The People’s Liberation Army (PLA) of the People’s Republic of China is currently executing the most comprehensive and technologically ambitious small arms modernization program in its history. This transformation is centered on the system-wide adoption of the QBZ-191 modular weapon family, a development that signifies a profound strategic and doctrinal evolution. The prevailing trend is a decisive pivot away from the isolated, proprietary, and ergonomically challenged designs of the past, most notably the bullpup QBZ-95 family. In its place, the PLA is embracing a design philosophy rooted in modularity, superior ergonomics, and the seamless integration of advanced electro-optics and accessories, aligning Chinese infantry weapons with global design paradigms for the first time.

This report provides a detailed technical and strategic assessment of the small arms currently in service across all branches of China’s armed forces, including the PLA Ground Force (PLAGF), Navy (PLAN), Air Force (PLAAF), the paramilitary People’s Armed Police (PAP), and the China Coast Guard (CCG). The analysis indicates that the current modernization is far more than a simple equipment upgrade. It is a direct reflection of a deeper doctrinal shift towards information-centric, combined-arms warfare, where the individual soldier is a networked sensor and shooter. The new generation of weapons is engineered to enhance the lethality, tactical flexibility, and operational sustainability of small units, empowering them to fight and win on a complex, multi-domain battlefield.

While the new QBZ-191 system is being prioritized for frontline combat units, a vast inventory of legacy weapons, including millions of QBZ-95 family rifles and a significant reserve of Type 81 rifles, remains in service. This demonstrates a pragmatic, tiered, and cost-conscious approach to modernization. Equipment is cascaded from elite units to second-line troops, reserves, and internal security forces, maximizing the combat effectiveness of the entire force structure within realistic fiscal and logistical constraints. This report will dissect each major weapon system, analyze its role within the PLA’s evolving doctrine, and provide a concluding assessment of China’s defense-industrial capacity and the future trajectory of its small arms development.

II. The New Generation: The QBZ-191 Modular Weapon System

The centerpiece of the PLA’s infantry modernization is the weapon family officially designated the QBZ-191. Its introduction marks a definitive break with the preceding generation of bullpup rifles and represents a wholesale adoption of contemporary, conventional rifle design principles. This shift is not merely stylistic; it is a fundamental realignment of the infantryman’s weapon with the demands of modern, informationized warfare.

Core Design Philosophy and Doctrinal Shift

The QBZ-191 (191式自动步枪, 191 Shì Zìdòng Bùqiāng, Type 191 Automatic Rifle) family abandons the bullpup configuration of its QBZ-95 predecessor in favor of a conventional layout. Mechanically, it operates on a short-stroke gas piston and rotating bolt system, a mechanism renowned for its reliability and adopted by many of the world’s most advanced assault rifles, such as the Heckler & Koch HK416 and the FN SCAR. The weapon’s architecture includes features now considered standard for a modern military rifle: a multi-position adjustable stock, improved ergonomics for varied shooting positions, and fully ambidextrous controls, including the fire selector and magazine release.

The decision to abandon the bullpup layout, after investing heavily in it for over two decades with the QBZ-95, is the most telling aspect of the new design philosophy. The QBZ-95, while offering the benefit of a long barrel in a compact overall length, was plagued by inherent design flaws that became increasingly untenable. These included a notoriously heavy and imprecise trigger due to the long linkage from the trigger to the rear-mounted action, awkward magazine changes that required breaking a firing grip, and ejection ports located close to the user’s face, making off-hand shooting difficult. Most critically, however, the QBZ-95 was a product of a different doctrinal era.

The most significant physical feature of the QBZ-191, and the clearest indicator of the new doctrine, is its full-length, monolithic MIL-STD-1913 Picatinny rail along the top of the receiver and handguard. The QBZ-95 featured only a short, proprietary dovetail mount that was poorly suited for mounting anything other than a single, specific optic. The adoption of the universal Picatinny standard is a revolutionary step for the PLA. This rail provides ample space for the flexible mounting of a suite of accessories in various combinations—for example, a variable-power magnified optic paired with a clip-on thermal or night vision sight, a laser aiming module, and backup iron sights. This physical change is the direct consequence of a profound doctrinal evolution. The PLA no longer views advanced optics as specialist equipment for designated marksmen but as standard-issue equipment for the common infantryman. This signals a massive parallel investment in the domestic electro-optics industry and a fundamental shift in training methodology. The PLA is moving from an “iron sights first” mentality to an “optics first” doctrine, aiming to increase the effective engagement range, first-hit probability, and all-weather, day/night fighting capability of every soldier. This, in turn, enhances small-unit lethality, situational awareness, and autonomy on the battlefield.

Ammunition: The DBP-191 5.8x42mm Cartridge

The development of the QBZ-191 rifle is inextricably linked to the simultaneous development of a new generation of ammunition: the DBP-191 5.8x42mm cartridge. The weapon and the cartridge were designed as a single, integrated system, with each component optimized to enhance the performance of the other. This holistic approach is a hallmark of a mature and sophisticated research and development process.

The original 5.8x42mm cartridge, DBP-87, was developed in the 1980s and was a contemporary of the 5.56x45mm NATO and 5.45x39mm Soviet rounds. While adequate for its time, it and its successor, the DBP-10, lacked the performance of modern intermediate cartridges, particularly at extended ranges. The DBP-191 was specifically designed to overcome these deficiencies. It features a heavier, longer, and more streamlined projectile with a superior ballistic coefficient. This results in a flatter trajectory, reduced wind drift, and greater retained energy at medium and long ranges. The projectile construction includes a hardened steel core for improved penetration against body armor and light barriers.

