In the first post I told you about the buying the SpitJack rotisserie system. I told my wife we better cook a test pig because I didn’t want the picnic the day after the wedding to be my first time cooking a pig. She agreed we better cook a test pig and we decided on July 1st.

The first thing I had to figure out was where to buy one. I’d read you can often get them at Hispanic groceries and while we tried, there was a big language barrier so we decided to keep searching. One of my best friends, John, recommended I try a local butcher shop down in Buchanan, Michigan, named Lowery’s Meat and Grocery. I talked to a great lady named Wanda who patiently answered my questions and offered up advice. Whatever size pig I ordered was the minimum weight and I would pay for the final weigh when I picked it up.

We settled on a 60 pound pig at $2.99/pound to be picked up on Friday, June 30. It would be a freshly slaughtered pig and I would need to put a deposit down two weeks before. “Cool” I thought and we made the 22 mile drive and paid our deposit. We knew where the store was but had never gone despite living in the area for almost 30 years.

As time got closer, my wife realized we had invited a lot of people and maybe we better bump the pig up to 70 pounds. I called Lowery’s, talked to Wanda again and if I ordered a 75 pound pig I would get a discount and it would be about $2.74/pound but the pig would likely be at least 8 pounds as they were having problems finding smaller pigs. “Ok – cool” I told her.

What is the recipe for lechon?

To keep the timeframe somewhat right, let’s switch gears to the recipe. My wife and I watched videos on Youtube, read blog posts and recipe websights about how to do lechon. It dawned on us that the recipe depends on the family – even the individual. Like so many recipes it can vary tremendously – one family will add hot peppers to the stuffing and another will not. One will use banana leaves and another will not, etc. There are no measures because it depends on the size of the pig, how firmly you stuff it, what ingredients you prefer, the ratios you prefer, and so forth.

We knew our pig was going to have a pretty big cavity to stuff but really had no idea for sure so we bought extra of everything. Here is our list for the stuffing:

- Coarse salt

- Bay leaves

- Black pepper

- Garlic

- Green Onions

- We put in fennel but will not do so again

- Lemon grass – it looks like thich stalks of green onion and has a slight lemon smell but without the acid taste of the citrus fruit

- Shallots

- Banana Leaves

- Sinigang Mix – this is a tamarind soup mix and two popular brands are Mama Sita and Knorr. We used Mama Sita.

What to baste with was all over the board as well – evaporated milk, canola oil, olive oil, drippings, and even Sprite. Well, we figured we would rub the skin with salt and maybe some drippings.

Charcoal

This is something you are going to need a lot of. I was told to plan at least a pound of charcoal per pound of pig and have 20 pounds just in case. So, an 80 pound pig would take 80 pounds of charcoal plus 20 pounds just in case is 100 pounds. Well, I went to Sam’s club and bought 120 pounds of Kingsford hardwood charcoal.

Over the coarse of a week I also made about 40-60 pounds of charcoal from our own wood supply. I’d put 2-4″ logs in my smoker, get it good and hot and then close the dampners and smother the fire. I’d let it sit and then scoop out the big chunks and dispose of the ash and tiny stuff.

This means your’s truly had at least 160-ish pounds of charcoal on hand because I didn’t want to run out while cooking. I also figured I could use whatever was left over when we cooked the wedding pig in October.

By the way, a caution I read that makes total sense that I will pass on to you is to not get any of the match light charcoals. They have a fuel impregnated in the charcoal and will pass the taste on to the meat – only use all wood charcoal.

By the way, my youngest daughter’s boyfriend also hooked me up with a bunch of dried cherry wood that I cut into small discs/chunks and put in water on the 30th to let it soak so I could add it on the charcoal for more taste. In general, the trees we cut are oak and maple and they make great for great grilling.

June 30th arrived

Okay, Jeff Lowery, the owner of Lower’s called and told me the freshly slaughtered pigs had arrived and they were all over 100 pounds. “Holy shit” I thought. “So much for starting small and learning”.

My wife, eldest daughter and I drove my truck down there. I had bought a body bag off Amazon to put the pig in and ice to keep it cold. I also had a few tarps to throw over it to help insulate and keep it cool.

A really nice fellow helped me take it out to my truck, slide it in the body bag and put it in the truck. I was really surprised how stiff the pig was. We poured in the ice, put the tarps on and drove home.

