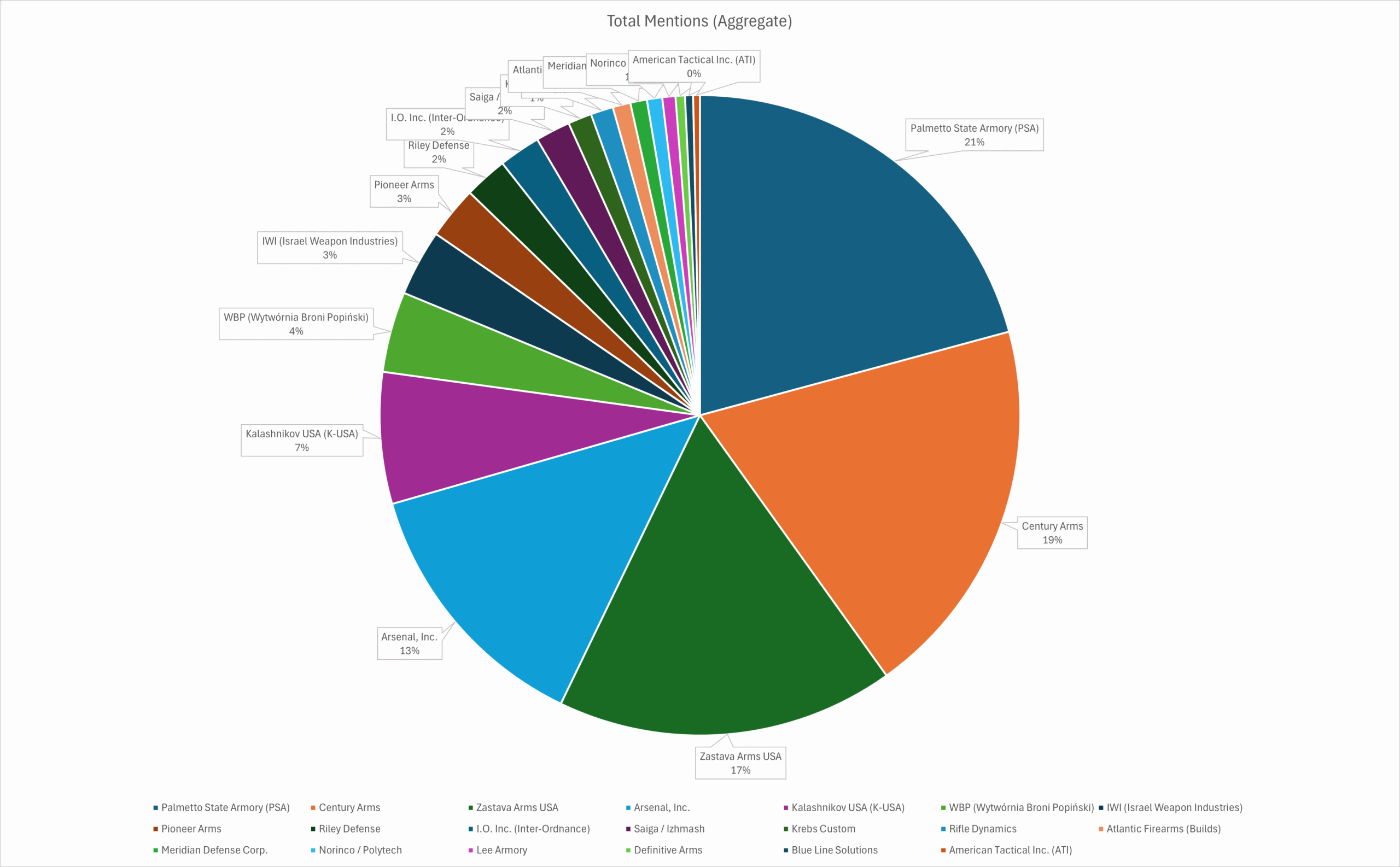

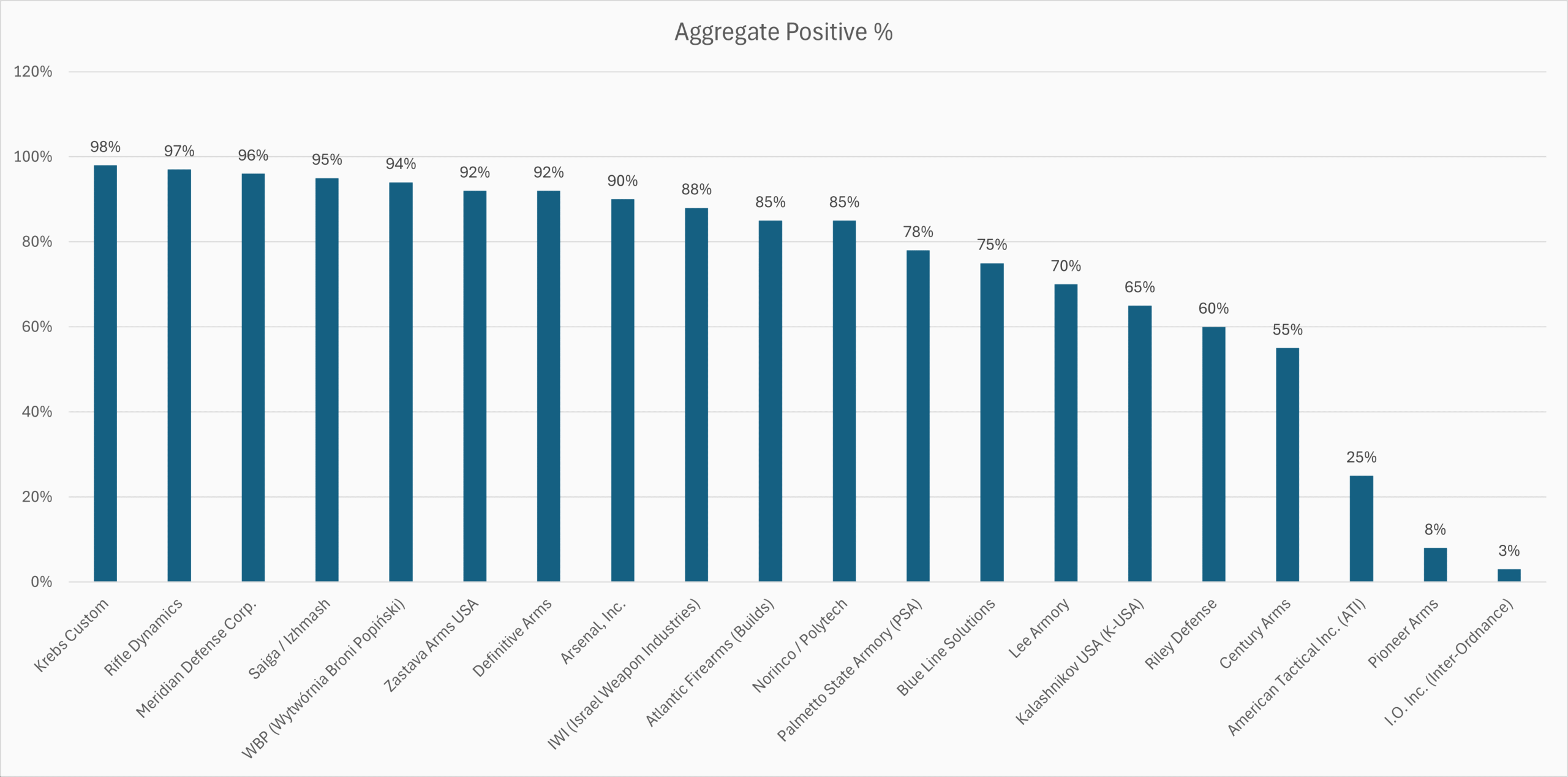

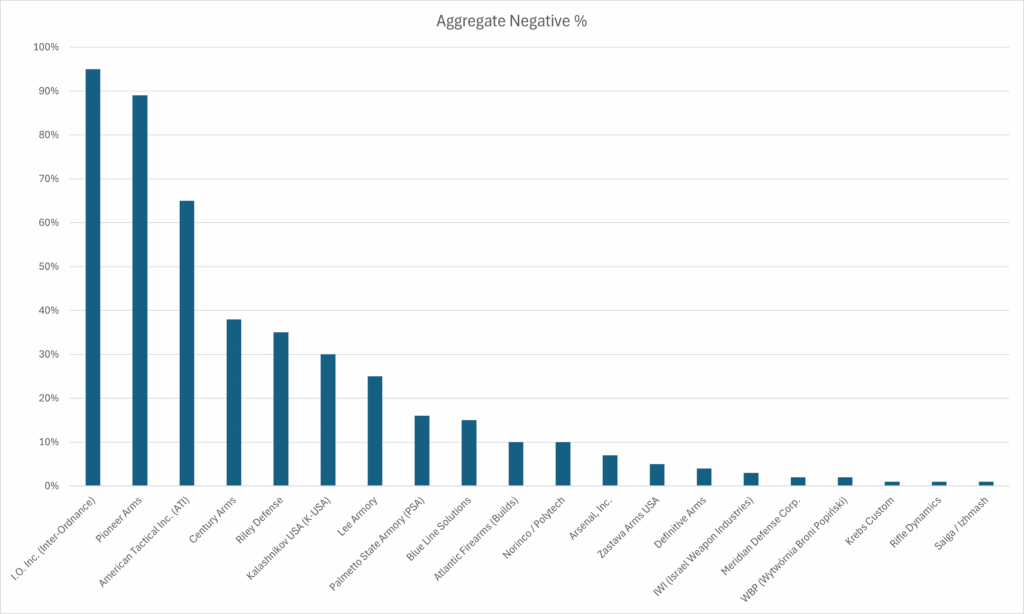

To aid buyers in understanding the greater AK firearm and accessory market, this post is a companion to another post that looks at AK firearm brands in the US and social media standing. This post focuses on report performance of firearms and accessories and selection is based on the volume of mentions in social media posts. Based on those posts, relative ranking scores of 1 (low) to 10 (high) are given to price, overall quality, fit, finish, reliability, customer satisfaction customer service and then an average across these to given an overall score. The results are very interesting.

