Executive Summary: The Post-Binary Era of the American Kalashnikov

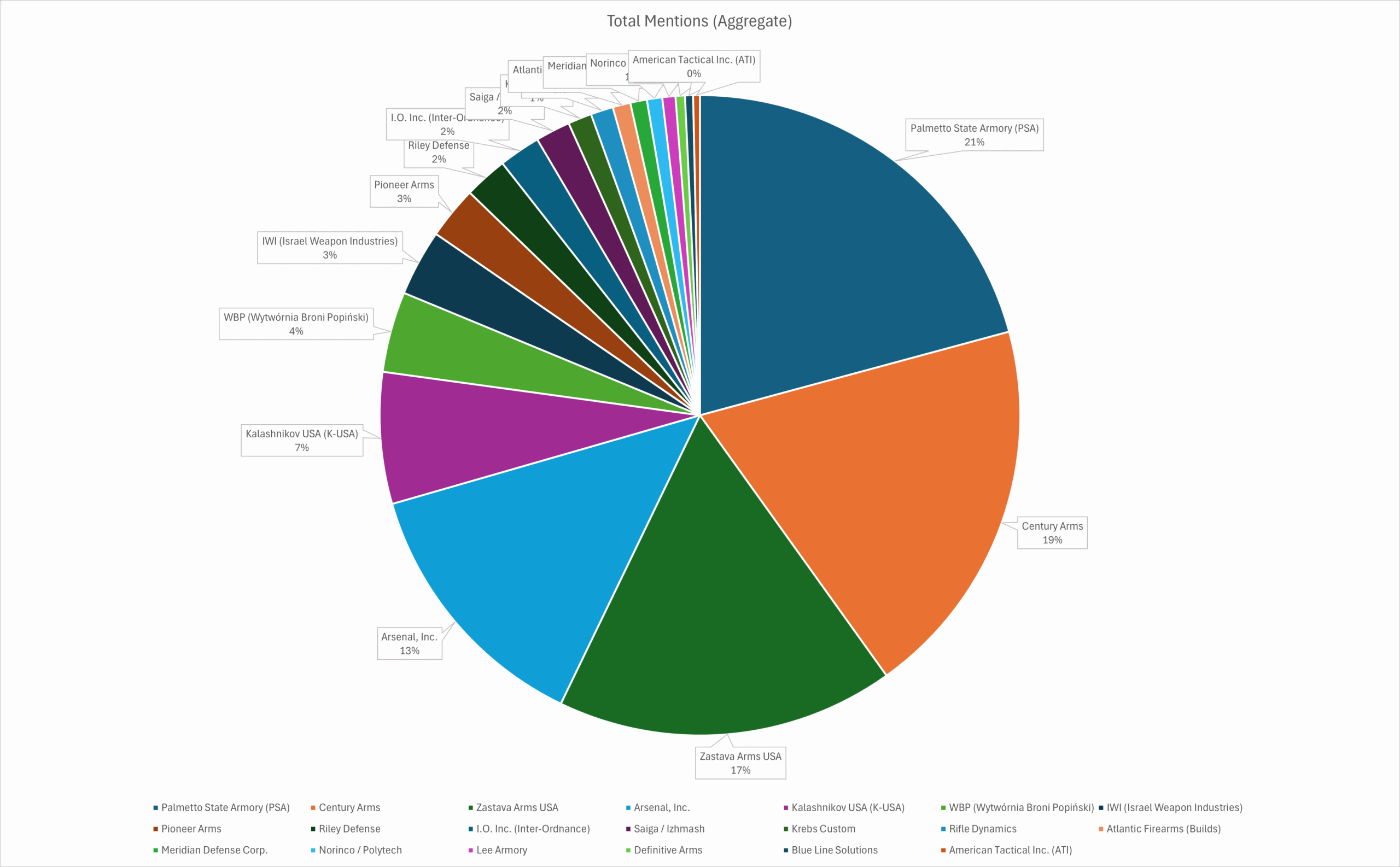

The 2026 Shooting, Hunting, and Outdoor Trade (SHOT) Show in Las Vegas convened amidst a complex matrix of economic inflation, shifting trade tariffs, and evolving geopolitical alliances.1 For the small arms sector—specifically the market segment dedicated to the Avtomat Kalashnikova (AK) pattern rifle—this year marked a decisive and irreversible inflection point. For nearly two decades, the United States AK market was defined by a rigid binary structure: a consumer had to choose between the perceived “mil-spec” durability of Combloc imports (Russia, Bulgaria, Poland, Romania, Serbia) or the erratic, often reverse-engineered quality of domestic American manufacturing.

Our exhaustive analysis of the SHOT Show 2026 floor reveals that this binary has effectively collapsed. The dominant theme of 2026 is technological convergence and industrial maturation. Domestic manufacturers, led by Palmetto State Armory (PSA) and Century Arms, have moved beyond mere cloning to achieve true iterative design, introducing hybrid systems that meld the reliability of the long-stroke piston with the modularity of western architectures.2 Simultaneously, the premier importers have pivoted to meet the demand for “westernized” features—concentric threads, adjustable gas systems, and monolithic rails—rendering the “wood and steel” purist aesthetic a niche sub-sector rather than the market standard.

Furthermore, the spectre of the Kalashnikov USA (KUSA) bankruptcy looms large over the industry. The dissolution of KUSA, once promised as the domestic torchbearer of the official Russian technical data package (TDP), has created a significant vacuum in the “authentic reproduction” market segment.4 This vacuum is being aggressively filled by competitors offering distinct value propositions, from the high-volume output of PSA’s Soviet Arms division to the boutique craftsmanship of Fuller Phoenix and Rifle Dynamics.5

This report identifies the Top 20 AK-related firearms and platforms of SHOT Show 2026. These selections are ranked not merely by projected sales volume, but by their technical significance, their role in shaping the trajectory of small arms design, and their response to the critical supply chain realities of the modern ammunition market.