We took the ice bags out of the body bag and carried it into our kitchen where it spent the night on our big kitchen island with all of the ice bag in the bag and covered with towels. It was nice and cold – no worries there,

We cut up the vegetables for the stuffing as we knew we were looking at close to 12 hours of cooking and we got everything ready that we could. Repeated advice, that I will pass along because I can tell you it is critical, is to prep everything you can the day before.

July First Arrived

My wife is a night owl and had stayed up until almost 3 AM cutting the vegetables and getting stuff ready. I got up at 4:30 and read messages from her about some last minute stuff I needed to buy at the 24 hour grocery, which I did with coffee on hand.

I woke up my brother-in-law, Banduy, a tad after 5am to help me. He and his wife and come down from Toronto and, like me, he loves to cook. He has a natural gift for it.

So, we take the pig in the body bag out to the picnic table in the yard near the grilling area to attach it to the spit and stuff it. Now this is where things went sideways.

Remember how I said the pig was stiff? We cut open the plastic wrapping and the porker was frozen. I had a serious WTF? moment. We didn’t have time to thaw it but what choice did we have. We took a hose and just started hosing it down. In fact, that is what we did for the next three and a half hours. I was not a happy camper. My wife started contacting guests and telling them we wouldn’t be beating until closer to 7pm and that was a best guess.

Luckily running cold water is far more efficient at thawing than air alone – something like 9 times morre efficient if I recall right. At any rate, at about three and a half hours we attached the pig to the pole as best we could.

Attaching an animal to the spit is known as “trussing” and there are tons of ways to do it. We were supposed to be able to use some nice 5.5″ stainless U-bolts that came with the system to clamp the spine to the spit but they were too short. Well crap, another lesson – bigger pigs need bigger clamps. SpitJack sells 7.5″ U-bolts and I would recommend them. You can’t adequately secure pig without them. We did use one long threaded rod that came with the system to help secure it but it wasn’t enough. If we had two threaded rods it would have been better.

One of the interesting parts of the SpitJack is a shackle system for securing the back legs so they are splayed out. The front legs are secured to the snout via a large hose clamp. Now we ran into another issue, With the legs outstretched the pig was longer than the cooking area. We decided to amputate the pig’s rear legs at the knee to make it shorter.

Given the size of the pig, we did install the recommended counter weight opposte of the bulk of the pig and moved the weight out as far as it would go on its retainer rod. This would help balance the load when properly trussed.

As we were trussing as best we could with what we had, we discovered the pig was a bit rear biased towards the motor. This is not a problem from a turning perspective but if we had looked a tad more carefully we may not have needed to cut the rear legs off below the knee. We were in a rush and just overlooked the bias. Lesson learned – center the pig on the spit, step back and look at it before you start trussing.

SkipJack gives you a spool of butcher’s twine and a giant needle. Banduy was a doctor years ago and had a ton of experience suturing. He stuffed the pig with the ingredients and then sutured it shut. I joking told him the pig wouldn’t have a scar he did such a good job!

