To comprehend the evolution of the modern high-capacity 1911-style pistol, one must first understand the foundational design from which it sprang: John Moses Browning’s iconic M1911. This firearm was not merely an invention but a direct response to the specific, harsh demands of early 20th-century warfare. Its architecture, materials, and mechanical principles established a baseline of performance and reliability that would influence handgun design for over a century.

Design Imperatives: The U.S. Army’s Quest for a Modern Sidearm

The genesis of the M1911 lies in the brutal combat experiences of the U.S. Army during the Philippine-American War. The standard-issue.38 caliber revolvers proved to have inadequate stopping power against determined Moro insurgents, creating an urgent military requirement for a more potent sidearm.1 This battlefield feedback drove the U.S. Ordnance Department to seek a new semi-automatic pistol chambered in a.45 caliber cartridge.1

This quest culminated in the legendary 1907 U.S. Army trials, which pitted Browning’s Colt-produced design against competitors, most notably the Savage Automatic pistol. While the Savage was lighter and held more rounds, the Colt entry demonstrated a level of reliability that was, and remains, extraordinary. During one exhaustive test, the Colt pistol fired 6,000 consecutive rounds without a single jam or malfunction, a feat it accomplished even after being deliberately subjected to sand and submerged in water.1 This unparalleled performance in adverse conditions secured its victory, and the Colt design was officially adopted as the Model 1911 on March 29, 1911.1

A critical aspect of this development was the symbiotic relationship between the firearm and its ammunition. Unlike previous practices where firearms were often designed before their cartridges, the M1911 was engineered specifically around the powerful.45 ACP (Automatic Colt Pistol) round.1 This powerful, relatively low-velocity projectile was designed to deliver maximum terminal energy, directly addressing the “man-stopper” requirement that the.38 caliber revolvers had failed to meet.1 This decision to design the pistol for the cartridge locked in the fundamental dimensions of the action and magazine well, creating an optimized system but also defining the engineering constraints that future innovators would have to overcome.

Architectural Analysis of the M1911: The Monolithic Frame and Single-Action Trigger

The M1911’s construction reflects a philosophy of over-engineering for absolute military reliability. At its core is a single-piece, or “monolithic,” frame, forged from solid steel for maximum strength and durability.2 In this design, the grip, trigger guard, and the slide rails are all integral to one serialized component, a hallmark of robust firearm construction for the era. The original specifications called for a 5.03-inch barrel, a 7-round single-stack magazine, and two key safety features mandated by the military: a manual thumb safety and a grip safety.3

The soul of the M1911, however, is its fire control group (FCG). Browning’s single-action mechanism is a masterpiece of mechanical simplicity and efficiency. The interaction between the trigger, the trigger bow, the disconnector, the sear, and the hammer produces the crisp, consistent, straight-pull trigger for which the platform is famous.6 During the cycle of operation, these parts work in perfect concert. Squeezing the trigger causes the trigger bow to push the disconnector, which in turn rotates the sear, releasing the hammer to strike the firing pin. As the slide recoils, it pushes the disconnector down, momentarily breaking the connection to the sear and allowing the sear to reset on the hammer’s full-cock notch. This prevents the pistol from firing automatically and ensures that the trigger must be released and squeezed again for the next shot.9 The genius of Browning’s design is evident in the multi-functionality of its parts, where components like the slide stop pin also serve as the pivot for the barrel link, minimizing complexity and potential points of failure.12

The M1911A1: Ergonomic Refinements for the Modern Soldier

After its trial by fire in the trenches of World War I, feedback from soldiers in the field led to a series of ergonomic, rather than mechanical, updates. These changes, officially adopted in 1924 and standardized as the M1911A1 by 1926, were focused on improving the interface between the shooter and the firearm.1

The key refinements included:

- An arched mainspring housing to create a grip angle that felt more natural for most shooters.3

- A shorter trigger to provide better reach for a wider range of hand sizes.3

- Scalloped relief cuts in the frame just behind the trigger, further improving trigger access.3

- An extended grip safety spur (or “beavertail”) to protect the web of the shooter’s hand from being pinched by the hammer, a common complaint known as “hammer bite”.3

- Slightly wider sights for a clearer and more easily acquired sight picture.3

These modifications did not alter the M1911’s core function but perfected its ergonomics, solidifying the classic feel that enthusiasts praise to this day. The M1911A1 became the definitive version of the platform, serving for over 60 more years as the standard-issue sidearm for the U.S. Armed Forces and establishing the true baseline for all subsequent commercial and competitive variants.3

The Pursuit of Capacity – The Dawn of the Double-Stack 1911

For decades, the M1911A1’s design remained largely static under military stewardship. The next major evolutionary leap was not driven by a government contract but by the demands of a new battlefield: the civilian practical shooting competition circuit. This shift marked a pivotal moment where the platform’s development trajectory turned from military reliability to civilian performance, with magazine capacity as the new frontier.