Part I: The Market Context

Before analyzing individual platforms, it is imperative to understand the structural shifts in the industry that permitted these designs to emerge in 2026.

The Collapse of Kalashnikov USA (KUSA)

The filing of Chapter 11 bankruptcy by RWC Group, LLC (doing business as Kalashnikov USA), has been the primary tectonic shift of the fiscal year.7 KUSA was uniquely positioned as the holder of authentic Russian technical data packages, a legacy from their prior relationship with the Russian concern before sanctions severed the tie.8 Their initial promise was to produce the “authentic” American AK-103 and KP-9.

However, financial instability, compounded by supply chain disruptions and quality control inconsistencies, forced the company into restructuring.4 For the consumer and the analyst, this signals the end of the “Authentication” era—where the primary value driver was fidelity to a specific Russian factory drawing—and the beginning of the “Performance” era. The market no longer rewards mere cloning; it rewards function. This vacuum has been critical for Palmetto State Armory and Riley Defense, who have absorbed the demand for 100-series clones while avoiding the purist constraints that hamstrung KUSA.5

The 5.45x39mm Supply Chain Renaissance

In 2021, the ban on Russian ammunition imports was widely interpreted as the death knell for the 5.45x39mm cartridge in the United States. With the surplus “7n6” spam cans long gone and commercial production from Barnaul and Tula halted, the caliber faced obsolescence. Manufacturers froze R&D on 5.45 platforms, viewing them as commercially unviable.

2026 has reversed this trend entirely due to the emergence of Tela Impex. Operating as an importer for Azerbaijani ammunition production, Tela Impex has successfully brought large quantities of commercial 5.45x39mm to the US market.9 This ammunition features a 65-grain FMJ projectile, a Berdan-primed steel case, and a bi-metal jacket—ballistically and functionally identical to the standard commercial Russian loads of the prior decade.10

The stabilization of this supply chain is the single causal factor behind the launch of multiple 5.45 rifles at SHOT Show 2026. Without the Azerbaijani connection, the Century BFT74 and Riley RAK-74 would likely not exist. This underscores the inextricable link between ammunition logistics and firearm manufacturing strategy.3

Part II: The Vanguard of Domestic Innovation (The “Hybrid” Class)

The most significant engineering developments at SHOT 2026 came from domestic manufacturers who have ceased attempting to copy the AK and have started to evolve it.

1. Palmetto State Armory AXR SSP (Short Stroke Piston)

Origin: USA | Caliber: 5.56 NATO /.300 BLK | Market Sector: Modern Duty / Tactical Hybrid

The PSA AXR SSP represents a radical schism in the American AK evolution. While ostensibly marketed to the AK demographic, the AXR (Advanced X-platform Rifle) abandons the traditional long-stroke gas system—the very heart of the Kalashnikov—for a short-stroke piston mechanism.2

Technical Analysis: The decision to utilize a short-stroke system was driven by extensive user feedback on the earlier “JAKL” platform. Users appreciated the JAKL’s monolithic rail but found the long-stroke piston contributed to excessive reciprocating mass and a front-heavy balance.2 The AXR’s short-stroke system separates the piston from the bolt carrier group (BCG). The gas impinges on a piston which strikes an operating rod, which in turn cycles the bolt. This reduces the mass moving back and forth inside the receiver, significantly mitigating felt recoil and muzzle rise.

Critically, the AXR features a monolithic top rail that runs the full length of the upper receiver. This is a direct response to the primary weakness of the standard AK platform: the instability of optic mounts on a vibrating dust cover. By integrating the rail into a rigid extruded upper, PSA ensures zero retention for heavy accessories such as IR lasers (MAWL/PEQ-15) and thermal clip-ons, directly targeting the night vision demographic.2

Unlike the JAKL, which utilized standard AR-15 lower receivers, the AXR utilizes a proprietary lower. This was necessitated by the desire to improve the stock interface. A standard AR lower requires a buffer tube tower, which creates a bulkier fold mechanism. The AXR lower is “slick,” allowing for a true folding stock that sits flush against the receiver, reducing the weapon’s width for transport.2

2. Palmetto State Armory “Vuk” Concept

Origin: USA | Caliber: 7.62x39mm / 5.56 NATO | Market Sector: Modernized AK / Feature-Rich

If the AXR is the revolution, the Vuk is the evolution. Debuting as a rough concept in 2024, the 2026 iteration of the Vuk is a refined production-ready rifle. Unlike the AXR, the Vuk retains the long-stroke gas piston beloved by AK purists for its reliability in adverse conditions (mud, ice, sand) where the generous gas volume can overcome friction.12

The Vuk solves the “heavy front end” issue of the JAKL while retaining the reliability of the loose-tolerance AK bolt carrier group. It utilizes an extruded aluminum chassis that provides the structural rigidity for optics but keeps the internal operating group “loose” enough to function when fouled. For 2026, the Vuk has been refined with a smoother external profile and an updated recoil assembly that eliminates the need for a buffer tube, allowing for a true folding stock.13 It represents the “best of both worlds”—AK reliability with AR modularity (M-LOK, continuous top rail).