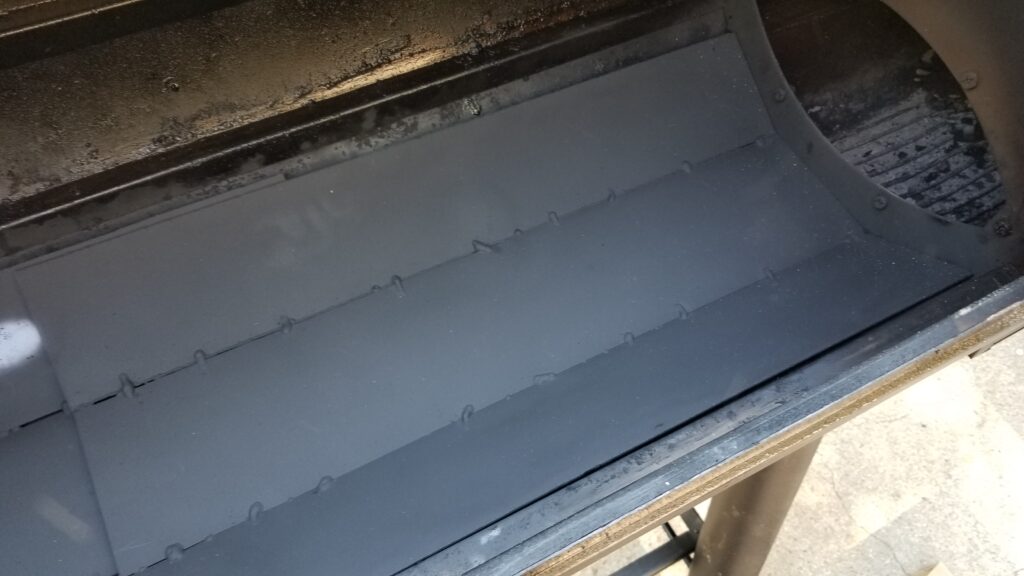

As he was stuffing the pig, I started the charcoal and let it get good and hot. I had an old landscaping rake for moving the coals around. The pig cooks from indirect heat from the sides – you don’t put them right under the pig or you will constantly be fighting flaring flames as dripping fats ignite.

The SkipJack XB85 comes with one dual zone thermometer and we bought a second. They report to you the heat from the coals that is reaching the surface of the pig and the internal heat of the meat like a regular meat probe does. We stuck one on the thick shoulder and one in the rump. They are totally worth it.

The big carcass weighed 101 pounds and with the stuffing and trussing I guessed it was pushing somewhere around 110-115 pounds. I knew there was no way we could safely attach the motor over the fire so we attached the motor to the spit. I did have to turn it off and on a few times to bump it around so the coupler would like up with the spit attached to the heavy pig.

We then carried the whole thing over – pig and motor to the jack stands over the fire, Holy crap was it hot. We decided going forward we would move the stands and everything to the side before we changed anything vs. trying to work on them close to the coals.

Cooking the pig

We turned on the power and the pig started rotating. As the bulk of the pig passed over the top it would shift slightly because it wasn’t adequately trussed. Oh man – what to do?

I had some really thick steel wire – maybe 1/8″ or thicker in the shop and thought maybe it would work. Some guys use chicken wire to secure their pig. So, we lifted the whole rostterie system off the coals and set it down to the side. We had high temp barbeque gloves so we could hold the hot metal. It was a three person job. Two people moved the pig, spit and stands and the third made sure everything lined up as we set it back down.

After some trial and error I found that I could put the wire on the pig, twist it down lightly and then use my big linesman’s pliers to twist the wire and form a jig or step about 3/4ths of an inch and what that did was take up some of the loose wire and make it tighter and tigher, So, after adding 4-5 of these impromptu bands on the pig, we put everything back. Also, to make sure the jack stands didn’t move we put a 25-40 pound patio block on the legs for each stand.

From here we started the long cooking process. You’ll hear guys say “low and slow” and I now know what they mean. The pig cooks over a low heat for a long time. I got the fire too hot at one point and burned some of the skin that we scraped off. The goal is to hit 160F internally – that is the target temperature recommended by the FDA for food safety. You don’t need an insane amount of heat – somewhere between 160 and 200F is fine. You can’t rush it.

We did experiment with the height a bit. You need to be about 8″ off the coals. We also moved two windshields around to block the breeze.

What was driving me nuts was that maybe a couple of hours in the thermometers still hadn’t moved off their minimum low-end pegged position. Were they broken? I went and got another basic meat thermometer from our kitched and shoved it into the shoulder – same thing. You know what? We had thawed most of the pig but not down deep in the thick shoulders and rump. Well, shit. It was what it was.

Around 10am I called Lowery’s and spoke to the owner, Jeff, and told him what happened. I could hear him shout out to someone named “Nate” and asked him if the pigs that were supposed to arrive fresh were instead frozen and I could hear Nate confirm they were. Jeff apologized profusely and gave me a discount. I really appreciated that.

Back to the cooking – the pig actually shrunk dramatically as the fat between the skin and the muscle cooked and dripped off. We had to tighten the fasteners 2-3 times over the hours it cooked. Any hope I had of nice crispy lechon skin disappeared as the wire cut up the skin.

BTW, we did trying using Sprite for basting towards the end and it seemed to burn. So, while some may use it – we will not next time. I think we’ll stick with salt and oil to start and switch to drippings as we collectt enough.

