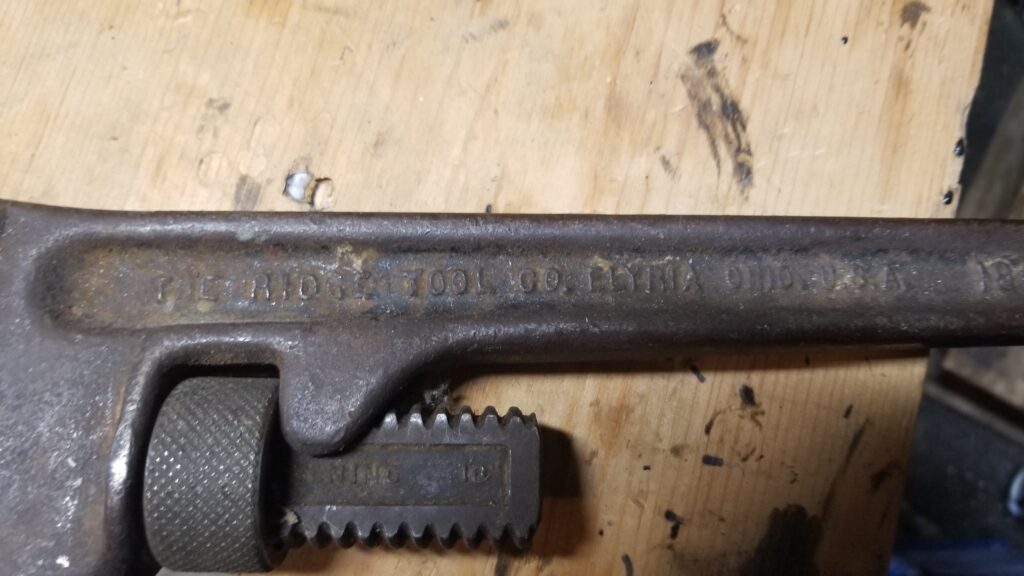

In the last post I told you about removing the rust from the old Ridgid pipe wrench using a solution of apple cider and Prep-N-Ethc. Now we’ll go over painting it. I considered three options – using a durable bake on weapons paint, a spray on epoxy paint or a basic spray paint. I went with the latter simply to save money. It just so happened that I had cans of Fusion All-In-One Gloss Red Pepper and Satin Black Krylon in stock. All-in-one meaning it contained both the primer and the paint.

What is Krylon?

Krylon is an acrylic laquer and not an enamel. In case you are wondering about the unique name, it comes from the founder’s first two letters of his last name – Krester – and that he was so impressed by Dupont’s discovery of nylon that he dropped the “n” and called his paint Krylon. This was a marketing move because he’d developed the basic formula in 1947 and nylon was introduced shortly after.

I like Krylon because it dries fast. I hate waiting for Rustoleum to dry and that pushes me in the direction of Krylon. With that said, Rustoleum’s enamel paint tends to be more durable. If I had it in stock, I would have used Rustoleum and baked it on.

Applying The Krylon

I took the wrench, disassembled it again and sprayed everything down again with brake cleaner to make sure there wasn’t any oil. A side benefit of acid rust removal is that it does acid etching of the surface as well creating little pockets/surface imperfection all over that give an excellent surface for finishes to adhere to.

When spray painting, you need to be patient. You build up to the final color you want by spraying successive coats of paint. Follow the directions for drying time per coat and the maximum time to wait to apply the next coat.

Because I acid etched the surface, I didn’t apply a primer plus Krylon’s Fusion series claims to have some primer in it. I noticed on the can they still recommended primer for a bare metal but I skipped that. I typically waited 15-20 minutes between light coats based on the instructions on the can. Light coats reduces the risk of runs and making a mess.

Be sure to let the paint have plenty of time to set before you turn it over. Either wait until just before the maximum time before next coats or you will need to wait until the first side fully cures. I would rather try and do it together to get the best adhesion that I can. If it fully cures then you either get a less than ideal bond or you have to scuff it. Some folks will hang their parts to avoid some of this.

So, I put the parts in my curing oven for a couple of hours at 175F to help stuff dry fully and let it sit overnight before reassembly. With enamel, a lot of folks say that baking helps. I don’t think it makes a big difference with Krylon but I do know that it pays to let parts have the full time to cure based on the instructions on the can. If they say 24 hours, give it 24 hours. I’ve ruined a ton of paint jobs being in a rush.

So here is the refinished wrench:

Conclusion

Well, it was interesting to learn about Ridgid and to bring some color back to the old wrench. I’ve already used this to tighten a pipe since I tool the photo. The paint did come right off the jaw as I knew it would but I’ll definitely be using it more in the future and remembering my dad and grandpa who passed it down.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, we are only paid if there is an affiliate program such as Avantlink, Impact, Amazon and eBay and only if you purchase something. If you’d like to directly contribute towards our continued reporting, please visit our funding page.