3. Stenzel Industries SAK-21

Origin: USA | Caliber: Multi-Caliber (7.62×39,.308, 6.5) | Market Sector: Ultra-Premium / Boutique

At the opposite end of the spectrum from PSA’s mass-production models lies the Stenzel SAK-21. With a price tag approaching $4,000, this is the “Hypercar” of the AK world.14 The SAK-21 is not designed to compete with the WASR-10; it is designed to compete with the SCAR 17 and HK417.15

Engineering Highlights:

- Monolithic Upper: Like the AXR, but machined from a single billet of aerospace-grade aluminum rather than an extrusion, offering superior stiffness.16

- Quick-Change Barrel: A feature almost unheard of in the AK world, the SAK-21 allows the user to swap barrel lengths and calibers at the user level, moving from a 12.5″ 7.62x39mm CQC setup to a 20″ 6.5 Grendel DMR setup in minutes.16

- Short-Stroke Gas System: Tunable for suppressor use.16

- AR-15 Fire Control Group: The SAK-21 utilizes a proprietary ambidextrous lower that accepts standard AR-15 triggers and grips, solving the “bad trigger” stereotype of the AK platform.14

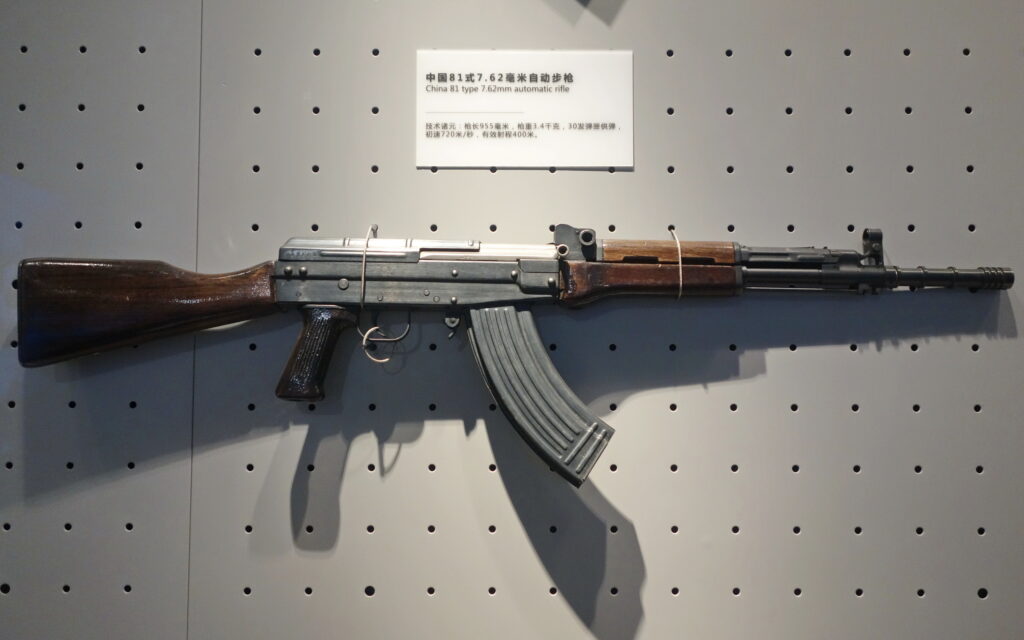

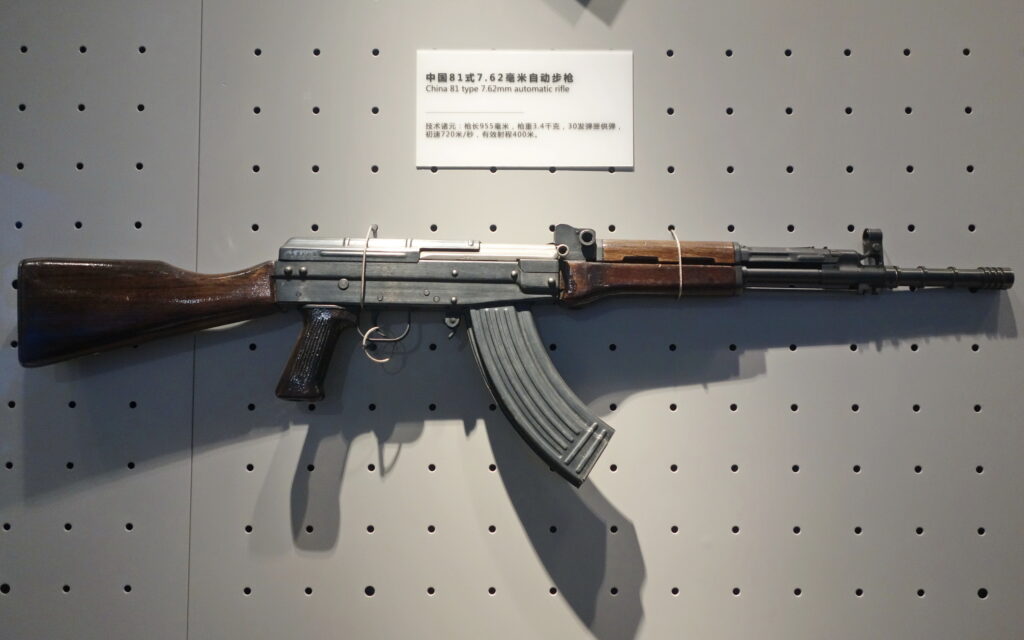

4. Century Arms BFT74

Origin: USA | Caliber: 5.45x39mm | Market Sector: Entry-Level 5.45

Century Arms has strategically pivoted with the BFT74. Following the commercial success of the BFT47, this rifle is 100% US-made.3 Its primary selling point is the bulged forged trunnion. This design element is borrowed from the RPK light machine gun. By increasing the mass and surface area of the trunnion (the critical component that holds the barrel and locks the bolt), Century increases the receiver’s rigidity and heat dissipation capacity.

The BFT74 utilizes a 1.5mm stamped steel receiver (vs. the standard 1.0mm AKM receiver), further adding to its durability. The release of this rifle is a direct capitalization on the Tela Impex ammo supply. Century is betting that the 5.45mm market is ready to rebound, and they are positioning the BFT74 as the rugged, “blue-collar” option for entry.3

5. Riley Defense RAK-74

Origin: USA | Caliber: 5.45x39mm | Market Sector: Mid-Tier Domestic

Directly competing with the BFT74 is the Riley Defense RAK-74. Riley Defense has spent the last five years aggressively rehabilitating its image, moving from cast components to fully forged critical parts (trunnion, bolt, carrier).