In weapons design, the internal and external ballistics of the cartridge are the foundational elements that dictate critical design parameters of the rifle, including barrel length, rifling twist rate, gas system tuning, and the practical effective range of the platform. The PLA’s ordnance establishment clearly identified a performance deficit in its existing 5.8mm ammunition and understood that a new rifle alone could not solve the problem. By developing a new, higher-performance round and then engineering a family of weapons optimized to fire it, they have achieved a synergistic leap in capability. The superior performance of the DBP-191 cartridge is precisely what enables the Designated Marksman Rifle variant of the family, the QBU-191, to be effective out to ranges of 600-800 meters and what gives the standard QBZ-191 rifle a tangible performance advantage over its predecessor.

System Variants

The QBZ-191 was designed from the outset as a modular family of weapons, sharing a common receiver and operating mechanism, to fulfill multiple battlefield roles.

- QBZ-191 (191式自动步枪, 191 Shì Zìdòng Bùqiāng, Type 191 Automatic Rifle): This is the standard infantry rifle and the core of the family. It features a 14.5-inch (368mm) barrel, providing a good balance between ballistic performance and maneuverability. It is slated to become the most widely issued variant, systematically replacing the QBZ-95-1 in frontline PLAGF combined arms brigades and PLAN Marine Corps units.

- QBZ-192 (192式短自动步枪, 192 Shì Duǎn Zìdòng Bùqiāng, Type 192 Short Automatic Rifle): This is the compact carbine variant, equipped with a shorter 10.5-inch (267mm) barrel. The reduced length makes it ideal for personnel operating in confined spaces, such as vehicle crews, special forces conducting close-quarters battle (CQB), and naval personnel aboard ships. It serves the same role as the American Mk 18 or the Russian AK-105.

- QBU-191 (191式精确射手步枪, 191 Shì Jīngquè Shèshǒu Bùqiāng, Type 191 Precision Marksman Rifle): This is the Designated Marksman Rifle (DMR) variant of the family. It is designed to provide accurate semi-automatic fire at the squad level beyond the effective range of standard assault rifles. It achieves this through a longer, heavier, free-floated barrel for enhanced accuracy and consistency, an improved trigger mechanism, and the standard issuance of a new 3-8.6x variable power magnified optic, the QMK-191. The QBU-191 is specifically designed to leverage the superior long-range ballistic performance of the new DBP-191 ammunition, enabling effective engagements out to 600-800 meters.

- QJB-201 (201式班用机枪, 201 Shì Bānyòng Jīqiāng, Type 201 Squad Machine Gun): While not officially designated as part of the ‘191’ family, the QJB-201 is a new-generation 5.8x42mm light machine gun whose development was concurrent with and complementary to the QBZ-191 program. It is designed to replace the magazine-fed QJB-95-1 Squad Automatic Weapon. The most significant improvement is its switch to a belt-feed mechanism, allowing for a much higher volume of sustained suppressive fire. This addresses a major deficiency of its predecessor and provides PLA squads with a true light machine gun capability comparable to the FN Minimi/M249.

III. Prevalent Service Rifles and Carbines: The QBZ-95 Era

Despite the rollout of the QBZ-191, the incumbent QBZ-95 family of bullpup rifles remains the most numerous and widely distributed weapon system in the PLA’s inventory. Its vast numbers ensure that it will continue to see service for at least another decade, particularly with second-line units, reserves, and the People’s Armed Police, as the PLA undertakes its phased modernization.

QBZ-95/95-1 Family (95/95-1式枪族, 95/95-1 Shì Qiāngzú, Type 95/95-1 Gun Family)

Introduced in the late 1990s to coincide with the handover of Hong Kong, the QBZ-95 was a radical departure for the PLA. It was a gas-operated, bullpup rifle chambered for the then-new, domestically developed 5.8x42mm DBP-87 cartridge. This move represented a major technological leap, transitioning the PLA from its lineage of 7.62x39mm Kalashnikov-derived platforms (the Type 56 and Type 81) to a proprietary design utilizing a modern small-caliber, high-velocity round. The bullpup configuration, placing the action and magazine behind the trigger, allowed for a full-length 18.2-inch barrel in an overall package shorter than many carbines, a significant advantage for mechanized infantry.

Around 2010, an upgraded version, the QBZ-95-1, was introduced. This model addressed some of the original’s ergonomic flaws, most notably by relocating the safety selector from the rear of the stock to a more accessible position above the pistol grip. It also featured a heavier barrel and was chambered for the improved DBP-10 ammunition, which used a heavier projectile for better long-range performance.

The rapid and expensive decision by the PLA to abandon the entire bullpup concept after only one major upgrade suggests that the perceived flaws of the QBZ-95 were not minor but fundamental to its design. The platform’s legacy is therefore complex. It should not be viewed simply as a failed rifle, but rather as a crucial and necessary transitional system. The QBZ-95 project achieved its primary strategic objective: it forced the Chinese defense industry to master modern rifle manufacturing techniques, including the use of engineering polymers, and successfully introduced a proprietary small-caliber cartridge, breaking the PLA’s long-standing dependence on Soviet calibers and designs. In this, it was an unqualified success. Its secondary goal, to be a world-class fighting rifle, was only partially met. The institutional flexibility demonstrated by the PLA and Norinco in critically evaluating their own flagship product and making the bold decision to replace it entirely is a sign of a mature and pragmatic military-industrial complex, one that prioritizes combat capability over institutional prestige.