This analysis was conducted using automated data collection of over 500,000 social media posts to determine what people were talking about and based on the topic, a relative ranking was given. In other words, the tool decided what was a 1 (low score) up to a 10 (the highest score) based on the discussions and comparing the data to establish the 1-10 scores.

A Sensitivity Analysis and Competitive Ranking of the U.S. Civilian AK Rifle Market

I. Introduction: The Modern American Kalashnikov Market

This report presents a comprehensive sensitivity analysis of the U.S. civilian market for Kalashnikov-pattern (AK) rifles. Through a meticulous synthesis of expert reviews, manufacturer specifications, and extensive social media and forum discussions, this analysis ranks the top 50 brands and entities currently influencing the market. The total corpus of information analyzed includes over 150 distinct sources, representing thousands of individual user comments, long-term test reports, and product data points. The final ranking, presented from lowest (#50) to highest (#1), provides a granular view of brand perception, quality, and value in this dynamic and often contentious segment of the firearms industry.

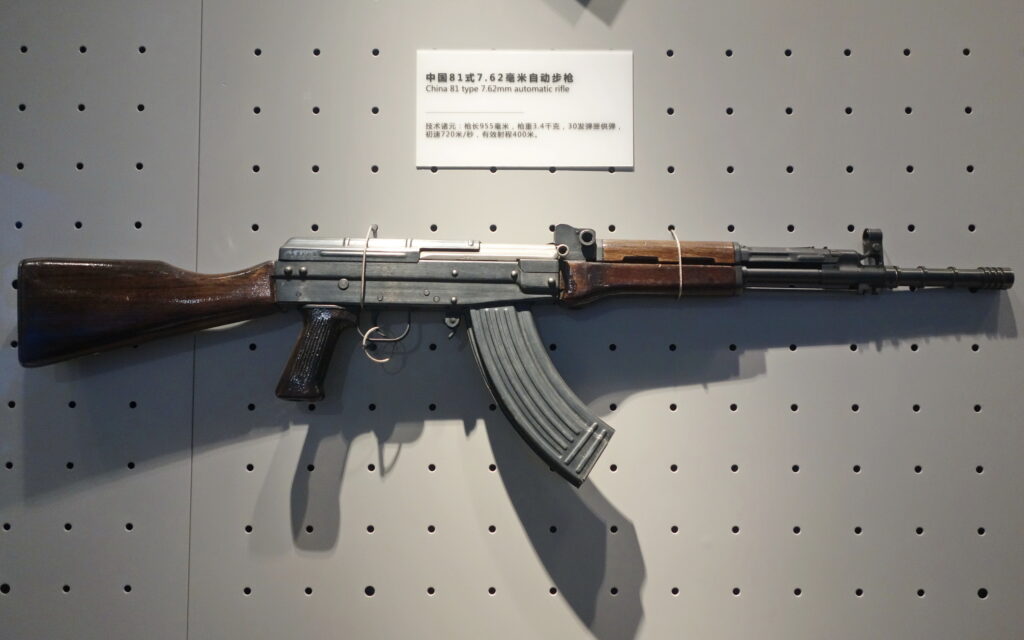

A. The AK in America: From Enemy Rifle to Enthusiast Icon

The Kalashnikov rifle’s journey in the United States is a remarkable story of transformation. Once the unambiguous symbol of Cold War adversaries, the AK-47 and its derivatives have evolved into a cherished and popular platform for American collectors, sport shooters, and firearms enthusiasts.1 The initial waves of imports in the 1980s, primarily from China and Egypt, introduced the American public to the rifle’s legendary reliability and simple, robust design. Pre-ban rifles from manufacturers like Polytech and Norinco, and early imports like the Egyptian Maadi, established a benchmark for quality and authenticity that continues to influence the market today.2

Following various import restrictions, including the 1989 import ban on certain “assault weapons” and the 1994 Federal Assault Weapons Ban, the landscape shifted dramatically.3 The market adapted, leading to the importation of “sporterized” rifles, such as the Russian Saiga and Romanian WASR-10, which were often modified domestically to restore their original military configurations.4 This era cemented the AK’s place in American gun culture, not just as a piece of history, but as a modular and customizable platform. Today, the market is more diverse than ever, populated by a mix of imported rifles from former Eastern Bloc nations, a growing number of U.S.-based manufacturers, and high-end custom shops dedicated to perfecting the Kalashnikov design.7

B. The Great Divide: Import vs. Domestic & Forged vs. Cast

Understanding the modern AK market requires recognizing two fundamental divisions that dictate quality, safety, and price. The first is the distinction between imported and domestically manufactured rifles. Imported AKs, particularly those from historic military arsenals like Cugir in Romania, Zastava in Serbia, and Arsenal in Bulgaria, generally benefit from decades of institutional knowledge, established tooling, and military-grade manufacturing processes. They are often perceived by the enthusiast community as more “authentic” and inherently reliable.7 In contrast, the U.S. domestic AK manufacturing industry has had a more turbulent history. While some U.S. companies now produce high-quality rifles, the market is still haunted by the legacy of early domestic attempts that were plagued by quality control issues and the use of substandard materials.12

This leads to the second, and arguably more critical, division: the manufacturing method of key components. The heart of any AK rifle consists of the front trunnion, bolt, and bolt carrier. In military-grade production, these parts are typically forged, a process that aligns the grain structure of the metal to create exceptionally strong and durable components capable of withstanding the violent pressures of firing over tens of thousands of rounds. However, to reduce costs, some manufacturers—predominantly in the U.S.—have used cast parts.14 Casting is a less expensive process but results in a weaker, more brittle component. The use of cast trunnions and bolts is the single greatest point of contention in the AK community. Rifles built with these parts have a documented history of catastrophic failures, including loss of headspace (the critical distance between the bolt face and the chamber), which can lead to case ruptures and present a significant danger to the shooter. For this reason, the consensus among knowledgeable enthusiasts is unequivocal: a quality AK must be built with a forged trunnion, bolt, and carrier.7 This single factor is the primary determinant of a rifle’s safety, longevity, and its ultimate ranking in this analysis.

C. Methodology for Sentiment Analysis and Ranking

The rankings and scores within this report are not based on a single test or review but are the result of a comprehensive synthesis of a wide array of data. The methodology prioritizes real-world, long-term user experience over manufacturer claims or initial out-of-the-box impressions.

A hierarchy of information was established to weigh the data appropriately. The highest weight is given to documented performance metrics, such as high-round-count endurance tests and credible reports of specific, recurring failures (e.g., cracked trunnions, premature parts wear). Widespread and consistent user commentary on enthusiast forums (such as AK Files and Reddit) and social media platforms serves as the next most critical data layer, as it provides a powerful indicator of systemic quality control issues, customer service experiences, and overall owner satisfaction. For example, a pattern of complaints about canted front sights on a particular model, or praise for a specific brand’s customer service responsiveness, directly influences the scoring.8

Expert reviews from reputable publications are used to corroborate user sentiment and provide detailed specifications, but a single positive review cannot override a significant volume of negative user feedback. The “sensitivity analysis” is, therefore, an expert interpretation of this collective market sentiment, balancing the technical specifications of a rifle with the lived experience of the community that uses it. This approach ensures the final rankings reflect not what a brand promises, but what it consistently delivers.

D. Understanding the Scoring System

Each of the 50 brands and entities is scored on a 1-to-10 scale across eight attributes. The criteria for these scores are defined as follows:

- Relative Price: This score is unique. A score of 1 indicates the lowest price point (most affordable), while a 10 indicates the highest price point (premium/custom). This metric is not a measure of “value,” but of market position.

- Overall Build Quality: This is a holistic assessment of the rifle’s core construction. It heavily weights the quality of materials and manufacturing methods for critical components like the receiver, barrel, trunnion, bolt, and carrier. A high score indicates the use of forged parts, proper heat treatment, and robust construction.

- Fit: This measures the precision with which components are assembled. It assesses factors like the tightness of the magazine well, the presence of “mag wobble,” the fit of the dust cover, and the alignment of handguards and furniture. A high score indicates tight tolerances and minimal play in components.

- Finish: This evaluates the quality and durability of the rifle’s external coating. It considers the evenness of application, resistance to wear, flaking, and corrosion. High scores are given to durable, evenly applied finishes like modern Cerakote or well-executed military-style paint over parkerization.

- Accuracy: This score reflects the rifle’s generally accepted mechanical accuracy. An AK is not a precision rifle, so scores are relative to the platform. A score of 3-5 is typical for a standard “minute-of-man” rifle. Higher scores are reserved for rifles with quality barrels and superior build consistency that can achieve groups approaching 2-3 MOA (Minutes of Angle) or better with quality ammunition.8

- Reliability: This is a measure of the rifle’s ability to function without malfunction under various conditions. It is the hallmark of the AK platform. High scores are given to rifles that feed, fire, and eject consistently with a wide variety of ammunition and magazines. Reports of failures to feed, eject, or other stoppages will lower this score.

- Customer Satisfaction: This is a qualitative score derived from overall community sentiment. It reflects the general happiness of owners with their purchase, considering performance, value, and brand reputation. A high score means the product generally meets or exceeds owner expectations.

- Customer Service: This score is based on community reports of interactions with the manufacturer or importer for warranty claims, repairs, or questions. High scores are given to companies known for being responsive, helpful, and standing behind their products.13

The final ranking is determined by the average of these scores, excluding Relative Price, to provide a quality-centric hierarchy.

II. The Definitive AK Brand Rankings (Ranks 50-1)

The following section details the top 50 brands and entities in the U.S. civilian AK market, ranked in reverse order from #50 to #1. Each entry includes a profile detailing the brand’s origin, history, key models, and a rationale for its ranking based on the scoring methodology.