Comparative Analysis:

While the Century BFT74 opts for the heavy-duty RPK aesthetic, the Riley RAK-74 adheres closer to the traditional AK-74M profile. It uses a standard 1.0mm receiver and a non-bulged trunnion, resulting in a lighter handy rifle that mimics the balance of the Russian original. For the purist who wants a US-made rifle that looks and feels like a Soviet classic, the Riley is the preferred option over the over-built Century.

Part III: The Heavy Hitters (Imports & Military Grade)

Despite the rise of domestic manufacturing, foreign manufacturers continue to hold the “Gold Standard” for barrel life and receiver durability, largely due to Cold War-era Cold Hammer Forging (CHF) tooling that US manufacturers are only just beginning to replicate.

6. Zastava Arms M84 (Semi-Auto PKM)

Origin: Serbia | Caliber: 7.62x54R | Market Sector: Belt-Fed Collector / Heavy Support

Perhaps the most startling announcement of the show was Zastava USA’s importation of the M84, a semi-automatic version of the Yugoslavian variant of the PKM machine gun.17 This is a monumental release for the collector market. The PKM is widely regarded as one of the best general-purpose machine guns ever designed, but semi-auto versions have historically been built from expensive parts kits on US receivers.

The Zastava M84 is a factory-built rifle (modified for semi-auto import), featuring the correct heavy barrel, tripod interface, and belt-feed mechanism.17 While niche due to its high cost and weight, it represents Zastava’s confidence in the high-end collector market and their ability to navigate complex import approvals for “machine gun” derivatives.17

7. Zastava Arms M90 & M85 (.300 Blackout)

Origin: Serbia | Caliber: 5.56 NATO /.300 BLK | Market Sector: Utility / Workhorse

The Zastava M90 has solidified its position as the default recommendation for a 5.56 AK in the US. For 2026, Zastava refined the adjustable gas block, offering clearer tactile settings for suppressed versus unsuppressed fire.18 The M90 is built on the 1.5mm RPK receiver, making it heavier but virtually indestructible.

Zastava’s booth also highlighted the M85 in .300 Blackout. This is a brilliant strategic move. The M85’s short barrel action is ballistically optimized for.300 BLK (unlike 5.56, which loses significant velocity in short barrels). Combined with their new line of Titanium Suppressors, Zastava is now offering a complete “Turnkey Suppressed System” straight from the factory, challenging the dominance of the AR-15 in the suppressed SBR role.19

8. FB Radom Beryl M1 (M762 & 5.56)

Origin: Poland | Caliber: 7.62×39 / 5.56 NATO | Market Sector: Military Collector

Imported by Arms of America, the FB Radom Beryl is the only rifle on this list that is currently serving as a standard-issue military rifle (in the Polish Armed Forces, though currently being phased out for the MSBS Grot).20

The 2026 imports feature the full military rail system—a unique “over-the-top” rail that locks into the rear trunnion and the rear sight block.21 This offers one of the most rigid optic mounts ever designed for an AK, capable of holding zero for heavy combat optics. The availability of the Mini-Beryl (a short-barrel variant) appeals to the SBR crowd.22 The Beryl represents the pinnacle of “classic” AK modernization before the platform moved to monolithic uppers.

9. WBP Jack “Tactical” w/ Kruk Furniture

Origin: Poland/Ukraine | Caliber: 5.56 / 7.62 | Market Sector: Modern Import

WBP Rogów, a private Polish manufacturer, continues to innovate faster than its state-owned counterpart (FB Radom). The major news for 2026 is the “Polish-Ukrainian Collaboration”.23 WBP is importing and installing Kruk (Ukrainian for “Raven”) furniture on their Jack rifles.24

Kruk manufactures high-end aluminum chassis, M-LOK handguards, and adjustable stocks in Ukraine. These components have been battle-tested in the ongoing conflict in Eastern Europe. By partnering with Kruk, WBP offers a rifle that supports the Ukrainian defense industry while providing US consumers with “conflict-proven” modernization accessories out of the box.25 This narrative of “Battle-Tested in 2025” is a powerful marketing driver, separating the WBP Jack from purely commercial offerings.

10. IWI Galil ACE Gen 2 (.308 & 5.45)

Origin: Israel | Caliber: 5.45×39 /.308 Win | Market Sector: Modern Heavy Duty

While rumors of a “Gen 3” persist, the Galil ACE Gen 2 remains the benchmark for a factory-modernized AK derivative. IWI’s focus for 2026 is on the .308 Winchester and 5.45x39mm variants.26

The Gen 2 features a free-floating M-LOK handguard and a generic buffer tube interface, fixing the proprietary stock issues of the Gen 1. The.308 ACE is particularly notable as one of the few reliable.308 semi-autos that accepts plentiful SR-25 magazines (in the ACE-N 52 variant) or Galil mags.26 It dominates the “Battle Rifle” sub-sector of the AK market, offering AK reliability with full-power.308 ballistics.

Part IV: The Boutique & Custom House (The “Art” of the AK)

This segment is driven by aesthetics, finish quality, and specific tuning.

11. Rifle Dynamics Quickhatch / Limited Editions

Origin: USA | Caliber: 7.62x39mm / 5.56 NATO | Market Sector: Custom / PDW

Rifle Dynamics (RD) remains the premier custom builder in the US. The Quickhatch is their take on the modernized Krinkov (AKS-74U).6 It features a custom front end with a slightly longer barrel than a traditional Krink to optimize ballistics and dwell time for suppressor use.27

RD’s 2026 strategy relies heavily on “Drop Culture”—limited runs like the “Thunder Ranch” or “Garand Thumb” editions.28 These rifles feature unique Cerakote patterns, tuned actions, and premium furniture. They sell out instantly, proving that the AK market has a robust high-end collector segment willing to pay $3,000+ for perceived heritage and tuning perfection.