Market Drivers: The Influence of Practical Shooting Competition

By the 1970s and 1980s, the rise of practical shooting sports like the International Practical Shooting Confederation (IPSC) and the United States Practical Shooting Association (USPSA) created a new set of performance metrics. Speed and round count became paramount. The 1911’s single-stack magazine, typically holding 7 or 8 rounds of.45 ACP, was a significant disadvantage against a new wave of European-designed “Wonder Nines”—pistols like the CZ-75 and Beretta 92 that featured double-stack magazines holding 15 or more rounds of 9mm ammunition.14 Competitive shooters revered the 1911’s superior trigger and ergonomics but were consistently handicapped by the need for more frequent reloads. This created a clear and fervent market demand for a pistol that combined the soul of a 1911 with the capacity of its modern rivals.14

The Pioneer: Para-Ordnance and the First “Widebody” Frame

The first company to successfully answer this call was Para-Ordnance, a Canadian firm founded by Ted Szabo.17 In the late 1980s, Para-Ordnance introduced a revolutionary product: a “high capacity conversion kit” for existing M1911A1 pistols.14 These kits provided a completely new, wider frame that could accept a proprietary double-stack magazine, effectively doubling the capacity to 13 or 14 rounds of.45 ACP.14 Gunsmiths and hobbyists could transfer the slide, barrel, and fire control components from a standard Colt or other 1911 onto the new Para-Ordnance frame.19

The popularity of these kits was immense, proving the commercial viability of a high-capacity 1911. By 1990, Para-Ordnance transitioned from selling kits to manufacturing complete pistols. Their flagship model, the P14-45 (denoting 14-round capacity in.45 ACP), became the first commercially successful, mass-produced double-stack 1911 and the progenitor of the “widebody” class of pistols.14

Engineering the Conversion: An Analysis of Frame, Trigger, and Magazine Modifications

The Para-Ordnance solution was an effective, if somewhat unsubtle, piece of engineering. They solved the capacity problem by widening the entire lower portion of the monolithic 1911 frame, creating what is now commonly referred to as a “widebody”.5 This approach, while direct, necessitated the redesign of several key components:

- Frame: The entire frame forging or casting had to be re-tooled to be significantly wider from the magazine well through the grip. A key visual identifier of this design is the distinct “step” or flare where the standard-width dust cover meets the wider grip frame.14

- Magazine: A new, proprietary double-column, single-feed magazine was developed. These magazines are specific to the Para-Ordnance pattern and are not interchangeable with later 2011-style magazines.5

- Trigger Assembly: The trigger bow—the U-shaped metal band that wraps around the magazine and connects the trigger shoe to the disconnector—had to be made substantially wider to allow the fatter double-stack magazine to pass through it. This is a critical, non-interchangeable component.20

- Magazine Catch and Grip Panels: Both the magazine release and the grip panels had to be redesigned to accommodate the wider frame and magazine body.

A crucial element of Para-Ordnance’s success was ensuring that the top half of the frame—the slide rails and fire control housing—retained standard 1911 dimensions. This allowed for continued compatibility with the vast majority of existing slides, barrels, and internal parts, making the transition easier for custom builders and manufacturers.14 However, this “brute force” approach of simply widening the frame created a new, unintended problem: the grip circumference was often too large and blocky for many shooters, a direct consequence of the monolithic widebody design.14 This ergonomic compromise, born from solving one problem, inadvertently created the specific design challenge that would lead to the next great evolutionary leap.