- Variants in Service:

- QBZ-95/95-1: The standard rifle variant. For two decades, it has been the primary individual weapon of the PLAGF, PAP, and other branches.

- QBZ-95B/95B-1: A compact carbine version with a significantly shorter barrel. It has been used by special forces, vehicle crews, and naval boarding parties, but its utility was hampered by a severe muzzle blast, flash, and a significant reduction in projectile velocity and effective range.

- QJB-95/95-1: The Squad Automatic Weapon (SAW) variant. It is essentially a heavy-barreled version of the rifle, designed to be fed from a 75-round drum magazine. While providing more sustained fire capability than a standard rifle, it is not a true light machine gun. It is prone to overheating during prolonged firing and lacks the advantages of a quick-change barrel or a belt-feed system.

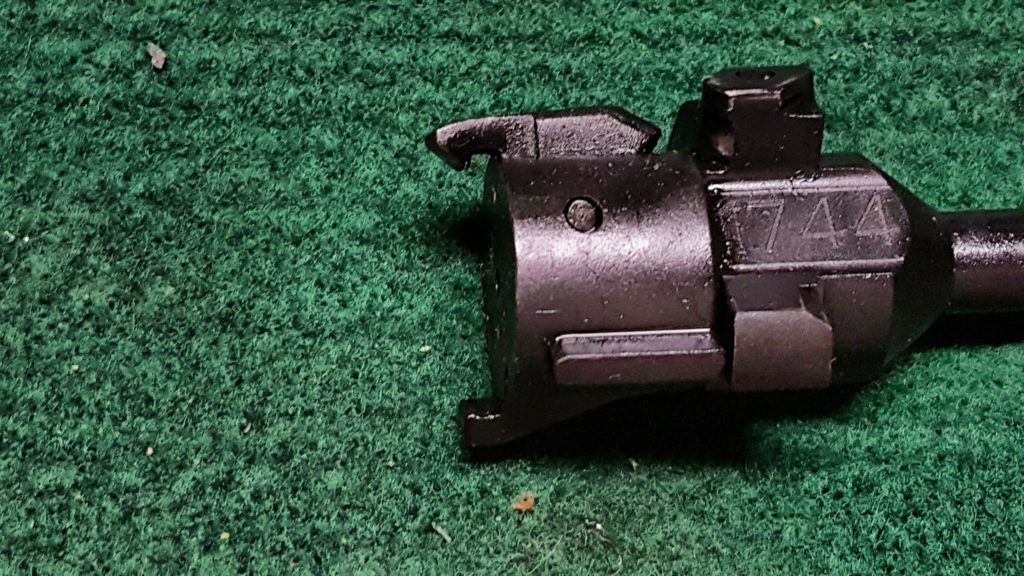

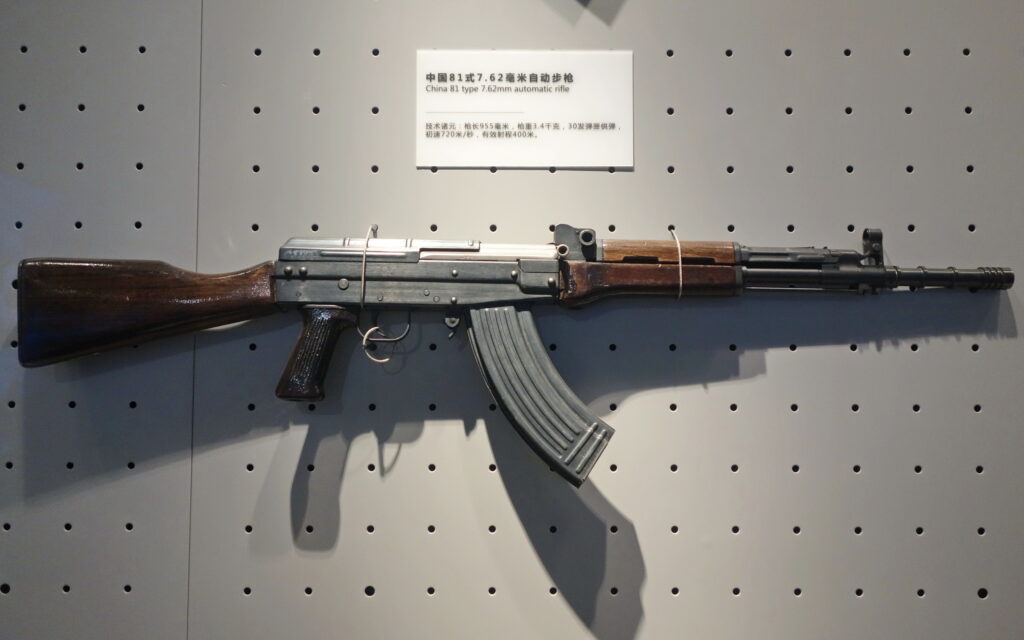

Legacy Systems in Reserve/Second-Line Service

The Type 81 (81式自动步枪, 81 Shì Zìdòng Bùqiāng) rifle, a 7.62x39mm weapon system, continues to serve with reserve formations, militia units, and some border defense forces. The Type 81, while visually resembling the Kalashnikov, is a distinct design featuring a short-stroke gas piston system (unlike the AK’s long-stroke piston), which contributed to its improved accuracy over the Type 56 (a direct Chinese copy of the AK-47). It is a robust, reliable, and simple weapon that remains effective for its intended role.