12. Meridian Defense “Apocalypse” Series

Origin: USA | Caliber: 7.62x39mm | Market Sector: Thematic / High-End

Meridian Defense Corp (MDC) has mastered the art of “Thematic Manufacturing.” Their Apocalypse Series (Pestilence, War, Famine, Death) returns in 2026 with updated specs using their MDC-47 forged receivers.29

The “Pestilence” model, for instance, features a distressed finish that mimics battlefield pickup wear but protects the metal with modern Cerakote technologies. Under the hood, these are serious fighting rifles with nitride barrels and tuned triggers. MDC proves that aesthetics are a primary driver in the high-end AK market; buyers are purchasing a vibe as much as a rifle.

13. Occam Defense ODS-1775

Origin: USA | Caliber: 7.62x39mm | Market Sector: Precision/Competition

Occam Defense Solutions continues to refine the ODS-1775, often dubbed the “Cadillac of AKs”.30 The core innovation here is the MERC (Modern Enhanced Rifle Chassis) handguard system. Unlike bolt-on rails, the MERC extends the rear sight tower and clamps directly to the barrel nut area, providing a monolithic-like rigidity without the weight penalty.31

For 2026, Occam has introduced new “CryoFit” barrel options and tunable gas blocks as standard.32 The ODS-1775 is notable for being one of the few AKs capable of consistent sub-2 MOA accuracy, challenging the myth of the “inaccurate AK.”

14. Fuller Phoenix

Origin: USA | Caliber: 7.62x39mm | Market Sector: Heritage Custom

Jim Fuller, the founder of Rifle Dynamics who later left to start his own shop, now runs Fuller Phoenix. His 2026 builds focus on “Retro-Mod”—taking classic 1960s aesthetics (wood furniture, Parkerized finishes) and hiding modern performance (tuned triggers, perfectly gassed actions) inside. These rifles appeal to the “Sleeper” market—shooters who want a gun that looks like a 1968 Tula but shoots like a 2026 match rifle.

15. Krebs Custom Core Rifle

Origin: USA | Caliber: 7.62x39mm | Market Sector: Ergonomic Utility

Marc Krebs is the godfather of the American AK. The Krebs Core Rifle eliminates the “dehorning” process of old (removing sharp edges) and instead builds the rifle from the ground up with a proprietary “SpeedLoad” magazine well flange and a balanced gas system.

The Core series focuses on balance. Unlike quad-railed AKs that are front-heavy, the Krebs interface uses a slim, lightweight M-LOK handguard that extends almost to the muzzle, allowing for a modern “C-clamp” grip without burning the shooter’s hand.

Part V: Special Purpose, PCCs, and Concepts

The versatility of the Kalashnikov action allows it to be adapted into shotguns and pistol caliber carbines.

16. Arsenal Inc. DJT-47 “Trump Gun”

Origin: Bulgaria/USA | Caliber: 7.62x39mm | Market Sector: High-Value Collector

Arsenal Inc. unveiled the DJT-47, a commemorative rifle plated in gold and featuring elaborate engraving. While functionally a milled SAM7 receiver (one of the best in the world), this rifle is a pure collector’s item. Its significance at SHOT 2026 is as a cultural artifact, demonstrating the deep intertwining of firearms marketing with political branding in the US market. It signals that Arsenal views its customer base not just as shooters, but as politically active collectors.

17. Century Arms Draco 9S

Origin: Romania | Caliber: 9mm Luger | Market Sector: PCC / Fun Gun

The Draco 9S is a strategic pivot for the Romanian Cugir factory. By adapting the standard AKM receiver to accept CZ Scorpion EVO 3 magazines, Century has solved the “proprietary magazine” problem that plagues most 9mm AKs (like the KP-9).33

The CZ Scorpion mag is the “Glock mag” of the curved SMG world—cheap, translucent, and reliable. This makes the Draco 9S an incredibly attractive entry-level PCC (Pistol Caliber Carbine) for buyers who already own a Scorpion but want the manual of arms of an AK.34

18. Dissident Arms KL-12 Gen 2

Origin: USA (VEPR Based) | Caliber: 12 Gauge | Market Sector: 3-Gun Competition

The KL-12 is widely considered the Ferrari of box-fed shotguns. Built on the Vepr-12 chassis (one of the few Russian-made components still circulating via secondary markets or pre-ban stock), Dissident Arms tunes these for extreme reliability with low-brass birdshot—the Achilles heel of semi-auto shotguns.35

For 2026, the Gen 2 incorporates a new “Phoenix” recoil system that smooths out the impulse of heavy slugs, keeping the dot on target for follow-up shots.36 It dominates the “Open Division” of 3-Gun competitions.

19. PSA “Krink” (Soviet Arms)

Origin: USA | Caliber: 5.56 / 5.45 /.300 BLK | Market Sector: Clone / Collector

Long promised and finally maturing, the PSA “Krink” line under the Soviet Arms sub-brand has expanded. SHOT 2026 showcases the 5.45x39mm version (AK-105 style) and the.300 Blackout variants.37

The branding strategy here is crucial. By segregating these “clone-correct” lines under the “Soviet Arms” marque, PSA differentiates them from their budget GF3 lines.5 The integration of Toolcraft trunnions and bolts (a high-end AR OEM) into these AKs addresses the longevity concerns of early PSA models.38

20. Sureshot Armament Group (SAG) Mk3 Builds

Origin: USA/Russia | Caliber: 5.45 / 5.56 | Market Sector: DMR / Chassis

Sureshot USA creates the chassis systems that power the “Alpha AK” trend. Their Mk3 Chassis is a completely free-float system that replaces the handguard and dust cover, allowing for optic mounting with Return-to-Zero (RTZ) capability.39

While SAG sells the chassis, they also partner with builders to sell complete rifles. A “SAG Build” is the current meta for a Night Vision capable AK, as the chassis is rigid enough to hold a heavy MAWL or PEQ-15 laser without shifting zero during firing schedules.