Other Notable Widebody Designs: Caspian, BUL, and the Evolution of the Monolithic Double-Stack

Following Para-Ordnance’s success, other manufacturers entered the widebody market. Caspian Arms, a respected maker of high-quality frames and slides, began producing all-metal widebody frames that became a favorite of custom gunsmiths like Les Baer.14 In a notable material innovation, the Israeli manufacturer BUL Armory created a polymer widebody frame with a permanently bonded steel insert, known as the M-5. This design was adopted by several major brands, including Kimber and Springfield Armory, to offer lighter-weight, high-capacity models.14 It is critical to distinguish these designs from the later 2011; while they used polymer, their frames were still single, non-modular units.14

The Paradigm Shift – The Genesis of the 2011 Modular Platform

The creation of the double-stack 1911 was a significant evolution, but the next step was a true revolution. It represented a fundamental shift in design philosophy, moving from simply modifying an existing architecture to completely reimagining it. This paradigm shift was driven by the desire to solve the ergonomic flaws of the widebody and create a high-capacity pistol that felt and handled like Browning’s original masterpiece.

The Visionaries: Virgil Tripp and Sandy Strayer’s Quest for a Better Competition Pistol

In the early 1990s, master gunsmith Virgil Tripp, a prominent figure in the competition shooting world, recognized the ergonomic limitations of the existing widebody 1911s. He envisioned a high-capacity pistol that could maintain the slim, comfortable grip profile of a single-stack 1911—a goal considered impossible with a monolithic frame. To bring this vision to life, he partnered with engineer Sandy Strayer, whose expertise in computer-aided design was crucial for the project’s complexity.14

Their collaboration resulted in the formation of Strayer-Tripp, Inc. (STI) and the creation of a radical new two-piece frame design.25 In May 1994, the final patent for their modular system was published. However, the partnership was short-lived. Just a month later, Strayer departed to form Strayer-Voigt Inc. (SVI) with professional shooter Michael Voigt. Because Tripp and Strayer were co-patent holders, their two companies became direct competitors, each producing high-end competition pistols based on their shared modular design.24 Tripp later sold his interest in STI, and the company, after decades of dominating the competition market, eventually rebranded as Staccato in 2020 to focus on the law enforcement and personal defense markets.24

Deconstructing the Innovation: A Deep Dive into U.S. Patent 5,293,708A

The core of the Tripp-Strayer innovation is detailed in U.S. Patent 5,293,708A, filed in 1992 and granted in 1994, for a “Frame/handgrip assembly for autoloading handgun”.28 The patent describes an architectural solution to the capacity-versus-ergonomics problem. Instead of a single, monolithic frame, it outlines a two-piece system:

- A “gripless preferably metal frame structure” that contains the slide rails and fire control housing.

- A separate “integral handgrip structure” that contains the magazine well and trigger guard.

The patent’s key claims explicitly state the design’s primary goals: to accommodate a “staggered row, enhanced volume cartridge magazine” while maintaining an “external handgrip width as compared with the standard 1911 A1 handgun”.28 This was achieved by making the grip module from a strong, rigid polymer. The material’s strength allowed for much thinner grip walls than a metal frame, creating the necessary internal space for a wide magazine without adding excessive external bulk.28 This architectural change was a paradigm shift, moving beyond the mechanical solution of the widebody to a fundamental redefinition of the firearm’s frame.