The continued presence of the Type 81 and the gradual displacement of the QBZ-95 is not an indication of logistical failure or economic hardship, but rather the product of a deliberate and cost-effective strategy of tiered modernization. Equipping the entirety of China’s massive armed forces—including millions of active duty personnel, PAP, and reservists—with the latest QBZ-191 system simultaneously is financially prohibitive and logistically unfeasible. Instead, the PLA employs a cascading procurement model. New QBZ-191 systems are fielded to high-readiness, frontline combat brigades. Their displaced QBZ-95-1 rifles are then refurbished and re-issued to second-line units, garrison troops, or the PAP. This pushes older but still serviceable weapons like the Type 81 further down the chain to reserve and militia units. This methodical approach maximizes the overall combat power of the force structure by ensuring that even lower-tier units receive upgraded equipment, all while managing the immense cost of a full-scale re-equipment program.

IV. Precision Fire Systems: From Marksman to Anti-Materiel

The PLA has made significant strides in developing and fielding a range of precision fire systems, recognizing the critical importance of engaging targets accurately at ranges beyond that of a standard service rifle. This capability area has evolved from rudimentary sniper rifles to a sophisticated ecosystem of designated marksman, bolt-action sniper, and heavy anti-materiel systems.

Designated Marksman Rifles (DMRs)

- QBU-191: As detailed previously, the QBU-191 is the PLA’s newest DMR and represents the future of squad-level precision fire. It is being fielded as an integral part of the new modular weapon family.

- QBU-88 (Type 88) (88式狙击步枪, 88 Shì Jūjí Bùqiāng, Type 88 Sniper Rifle): The QBU-88 was the PLA’s first purpose-built DMR, introduced alongside the QBZ-95 family. It is a semi-automatic, bullpup rifle chambered for the 5.8x42mm “heavy round” (a predecessor to the DBP-10). While officially designated a “sniper rifle,” its performance characteristics and intended role place it squarely in the DMR category. For its time, the QBU-88 was a revolutionary concept for the PLA, introducing the principle of a squad-level precision rifle. However, it is based on the QBZ-95 action and suffers from many of the same limitations, including poor ergonomics, a heavy trigger, and inadequate provisions for mounting modern optics. Its accuracy is considered adequate for its role but is surpassed by more modern designs. The QBU-88 is being actively replaced by the superior QBU-191.

Bolt-Action Sniper Rifles

- CS/LR4 (and variants): The CS/LR4 represents a significant departure in PLA small arms procurement philosophy. It is a modern, high-precision bolt-action sniper rifle system chambered in 7.62x51mm NATO. This system, used by PLAGF special operations forces and elite PAP counter-terrorism units like the Snow Leopard Commando Unit, is a direct equivalent to Western precision rifles like the Remington M24 or Accuracy International Arctic Warfare.

The adoption of a foreign, NATO-standard caliber for a premier sniper rifle is a highly revealing decision. It breaks with the PLA’s long-standing doctrine of logistical self-sufficiency and reliance on domestic calibers. This choice was not made lightly. It indicates that the performance requirements for high-precision, long-range sniping—specifically, consistent sub-Minute of Angle (MOA) accuracy—were so stringent that existing domestic cartridges, such as the 5.8mm or the legacy 7.62x54mmR, were deemed insufficient. The PLA’s ordnance experts and procurement officers made a pragmatic choice, recognizing that the global commercial and military ecosystem for high-quality, match-grade 7.62x51mm ammunition was far more mature and offered superior performance compared to any domestic equivalent. This prioritization of raw capability over logistical purity for a specialized, high-value role suggests a sophisticated, two-tiered approach to ammunition philosophy. For general-issue weapons, domestic calibers are paramount for strategic independence during a major conflict. For elite, special-purpose units where mission success hinges on the highest possible performance, they will adopt the best available global standard.

Anti-Materiel Rifles

- QBU-10 (10式大口径狙击步枪, 10 Shì Dàkǒujìng Jūjí Bùqiāng, Type 10 Large-Caliber Sniper Rifle): The QBU-10 is a semi-automatic anti-materiel rifle chambered in the powerful 12.7x108mm cartridge, the Eastern Bloc equivalent of the.50 BMG. This is a heavy, team-served weapon, typically deployed on a tripod or mounted on a vehicle. Its purpose is to engage and destroy high-value materiel targets at very long ranges (up to 1,500 meters), such as light armored vehicles, radar and communications equipment, parked aircraft, and enemy personnel behind substantial cover. A key feature of the QBU-10 system is its sophisticated, integrated day/night optic, which reportedly incorporates a laser rangefinder and a ballistic computer to aid the gunner in achieving first-round hits at extreme distances. This weapon provides PLA infantry units with an organic capability to defeat targets that would otherwise require dedicated anti-tank guided missiles or heavier fire support, making it a key asset for long-range interdiction and battlefield dominance.