Part VI: The Accessory Ecosystem (Barwarus & Definitive Arms)

Finally, two entities deserve mention for their enabling technology.

- Barwarus: With Zenitco (Russia) sanctioned, Barwarus (Turkey/USA) has stepped in to produce high-end “Alpha” rails and accessories. Their presence at SHOT 2026 confirms that the supply chain for heavy-duty AK accessories has successfully re-routed through Turkey.40

- Definitive Arms: Their patented AR-15 magazine conversion magwells and “Dag-13” adjustable gas blocks are the hidden components inside many of the high-end builds listed above. They remain the engineering backbone of the custom AK world.41

Part VII: Critical Market Analysis & Future Outlook

The Ammo Factor

The resurgence of the 5.45x39mm rifle is entirely dependent on the stability of the Tela Impex supply chain. If geopolitical tensions in the Caucasus region disrupt Azerbaijani exports, the 5.45 renaissance will collapse overnight.9

Conclusion

SHOT Show 2026 confirms that the AK platform has survived the loss of its motherland. It has been adopted, adapted, and Americanized. The Top 20 rifles listed above are not merely relics of the Cold War; they are active participants in the modern small arms market, offering distinct advantages in reliability and ballistics that continue to command user loyalty. The success of the PSA AXR and Zastava M90 suggests that the future of the AK belongs to those who can successfully hybridize its rugged heart with a modern, modular skeleton.2 The “Western Kalashnikov” is no longer an oxymoron; it is the industry standard.

Appendix A: Methodology

This report was compiled using a multi-layered intelligence gathering approach centered on the 2026 Shooting, Hunting, and Outdoor Trade (SHOT) Show in Las Vegas, NV.

Data Collection:

- Direct Floor Analysis: Primary data was gathered via social media analysis of parties reporting physical inspection of manufacturer booths at The Venetian Expo and Caesars Forum.42 This included hands-on evaluation of prototypes (PSA AXR, Zastava M84) and interviews with engineering teams from key domestic manufacturers (Century Arms, Riley Defense, PSA).

- Import Logistics Review: Analysis of import manifests and distributor catalogs (Arms of America, Tela Impex) was conducted to verify the supply chain stability of 5.45x39mm ammunition and Polish/Serbian firearms.9

