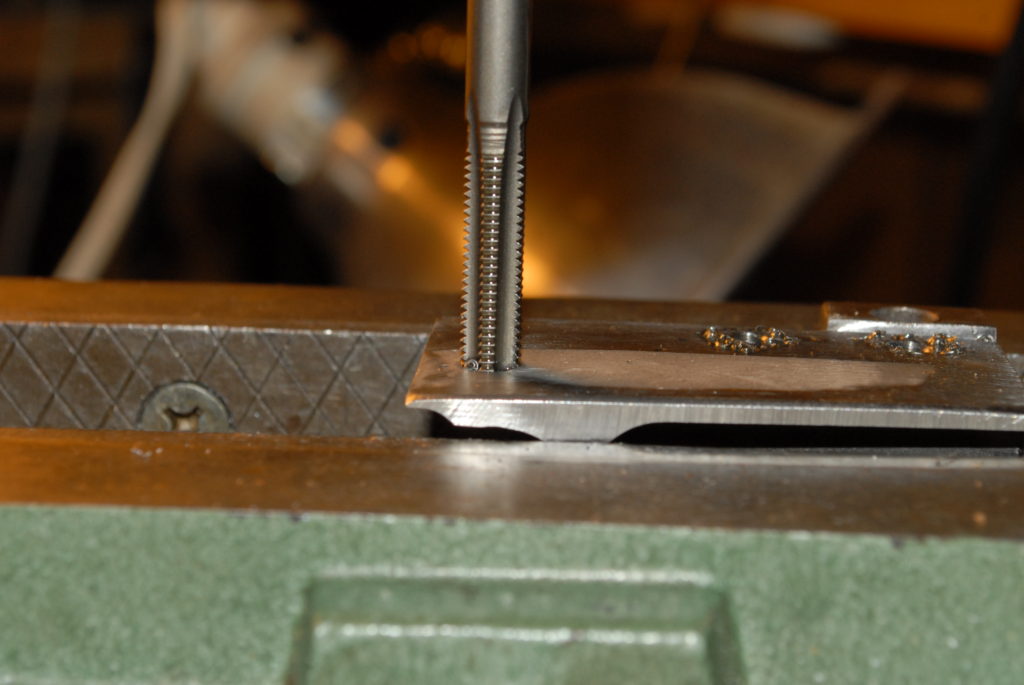

The Soviets had plenty of labor, that wasn’t a problem so in a manually intensive manner, they machined a six pound block of steel that required 120 steps into a finished 1.4 pound receiver. That means they wasted almost 3.6 pounds of quality steel and used a ton of consumables and machine time. To be honest, it boggles my mind but they accomplished their mission – the QC problems with the receiver were addressed.