V. Sidearms and Close-Quarters Systems

This category includes weapons designed for personal defense, urban combat, and special operations, where compactness, rate of fire, and specialized capabilities like sound suppression are paramount. Recent developments in this area show a clear trend towards standardization on globally accepted calibers.

Pistols (手枪, Shǒuqiāng)

- QSZ-92 (92式手枪, 92 Shì Shǒuqiāng, Type 92 Pistol): The QSZ-92 has been the standard service pistol for the PLA and PAP for over two decades. It is a polymer-framed, short-recoil-operated pistol. Uniquely, it was produced in two distinct caliber variants. The primary military version fires the proprietary 5.8x21mm DAP-92 armor-piercing cartridge, issued to officers and combat troops. A second version, chambered in the ubiquitous 9x19mm Parabellum, was produced primarily for PAP units and for export. The 5.8mm version was designed with the specific doctrinal goal of defeating enemy body armor, a concept shared by the Western FN 5.7x28mm. However, like its Western counterparts, the small-caliber pistol round concept has been widely criticized for having questionable terminal ballistics and stopping power against unarmored targets compared to larger, heavier conventional pistol rounds.

- QSZ-193 (193式手枪, 193 Shì Shǒuqiāng, Type 193 Pistol): The QSZ-193 is a new, compact, striker-fired pistol that has been observed in service with PLAAF pilots and special forces units. Crucially, it is chambered in 9x19mm Parabellum. The emergence of this new 9mm pistol as the apparent next-generation sidearm for specialized roles effectively signals the end of the PLA’s two-decade experiment with the 5.8x21mm pistol cartridge. The decision to standardize on the globally dominant 9x19mm caliber for its new sidearm indicates that the PLA has reached the same conclusion as many Western militaries: modern 9mm ammunition, particularly with advanced hollow-point or controlled-expansion projectiles, offers a superior overall balance of terminal performance, magazine capacity, and controllability, while the perceived advantage of armor penetration from small-caliber pistol rounds is marginal in most real-world scenarios.

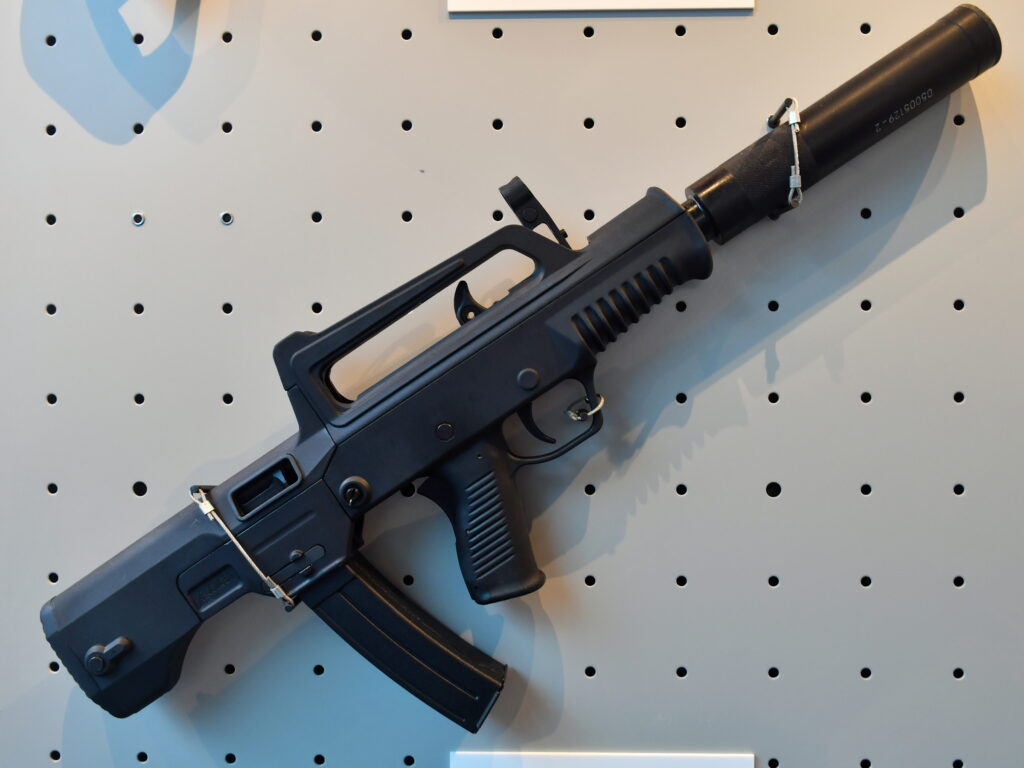

Submachine Guns (冲锋枪, Chōngfēngqiāng)

- QCQ-171 (171式冲锋枪, 171 Shì Chōngfēngqiāng, Type 171 Submachine Gun): A modern, lightweight submachine gun (SMG) chambered in 9x19mm, the QCQ-171 is being issued to special operations forces and other units with a specific requirement for a compact, high-rate-of-fire weapon for close-quarters combat. It features a telescopic stock, accessory rails for optics and lights, and appears to be a direct competitor to Western designs like the Heckler & Koch MP5 or B&T APC9.