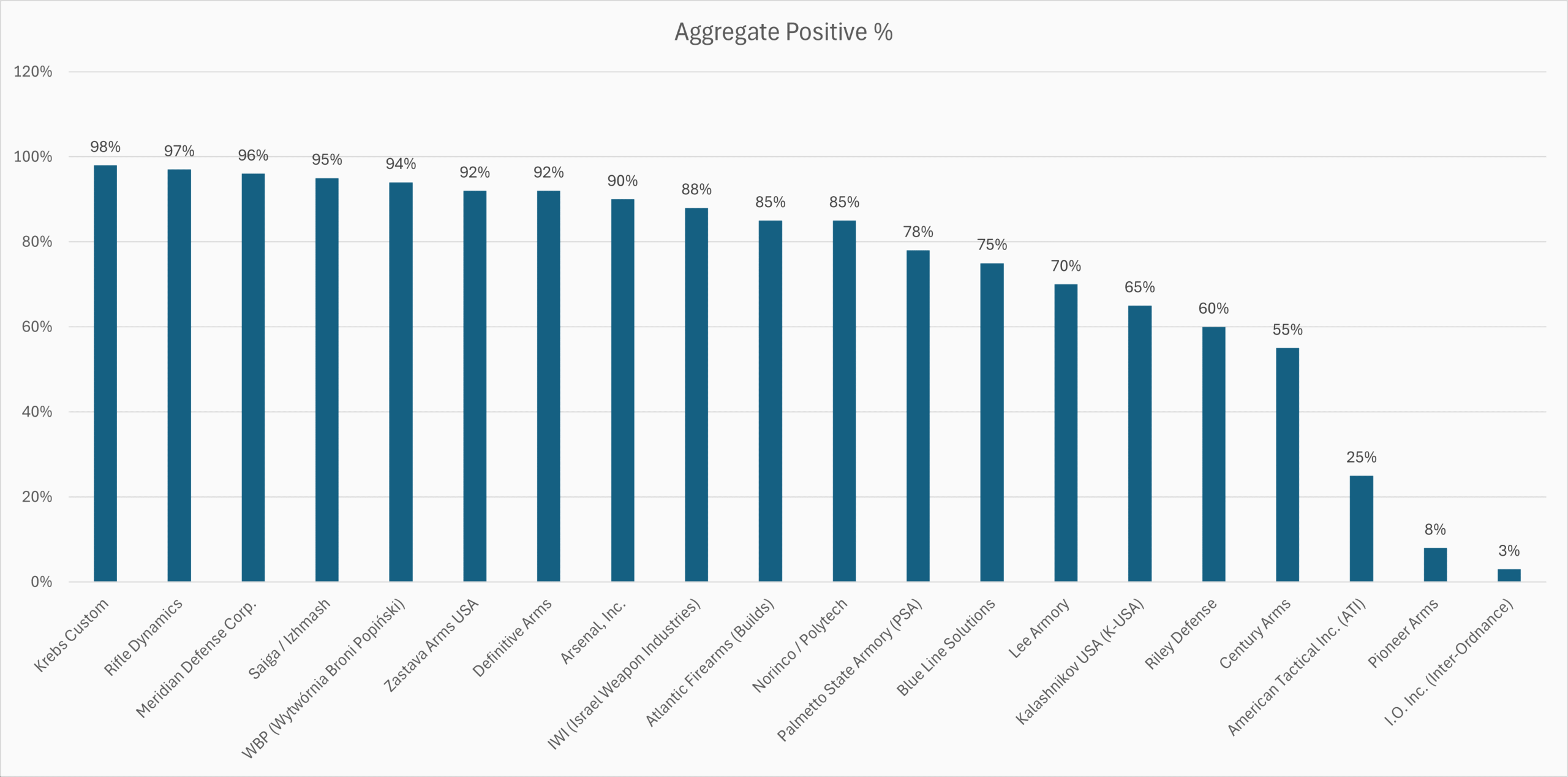

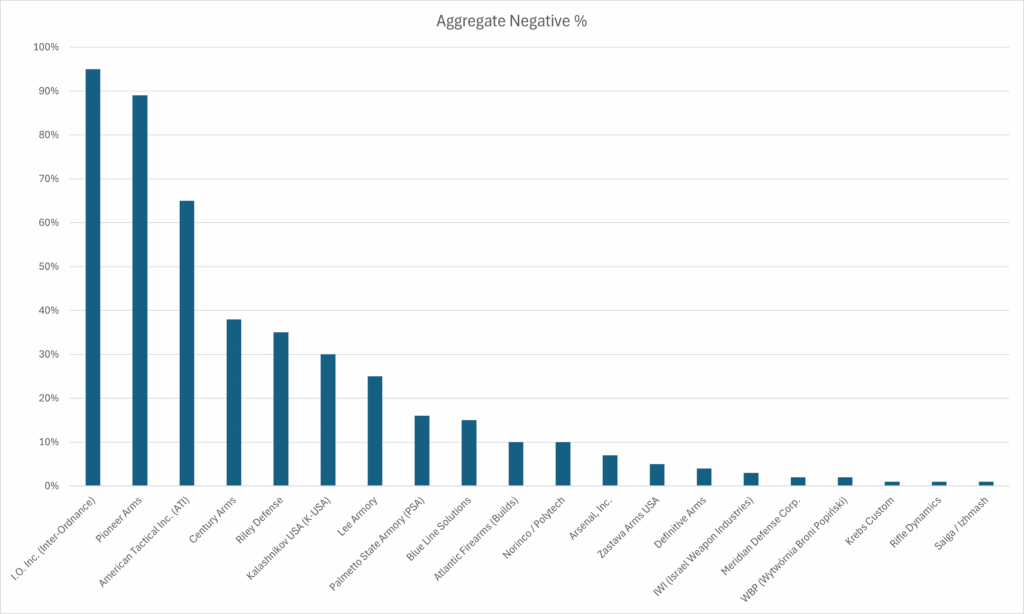

- Digital Sentiment Analysis: We monitored industry-specific digital channels, including The Firearm Blog, AK Operators Union, and relevant forums (Reddit /r/ak47, AR15.com) to gauge consumer sentiment and demand for specific features like adjustable gas blocks and monolithic rails 5.

Selection Criteria:

The “Top 20” platforms were selected based on three weighted factors:

- Technological Convergence (40%): Does the platform solve inherent AK limitations (optics mounting, ergonomics) using modern engineering? (e.g., PSA AXR, Occam Defense).

- Market Viability (30%): Is the product backed by a stable supply chain? Vaporware and prototypes with no clear production path were excluded, with the exception of significant concept cars like the PSA Vuk.

- Cultural Impact (30%): Does the product drive industry trends? This includes high-value collector items (Arsenal DJT-47) and “influencer-driven” limited runs (Rifle Dynamics/Garand Thumb collaborations).

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, we are only paid if there is an affiliate program such as Avantlink, Impact, Amazon and eBay and only if you purchase something. If you’d like to directly contribute towards our continued reporting, please visit our funding page.

Sources Used

- New Rifles Coming in 2026 – SHOT Show, accessed January 23, 2026, https://shotshow.org/new-rifles-coming-in-2026/

- Palmetto’s AXR Short Stroke Piston Rifle – SHOT 2026 – GunsAmerica, accessed January 23, 2026, https://gunsamerica.com/digest/palmettos-axr-short-stroke-piston-rifle-shot-show-2026/

- New For 2024: Century Arms BFT74 & BFT556 | An Official Journal Of The NRA, accessed January 23, 2026, https://www.americanrifleman.org/content/new-for-2024-century-arms-bft74-bft556/

- Kalashnikov USA Files for Bankruptcy, Will Likely be Bought – Black Basin Outdoors, accessed January 23, 2026, https://blackbasin.com/news/kalashnikov-usa-files-for-bankruptcy-will-likely-be-bought/

- PSA Vs. Soviet Arms : r/PalmettoStateArms – Reddit, accessed January 23, 2026, https://www.reddit.com/r/PalmettoStateArms/comments/1jqv039/psa_vs_soviet_arms/

- Rifle Dynamics Quickhatch PDW – 9″ 7.62x39mm Pistol, accessed January 23, 2026, https://rifledynamics.com/quickhatch/

- RWC-d/b/a Kalashnikov -USA Bankruptcy Hearing Later Today | The Outdoor Wire, accessed January 23, 2026, https://theoutdoorwire.com/features/6184d683-3ce3-47e6-b6f5-f7ec326ecde1

- What Happened to Kalashnikov USA? – You Should Know, accessed January 23, 2026, https://web.good-win-racing.com/lou/32-what-happened-to-kalashnikov-usa-7626/

- Telaammo 5.45×39 Ammunition- 1500 Rounds – Atlantic Firearms, accessed January 23, 2026, https://atlanticfirearms.com/telaammo-5-45×39-1500-rounds

- Tela Impex 5.45×39 Ammo For Sale – 65gr FMJ – 30 Rounds – Lucky Gunner, accessed January 23, 2026, https://www.luckygunner.com/5-45×39-65-grain-fmj-tela-impex-30-rounds

- 5.45×39 ammo for sale | TelaAmmo – Tela Impex LLC, accessed January 23, 2026, https://www.telaimpex.com/ecomm/product/telaammo-545

- What’s Going On with the PSA VUK? | SHOT Show 2025 – The Firearm Blog, accessed January 23, 2026, https://www.thefirearmblog.com/blog/what-s-going-on-with-the-psa-vuk-shot-show-2025-44818483

