The Following is a Basic Do-it-yourself Manganese Parkerizing Formula

A couple of friends online, Elkaholic and Ding, got me interested in parkerizing years ago and gave me a home brew formula and process steps they use. I have been tuning that formula for a few years and thought I would share it as I use it both for blades and firearms. It works great as either the base for a top finish, such as Molyresin or as a finish all by itself. You may be wondering “why not just buy a premade formula such as the great parkerizing solution from Brownell’s” – the short answer is because tinkering can be fun and more rewarding. I like to experiment and try different things. So, with that said, here is the recipe:

Ingredients

– 2 gallons of distilled water (it gives more consistent results because impurities have been removed – sold at supermarkets and drug stores)

– 2 “biscuits” of clean plain 0000 steel wool (thinner steel wool dissolves faster hence the use of 0000 grade)

– 1 cup of Klean Strip brand Phosphoric Prep & Etch (or other phosphoric acid etching solution around 35-45% concentrate per the Prep & Etch MSDS sheet. Dilute the acid if higher. For example, if 100% pure then go 60 water:40 acid – you can always experiment with the ratio that works for you)

– 6 rounded tablespoons of manganese dioxide (available at pottery supply stores, Amazon or eBay)

Do this outside – never in your house or shop (unless you have a great vent hood). If you do it indoors, you will likely make stuff rust fast!

As you can see, I use a camp stove. For the first couple of years I just used a Coleman stove but that was always a balancing act with my 48″ long stainless pakerizing tank that I used for barreled actions. I found the above great Camp Chef stove at Amazon and it is fantastic but any heat source will work. I like propane because its portable and not electric (to avoid any chance of electric shock) and there are tons of propane camp stoves on Amazon.

Also, be sure to use stainless steel for your tanks. I watch for sales or buy stuff off eBay. The big cooker above is from Walmart and the rectangular pan shown below is from Amazon and is normally the water pan for buffet lines.

For tongs to move stuff around, use solid stainless. I tried the plastic ones and they can leave a plastic residue on blasted surfaces and mess up your finish.

Just like baking, if you want more of the solution, take the recipe and multiply it by two, four or however many multiples you want. Just be sure you have a place to store it when done. I use 5 gallon jugs and label them.

Steps to Follow

- Add acid to water in a stainless pan/pot and heat to 190F – don’t boil and waste it. I use a baking thermometer clipped to the side of the pan.

- Spray each wool biscuit with brake cleaner to remove oils and allow each time to dry

- As the solution warms shred the steel wool into the liquid and add the manganese dioxide

- Let the mix simmer and dissolve the steel wool before adding parts

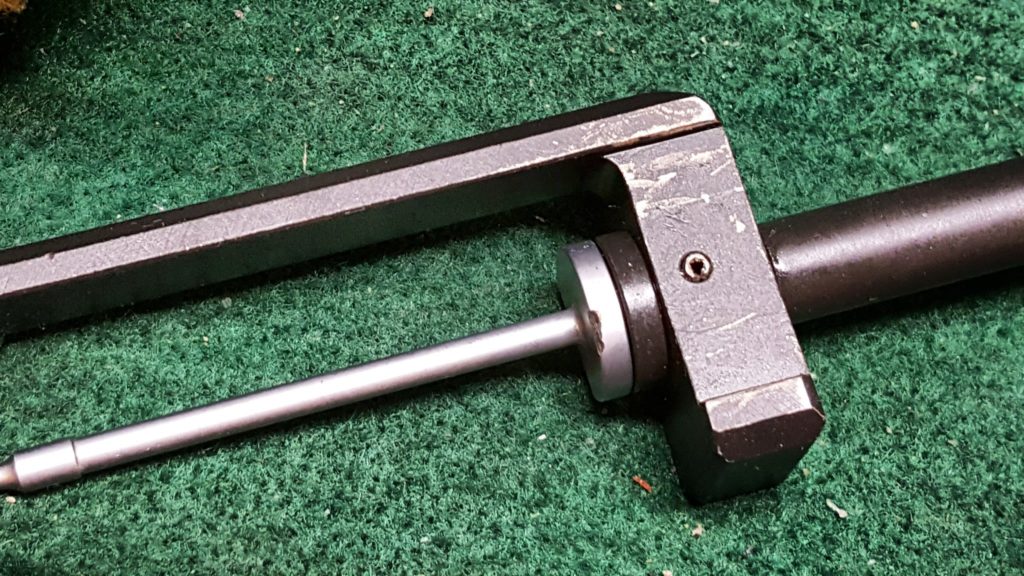

- I always blast my parts before I parkerize them – I’ve heard guys tell about using a wire brush on a buffer or drill press as well but I’ve not tried that. Blasting removes the oxides and exposes the bare steel.

- Make sure your parts are very, very clean and degreased — only handle with rubber gloves after they are cleaned or oils from your skin can mess things up

- You can suspend your parts in the liquid with stainless wire. Leave them until the fizzing stops or about 30-40 minutes. The time varies.

- Rinse the parts with boiling water thoroughly to remove the acid.