The Two-Piece System: Analyzing the Metal Upper Frame and Polymer Grip Module

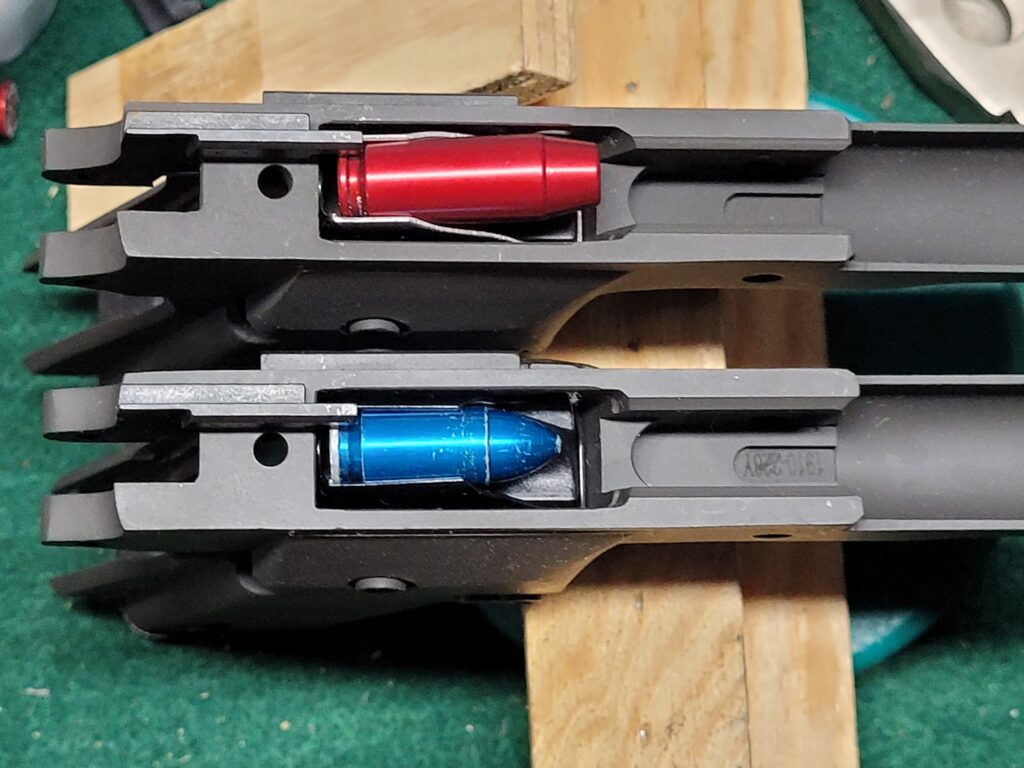

The 2011 design bifurcates the traditional 1911 frame into two distinct components with separate functions and materials:

- The Upper Frame (The “Firearm”): This component, typically machined from steel or aluminum, is the serialized part of the pistol and is legally considered the firearm. It contains the slide rails, dust cover, and the housing for the fire control group.5 Its “gripless” design was a radical departure from every 1911 that had come before.29

- The Grip Module (The “Accessory”): This non-serialized component, most often made of polymer but also available in aluminum or steel, integrates the grip, the mainspring housing, and the trigger guard into a single, user-replaceable unit. It attaches securely to the upper frame with screws, most visibly one located at the front of the trigger guard.5

This modularity transformed the high-capacity 1911 from a single model of pistol into a true, user-configurable platform. A single serialized upper frame could be adapted for different roles—concealed carry with a short grip, competition with a flared magwell, or duty use—simply by swapping the unregulated grip module. This level of adaptability is the defining characteristic of modern firearm platforms and is the 2011’s most significant contribution to handgun design. STI trademarked the term “2011” for this platform, and while technically only STI/Staccato pistols are true 2011s, the name has become the generic industry term for any 1911-style pistol with this two-piece modular frame system.16

The Patent Expiration and Market Proliferation

A monumental event in the platform’s history occurred in 2016 when the original patent on the modular grip expired.24 This opened the floodgates for any manufacturer to produce pistols based on the 2011 design without needing to license the technology. This led to an explosion of new models from companies like Springfield Armory (the Prodigy), Bul Armory, and others, dramatically increasing the platform’s availability and creating more accessible price points for consumers.14

A Comparative Analysis – Defining the Platforms

The evolutionary path from the original M1911 to the modern 2011 has resulted in three distinct, albeit related, classes of firearm. A direct comparison of their architecture, component compatibility, and performance characteristics reveals the significance of each developmental stage.

Architectural Divergence: Monolithic vs. Modular Frame Design

The most fundamental difference between the platforms lies in the construction of the frame.

- Classic 1911: Features a single-piece, monolithic frame where the grip is an integral part of the structure. Customization is limited to attaching different grip panels to this frame.5

- Double-Stack 1911 (“Widebody”): Employs the same single-piece, monolithic architecture as the classic 1911, but the entire grip portion is scaled up to be wider. It is not a modular design.5

- 2011: Utilizes a two-piece, modular frame. A serialized metal upper frame is mated to a separate, non-serialized, and replaceable lower grip module. This is the defining structural difference that sets it apart from all other 1911 variants.5