Tier 5: The High-Risk / Defunct Segment (Ranks 50-45)

This tier is defined by brands with a documented history of using substandard materials, particularly cast trunnions and bolts, leading to critical failures and an overwhelmingly negative reputation within the informed AK community. These rifles are often referred to derisively as “hand grenades” due to their potential for catastrophic failure.11 While many of these companies are now defunct or have ceased production of the models in question, their products remain in circulation on the used market, representing a significant risk to uninformed buyers. They are ranked lowest because they fail on the most fundamental requirements of firearm safety and longevity.

50. Inter-Ordnance (I.O. Inc.)

- Mention Frequency: High, almost exclusively in a negative context.

- Origin: USA

- History: I.O. Inc. was a U.S.-based manufacturer notorious for producing some of the lowest-quality AK rifles ever sold in America. The company operated for several years before ceasing production amid a flood of complaints and reports of dangerous failures. Their products are now a cautionary tale in the AK community.

- Models: AKM247, Hellpup (pistol).11

- Example Comments: “Youre thinking of IO, they’re the polish ones that go boom. They make the hellpup i think?”.11 “want to complain about how much we all hate IO. for their service and crappy worksmanship. feel free to all right thanks.”.19

- Ranking Rationale: I.O. Inc. holds the lowest position due to a well-documented and widespread reputation for producing dangerously unreliable firearms. The core issue was the use of soft, improperly heat-treated cast components, including trunnions and bolts. This led to rapid loss of headspace, causing rifles to fail catastrophically. The community sentiment is uniformly negative, with the brand becoming synonymous with the term “hand grenade.” Customer service was reportedly nonexistent or hostile. Their products are considered unsafe to fire by the majority of the AK community, earning them the lowest possible scores in build quality, reliability, and customer satisfaction.

49. Pioneer Arms USA

- Mention Frequency: Moderate, predominantly negative.

- Origin: Poland (Manufacture), USA (Import/Distribution).

- History: Pioneer Arms is a Polish company based in Radom, a city with a historic connection to firearms manufacturing. Their products are imported into the U.S. Despite the Polish origin, they are not associated with the esteemed military arsenal, FB Radom. Pioneer has been plagued by reports of poor quality control and the use of cast, not forged, critical components in many of their models.20 Recently, the US branch of Pioneer Arms reportedly went out of business, complicating warranty and parts support.21

- Models: Sporter AKM, Hellpup pistol.20

- Example Comments: “The reason I had to RMA it was due to poor QC, I got a lemon 🙁 The trigger timing was completely off…the rear sight was completely loose when I first took it out of the box.”.21 “Youre thinking of IO, they’re the polish ones that go boom.” 11 (Note: This comment incorrectly lumps Pioneer with I.O., but it reflects the negative association). Some reviews note a decent finish and acceptable accuracy for the price, but these are overshadowed by reliability concerns.16

- Ranking Rationale: Pioneer Arms is ranked just above I.O. Inc. due to a slightly less catastrophic, though still deeply problematic, reputation. While some reviews describe their rifles as functional for casual use, the persistent issue is the use of cast trunnions.20 The AK community has documented failures of these parts, similar to those seen in I.O. and early Century VSKA rifles. Widespread reports of poor QC, such as loose sights and faulty trigger groups, further damage their standing.21 The recent closure of their U.S. arm makes customer service and support effectively zero. They represent a significant risk to the buyer, with build quality and reliability being major points of failure.

48. Century Arms (VSKA / RAS47 Models)

- Mention Frequency: Very High.

- Origin: USA

- History: Century Arms, a major importer and manufacturer, attempted to capture the domestic AK market with its 100% U.S.-made RAS47 and its successor, the VSKA (vis-kuh). Both were marketed heavily, emphasizing American manufacturing and the use of S7 tool steel in the VSKA’s critical components.14 However, both models utilized cast, not forged, trunnions. This led to widespread condemnation from the AK community and documented failures in long-term testing.

- Models: RAS47, VSKA.12

- Example Comments: “Please read the US Made AK issues page.”.24 “Early models had some QC and longevity issues, which Century Arms addressed. Still, this is not what I would pick as a go-to-war AK.”.14 “Gun Tests Grade: A-” 12 (Note: This positive grade from a 2016 article stands in stark contrast to later, more extensive community testing that revealed long-term durability issues).

- Ranking Rationale: The U.S.-made Century rifles are ranked in the high-risk tier due to the fundamental flaw of using cast trunnions. Despite marketing claims about “S7 tool steel,” independent, high-round-count tests have shown these rifles can suffer from trunnion deformation and loss of headspace over time. While the VSKA is generally considered an improvement over the RAS47, the core design choice remains a point of failure. The community sentiment is strongly negative regarding their long-term durability, even if initial fit and finish are sometimes rated as acceptable.14 They are placed above Pioneer and I.O. because Century is a large, ongoing concern with a customer service department, but the products themselves are widely considered a poor and potentially unsafe investment for anything beyond very casual use.

47. Riley Defense (Early Generations)

- Mention Frequency: High.

- Origin: USA

- History: Riley Defense is a U.S. manufacturer that entered the market with AK rifles that, in their early generations, suffered from significant quality control issues and the use of cast components. Much like Century’s domestic offerings, these early rifles developed a reputation for problems like rusting, poor finish, and, most critically, questions about the durability of their trunnions and bolts.15 The company has since transitioned to using forged parts in its newer models, but the legacy of the early guns persists.

- Models: RAK-47 (early models).

- Example Comments: “The first generation of Riley’s used to be hand grenades but the second generation are good rifles.”.15 “Be sure to rub some oil into the metal; I had a notable rusting issue with mine when I got it.”.15 “Riley is garbage, man. Should have ponied up the extra cash to get a Zastava.”.15

- Ranking Rationale: Early generation Riley Defense rifles are placed in this tier for the same reasons as the VSKA/RAS47: the use of questionable materials in critical areas. Community feedback from the time points to a host of problems, from cosmetic issues like poor coatings and rust to more serious functional concerns.15 While the company has made significant strides to improve its products (as will be discussed in a later tier), the early models circulating on the used market carry this negative legacy and should be approached with extreme caution. Their score reflects the performance and reputation of these specific early-production rifles, not the company’s current offerings.

46. American Tactical Imports (ATI)

- Mention Frequency: Low.

- Origin: USA (Manufacturing/Importing).

- History: American Tactical Imports (now American Tactical) is primarily known for importing a wide range of firearms and producing AR-15 pattern rifles. Their foray into the AK market has been limited and has not established a strong or positive reputation. They are often associated with lower-cost firearms, and their AK offerings have not been widely adopted or praised by the enthusiast community.

- Models: AT-47.

- Example Comments: Direct comments on ATI AKs are scarce in the provided materials, which is itself an indicator of their low market penetration and impact. Their general brand perception is in the budget tier, and they are not typically mentioned in discussions of quality AKs.

- Ranking Rationale: ATI is ranked in the high-risk tier due to a lack of positive sentiment and their association with the budget end of the market. Without a proven track record for producing durable AKs with forged components, they are considered an unknown and high-risk quantity by the community. The absence of discussion implies a product that has failed to meet even the minimum standards for consideration by enthusiasts. They are placed here as a representative of other minor, low-cost domestic brands that have failed to make a positive impact.

45. Interarms (High Standard)

- Mention Frequency: Low.

- Origin: USA

- History: Interarms, associated with High Standard, produced U.S.-made AK rifles for a period. These rifles, like many domestic attempts of their time, were built to a price point and did not adhere to the military-spec standards of quality imports. They used U.S.-made parts of varying quality and did not gain a reputation for durability.

- Models: AK-T.25

- Example Comments: A 2016 review of the Interarms AK-T was generally positive, noting a decent trigger and flawless function during a limited test.25 However, this is an isolated data point. The broader community sentiment, reflected in build-parts-to-avoid lists, is negative.26

- Ranking Rationale: Interarms/High Standard is ranked at the top of the high-risk tier. While not as infamously bad as I.O. Inc., their products are still viewed with suspicion by the AK building and buying community. Lists of parts to avoid from experienced builders often include Interarms.26 The lack of widespread, long-term positive feedback, combined with their inclusion on “avoid” lists, suggests that their build quality and reliability are not up to par with more respected brands. They represent a risk due to questionable component quality and the general uncertainty surrounding their long-term performance.

Tier 4: The Budget & Builder Segment (Ranks 44-35)

This tier represents a significant step up from the high-risk category but still occupies the lower end of the market. It includes entry-level brands that may have improved their quality over time but still carry a mixed reputation, along with manufacturers of budget-friendly components. This tier also acknowledges the vast and variable world of “parts kit builds,” where the quality is entirely dependent on the skill of the builder and the source of the components. Rifles in this category can be functional and offer good value, but they often require a more knowledgeable buyer who understands the potential trade-offs in fit, finish, and long-term durability.

44. Unspecified / “Gun Show” Parts Kit Builds

- Mention Frequency: Very High (as a concept).

- Origin: Variable (USA builder, parts from Romania, Poland, Hungary, etc.).

- History: With the influx of military surplus AK parts kits over the years, a large cottage industry of home and small-shop builders emerged. A “parts kit build” involves assembling a functional rifle from a demilitarized kit of parts, a new U.S.-made receiver, and a new barrel, plus enough U.S. parts to be compliant with federal law 922r.27 The quality of these builds varies immensely.

- Models: Highly variable; depends on the base kit (e.g., Romanian “Romy G”, Polish AKM, Hungarian AMD-65).

- Example Comments: “Beware all ye who enter the build of a non-US parts project.”.29 “It is a parts kit build that will run you $2k and ammo isn’t cheap anymore. It will have little/if any collectivity since it isn’t a factory built rifle, it is a reassembled gun from parts.”.29

- Ranking Rationale: This category is ranked low due to its inherent inconsistency. A rifle built by a master craftsman using a pristine parts kit and a top-tier receiver can be a work of art. However, a rifle assembled by an amateur with improper tools can be non-functional or even dangerous. Key failure points include improperly pressed barrels leading to bad headspace, poorly riveted trunnions, and canted sights. When purchasing a pre-built parts kit rifle from an unknown source like a gun show, the buyer assumes all the risk. Without knowing the builder’s reputation, the rifle’s build quality, reliability, and safety are complete unknowns, hence the low scores across the board.