- QCW-05 (05式轻型冲锋枪, 05 Shì Qīngxíng Chōngfēngqiāng, Type 05 Light Submachine Gun): The QCW-05 is a unique bullpup SMG chambered in the proprietary 5.8x21mm pistol cartridge. Its most notable feature is its large, integral sound suppressor, which makes the weapon very quiet. It is fed from a 50-round, four-column “quad-stack” magazine located in the pistol grip. While effective in its niche role for stealth operations, it suffers from the same ballistic limitations as the QSZ-92 pistol in the same caliber. Its use is primarily confined to PLA special forces and PAP counter-terrorism units. The fielding of the 9mm QCQ-171 in many frontline SOF roles further reinforces the PLA’s strategic move away from the 5.8x21mm cartridge ecosystem.

VI. Crew-Served and Support Weapons

These weapons provide sustained fire support at the platoon and company level, giving infantry units the ability to suppress and destroy enemy positions and light vehicles. This category includes machine guns and automatic grenade launchers.

Machine Guns (机枪, Jīqiāng)

- QJY-88 (88式通用机枪, 88 Shì Tōngyòng Jīqiāng, Type 88 General Purpose Machine Gun): The QJY-88 was developed as the PLA’s first true General Purpose Machine Gun (GPMG), intended to be fired from a bipod in the light machine gun role or from a tripod in the sustained-fire medium machine gun role. It was designed to replace the aging 7.62x54mmR Type 67 machine gun. However, in a highly unusual design choice, the QJY-88 was chambered in the 5.8x42mm “heavy round”. This decision represents a rare doctrinal mismatch in PLA weapon development. The GPMG concept, epitomized by the German MG3, the American M240, and the Russian PKM, is predicated on the use of a full-power rifle cartridge (e.g., 7.62x51mm or 7.62x54mmR). These powerful rounds are essential for providing effective, long-range suppressive fire and for penetrating cover, light vehicles, and field fortifications. By chambering their GPMG in an intermediate cartridge, even a heavy-for-caliber one, the PLA created a weapon that lacked a significant performance advantage in range and barrier penetration over a modern squad automatic weapon, yet was heavier and more cumbersome. The weapon has been widely criticized as being underpowered for its intended role, and the notable lack of a clear successor suggests that the PLA is re-evaluating its entire machine gun doctrine.

- QJZ-89 (89式重机枪, 89 Shì Zhòng Jīqiāng, Type 89 Heavy Machine Gun): The QJZ-89 is the PLA’s standard heavy machine gun (HMG), chambered in 12.7x108mm. Its most remarkable feature is its exceptionally low weight. At approximately 26 kg (57 lbs) for the gun and tripod combined, it is the lightest HMG in service anywhere in the world, weighing significantly less than the American M2 Browning or the Russian Kord. This light weight is achieved through the use of advanced alloys and a hybrid direct-impingement/short-stroke piston operating system. This makes it more man-portable than its peers, allowing infantry units to reposition it on the battlefield more rapidly. It is used in both tripod-mounted infantry support roles and as a primary or secondary armament on a wide variety of PLA vehicles.

Automatic Grenade Launchers (榴弹发射器, Liúdàn Fāshèqì)

- QLZ-87/11 (87/11式榴弹发射器, 87/11 Shì Liúdàn Fāshèqì, Type 87/11 Grenade Launcher): The QLZ-87 is a 35mm automatic grenade launcher (AGL) that provides devastating anti-personnel and light anti-materiel fire support for infantry units. It is a selectively-fired weapon that can be fired from an integral bipod in a direct-fire role or from a tripod for indirect fire. It is fed from 6- or 15-round drum magazines. The newer QLZ-11 is a lightened and improved version of the design. The 35mm grenades provide a significant area-effect capability, allowing a small infantry unit to suppress and neutralize enemy troops in trenches, behind cover, or in the open at ranges out to 1,700 meters.

VII. Armament by Service Branch: A Comparative Analysis

While there is increasing standardization around the new QBZ-191 family, the specific small arms loadouts vary between the different branches of China’s armed forces, reflecting their unique operational requirements and mission sets.

PLA Ground Force (PLAGF) (中国人民解放军陆军, Zhōngguó Rénmín Jiěfàngjūn Lùjūn)

- Standard Infantry: The PLAGF’s frontline combined arms brigades are at the forefront of the modernization effort. Standard infantry squads are actively transitioning from the QBZ-95-1 to the new QBZ-191 as their primary service rifle. A typical squad will be augmented with the QBU-191 for designated marksman duties and the new belt-fed QJB-201 as the squad’s light machine gun. Officers and vehicle crews are typically issued the QSZ-92 pistol for personal defense. Second-line and garrison units will continue to operate the QBZ-95-1 for the foreseeable future.

- Special Operations Forces (SOF): PLAGF special forces are among the first to receive the full suite of new-generation weapons. They are likely to be fully equipped with the compact QBZ-192 carbine for its maneuverability in direct action missions. Their specialized inventory also includes the high-precision CS/LR4 bolt-action sniper rifle for long-range engagements and the new 9mm QCQ-171 SMG for suppressed, close-quarters operations.

PLA Navy (PLAN) (中国人民解放军海军, Zhōngguó Rénmín Jiěfàngjūn Hǎijūn)

- Marines (海军陆战队, Hǎijūn Lùzhànduì): As an elite expeditionary force analogous to the USMC, the PLAN Marine Corps is receiving the QBZ-191 family concurrently with the PLAGF’s frontline units. Given their focus on amphibious assault, littoral operations, and potential urban warfare scenarios, the compact QBZ-192 carbine is expected to be a common issue weapon alongside the standard QBZ-191 rifle.