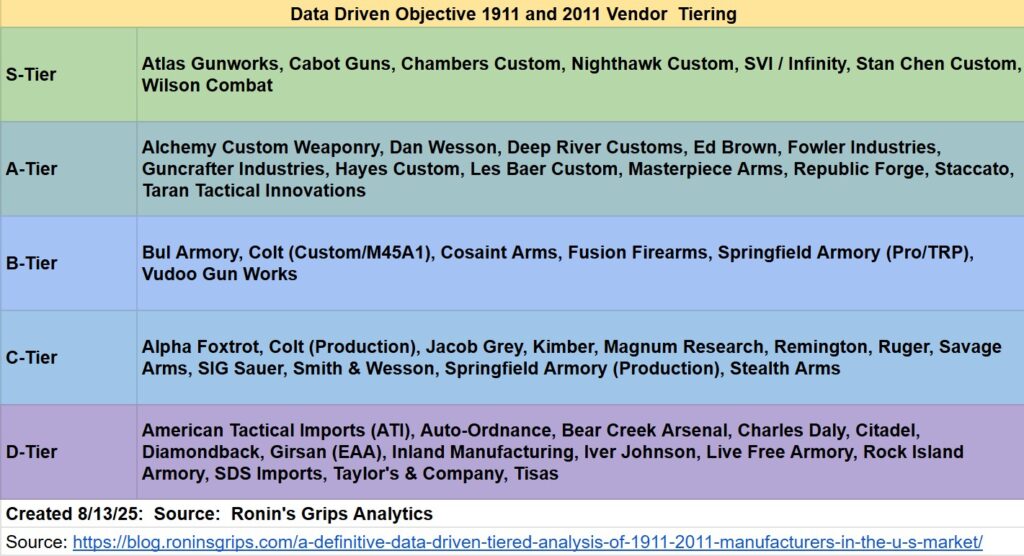

The following table provides a clear, at-a-glance summary of these critical distinctions.

| Feature | Classic 1911 (M1911A1) | Double-Stack 1911 (“Widebody”) | Modern 2011 |

| Frame Construction | Single-piece, forged steel/alloy | Single-piece, widened steel/alloy/polymer | Two-piece, modular (metal upper, polymer/metal grip) |

| Serialized Component | Entire frame | Entire frame | Metal upper frame only |

| Grip System | Removable grip panels | Removable grip panels on a wider frame | Integral, replaceable grip module |

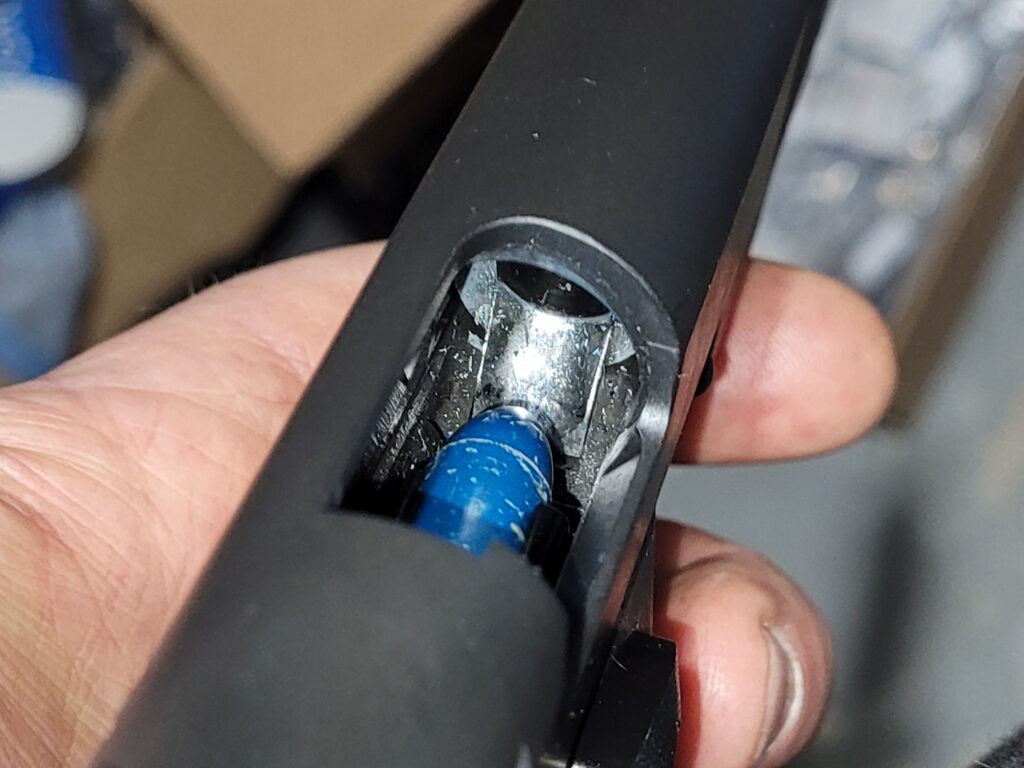

| Magazine Type | Single-stack | Proprietary double-stack (e.g., Para-type) | Proprietary double-stack, tapered feed lips (2011-type) |