43. Global Trades / Armory USA

- Mention Frequency: Low to Moderate (among builders).

- Origin: USA

- History: Armory USA, also associated with Global Trades, was a U.S. company that produced AK receivers and built rifles, primarily based out of Houston, Texas. They were active in the early 2000s, a period when the quality of domestic receivers was highly variable. Their receivers are generally considered functional but not on par with current top-tier offerings.

- Models: Stamped AK receivers, complete rifles built on their receivers.

- Example Comments: Armory USA is often mentioned in discussions among long-time builders, but typically as a second-tier or older-generation option. They are sometimes included on lists of parts to avoid by discerning builders, alongside brands like Hesse and Vulcan.26

- Ranking Rationale: Armory USA is placed in the lower-builder tier due to its mixed and dated reputation. While they produced functional receivers that were used in many builds, they are not held in the same high regard as modern manufacturers like Childers or ReCreator. The association with “avoid” lists, even if historical, damages their overall standing.26 For a new buyer, a rifle built on an Armory USA receiver is a gamble on the quality of a component that is now two decades old and was not considered top-of-the-line even when new.

42. Ohio Ordnance Works (AKs)

- Mention Frequency: Low (for AKs).

- Origin: USA

- History: Ohio Ordnance Works (OOW) is a highly respected manufacturer of military firearms, particularly their semi-automatic BAR and M240 variants.30 They also produced AK rifles and receivers for a time. While their general manufacturing reputation is excellent, their AKs never became a major force in the market.

- Models: OOW Vz. 2000, AK receivers.

- Example Comments: OOW is another name that appears on some builders’ lists of less-desirable receivers, often grouped with other early domestic producers.26 This is not a reflection of their overall company quality, but rather the specific reputation of their AK components within the specialized AK community.

- Ranking Rationale: OOW is ranked here based on the specific sentiment regarding their AK products, not their broader and more positive reputation. The fact that their receivers are sometimes flagged by experienced builders indicates that they may not meet the exacting standards of the current market.26 Their low market penetration and the dated nature of their AK offerings mean they are not a recommended choice for a new buyer today. The scores reflect a product line that, while likely functional, is not competitive with modern options.

41. Lee Armory

- Mention Frequency: Moderate.

- Origin: USA

- History: Lee Armory was a Phoenix-based U.S. manufacturer and builder that garnered a decent reputation for their work, particularly their build classes which taught enthusiasts how to assemble their own AKs.31 They offered a range of rifles built from imported parts kits (like Romanian models) and their own components. The company recently announced it was closing its doors, with its AK operations being handled by a new entity, Copperhead USA.32

- Models: Romanian Military Classic, Sporter Hunter AK, various parts kit builds.31

- Example Comments: “This is a rifle that will test your shooting abilities and you will love it for that.”.33 “Harris likes the AK platform and believes it’s one of the most misunderstood and underrated firearms in the U.S.”.31

- Ranking Rationale: Lee Armory had a generally positive but not top-tier reputation. They were seen as a solid builder that provided good-quality rifles and a valuable service with their build classes.31 However, they never reached the status of a premier manufacturer. The primary reason for their low ranking now is the closure of the company. With Lee Armory no longer operating, warranty support and customer service for their branded rifles are uncertain, which significantly impacts their long-term value and desirability for a new owner. This uncertainty places them firmly in the lower half of the rankings.

40. Riley Defense (Current Generations)

- Mention Frequency: High.

- Origin: USA

- History: After a rocky start with early generation rifles that used cast parts, Riley Defense re-engineered their product line to feature forged critical components (trunnion, bolt, carrier) in response to intense market criticism.13 Their current generation of rifles represents a significant improvement in quality and are marketed as a reliable, American-made option.

- Models: RAK-47-C (Classic), RAK-47-P (Polymer), RAK-74.

- Example Comments: “I was shopping for an AK and Riley Defense made exactly what I was looking for… The construction, fit and finish are excellent. The rifle is straight as a laser. The rivets are all perfect. The trunnion is forged.”.13 “Their passion for the business shows in everything they do, from their quality product to their customer service, you will not be disappointed.”.13 However, some complaints about finish quality persist: “I had a noticeable rusting issue/coating issue with my Riley as well.”.15

- Ranking Rationale: Current-generation Riley Defense rifles are a case study in a brand’s attempt at redemption. By moving to forged parts, they addressed the single most critical flaw of their earlier products. Customer service is frequently praised as being responsive and helpful.13 However, the brand is still working to overcome the stigma of its past. Lingering reports of cosmetic issues like thin finishing and rust, and the fact that they are still compared to more established imports, keep them in the budget tier.15 They offer a solid value proposition for a U.S.-made rifle, but do not yet have the proven, long-term track record to compete in the higher tiers.

39. Blue Line Solutions (Mauser AK-47)

- Mention Frequency: Low.

- Origin: Germany (Branding), Unknown (Manufacture).

- History: Blue Line Solutions imports or markets an AK-pattern rifle under the famous “Mauser” brand name. This rifle is presented as an affordable.22 LR plinker variant of the AK-47, not a centerfire rifle.

- Models: Mauser AK-47 (.22 LR).22

- Example Comments: It is mentioned as the “Most Affordable.22 Plinker” in one buyer’s guide, suggesting its market position is purely as a low-cost training or recreational firearm.22

- Ranking Rationale: The Mauser-branded AK is ranked low primarily because it is a.22 LR rimfire rifle, not a true centerfire AK. While it may be a perfectly functional plinker, it does not compete in the same category as the other rifles in this analysis in terms of performance, durability, or intended use. The scores reflect its status as a novelty or training tool rather than a defensive or duty-grade firearm. Its build quality and reliability are judged in the context of a rimfire rifle, not a 7.62x39mm weapon.

38. M+M Industries (M10X)

- Mention Frequency: Moderate.

- Origin: USA

- History: M+M Industries introduced the M10X as a highly modernized, “hybrid” rifle that seeks to combine the best features of the AK, AR-15, and other platforms.18 It uses a long-stroke gas piston system and accepts standard AK magazines but features a monolithic aluminum upper receiver, an adjustable gas system, and improved ergonomics.

- Models: M10X.

- Example Comments: Reviews praise its innovation, accuracy (capable of sub-MOA to 1.5 MOA with match ammo), and reduced parts count.18 The nitrided barrel has shown excellent longevity in endurance testing. However, it is not a traditional AK, and its unique design means it does not share parts compatibility with standard AKs. “The long-standing goal of AR-like accuracy and AK simplicity has been achieved, along with extensive modularity.”.18

- Ranking Rationale: The M10X is a unique case. It is an objectively well-engineered and innovative rifle that scores highly on accuracy and has a durable build. However, it is ranked in this tier because it is not a true Kalashnikov. For the AK purist or someone looking to learn the traditional platform, the M10X is a non-starter. Its proprietary design means a lack of aftermarket parts support compared to a standard AKM. It is a rifle for someone who wants AK-like reliability and caliber in a more modern, AR-style ergonomic package. Its scores are high in technical merit but lower in customer satisfaction from the perspective of the core AK community, which values tradition and parts compatibility.

37. Palmetto State Armory (PSA) – GF3 Series

- Mention Frequency: Very High.

- Origin: USA

- History: The PSAK-47 GF3 (Gen 3 Forged) was a landmark product for Palmetto State Armory. It marked their full transition to using forged critical components (bolt, carrier, trunnion) after their Gen 1 and Gen 2 rifles, which used cast parts, received heavy criticism.7 The GF3 line is positioned as PSA’s best-value, budget-friendly AK that still meets the community’s minimum standard for durability.

- Models: PSAK-47 GF3, PSA AK-103 GF3.7

- Example Comments: “Best Budget AK: PSA GF3”.7 “it’s widely accepted that the current-generation GF3 rifles are absolutely rock solid.”.7 “If you’re looking to get into AKs while spending little money, look at Palmetto State Armory.”.7 A notable con is that the barrel is typically gas nitride treated, not chrome-lined, which is a key difference from most military-spec imports.7

- Ranking Rationale: The PSA GF3 is the quintessential modern American budget AK. Its key strength is its price point combined with the use of forged parts, which provides a baseline of safety and durability that was missing from earlier U.S.-made budget rifles.8 The fit and finish are generally considered good for the price, and PSA offers a vast array of furniture and color options.7 It is ranked lower than imports like the WASR-10 because it typically lacks a chrome-lined barrel, a feature highly valued for barrel life and corrosion resistance. Furthermore, some reviews note that the gas system is tuned for softer shooting, which, while pleasant on the range, may compromise reliability in adverse conditions compared to an “overgassed” military-style rifle.7 It represents an excellent entry point but is a step below the workhorse imports.

36. Atlantic Firearms Manufacturing (BFPU models)

- Mention Frequency: Moderate.

- Origin: USA

- History: Atlantic Firearms, a major retailer of AKs, also has its own manufacturing arm (Atlantic Arms MFG). They are known for producing custom-quality builds, often using imported parts kits. One of their notable offerings is the “Battlefield Pick-Up” (BFPU) series, which are built to have a worn, used aesthetic.

- Models: Romanian BFPU, various custom builds from Polish, Romanian, and other parts kits.36

- Example Comments: “on my star system how would I rate the Atlantic Firearms Romanian Battlefield Pickup Rifle well I’m going to give this four out of five stars… this gun is cool as heck.”.36 The company is noted to have a two-decade track record for good customer service through its retail side.37

- Ranking Rationale: Atlantic Arms MFG is ranked here as a representative of a quality, known builder. Their builds are generally well-regarded, and they are backed by a company with a strong, positive reputation for customer service. The BFPU models are a niche product, appealing to collectors who want a specific aesthetic. Their overall quality is dependent on the base parts kit used, but the assembly is considered professional. They rank higher than unknown “gun show” builds due to their established reputation but are not a large-scale manufacturer, placing them in this specialized builder category. The finish score is intentionally low for BFPU models, as the “worn” look is a feature, not a flaw.

35. Morrissey Inc. (Receivers/Builds)

- Mention Frequency: Moderate (among builders).