- Shipboard Personnel: For general security, anti-piracy, and visit, board, search, and seizure (VBSS) operations, compactness is the key driver of weapon selection. Personnel were historically armed with the QBZ-95B carbine, but are now likely transitioning to the superior QBZ-192 carbine. The QSZ-92 pistol remains the standard sidearm.

PLA Air Force (PLAAF) (中国人民解放军空军, Zhōngguó Rénmín Jiěfàngjūn Kōngjūn)

- Base Security/Ground Personnel: PLAAF ground personnel, such as those in airfield security units, are typically equipped with standard infantry rifles. They currently operate the QBZ-95-1 and will likely be among the later recipients of the QBZ-191 as production ramps up.

- Pilots: Aircrew are issued compact weapons for survival and self-defense in the event of an ejection over hostile territory. This role was historically filled by machine pistols like the Type 80, but is now transitioning to the new, more reliable, and compact QSZ-193 pistol in 9x19mm.

People’s Armed Police (PAP) (中国人民武装警察部队, Zhōngguó Rénmín Wǔzhuāng Jǐngchá Bùduì)

The PAP is a massive paramilitary force responsible for internal security, counter-terrorism, and border control. Its armament reflects this dual law enforcement and military role.

- Internal Security Units: The vast majority of PAP units, tasked with roles like riot control and guarding critical infrastructure, widely use the QBZ-95-1 rifle and the QSZ-92 pistol (often the 9mm version).

- Counter-Terrorism Units: Elite PAP units, such as the Beijing-based Snow Leopard Commando Unit and various regional special police units, maintain a diverse and highly specialized inventory. Their requirements overlap significantly with military SOF but with a greater emphasis on surgical urban operations. They utilize the CS/LR4 sniper rifle for precision hostage rescue shots, both the integrally suppressed 5.8mm QCW-05 and the new 9mm QCQ-171 SMGs for close-quarters battle, and specialized tactical shotguns like the QBS-09 (09式军用霰弹枪, 09 Shì Jūnyòng Xiàndànqiāng, Type 09 Military Shotgun).

China Coast Guard (CCG) (中国海警局, Zhōngguó Hǎijǐng Jú)

As a paramilitary maritime law enforcement agency, the CCG’s armament is more standardized and focused on its mission set. Boarding teams are typically equipped with compact weapons suitable for use on ships, primarily the QBZ-95B carbine and the QSZ-92 pistol. Their cutters and larger vessels are armed with deck-mounted heavy machine guns and autocannons.

VIII. Concluding Analysis: Industrial Capacity and Future Trajectory

The ongoing modernization of the PLA’s small arms inventory reveals several key strategic trends and provides a clear indication of the capabilities of China’s domestic defense industry. The trajectory points towards a force that is rapidly closing the technological and doctrinal gap with leading Western militaries at the level of the individual soldier.

The analysis synthesizes four dominant trends. First is the primacy of modularity and optics integration, exemplified by the QBZ-191’s conventional layout and full-length Picatinny rail. Second is the shift towards a holistic, systems-based design approach, where the rifle, cartridge (DBP-191), and optic (QMK-191) are developed concurrently as an optimized package. Third is the pragmatic adoption of international standards, such as the MIL-STD-1913 rail and the 9x19mm pistol caliber, when they offer a clear performance advantage over proprietary solutions. Fourth is the implementation of a deliberate, cost-effective, tiered modernization strategy that maximizes the combat power of the entire force structure during a prolonged transition period.

The development and mass production of the QBZ-191 family is a testament to the maturity of China’s state-owned defense industry, primarily represented by the corporate giant Norinco. It demonstrates a sophisticated capability for rapid, clean-sheet design, the use of modern materials and manufacturing methods (such as advanced polymers for furniture and aluminum forgings and extrusions for receivers), and the large-scale production and integration of complex electro-optics. The ability to identify the doctrinal shortcomings of a previous flagship system (QBZ-95) and execute a complete and rapid course correction speaks to an agile and capability-focused industrial base.

Looking forward, the full replacement of the QBZ-95 family in all frontline PLAGF and PLAN Marine Corps units is likely to be completed within the next 5-10 years. Future development will likely focus on addressing remaining gaps in the PLA’s small arms portfolio. A high-priority area will likely be the development of a new GPMG, probably chambered in a full-power cartridge, to rectify the doctrinal and performance shortcomings of the 5.8mm QJY-88. Furthermore, the PLA will almost certainly continue the trend of integrating “smart” technologies into the infantry weapon system, including networked sights that can share data, integrated command and control links, and other technologies that further embed the individual soldier into a digital battlefield network. The overall trajectory is clear: China is committed to equipping its infantry with small arms systems that are not merely sufficient, but are technologically on par with, and in some cases potentially superior to, those of any potential adversary.