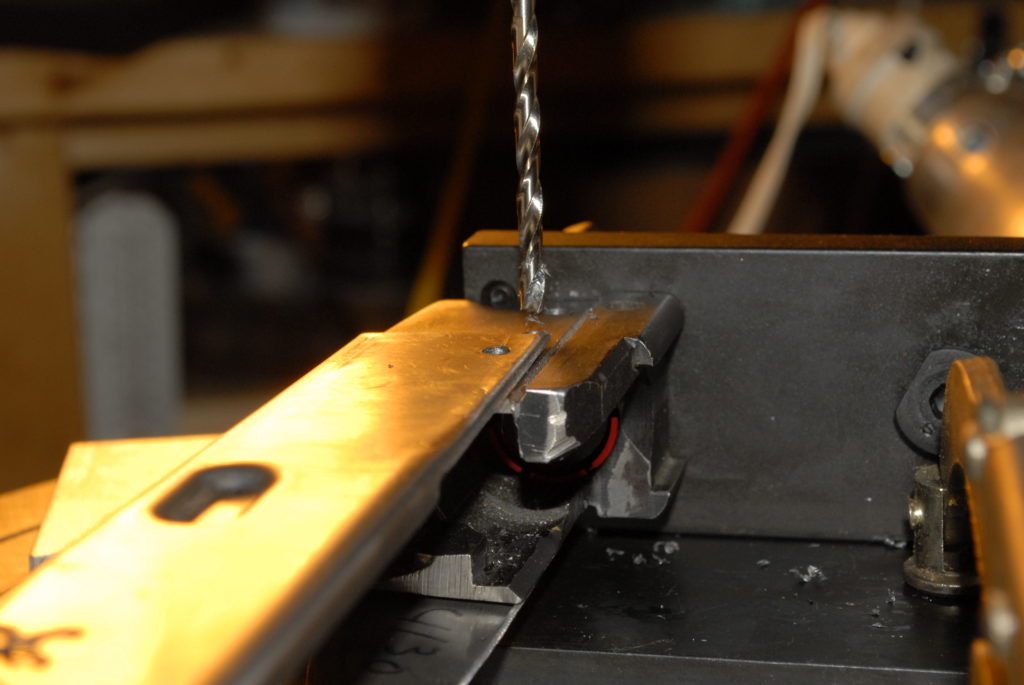

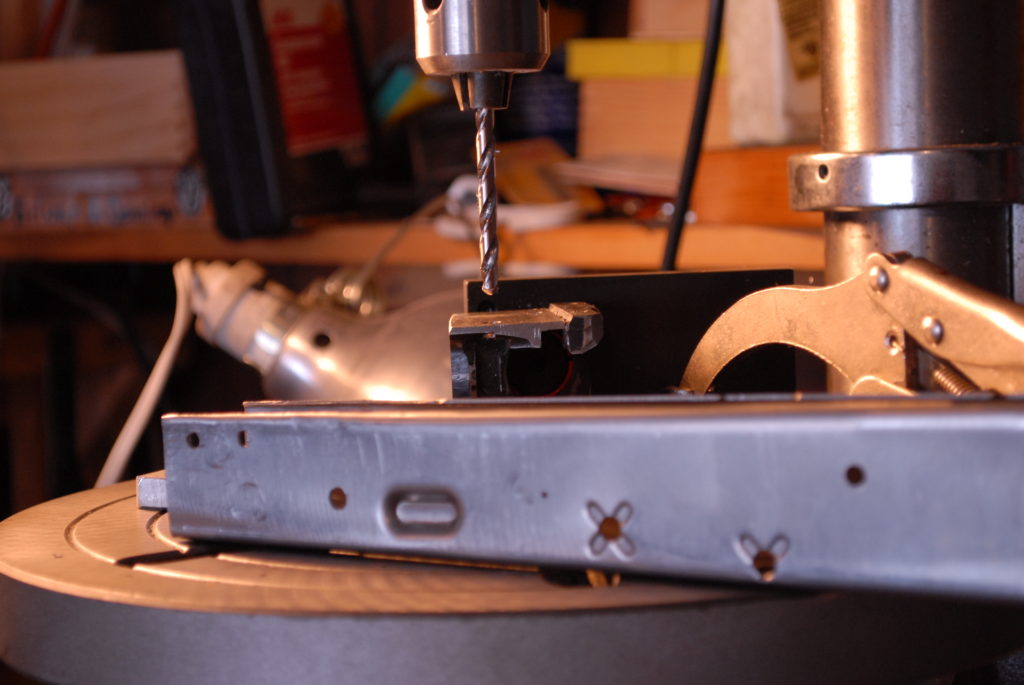

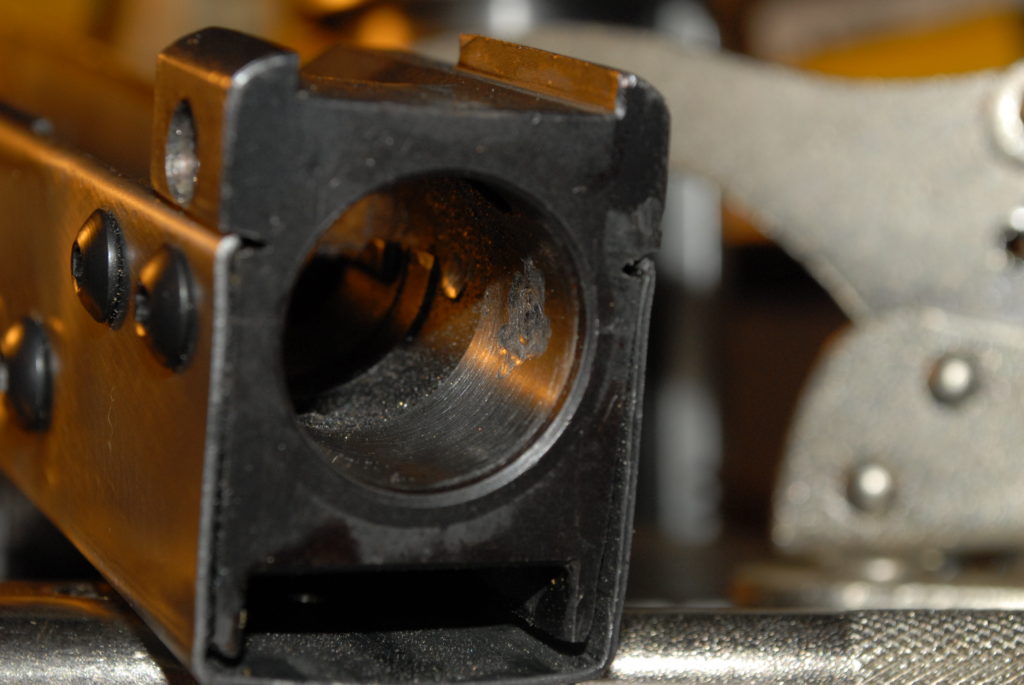

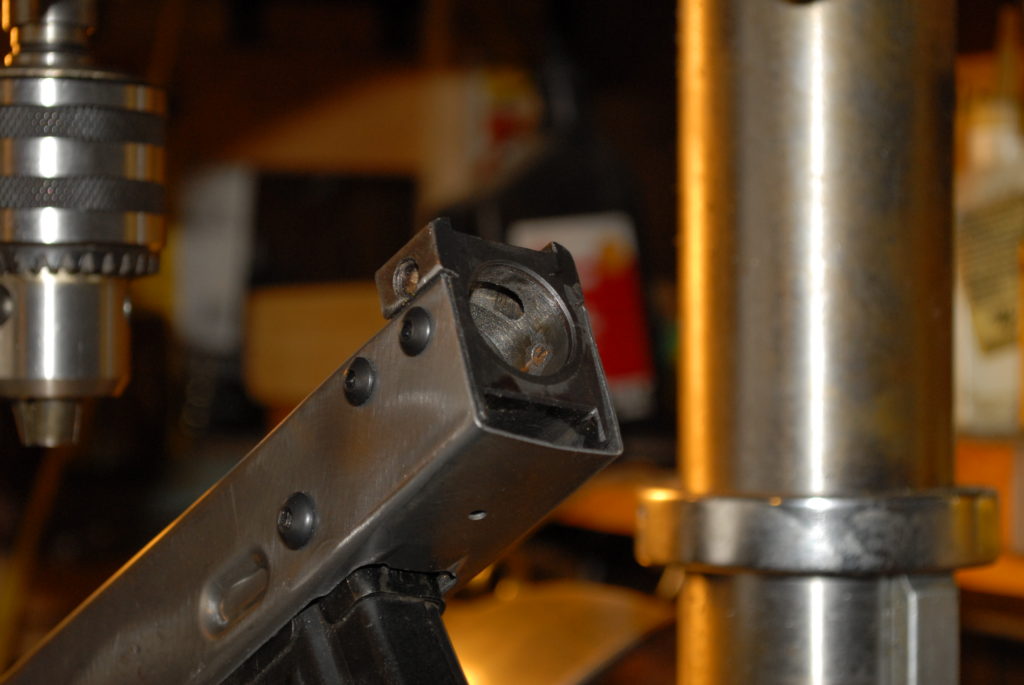

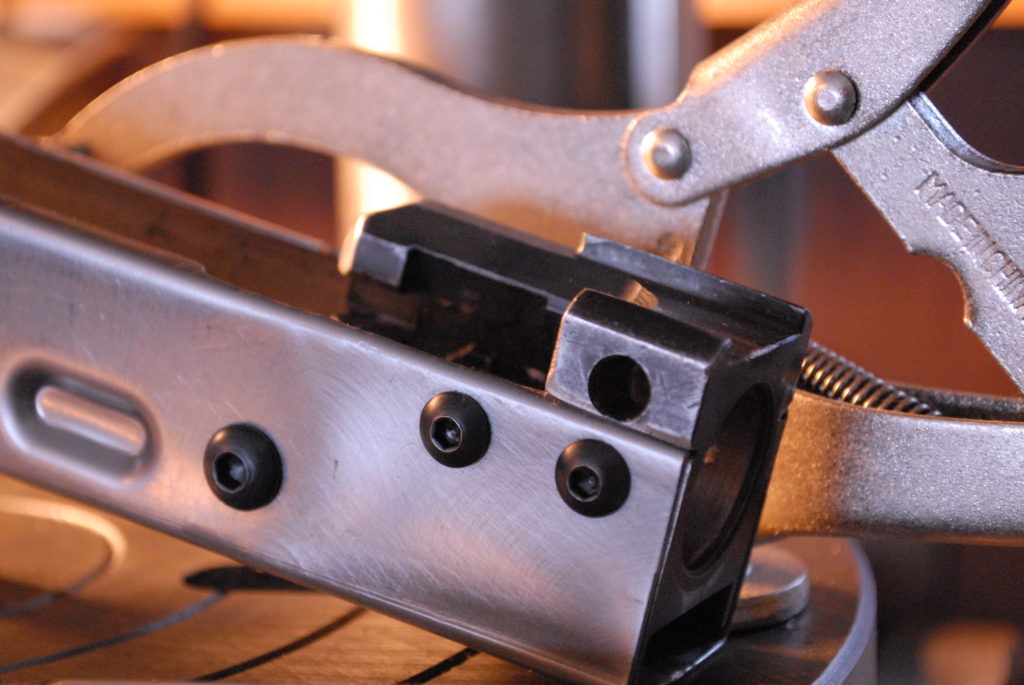

In the following video, Ian McCollum does a great job showing a type 2 and describing the differences between it, the type 1 and the following type 3. For example, he points out the rear receiver extension that is made from sheet metal that is an instant identifier of a Type 2 fixed stock rifle (sometimes referred to as the “2A”). Note, they made the type 2 with an underfolder stock also (the “2B”).

Another tell is that the lightening cuts are parallel to the top of the receiver in the type 2 and in the type 3 they are parallel to the bottom.

There are quite a few other changes such as the grip now being a single piece, the selector lever having an additional clearance added above the pins, gas vent holes moved to 10 and 2 o-clock and more.

By the way, one thing Ian does is refer to it as the AK-49 and I have never read anything that supports that nomenclature. If you Google AK-49, nothing turns up. I would recommend you refer to it as an AK-47 Type 2. Other than that, I think it is a great video and you can actually see the many details as Ian points them out:

If you want to read a book that does a great job detailing the Type 2 and its history, I would recommend The Grim Reaper by Frank Iannamico. Poyer’s book has details but not as much history.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, we are only paid if there is an affiliate program such as Avantlink, Impact, Amazon and eBay and only if you purchase something. If you’d like to directly contribute towards our continued reporting, please visit our funding page.