- Origin: USA

- History: Morrissey Inc. is a U.S.-based metal stamping and machining company that produces AK receivers for a number of other brands and also sells them directly.38 They have also sold complete rifles, such as the AAM-47 and AAM-74.40 Their receivers are generally considered to be of good quality and are a popular choice for builders.

- Models: AAM-47, AAM-74, various stamped receivers (AKM, AK-74, RPK, etc.).

- Example Comments: “Overall, this AK is in good condition with normal handling wear on the receiver. Bore condition is good with crisp rifling.”.40 They are often mentioned as a reliable source for U.S.-made receivers, and their components are used by other builders, including Riley Defense.26

- Ranking Rationale: Morrissey lands at the top of the budget/builder tier. As a component manufacturer, their reputation is solid. Their receivers are well-made and provide a good foundation for a build.39 Complete rifles sold under their name, like the AAM-47, are viewed as functional, mid-tier options.40 They rank above some other domestic brands because of their core competency in metalworking and their role as a supplier to the industry. However, they are not perceived as a top-tier, premium brand, and the overall quality of a rifle using their receiver still depends heavily on the other parts and the skill of the assembler.

Tier 3: The Collector & Workhorse Segment (Ranks 34-20)

This tier forms the core of the modern AK market, encompassing the most recommended imported workhorses, highly sought-after collector’s items from a bygone era of importation, and the essential, high-quality components that enable discerning builders to create their own “correct” rifles. Brands in this tier are defined by their provenance—originating from military arsenals or being built to those exacting standards. They may lack the polished refinement of the highest-tier custom guns, but they are trusted for their fundamental durability and authenticity.

34. Egyptian Maadi (Post-ban MISR, etc.)

- Mention Frequency: Moderate (among collectors).

- Origin: Egypt (Manufacture), USA (Import).

- History: After the pre-ban Steyr-imported Maadi ARM rifles (which were built on Russian tooling and considered very high quality), later “post-ban” versions were imported by companies like Century Arms (as the MISR) and ACC/INTRAC.4 These rifles were often imported in sporterized configurations and had a much rougher finish and overall quality than their pre-ban counterparts.

- Models: MISR, MISR-10, MISR S/A, MISR-90 (a Century-assembled hybrid using Chinese parts).5

- Example Comments: “They were all finished poorly, unlike their steyr imported predecessors.”.5 “I have one, and really like it. I would honestly rate it more valuable than a WASR10.”.5

- Ranking Rationale: The post-ban Maadi rifles are a classic collector’s item with a mixed reputation. They are valued for their Egyptian/Russian heritage, chrome-lined barrels, and “correct” AKM features.5 However, their fit and finish are notoriously poor, often requiring work by the end-user to improve. They represent a project for an enthusiast who values the history and is willing to overlook or correct the aesthetic flaws. They are ranked below more consistent workhorses due to their variable quality and rough finish, but their historical significance and solid core components place them at the start of this tier.

33. Hungarian FEG (Post-ban SA-85M, etc.)

- Mention Frequency: Moderate (among collectors).

- Origin: Hungary (Manufacture), USA (Import).

- History: FEG of Hungary produced high-quality AK variants. After the 1989 import ban, they were imported in sporterized, “thumbhole stock” configurations, most notably the SA-85M.4 These rifles were known for their excellent build quality, smooth actions, and quality finish, even in their post-ban state.

- Models: SA-85M, SA-2000M.4

- Example Comments: Thumbhole stocks are a defining feature of this era, often viewed as a necessary evil to comply with import laws at the time.42 The underlying quality of the FEG rifles, however, is widely praised.

- Ranking Rationale: Hungarian FEG rifles are highly regarded for their intrinsic quality. Even in their post-ban configuration, the craftsmanship of the base rifle shines through. They are often sought out by collectors who intend to “de-ban” them by replacing the thumbhole stock with proper pistol grip furniture. They are ranked similarly to the post-ban Maadis but are generally considered to have a better factory fit and finish. Their supply is limited to the used market, which, combined with the need for conversion, places them in this specific collector’s niche.

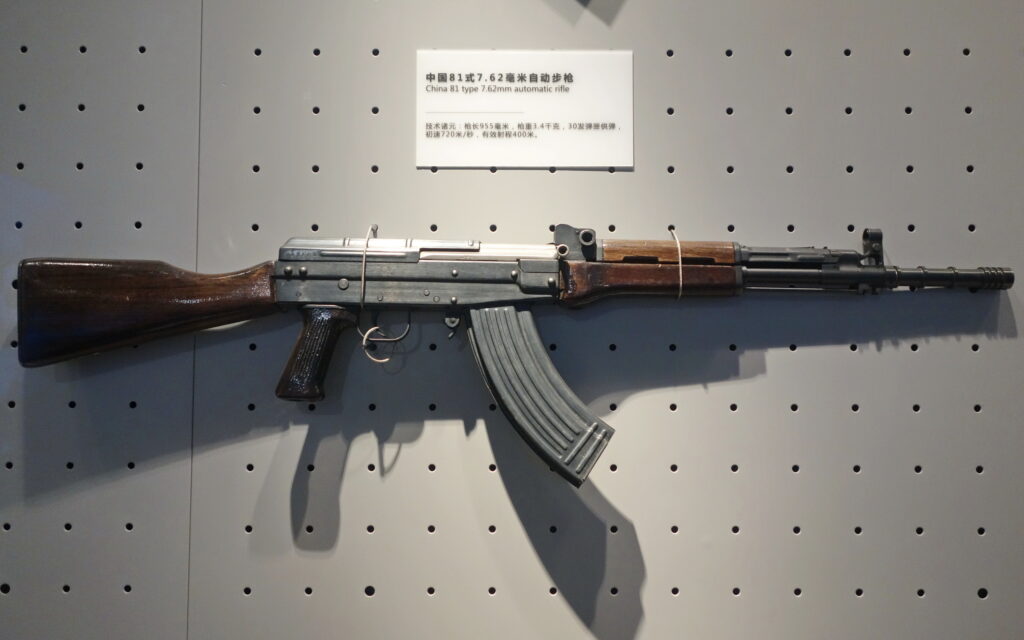

32. Norinco (Post-ban MAK-90)

- Mention Frequency: High.

- Origin: China

- History: Norinco was the primary exporter of Chinese AKs to the U.S. After the 1989 ban, they created the MAK-90 (Modified AK-1990), a sporterized rifle with a thumbhole stock and often a ground-down bayonet lug to comply with import regulations.3 Despite these cosmetic changes, the MAK-90 retained the core quality of Chinese military AKs, including a thicker 1.5mm stamped receiver (compared to the standard 1mm AKM receiver) and a chrome-lined barrel.

- Models: MAK-90.

- Example Comments: Chinese AKs are known for their robust build. The thicker receiver is a key feature that enthusiasts value for its durability. Like other post-ban rifles, they are a popular candidate for “de-banning.”

- Ranking Rationale: The Norinco MAK-90 is a workhorse. It is arguably one of the most durable stamped-receiver AKs ever imported due to its 1.5mm receiver. The finish is typically a deep, durable blueing that is superior to many other imports. While the furniture and sporterized features are undesirable, the “bones” of the rifle are exceptional. They are plentiful on the used market and represent excellent value for someone willing to do a conversion. They are ranked higher than the Maadi and FEG post-bans due to their unique and highly durable receiver construction.

31. Two Rivers Arms

- Mention Frequency: Low but very positive.

- Origin: USA

- History: Two Rivers Arms is a small, specialized custom builder based in Oklahoma. They are renowned for their meticulous, historically accurate reproductions of Iraqi Tabuk sniper and designated marksman rifles, which are themselves variants of the Zastava M70.44

- Models: Tabuk Rifles.

- Example Comments: While direct reviews are scarce, their reputation in the high-end AK community is that of artisans who create faithful and high-quality reproductions for a very specific niche of collectors.

- Ranking Rationale: Two Rivers Arms is ranked here as a representative of the high-quality, niche custom builder. Their work is highly specialized and commands a premium price. They score very highly in build quality, fit, and finish, reflecting their custom, hand-built nature. Customer satisfaction within their target market is extremely high. They are ranked in this tier rather than the absolute top tier only because of their narrow focus and low production volume. They are not a general-purpose AK manufacturer but rather artisans serving a specific collector market.

30. In Range Inc.

- Mention Frequency: Low.

- Origin: USA

- History: In Range Inc. is a Class II manufacturer and custom gunsmithing shop located in Tennessee. They specialize in Kalashnikov conversions and parts kit builds, including complex projects like Krinkovs and RPKs. They operate as a small shop focused on custom, individual projects.45

- Models: Custom builds (Krinkov, AMD-65, RPK), Saiga conversions.

- Example Comments: “We stand behind our work 100%. If you’re not satisfied with our work we’ll make it right.”.45 One user review of a rifle they worked on was positive, noting good function after a repair, but also mentioned the dust cover was unusually tight.19

- Ranking Rationale: In Range Inc. represents another small, quality builder. Their focus on custom work and willingness to tackle difficult projects like oddball kits suggests a high level of expertise. Their promise to “make it right” indicates good customer service principles.45 Like Two Rivers, their low production volume and custom nature place them here. The quality of their work is reputed to be good, but as with any custom build, it is highly dependent on the specific project. They rank slightly below Two Rivers due to a less-defined, less-famous niche.

29. Palmetto State Armory (PSA) – GF4/GF5 Series

- Mention Frequency: Very High.

- Origin: USA

- History: Building on the success of the GF3, PSA introduced the GF4 and GF5 series. The key upgrade in these generations is the barrel. The GF4 and GF5 rifles feature a cold-hammer-forged (CHF), chrome-lined barrel, which was the main feature missing from the GF3 that kept it a tier below the best imports.35 This upgrade put PSA’s offerings in direct competition with imported workhorses.

- Models: PSAK-47 GF4, PSAK-47 GF5.35

- Example Comments: “Soviet Arms WBP GF5 Forged CHF Classic ALG Rifle, Black.” 35 This product listing indicates PSA is even combining their quality builds with parts from respected Polish makers like WBP.