| Typical Capacity (.45 ACP) | 7-8 rounds | 12-14 rounds | 12-14 rounds |

| Typical Capacity (9mm) | 9-10 rounds | 15-18 rounds | 17-21+ rounds |

| Trigger Bow | Standard width | Widened to clear magazine | Widened to clear magazine |

| Primary Design Intent | Military sidearm | High-capacity upgrade (civilian/competition) | High-performance competition/duty |

Parts Interchangeability: What Remains and What Has Changed

Despite the significant architectural changes, a testament to the brilliance of Browning’s original design is that many core components remain compatible across all three platforms. The slide assembly, barrel, recoil system, and most fire control parts (sear, hammer, disconnector) are largely interchangeable.5

The points of divergence are centered around the frame and magazine well. The frame, grip, magazine, magazine catch, and the trigger/trigger bow assembly are platform-specific. A standard 1911 trigger will not fit a widebody or 2011 frame due to the wider trigger bow required to clear the double-stack magazine.5 Furthermore, the magazines themselves are not cross-compatible; a Para-Ordnance-style widebody magazine will not function in a 2011, and vice-versa.5 The 2011 magazine is a distinct piece of engineering, tapering from a wide, double-stack body to a narrow, single-feed presentation at the top, allowing it to work with a slide built to standard 1911 dimensions.5 This highlights that the magazine is not merely an accessory but a critical subsystem whose design is inextricably linked to the frame’s architecture.

Performance and Ergonomics: Recoil Impulse, Weight, and Customization Potential

The architectural and material differences create distinct shooting experiences.

- Recoil Impulse: All-steel 1911s and widebodies are known for their solid feel and distinct recoil impulse. The 2011, with its polymer grip module, is often described as having a “softer” shooting characteristic. The inherent flex of the polymer absorbs high-frequency vibrations, changing the perceived recoil for the shooter.24 Additionally, the sheer mass of a fully loaded 17- or 20-round magazine significantly increases the pistol’s static weight, helping to dampen muzzle rise during firing.21

- Weight and Balance: While a classic 1911 can be made lighter with an aluminum frame 2, a polymer-gripped 2011 is generally lighter than its all-steel widebody counterpart. This combination of a steel upper and polymer lower tends to shift the balance point higher and more forward, a characteristic many competitive shooters find enhances pointability and sight tracking.5

- Customization: The classic 1911 is one of the most customizable handguns in the world, but those modifications are ultimately bound by its monolithic frame.36 The 2011’s modularity offers a revolutionary level of ergonomic customization. A shooter can change the grip’s size, texture, material, and shape to perfectly fit their hand or intended application, all without needing to modify the core firearm.5

Conclusion – Is a 2011 Still a 1911?

The question of whether a 2011 is truly a 1911 is central to understanding its place in firearms history. The answer is nuanced, requiring an appreciation for both its direct lineage and its revolutionary departures. It is a debate that pits shared mechanical principles against a fundamental architectural reinvention.

The Argument for Direct Lineage: A Shared Mechanical Soul

The strongest argument for classifying the 2011 as a 1911 lies in its unchanged core operating system. The “1911-ness” of a firearm is often defined by two key elements, both of which the 2011 retains perfectly. First, it uses John Browning’s brilliant short-recoil, tilting-barrel lockup mechanism, the same system that proved its worth in the 1907 trials.5 Second, and perhaps more importantly, it retains the single-action fire control group. The resulting crisp, clean, straight-pull trigger is functionally identical to that of a tuned 1911. The manual of arms, including the “cocked-and-locked” carry method, is a direct inheritance.5 For many, this shared mechanical soul is the definitive link that makes the 2011 a member of the 1911 family.