IX. Appendix: Comprehensive Small Arms Summary Table

The following table provides a consolidated, at-a-glance reference for the primary small arms systems currently in service with the armed forces of the People’s Republic of China.

| Category | Chinese Designation (Hanzi) | Pinyin Romanization | U.S. English Name/Translation | Manufacturer | Caliber | Operating Principle | Weight (Unloaded) | Overall Length | Primary Users |

| Service Rifle | 191式自动步枪 | 191 Shì Zìdòng Bùqiāng | Type 191 Automatic Rifle | Norinco State Arsenals | 5.8x42mm DBP-191 | Short-stroke gas piston, rotating bolt | ~3.25 kg | ~950 mm (stock extended) | PLAGF, PLAN Marines |

| Carbine | 192式短自动步枪 | 192 Shì Duǎn Zìdòng Bùqiāng | Type 192 Short Automatic Rifle | Norinco State Arsenals | 5.8x42mm DBP-191 | Short-stroke gas piston, rotating bolt | ~3.0 kg | ~810 mm (stock extended) | SOF, Vehicle Crews, PLAN |

| Service Rifle | 95-1式自动步枪 | 95-1 Shì Zìdòng Bùqiāng | Type 95-1 Automatic Rifle | Norinco State Arsenals | 5.8x42mm DBP-10 | Short-stroke gas piston, rotating bolt | 3.25 kg | 745 mm | PLAGF, PAP, PLAN, PLAAF |

| Legacy Rifle | 81式自动步枪 | 81 Shì Zìdòng Bùqiāng | Type 81 Automatic Rifle | Norinco State Arsenals | 7.62x39mm | Short-stroke gas piston, rotating bolt | 3.4 kg | 955 mm (fixed stock) | PLA Reserve, Militia |

| Pistol | 92式手枪 | 92 Shì Shǒuqiāng | Type 92 Pistol | Norinco State Arsenals | 5.8x21mm / 9x19mm | Short recoil, rotating barrel | 0.76 kg | 190 mm | PLA, PAP |

| Pistol | 193式手枪 | 193 Shì Shǒuqiāng | Type 193 Pistol | Norinco State Arsenals | 9x19mm | Short recoil, striker-fired | N/A (Compact) | N/A (Compact) | PLAAF Pilots, SOF |

| SMG | 171式冲锋枪 | 171 Shì Chōngfēngqiāng | Type 171 Submachine Gun | Norinco State Arsenals | 9x19mm | Blowback | ~2.8 kg | ~690 mm (stock extended) | SOF, PAP |

| SMG | 05式轻型冲锋枪 | 05 Shì Qīngxíng Chōngfēngqiāng | Type 05 Light Submachine Gun | Norinco State Arsenals | 5.8x21mm | Blowback, integrally suppressed | 2.2 kg | 500 mm | SOF, PAP |

| DMR | 191式精确射手步枪 | 191 Shì Jīngquè Shèshǒu Bùqiāng | Type 191 Precision Marksman Rifle | Norinco State Arsenals | 5.8x42mm DBP-191 | Short-stroke gas piston, rotating bolt | ~4.5 kg (est.) | ~1100 mm (est.) | PLAGF, PLAN Marines |

| DMR | 88式狙击步枪 | 88 Shì Jūjí Bùqiāng | Type 88 Sniper Rifle | Norinco State Arsenals | 5.8x42mm (Heavy) | Short-stroke gas piston, rotating bolt | 4.1 kg | 920 mm | PLAGF, PAP |

| Sniper Rifle | CS/LR4 | CS/LR4 | CS/LR4 High-Precision Sniper Rifle | Norinco State Arsenals | 7.62x51mm NATO | Bolt-action | 6.5 kg | 1100 mm | PLAGF SOF, PAP CTU |

| Anti-Materiel | 10式大口径狙击步枪 | 10 Shì Dàkǒujìng Jūjí Bùqiāng | Type 10 Large-Caliber Sniper Rifle | Norinco State Arsenals | 12.7x108mm | Gas-operated, semi-automatic | 13.3 kg | 1380 mm | PLAGF |

| LMG | 201式班用机枪 | 201 Shì Bānyòng Jīqiāng | Type 201 Squad Machine Gun | Norinco State Arsenals | 5.8x42mm DBP-191 | Gas-operated, belt-fed | < 5 kg (est.) | N/A | PLAGF |

| SAW | 95-1式班用机枪 | 95-1 Shì Bānyòng Jīqiāng | Type 95-1 Squad Machine Gun | Norinco State Arsenals | 5.8x42mm DBP-10 | Short-stroke gas piston, rotating bolt | 3.95 kg | 840 mm | PLAGF, PAP |

| GPMG | 88式通用机枪 | 88 Shì Tōngyòng Jīqiāng | Type 88 General Purpose Machine Gun | Norinco State Arsenals | 5.8x42mm (Heavy) | Gas-operated, belt-fed | 11.8 kg (gun & bipod) | 1150 mm | PLAGF |

| HMG | 89式重机枪 | 89 Shì Zhòng Jīqiāng | Type 89 Heavy Machine Gun | Norinco State Arsenals | 12.7x108mm | Gas-operated, belt-fed | 17.5 kg (gun only) | 1192 mm | PLAGF |

| AGL | 87/11式榴弹发射器 | 87/11 Shì Liúdàn Fāshèqì | Type 87/11 Grenade Launcher | Norinco State Arsenals | 35x32mmSR | Blowback, semi/full auto | 12 kg (gun & bipod) | 970 mm | PLAGF |

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, we are only paid if there is an affiliate program such as Avantlink, Impact, Amazon and eBay and only if you purchase something. If you’d like to directly contribute towards our continued reporting, please visit our funding page.