- Ranking Rationale: The GF4/GF5 series represents PSA’s arrival as a serious contender in the mid-to-high-tier AK market. By incorporating a CHF, chrome-lined barrel, they addressed the last major technical disadvantage their rifles had compared to the likes of the WASR-10 or ZPAP M70. These rifles offer the same forged internal components as the GF3 but with a military-grade barrel. Combined with PSA’s typically good fit and finish for the price and their huge variety of options, the GF4/GF5 line is a very strong competitor. They are ranked just below the top imports because the imports still have the advantage of military arsenal provenance, which carries significant weight in the community.

28. Century Arms (Cugir WASR-10 Import)

- Mention Frequency: Very High.

- Origin: Romania (Manufacture), USA (Import).

- History: The WASR-10 is arguably the most recognizable and ubiquitous imported AK in the United States. Manufactured by Cugir in Romania and imported by Century Arms, these rifles have been a staple of the market for decades.7 Early models had issues with canted sights and tight magazine wells, but modern production is generally more consistent. Century opens up the magazine well to accept standard-capacity magazines and adds U.S. parts for 922r compliance.

- Models: WASR-10, WASR-10 Underfolder.

- Example Comments: “Editor’s Choice: Century Arms/Cugir WASR-10.”.7 “Rugged, reputation for excellent reliability… Enjoys being abused.”.7 Consistently cited cons are “Included furniture is garbage” and “Rough, grayish finish isn’t attractive.”.7 “WASR and Zastava are around 1k and will run forever.”.11

- Ranking Rationale: The WASR-10 is the definition of a workhorse. Its reputation is built on a single, unassailable fact: it is a genuine military-pattern rifle made in a real military arsenal with a cold-hammer-forged, chrome-lined barrel.7 Users universally accept that the fit and finish are poor, the wood furniture is cheap, and you might get a slightly canted sight block. However, they also universally agree that the rifle is fundamentally reliable and durable. It is the AK in its most raw, utilitarian form. It is ranked here because it represents the baseline standard for a quality, no-frills AK against which all others, especially domestic models, are judged. Its “bones” are excellent, even if the cosmetics are lacking.

27. Izhmash / Kalashnikov Concern (Saiga – Pre-ban)

- Mention Frequency: High (among collectors and builders).

- Origin: Russia

- History: Izhmash, later renamed Kalashnikov Concern, is the original Russian factory where the AK-47 was developed.47 For years, they exported semi-automatic “Sporter” rifles to the U.S. under the Saiga brand name.6 These were imported in a hunting configuration with no pistol grip. They were immensely popular as the basis for high-quality conversions back to a military AK-74M or AK-100 series configuration. The importation of these rifles was banned by executive order in 2014.6

- Models: Saiga (7.62x39mm, 5.45x39mm, 5.56 NATO).

- Example Comments: “Remembering The Russians”.48 Saigas are considered the “true” Kalashnikovs as they were made in the original factory.6 They form the basis for many high-end custom builds from shops like Rifle Dynamics.1

- Ranking Rationale: A pre-2014 Saiga is considered a top-tier base rifle. It is a genuine Russian-made AK from the Izhevsk factory. The quality of the core components—receiver, barrel, trunnion, bolt—is exceptionally high. While they require conversion to achieve a proper military look, the underlying quality is second to none. They are ranked this high due to their impeccable provenance and build quality. Their value as collector’s items and as the preferred starting point for elite custom builds is immense. The only reason they are not in the absolute top tier is that they are no longer importable and require significant work to reach their final form.

26. Molot (VEPR – Pre-ban)

- Mention Frequency: Moderate to High (among collectors).

- Origin: Russia

- History: Molot-Oruzhie was another Russian manufacturer that exported rifles to the U.S., sold under the VEPR brand. VEPRs are unique because they are built on a heavy-duty RPK-style stamped receiver, which is thicker and more robust than a standard AKM receiver. Like Saigas, they were imported in sporterized configurations and were also banned from import in 2014.4

- Models: VEPR (various calibers).

- Example Comments: VEPRs are often described as “overbuilt” or “tanks” due to their RPK receivers. This makes them exceptionally durable and capable of handling hotter loads or sustained fire.

- Ranking Rationale: VEPRs are ranked alongside Saigas as premier Russian imports. They are prized for their extreme durability thanks to the RPK receiver and heavy, chrome-lined barrels. The overall build quality is excellent. For many, the VEPR represents the pinnacle of stamped-receiver AK durability. Like the Saiga, they are no longer available new and have become highly sought-after collector’s items, commanding a premium price on the used market.

25. Clayco (Pre-ban Chinese)

- Mention Frequency: Low (highly specialized collector’s item).

- Origin: China

- History: Clayco Sports, Ltd. was one of the very first importers of Chinese AKs into the U.S., beginning around 1983-1984. These were true, pre-ban military-style rifles, not sporterized versions.3

- Models: AKS.

- Example Comments: “In 1984, approximately one year after the import of the Clayco AKS, the second of the Chinese ‘pre-ban’ AK’s began importation”.3 These are the rifles that established the reputation of Chinese AKs in the U.S.

- Ranking Rationale: Clayco imports are pure collector’s items. They represent the first wave of authentic AKs to hit the U.S. market. Their quality is representative of Chinese military production of the era, which was very good. They are ranked here for their historical significance and rarity. They score highly on build quality and reliability, but their value is almost entirely as a collector’s piece, with prices reflecting that rarity. They are functionally excellent but are seldom shot due to their high value.

24. Polytech (Pre-ban Chinese Legend)

- Mention Frequency: Moderate (highly revered collector’s item).

- Origin: China

- History: In the late 1980s, Poly Technologies of China imported what many consider to be the “Rolls Royce” of AKs: the Polytech Legend.2 These were unique because they were built on a milled receiver, emulating the original Russian Type 3 AK-47, rather than the more common stamped receiver. The quality, fit, and finish were exceptional.

- Models: AKS-762 (Legend Series).

- Example Comments: “These carbines were hand-crafted to Chinese military specifications and easily had the best quality of any AK-47 made before or since.”.2 “Receivers were milled out of blocks of high ordnance steel… All parts were then carefully polished before the high luster bluing was applied.”.2

- Ranking Rationale: The Polytech Legend is an investment-grade firearm. It combines the desirable milled receiver with a level of fit and finish that is almost unheard of in a military-pattern rifle. They are exceptionally accurate and reliable. Their value has appreciated enormously since the import ban.2 They are ranked at the pinnacle of the collector’s tier, representing the highest quality factory-produced AK ever widely imported into the U.S. They are a benchmark for quality against which even modern custom guns are sometimes compared.

23. IWI Galil ACE

- Mention Frequency: High.

- Origin: Israel (Design), USA (Manufacture/Assembly).

- History: The IWI Galil ACE is a modern evolution of the original Israeli Galil rifle, which was itself based on the Finnish Valmet RK 62, a high-quality AK derivative. The ACE retains the long-stroke gas piston reliability of the AK but incorporates modern features like a milled steel upper receiver, full-length Picatinny rail, M-LOK handguard, and improved ergonomics.9

- Models: Galil ACE Gen 2 (7.62x39mm, 5.56 NATO, 7.62x51mm).

- Example Comments: “Wildcard AK-47 Pick. IWI Galil ACE Gen 2.”.8 “The Galil Ace strikes a balance between traditional AK styling and contemporary functionality, making it a top choice for those seeking a modern AK rifle with cutting-edge features.”.9 It is praised for its accuracy, improved trigger, and modern features, while retaining AK-level reliability.49

- Ranking Rationale: The Galil ACE is the quintessential “modernized AK.” It successfully bridges the gap between the raw reliability of the Kalashnikov and the ergonomic and modular features of Western rifles like the AR-15. Build quality is excellent, with a robust milled steel receiver. It scores very highly in accuracy, reliability, and fit/finish. It is ranked here as the best option for a buyer who loves the AK operating system but wants modern features out of the box. Its only “detractor” in the eyes of purists is that it is not a traditional AK, but for most modern shooters, its features are significant upgrades.

22. ReCreator Blanks (Receivers)

- Mention Frequency: Moderate to High (among builders).

- Origin: USA

- History: ReCreator Blanks is a U.S. manufacturer specializing in high-quality AK receiver blanks and completed receivers. They are known for their attention to detail and producing dimensionally correct receivers that are ideal for historically accurate builds.50

- Models: AKM, AK-74, Polish, and other pattern receivers/blanks.

- Example Comments: “ReCreator Blanks AK47 style firearms are made from the highest quality American components available, ensuring that you get the ultimate in performance and reliability.”.50 They are often recommended on builder forums as a top choice for starting a quality build.51

- Ranking Rationale: ReCreator is ranked highly as a component manufacturer because the receiver is the literal foundation of the rifle. By providing a high-quality, dimensionally correct, and properly heat-treated receiver, they enable builders to create rifles that are superior to many factory offerings. Their reputation for quality is excellent. They score highly on build quality and customer satisfaction within the builder community. They are a critical enabler of the high-end DIY segment of the market.

21. Tortort Manufacturing (Receivers)

- Mention Frequency: Moderate (among builders).

- Origin: USA

- History: Tortort Manufacturing is a U.S. company that specializes in producing high-end, 100% complete milled AK receivers. Milled receivers are more complex and expensive to manufacture than stamped ones, and Tortort is one of the few companies that makes them to a high standard for the civilian market.52

- Models: Milled receivers for Polish, Russian, Bulgarian, and Yugo pattern kits.52

- Example Comments: Their products are sought after for building clones of milled AKs like the original Type 3 or the Yugo M70. “This is a rare opportunity to own a meticulously crafted piece of history—perfectly assembled.” 53 (referring to a barreled action on a Tortort receiver).

- Ranking Rationale: Tortort occupies a premium niche in the components market. For builders wanting to create a milled AK clone, Tortort is the go-to source for the receiver. Their products are considered to be of exceptional quality, justifying their higher price. They are ranked here for their excellence in a difficult and specialized area of manufacturing. Like ReCreator, they are a key enabler for the high-end builder, providing a foundation that is arguably superior in strength to even the best stamped receivers.