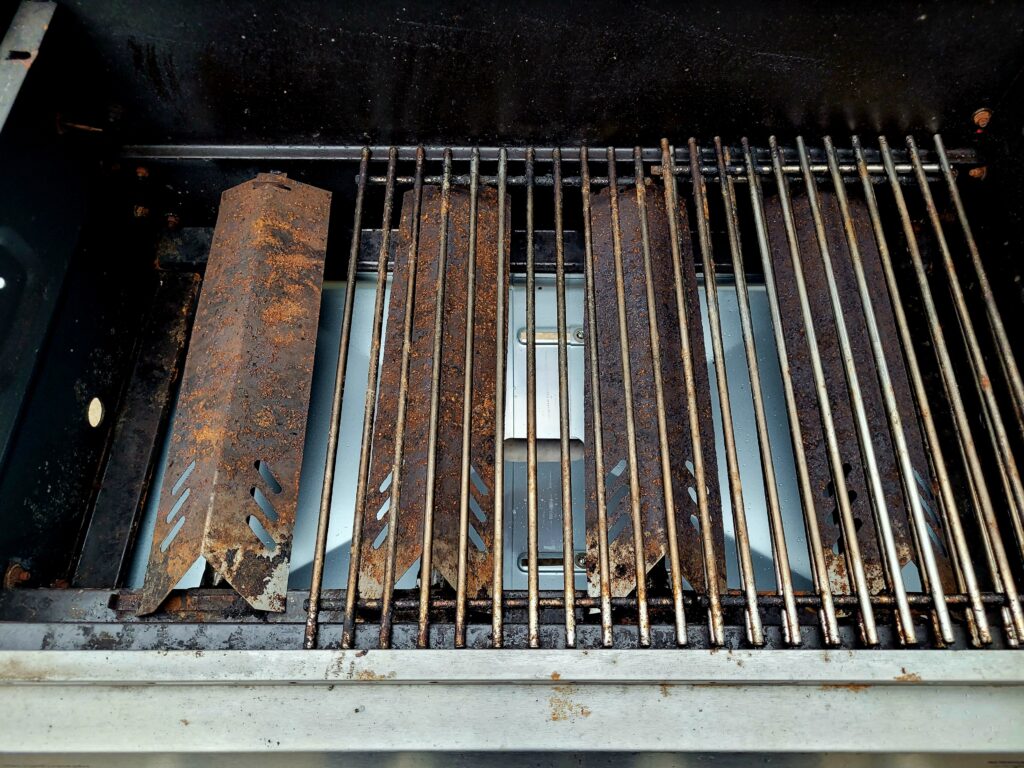

We cooked the pig for over 10 hours and then decided to pull it from the spit and anybody with rare meat who wanted it cooked more we would grill it the rest of the way on my CharGriller wood grill. So, with high temp gloves on, we carried it over to the picnic table and Banduy started carving off the meat and 90-95% of it was cooked all the way. The deepest parts of the shoulder and rump were the only ones that were rare so we set them to the side.

People were very happy with the results. The meat was moist and delicious. So, from a 101 pound pig, let’s say we got 50 pounds of meat. We only had about 10 pounds left when everyone went home for the night – some with to-go plates. Banduy then made a traditional stew from the rare meat and leftovers called “packsiw” that was absolutely delicious.

So, the day started out stressful but Banduy and I actually had a great time – I couldn’t have done it without him. I really did learn a ton and he said he did too – there are more things he wants to prepare in advance such as the lechon sauce. Both he and I are ready to tackle the wedding picnic pig now.

Lessons learned

Here is what I learned from doing this first pig:

- First and foremost, inspect your pig and confirm whether it is frozen or not despite what the seller says. I feel pretty stupid on this one. The pig was stiff when we loaded it and I thought it was just the way they were. If we had known it was frozen we could have used cold water to thaw it overnight all of the way. A big chunk of my confusion and adding more heat than I needed stemmed from the pig being frozen in the deepest parts of its shoulders and rump.

- Prepping all of the vegetables and stuffing ingredients the night before really helped.

- The tip I was given to get a body bag off of Amazon worked amazingly well. Having the ice and towels, everything stayed cold which is ironic given it was mostly frozen. In hindsight we could have run a hose into the body bag and mostly sealed it so the water could circulate but ruin out thaw it overnight had we known.

- Center the pig on the spit before you start clamping it.

- Make sure you have the right size of clamps for your size of pig. The longer U-bolts or one or two more long clamping bolts would have done the trick.