The Argument for a New Classification: A Fundamental Evolutionary Leap

Conversely, the argument for classifying the 2011 as a new platform rests on its revolutionary frame architecture. The transition from a single-piece, monolithic frame to a two-piece modular system is not an incremental update; it is a complete reinvention of the firearm’s foundation.5 This architectural shift enables the use of modern materials like polymer in the grip, which in turn alters the pistol’s weight, balance, and recoil dynamics.5 The lack of interchangeability for critical components like the frame, grip module, magazine, and trigger further solidifies the argument that the 2011 has diverged significantly from its ancestor. It was designed with a different intent—optimizing for competition and duty use—and its core structure reflects that new purpose.5

Final Assessment: A Modern Descendant Forged in Competition

Ultimately, the evidence supports a clear distinction. A traditional “double-stack 1911,” such as a Para-Ordnance P14-45, is unequivocally still a 1911. It is an M1911A1 with a wider frame, an incremental, mechanical evolution.

The 2011, however, represents a speciation event in the design’s lineage. It is a direct descendant that shares critical DNA with its progenitor, most notably in its superb trigger and reliable action. However, the architectural leap to a modular, multi-component frame is a defining evolutionary change that fundamentally alters its construction, material composition, ergonomic potential, and performance characteristics.

The relationship is perhaps best understood through an analogy: the 2011 is to the 1911 what a modern, specialized domestic dog breed is to the gray wolf. They share a common ancestor and undeniable genetic links, but selective pressures—in the 2011’s case, the demands of high-level competition—have forged a new entity optimized for a completely different environment.

Therefore, a 2011 is not just a 1911. It is the next stage of its evolution, a platform that honors its heritage by preserving the 1911’s most beloved features while fully embracing modern design principles of modularity, capacity, and material science. It is most accurately classified as a distinct and revolutionary platform within the broader “1911 family.”

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, we are only paid if there is an affiliate program such as Avantlink, Impact, Amazon and eBay and only if you purchase something. If you’d like to directly contribute towards our continued reporting, please visit our funding page.

Works cited

- M1911 .45 Caliber Pistol – The Army Historical Foundation, accessed August 17, 2025, https://armyhistory.org/m1911-45-caliber-pistol/

- The Complete Guide to 1911 Frames – Concealed Coalition, accessed August 17, 2025, https://my.concealedcoalition.com/the-complete-guide-to-1911-frames/

- Model of 1911: History of Use During the World War Era – Turnbull Restoration, accessed August 17, 2025, https://www.turnbullrestoration.com/model-of-1911-history-use-during-wwi-and-wwii/

- 1911 Mil-Spec Handguns – Springfield Armory, accessed August 17, 2025, https://www.springfield-armory.com/1911-series-handguns/1911-mil-spec-handguns/

- What Is A 2011? Double-Stack 1911s vs Widebody Frames Explained – Alien Gear Holsters, accessed August 17, 2025, https://aliengearholsters.com/blogs/news/what-is-a-2011

- Exploring the Enduring Popularity of the 1911 Pistol, accessed August 17, 2025, https://blog.primaryarms.com/guide/1911-pistol-popularity-explored/

- M1911 pistol – Wikipedia, accessed August 17, 2025, https://en.wikipedia.org/wiki/M1911_pistol

- The Different Types of Magazine Capacity for the 1911 – 1911LeatherHolsters, accessed August 17, 2025, https://1911leatherholsters.com/blogs/news/the-different-types-of-magazine-capacity-for-the-1911

- Theory of Operation of the Colt .45 ACP Government Model Pistol, accessed August 17, 2025, https://sightm1911.com/lib/tech/theory_op.htm

- How Your Pistol Works: 1911 Parts & Pieces – Rock Island Armory, accessed August 17, 2025, https://news.armscor.com/how-your-pistol-works-1911-parts-pieces

- How a gun (Colt M1911) works! (Animation) – YouTube, accessed August 17, 2025, https://www.youtube.com/watch?v=EjQrhDKDWFk&pp=ygUGI2d1bmpo

- The 1911 It’s Parts & their functions – YouTube, accessed August 17, 2025, https://www.youtube.com/watch?v=_-kCPHkb9MY

- The Complete Guide To 1911 Pistols – Alien Gear Holsters, accessed August 17, 2025, https://aliengearholsters.com/blogs/news/guide-to-the-1911-pistol

- A Guide To Double-Stack 1911s | An Official Journal Of The NRA, accessed August 17, 2025, https://www.americanrifleman.org/content/a-guide-to-double-stack-1911s/