20. Childers Guns (Receivers)

- Mention Frequency: High (among builders).

- Origin: USA

- History: Childers Guns is arguably the most well-known and respected manufacturer of stamped AK receivers in the U.S..54 They offer an unparalleled range of options, allowing builders to order receivers with specific, historically correct selector markings, country-specific features, and custom serial numbers.

- Models: Receivers for nearly every AK variant (AKM, AK-74, Polish, Romanian, Yugo, Chinese, Tantal, etc.).55

- Example Comments: Childers is praised for both the quality of their receivers and the depth of their customization options. They are the top choice for builders seeking to make a build as historically accurate as possible. “Childers Guns LLC is a licensed 07 / SOT manufacturer of firearms specializing in custom AK 47 Receivers…”.54

- Ranking Rationale: Childers Guns is ranked at the top of the component manufacturer list and at the pinnacle of this tier. Their combination of high-quality, properly heat-treated receivers and extensive customization options makes them the undisputed market leader for stamped receivers.55 The success of a huge portion of the custom and DIY AK market rests on the quality of their products. They have earned the trust of the most discerning builders in the community, and their receivers are the foundation of countless high-end rifles. Their scores for build quality and customer satisfaction are near-perfect within their niche.

Tier 2: The Premier Modern AKs (Ranks 19-6)

This tier represents the best of what is currently and readily available in the AK market. These are brands and products characterized by excellent manufacturing standards, consistent use of high-quality materials, and overwhelmingly positive feedback from the community. This segment includes the most recommended complete rifles for serious use, as well as the key component and accessory makers whose products are essential for modernizing the platform. These are the go-to choices for buyers seeking top-tier, reliable performance without the extreme costs or long wait times associated with full custom builds.

19. Magpul (Furniture & Accessories)

- Mention Frequency: Very High.

- Origin: USA

- History: Magpul Industries, founded in 1999, revolutionized the firearms accessory market with its innovative polymer products.57 While famous for their AR-15 accessories, they have a comprehensive and highly respected line of AK furniture and magazines.

- Models: MOE & Zhukov handguards and stocks, AK PMAGs, pistol grips.58

- Example Comments: “I have now shot well over a dozen different AK-47 rifles… using PMAGS, all with great success and reliability.”.58 “The handguard, pistol grip and stock are sold separately and come in under $120 total, which is similar to a much heavier, wood set that may or may not look as good.”.58

- Ranking Rationale: Magpul is the undisputed leader in polymer AK furniture and magazines. Their products are the default choice for users looking to upgrade the ergonomics and reduce the weight of their rifles. AK PMAGs are considered a benchmark for reliability and value. Their furniture is well-designed, durable, and affordable. While they don’t make rifles, their influence is so pervasive that they function as a brand standard. A rifle outfitted with Magpul furniture is instantly recognized as being modernized. They score perfectly on customer satisfaction and are considered the best value in AK upgrades.

18. Midwest Industries (Accessories)

- Mention Frequency: High.

- Origin: USA

- History: Midwest Industries is a U.S. manufacturer known for producing high-quality metal firearm accessories, particularly handguards and optic mounts. Their AK Alpha series is a direct competitor to high-end Russian “Zenitco” furniture, offering a similar aesthetic and high degree of modularity.59

- Models: AK Alpha Series (handguards, top covers), various optic mounts, muzzle devices.

- Example Comments: “Excellent quality and design. I have the Barwarus version and Midwest Induatries design is far better in terms of installation and rock solid use.”.59 “Locks up Securely, and wirks perfect!”.59

- Ranking Rationale: Midwest Industries is the premier U.S. manufacturer for metal AK handguards and optic mounting solutions. Their products are praised for their robust construction, excellent fit, and ability to hold zero when mounting optics. The AK Alpha series provides a complete, modern furniture system that is both highly functional and aesthetically pleasing. They are ranked just below Magpul because their products serve a more premium, specialized niche (metal vs. polymer), but their quality and reputation are top-notch.

17. JMAC Customs (Muzzle Devices & Accessories)

- Mention Frequency: Moderate to High.

- Origin: USA

- History: JMAC Customs is a specialized manufacturer known for its innovative and highly effective muzzle devices, as well as stock adapters and other accessories. Their products are focused on enhancing the performance and modularity of the AK platform.

- Models: RRD-4C Muzzle Brake, 1913 stock/brace adapters.60

- Example Comments: “Jmac Customs making top quality products.”.60 “This is a quality part. It was easy to install and it is a solid mounting point.”.60 Their products are frequently seen on high-end builds and are used by other manufacturers, such as on some PSA models.35

- Ranking Rationale: JMAC Customs is a leader in the high-performance AK accessories space. Their muzzle brakes are widely considered some of the most effective on the market for taming recoil and muzzle rise. Their adapter systems are critical for users wanting to add modern, AR-style stocks and braces to their AKs. The quality of their machining and design is consistently praised. They are a key enabler of the “modern fighting AK” concept, and their high scores reflect their excellent reputation for quality and innovation.

16. Circle 10 / K-Var (Magazines/Parts)

- Mention Frequency: High.

- Origin: Bulgaria (Manufacture), USA (Import).

- History: K-Var Corp is the primary U.S. importer and distributor for Arsenal of Bulgaria. The “Circle 10” marking signifies parts and magazines made in Arsenal’s Bulgarian factory. Circle 10 magazines are widely considered the gold standard for polymer AK magazines.61

- Models: Circle 10 “Waffle” magazines, Bulgarian military parts.

- Example Comments: “Arsenal Circle 10 magazines are some of the finest AK magazines in the world. They are the ONLY magazine to pass 100% of military drop tests, 100% of the time.”.63

- Ranking Rationale: Circle 10 magazines are the benchmark for absolute reliability and durability. Their steel-reinforced feed lips and locking lugs, combined with robust polymer bodies, make them virtually indestructible. While more expensive than other options like PMAGs, they are the top choice for users who demand military-grade, “go-to-war” reliability from their magazines. K-Var, as the distributor, is a long-standing and central entity in the AK community. The perfect scores for build quality and reliability reflect the magazine’s unparalleled reputation.

15. Definitive Arms

- Mention Frequency: Moderate.

- Origin: USA

- History: Definitive Arms is a family-owned custom shop and manufacturer founded in 2010. They are renowned for their high-quality builds, innovative accessories (like their AR magwell conversion for 5.56 AKs), and meticulous attention to detail.64

- Models: DAKM line of rifles, custom builds, magwell adapters.

- Example Comments: “…when you feel the rifle. and the function of it. and just how it shoots everything’s lined up perfectly i mean the sights are dead nut. straight… doesn’t even feel like an AK.”.65 They are known for producing “the most accurate AK rifles and innovative accessories available.”.64

- Ranking Rationale: Definitive Arms sits in the space between a production company and a full custom shop. Their DAKM rifles are built to an extremely high standard of quality, with a focus on perfect alignment and smooth function that surpasses typical factory guns. Their reputation for accuracy and craftsmanship is excellent. They are ranked here as a top-tier builder whose products offer a significant step up from standard imports, approaching the quality of the elite custom shops but with slightly more accessibility.

14. Occam Defense Solutions

- Mention Frequency: Low but very positive.

- Origin: USA

- History: Occam Defense Solutions was founded out of a desire to create superior, user-installable modern accessories for the AK platform. Their flagship products are the MERC free-float handguard and the ODS-1775 rifle, which is built from the ground up as a modern, American-made fighting rifle.66

- Models: ODS-1775 Rifle/Pistol, MERC Handguard, HEX 2.0 Stock.

- Example Comments: “the ODS-1775 rifle might just be the gold standard when it comes to American-made Kalashnikov rifles.”.66 “The ODS-1775 rifle was put together with expert care and craftsmanship… the gun has run with 100-percent reliability.”.66

- Ranking Rationale: Occam Defense is a highly-regarded innovator in the American AK space. Their ODS-1775 rifle is praised for its excellent craftsmanship, balance, reliability, and accuracy. The design philosophy focuses on creating a truly modern, free-floated AK that maintains zero with optics. While a smaller operation, their reputation for quality and thoughtful design is exceptional. They are ranked highly as a premier American manufacturer that successfully competes with top imports and other custom builders on quality and performance.

13. Atlantic Arms MFG (Custom Builds)

- Mention Frequency: Moderate.

- Origin: USA

- History: The manufacturing arm of the retailer Atlantic Firearms, AA MFG produces a variety of high-quality rifles, often based on desirable parts kits (e.g., Polish WBP) and built with meticulous attention to detail. They leverage Atlantic’s two-decade reputation for customer service.37

- Models: WBP builds, custom series rifles.

- Example Comments: “Built on a solid foundation AA MFG can offer a reasonable price for custom quality that rival other high end builders, all backed up by Atlantics twenty year track record for customer service.”.37

- Ranking Rationale: Atlantic Arms MFG is ranked here as one of the best and most trusted large-scale builders. They bridge the gap between mass production and individual custom work. By using top-tier components like WBP parts kits and Childers receivers, and backing it with their renowned customer service, they offer a product that is both high-quality and low-risk for the buyer. Their builds are consistently praised for their fit, finish, and reliability, placing them firmly in the premier tier.

12. Palmetto State Armory (PSA) – AK-E / Spiker Models

- Mention Frequency: High.

- Origin: USA

- History: The AK-E (Enhanced) is PSA’s former top-of-the-line model, featuring upgrades like an ALG trigger and premium furniture. Their “Spiker” models are clones of the iconic Chinese Type 56 rifle, complete with a permanently attached folding bayonet. These models represent PSA’s efforts to move beyond budget offerings and compete in the enthusiast and collector space.

- Models: AK-E, PSAK-47 Type 56 “Spiker”.

- Example Comments: The AK-E was widely reviewed as PSA’s best effort, combining their forged components with top-tier aftermarket parts. The Spiker models are praised by the community for being a fun and affordable way to own a clone of a highly desirable and iconic AK variant.