- Spray parts with WD40 to get the water away from the steel

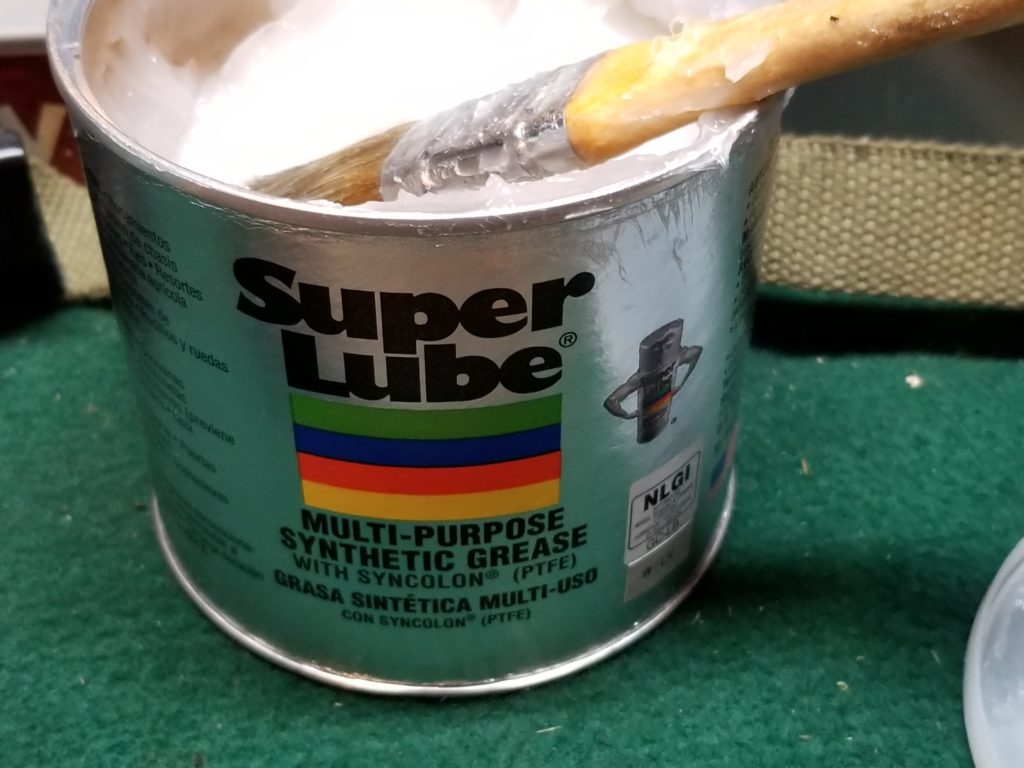

- Wipe down with oil or apply whatever secondary finish you want – don’t do both 🙂 If you are going to apply a finish on top of the parkerized surface, use acetone or brake cleaner to remove any oils and then follow their instructions.

At the bottom of the post are links to Amazon products including long parkerizing tanks.

Cleaning Up

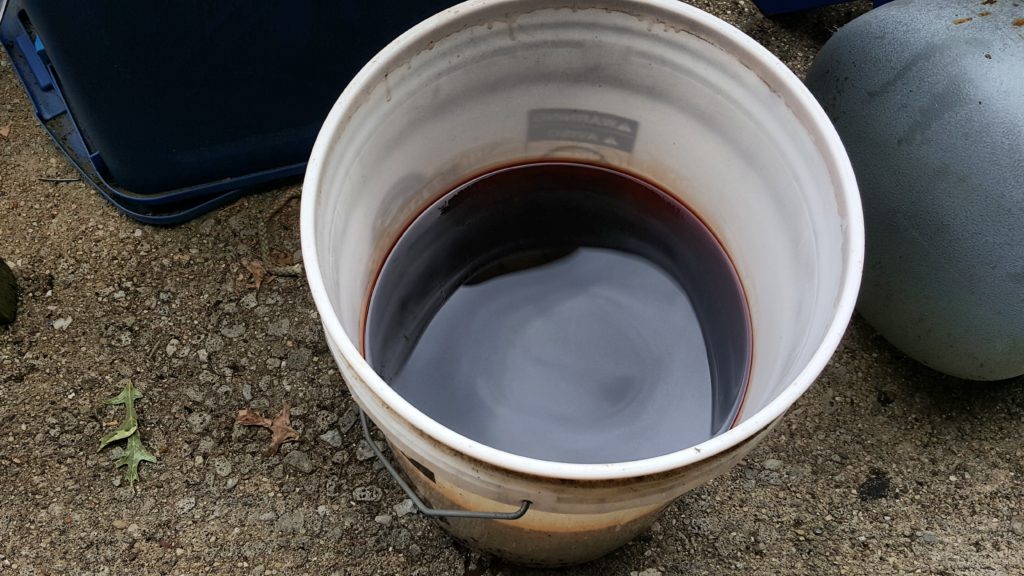

When you are done, let your mixture cool and strain the liquid through a coffee filter into a plastic can for future use. I use a blue kerosene 5 gallon container because it is a different color from all my other 5 gallon containers plus I label it. Point being, you do not want to get confused and pour this stuff in when you meant to use a fuel, etc.

The precipitate, the stuff on the bottom, should be scooped onto a shallow pan, allowed to dry and be disposed of as a hazardous waste. For example, where ever your community collects old paints, batteries, etc.

Brownells Has Great Parkerizing Solutions and Kits

Brownells sells very well regarded ready-to-use formulations. I have no hesitation at all to recommend the below items to you – they are top notch.

- Click here for their manganese parkerization supplies. Their formula meets Mil Spec STD171

- Click here for their zinc parkerization supplies

- If you have a lot small parts you want to park, they have a bench top kit ready to go that you can buy – click here

- Click here for their complete parkerizing tank system. This is a complete system for gunsmiths or others who need to park everything from small parts and pistols up to firearms and swords.

In Summary

I hope this helps you out. I’ve used the above many times and the results are solid.

Updated 2/13/24 with new sources and fixed some grammar issues.

Note, I have to buy all of my parts – nothing here was paid for by sponsors, etc. I do make a small amount if you click on an ad and buy something but that is it. You’re getting my real opinion on stuff.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, we are only paid if there is an affiliate program such as Avantlink, Impact, Amazon and eBay and only if you purchase something. If you’d like to directly contribute towards our continued reporting, please visit our funding page.