- What took so long for double-stack magazines to become mainstream in handguns? : r/WarCollege – Reddit, accessed August 17, 2025, https://www.reddit.com/r/WarCollege/comments/1848gvr/what_took_so_long_for_doublestack_magazines_to/

- The 2011 Pistol Concept: Incredible Popularity – The Mag Life – GunMag Warehouse, accessed August 17, 2025, https://gunmagwarehouse.com/blog/the-2011-pistol-concept-incredible-popularity/

- Para-Ordnance P14-45 – Wikipedia, accessed August 17, 2025, https://en.wikipedia.org/wiki/Para-Ordnance_P14-45

- en.wikipedia.org, accessed August 17, 2025, https://en.wikipedia.org/wiki/Para-Ordnance_P14-45#:~:text=In%20the%20late%201980s%2C%20Toronto,and%20a%20new%20trigger%20assembly

- A Basic Guide to Para-Ordnance Pistol Sizes, accessed August 17, 2025, https://ezine.m1911.org/showthread.php?287-A-Basic-Guide-to-Para-Ordnance-Pistol-Sizes

- 2011 vs. 1911 – What’s the Difference? – The Broad Side – Target Barn, accessed August 17, 2025, https://www.targetbarn.com/broad-side/2011-vs-1911/

- Why 1911 or 2011? | The Armory Life Forum, accessed August 17, 2025, https://www.thearmorylife.com/forum/threads/why-1911-or-2011.22346/

- Foster – Caspian Arms | Serving the custom pistolsmith since 1983, accessed August 17, 2025, https://www.caspianarms.com/product-category/foster

- Caspian Arms for Sale | Buy Online at GunBroker, accessed August 17, 2025, https://www.gunbroker.com/caspian-arms/search?keywords=caspian%20arms&kwop=2&s=f

- The 2011 Pistol: Refitting the 1911 for a New Century, accessed August 17, 2025, https://freerangeamerican.us/2011-pistol/

- History – Tripp Research, accessed August 17, 2025, https://www.trippresearchinc.com/about-us/

- STI International Archives – The Sporting Shoppe Richmond, Rhode Island, accessed August 17, 2025, https://thesportingshoppe.com/brands/sti-international/

- Staccato (formerly STI International) – Golden, accessed August 17, 2025, https://golden.com/wiki/Staccato_(formerly_STI_International)-GNGBBN

- US5293708A – Frame/handgrip assembly for autoloading handgun – Google Patents, accessed August 17, 2025, https://patents.google.com/patent/US5293708A/en

- Sandy L. Strayer Inventions, Patents and Patent Applications, accessed August 17, 2025, https://patents.justia.com/inventor/sandy-l-strayer

- Virgil P. Tripp Inventions, Patents and Patent Applications, accessed August 17, 2025, https://patents.justia.com/inventor/virgil-p-tripp

- Strayer Voigt Inc – Wikipedia, accessed August 17, 2025, https://en.wikipedia.org/wiki/Strayer_Voigt_Inc

- 1911 vs 2011 – What’s A Better Choice? – Ammo To Go, accessed August 17, 2025, https://www.ammunitiontogo.com/lodge/1911-vs-2011/

- So what makes a 2011 different from a 1911? I just bought a Staccato XL (won’t be available for 200 days) and then a Rock Island Armory double stack 9mm with a rail. Below is a picture of the 1911 – Reddit, accessed August 17, 2025, https://www.reddit.com/r/2011/comments/14968na/so_what_makes_a_2011_different_from_a_1911_i_just/

- Modular firearm trigger system – Justia Patents, accessed August 17, 2025, https://patents.justia.com/patent/12379178

- The Best 2011 Pistols of 2025, Tested and Reviewed – Outdoor Life, accessed August 17, 2025, https://www.outdoorlife.com/guns/best-2011-pistols/

- 1911 vs 2011: The Ultimate Handgun Showdown – Craft Holsters, accessed August 17, 2025, https://www.craftholsters.com/1911-vs-2011-which-one-is-better

- What makes a 2011 so special? – Reddit, accessed August 17, 2025, https://www.reddit.com/r/2011/comments/1egq052/what_makes_a_2011_so_special/

- 2011 vs 1911: Modern Competitor or the Classic Carry? – Gun Made, accessed August 17, 2025, https://www.gunmade.com/2011-vs-1911/