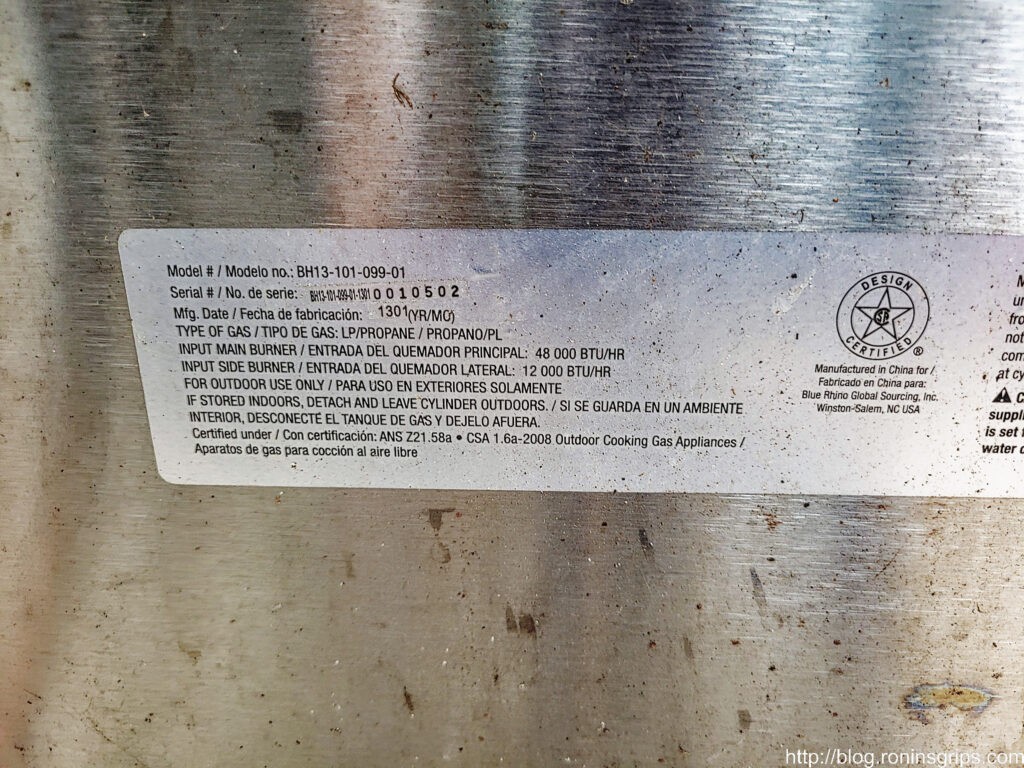

- We bought the CXB85 SpitJack and upgraded the spit and motor to save money. We should have bought the CXB125 to get the longer U-bolts and threaded rods. If you think you are going to do a pig that might be 100-124 pounds – get the CXB125. Bigger than that and you will need to get one of semi-custom or custom trailer from what I saw.

- Do not try and rush things – you will only burn the skin. Towards the end, we raked the coals to the front and end of the fire tray / charcoal tray to concentrate the heat on the rump and the shoulders.

- As the pig cooks it shrinks so the various clamps will need to be tightened down periodically.

- I think I will either get some cinder blocks or sheet metal to make side walls so we can capture more of the heat and direct it to towards the pig. We had a large heat shield and a smaller one that I made out of left over steel but they weren’t enough.

- We used all of the home made charcoal and were on our last bag of the commercial charcoal. That means we used 120-140 pounds of charcoal. Note – the walls would have reduced that plus I wasted some making the fire too hot for a while but that is quite a bit of charcoal regardless.

- We had two pair of high-temperature barbecue gloves that can be used for meat – they are some form of insulated rubber and allowed us to move things around. Due to the coating you can actually safely handle hot meat and was very happy we had them for moving the relatively hot spit around.

- I need to learn the practice of “low and slow”. Getting frustrated that it wasn’t heating faster caused me to add charcoal and I should have just rode it out. Again, next time I will be sure to check out the pig and decide what to do if it is frozen or thawed/fresh.

Summary

Doing a test pig vs. cooking one for the first time at the wedding picnic was very much worth it. I would have hated to run into the above issues for the first time with a ton of people waiting. The SpitJack system worked without a flaw – the sizing issue with trussing was my inexperience vs. any equipment issue.

Cooking the pig on a spit rotisserie is one of those things in life where you can read and read but sooner or later you just need to do it and learn. I’d tell you to do a test one also before you really need to count on it. If I can do it – so can you.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, I may be paid via an affiliate program such as Avantlink, Impact, Amazon and eBay.