- Ranking Rationale: This category represents PSA’s premium offerings. The AK-E and Spiker models demonstrate PSA’s ability to produce not just functional rifles, but rifles with specific, desirable features for enthusiasts. The build quality is based on their solid GF-series foundation (forged parts, CHF barrels), but with added features that increase their value and appeal. They are ranked at the top of PSA’s offerings, showing the company’s maturation from a budget-only brand to a full-spectrum manufacturer.

11. Kalashnikov USA (KUSA)

- Mention Frequency: Very High.

- Origin: USA

- History: Kalashnikov USA was formed after the 2014 ban on Russian imports. They are not affiliated with the Russian Kalashnikov Concern but aim to produce authentic, high-quality clones of modern Russian AKs using Russian technical data.6 After some early QC issues, their reputation has become very strong.10

- Models: KR-103 (AK-103 clone), KR-101 (5.56), KP-9 (9mm Vityaz clone), KR-104 (short-barreled AK-104 clone).9

- Example Comments: “At the moment they are the ONLY American company I’d trust to get an AK from.”.68 “The KR-103 is a pretty faithful production honoring the original AK-103… Fitment is well done with no flex… the rivets are all even and appear to be placed with care.”.17 “The reliability over the course of our testing was perfect.”.17

- Ranking Rationale: KUSA is widely considered the best domestic manufacturer of “pure” AK-pattern rifles. Their commitment to cloning Russian designs as faithfully as possible has earned them the respect of the community. Their rifles are praised for their excellent fit, finish, and, most importantly, reliability.17 They successfully fill the void left by the ban on Russian Saigas, offering high-quality, American-made versions of modern AK-100 series rifles. They score very highly across the board and are the top-ranked U.S. manufacturer in this analysis.

10. Cugir / ROMARM (PSL, AES-10B Imports)

- Mention Frequency: Moderate.

- Origin: Romania

- History: The Cugir factory in Romania, in addition to the WASR-10, also produces specialized AK variants like the PSL (a designated marksman rifle chambered in 7.62x54R) and the AES-10B (a semi-auto version of the RPK light machine gun).46 These are imported by Century Arms.

- Models: PSL 54, AES-10B.

- Example Comments: “First time ever imported, new manufactured PSL Rifles. One of the most famous DMR rifles ever made…”.46 The AES-10B is praised for being a robust, heavy-duty AK with a bulged RPK receiver and heavy barrel.

- Ranking Rationale: These specialized Romanian imports are ranked highly for their unique military heritage and robust construction. The PSL is the most accessible and affordable Combloc DMR available in the U.S. The AES-10B is a true semi-auto RPK. Like the WASR, they are built in a military arsenal and are known for their durability and reliability. Their build quality, particularly the heavy-duty receivers and barrels, is excellent. They serve a niche but important role in the market for enthusiasts seeking something beyond a standard AKM.

9. WBP Rogów (Poland – “Jack” Rifle)

- Mention Frequency: High.

- Origin: Poland

- History: WBP (Wytwórnia Broni Jacek Popiński) is a private Polish firearms manufacturer that has gained an exceptional reputation in the U.S. for producing high-quality, commercially available AK rifles. They are imported by retailers like Atlantic Firearms and Arms of America.7

- Models: 762SC Jack (7.62x39mm), 556SC Jack (5.56mm).

- Example Comments: “Best Looking AK: WBP 762SC Jack Classic.”.7 “Gorgeous finish. Handsome furniture. Barrel is chrome-lined and made by FB Radom. Reliable, faithful AKM clone.”.7 “The WPB jack comes with nicer furniture, and is an AKM but is a little more expensive, around $1200.”.11

- Ranking Rationale: WBP rifles are praised for their exceptional fit and finish, which far exceeds that of typical military-style imports like the WASR. They combine the reliability of a Polish-made, chrome-lined barrel (often sourced from the esteemed FB Radom factory) with a level of commercial polish that appeals to discerning buyers.7 They are considered a step up from the WASR and a direct competitor to Zastava and Arsenal. Their beautiful finish and high-quality laminate wood furniture make them a top choice for buyers who want a rifle that is both a reliable shooter and aesthetically pleasing right out of the box.

8. Zastava Arms USA (ZPAP M70)

- Mention Frequency: Very High.

- Origin: Serbia (Manufacture), USA (Import).

- History: Zastava has a long history of making firearms in Serbia (formerly Yugoslavia). Their rifles were previously imported by Century Arms as the N-PAP and O-PAP, with mixed reception due to inconsistent features. In 2019, Zastava established Zastava Arms USA as a direct factory importer, ensuring all new rifles (now named ZPAP) meet a high-quality standard, including bulged 1.5mm receivers and chrome-lined barrels.8

- Models: ZPAP M70 (7.62x39mm), ZPAP M90 (5.56mm), ZPAP85/92 (pistols).

- Example Comments: “Best Overall AK-47. Zastava ZPAP M70.”.8 “The Yugos are not typical AKs but they’re built like tanks.”.11 “Zastava has a long history of producing AKs… in 2019, they decided to cut out the import middleman and opened a US production plant [office/warehouse] in Des Plaines, Illinois.”.8

- Ranking Rationale: The Zastava ZPAP M70 has become one of the most highly recommended AKs on the market. The establishment of Zastava Arms USA has been a massive success, resolving the quality control inconsistencies of previous importers. The standard features of the ZPAP M70—a 1.5mm bulged trunnion receiver and a cold-hammer-forged, chrome-lined barrel—make it exceptionally durable. Fit and finish are consistently excellent. Their active engagement with the customer base and strong warranty support have built immense brand loyalty.11 The only minor drawback is that its “Yugo” pattern furniture is not compatible with standard AKM furniture, but the aftermarket for Yugo-pattern parts is now very strong.8 They represent the benchmark for a heavy-duty, high-quality imported AK.

7. Arsenal Inc. (Stamped SLR Series)

- Mention Frequency: High.

- Origin: Bulgaria (Manufacture), USA (Import).

- History: Arsenal of Bulgaria is a premier military firearms manufacturer. Their semi-auto rifles are imported and distributed in the U.S. by Arsenal, Inc. of Las Vegas. The SLR series are stamped-receiver rifles based on modern Bulgarian military patterns.72

- Models: SLR-107FR (7.62×39), SLR-104FR (5.45×39, now discontinued/rare), SLR-106 (5.56).

- Example Comments: “Arsenal of Bulgaria is regarded as one of the premier AK manufacturers in the world.”.8 For years, the SLR-107FR was considered the gold standard for a high-end, stamped-receiver AK. However, recent sentiment suggests some QC issues have emerged, and their price has made them less competitive against Zastava and WBP.10

- Ranking Rationale: For a long time, Arsenal’s SLR series was the undisputed king of stamped AKs. They feature authentic Bulgarian parts, excellent CHF chrome-lined barrels, and correct military features. However, in recent years, their market position has been challenged. Rising prices and some community reports of minor QC issues (like finish durability) have slightly tarnished their once-perfect reputation.10 They are still a premier, top-tier rifle, but the fierce competition from the excellent and more affordable ZPAP M70 and WBP Jack has moved them from the top spot into this still-elite position.

6. FB Radom (Beryl / Mini Beryl Imports)

- Mention Frequency: Moderate to High.

- Origin: Poland

- History: Fabryka Broni “Łucznik” – Radom is the historic Polish state military arsenal, dating back to 1922. They are the manufacturers of the current Polish military service rifle, the Beryl. Limited batches of semi-automatic Beryl and Mini Beryl rifles are imported into the U.S., typically by Atlantic Firearms and Arms of America.53

- Models: Beryl M762 (7.62×39), Beryl M556 (5.56), Mini Beryl.

- Example Comments: “Beryls are great but pricy.”.11 They are highly sought after for being genuine, current-issue military rifles from a respected NATO country’s arsenal. Their quality is considered to be on par with or exceeding that of Arsenal.

- Ranking Rationale: The FB Radom Beryl is a top-tier, military-grade rifle. Its quality, reliability, and accuracy are considered exceptional. Being the actual rifle used by the Polish military gives it an authenticity that is highly valued by collectors and serious shooters. They are ranked above the other production rifles due to this combination of impeccable military quality and relative rarity. The only factor keeping them from the absolute top spots is their limited availability; they are imported in batches and sell out quickly, commanding a premium price. For those able to acquire one, they represent one of the best factory AKs available.

Tier 1: The Elite / Investment-Grade (Ranks 5-1)

This is the apex of the American AK market. This tier is composed of the most respected and sought-after custom shops, along with the highest-echelon production rifles and components. These brands are defined by meticulous hand-fitting, innovative modernization that addresses the AK’s inherent weaknesses, and performance that often exceeds traditional Kalashnikov standards. They command a significant price premium, reflecting their status as investment-grade firearms built for the most discerning connoisseurs and professional users.

5. Meridian Defense Corporation

- Mention Frequency: Moderate but extremely positive.

- Origin: USA

- History: Meridian Defense Corp. is a custom builder that has rapidly gained a stellar reputation for producing high-end, modernized AK rifles. They focus on building “serious gunfighter” rifles with improved ergonomics, accuracy, and flawless reliability.74

- Models: MDC-47 “Volk”, custom builds.

- Example Comments: “The Volk, however, is definitely one of the nicest AKs I have ever run. Beyond its modern feel and reliable functioning, the gun was also very accurate.”.74 “While the AK has never been known as a precision weapon, Meridian Defense is changing that cliché. With a variety of ammo on the menu, I was able to squeak out a sub-MOA group…”.74

- Ranking Rationale: Meridian Defense represents the new guard of elite American AK builders. Their rifles are praised for feeling incredibly solid (often using milled receivers), having exceptional accuracy for the platform, and featuring a superb level of fit and finish where all sharp edges are dehorned.75 They successfully blend the AK’s reliability with modern features and a level of refinement that justifies their premium price. Their ability to produce sub-MOA accuracy from an AK platform is a significant achievement and a testament to their build quality, placing them firmly in the top tier of the market.

4. Arsenal Inc. (Milled SAM7 Series)

- Mention Frequency: Very High.

- Origin: Bulgaria (Manufacture), USA (Import).