- Why did they make the Vuk look ugly? – General Discussion – Palmetto State Armory | Forum, accessed January 23, 2026, https://palmettostatearmory.com/forum/t/why-did-they-make-the-vuk-look-ugly/39662

- I think it’ll be priced at $4000, but do we really even consider this an AK? : r/ak47 – Reddit, accessed January 23, 2026, https://www.reddit.com/r/ak47/comments/1m8axyt/i_think_itll_be_priced_at_4000_but_do_we_really/

- SHOT Show 2026: first new products seen and test fired at the Industry Day at the Range, accessed January 23, 2026, https://www.all4shooters.com/en/shooting/culture/shot-show-2026-industry-day-at-the-range/

- [SHOT 2026] The American Kalashnikov – Stenzel Industries SAK-21 | thefirearmblog.com, accessed January 23, 2026, https://www.thefirearmblog.com/blog/shot-2026-the-american-kalashnikov-stenzel-industries-sak-21-44825416

- [SHOT 2026] Zastava M84 Machine Gun Cometh! | thefirearmblog.com, accessed January 23, 2026, https://www.thefirearmblog.com/blog/shot-2026-zastava-m84-machine-gun-cometh-44825476

- New Zastava PAP M90-PS 5.56 NATO Modernized AK Rifle (Range Review, Features, & Mag Compatability) – YouTube, accessed January 23, 2026, https://www.youtube.com/watch?v=RIO5Jm1XFFw

- Zastava AK rifles | Zastava Arms USA, accessed January 23, 2026, https://zastavaarmsusa.com/

- NEW! Mini-Beryl 5.56 Pistol from FB Radom! – YouTube, accessed January 23, 2026, https://www.youtube.com/watch?v=lbtC32MW-V8

- FB Radom – Beryl Rifle – 5.56/.223 – Arms of America, accessed January 23, 2026, https://armsofamerica.com/fb-radom-beryl-rifle-5-56-223-full-package/

- FB Radom Mini Beryl Pistols in 5.56/223 and .22LR to be Imported by Arms of America – The Firearm Blog, accessed January 23, 2026, https://www.thefirearmblog.com/blog/2020/02/03/shot-2020-5-56-223-and-22lr-radom-mini-beryl-pistols-to-be-imported-by-arms-of-america/

- New WBP Jack AK Models w/ Ukrainian-made KPYK Furniture | IWA 2025 – YouTube, accessed January 23, 2026, https://www.youtube.com/watch?v=GXDSTcyN7-U

- KRUK Accessories for Rifles from Polish Company WBP Rogów Now Available! – MILMAG, accessed January 23, 2026, https://milmag.pl/en/kruk-accessories-for-rifles-from-polish-company-wbp-rogow-now-available/

- The NEW KRUK Polish-Ukrainian AK – YouTube, accessed January 23, 2026, https://www.youtube.com/watch?v=ncXkL2_YLdM

- IWI Announces New ACE-N 52 Rifle | thefirearmblog.com, accessed January 23, 2026, https://www.thefirearmblog.com/blog/2021/10/15/iwi-announces-new-ace-n-52-rifle/

- Rifle Dynamics Quickhatch AK Pistol | thefirearmblog.com, accessed January 23, 2026, https://www.thefirearmblog.com/blog/2022/02/04/rifle-dynamics-quickhatch-ak-pistol/

- Firearms – Page 1 – RD – Rifle Dynamics, accessed January 23, 2026, https://rifledynamics.com/firearms/

- APOCALYPSE – Meridian Defense Corp., accessed January 23, 2026, https://meridiandefensecorp.com/special-projects-division/apocalypse/

- Occam ODS-1775: the Cadillac of AKs – Shoot On, accessed January 23, 2026, https://shoot-on.com/occam-ods-1775-the-cadillac-of-aks/

- ODS-1775 Pistol Deposit – Occam Defense Solutions, accessed January 23, 2026, https://occamdefense.com/ods-1775-pistol-deposit/

- ODS-1775 Rifle Deposit – Occam Defense Solutions, accessed January 23, 2026, https://occamdefense.com/ods-1775-rifle-deposit/

- DRACO 9s – Century Arms, accessed January 23, 2026, https://www.centuryarms.com/draco9s-series

- Century Arms – AK Rifles – Canik Pistols – Surplus Firearms – Surplus Accessories, accessed January 23, 2026, https://www.centuryarms.com/

- Home ⋆ Dissident Arms, accessed January 23, 2026, https://dissidentarms.com/

- I’m Back! My New Dissident Arms KL-12 Test Fire Sight In/Slug Testing! – YouTube, accessed January 23, 2026, https://www.youtube.com/watch?v=_bi6RhBUEG0

- Zastava M84 PKM, 300 Blackout AKs and Export Ban Update Shot Show 2026 – YouTube, accessed January 23, 2026, https://www.youtube.com/watch?v=lWIgShzqcaA

- AK-105 Rifles for Sale | Palmetto State Armory, accessed January 23, 2026, https://palmettostatearmory.com/ak-47/ak-100-series/ak-105.html

- Sureshot Armament Group, accessed January 23, 2026, https://sureshot-armament.com/

- Barwarusa Alpha rail: How does it compare to Zenitco? – YouTube, accessed January 23, 2026, https://www.youtube.com/watch?v=PwBbFhLnpDY

- AK Parts – DEFINITIVE ARMS, accessed January 23, 2026, https://definitivearms.com/product-category/accessories/akparts/

- SHOT Show 2026 Facts and Figures | thefirearmblog.com, accessed January 23, 2026, https://www.thefirearmblog.com/blog/shot-show-2026-facts-and-figures-44825134

FB Radom – Beryl Rifle – 5.56 – Arms of America, accessed January 23, 2026, https://armsofamerica.com/fb-radom-beryl-rifle-5-56-223/