At this point, the AK-V is almost ready. As you may have noticed in the first post about impressions out of the box, it shipped pretty dry with just some oil to prevent rust and that’s just fine. In this post I’ll outline what I did to lubricate it and also the cool US Peacekeeper case it will be carried in.

Cleaning the AK-V

On any new weapon, you need to run a bore snake or whatever your preferred method is to get any remnants from machining, dust, etc. out of the barrel. I ran a RamRodz tip down the length of the barrel coated in CLP and it came out fairly dirty. I did this four times with two RamRodz and was set. Note, I usually use the RamRodz on my 9mm pistols and happened to have them sitting there. The wood push sticjs were too short for the AK-Vs barrel so I used a small nut driver to push the wood stick down. I would normally use a Hoppes 9mm Bore Snake.

Lubricating the AK-V

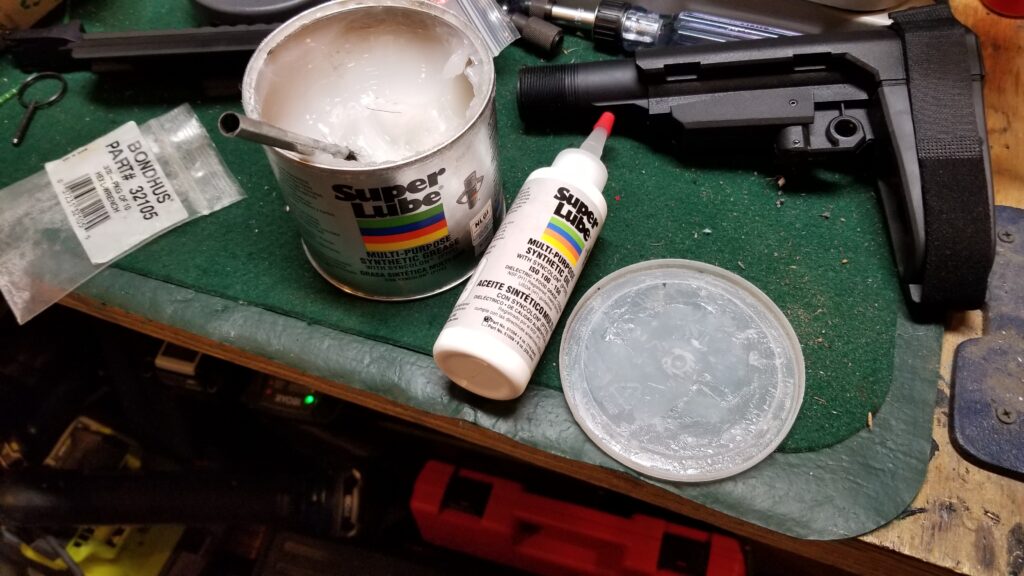

To lubricate the weapon, I pretty much did what I normally do with any AK and I follow and old saying “If it slides, grease it. If it rotates, oil it”. My grease of choice these days is Super Lube. It works great on weapons in a wide range of temperatures, is a synthetic grease and includes very fine particles of PTFE (Telfon) in it. I apply it to the bottom of the bolt carrier, rails, fire control group (FCG) surfaces and a light film in the hole for the recoil spring in the bolt group. I wanted to say bolt carrier but in the AK-V, the bolt is a one piece combination of the traditional bolt barrier and bolt body.

I then used Super Lube oil on the FCG pins plus a drop on each end of the firing pin. Technically, I tried to put a drop in the hole on the bolt face and a drop on the exposed firing on on the rear. I also made sure the extractor was oiled as well.

After lubricating the AK-V, I function tested it. Wow. What an amazing difference. We’re talking night and day difference. It was incredibly smooth and hadn’t even been broke in yet!

US Peacekeeper 28″ Rapid Assault Tactical Case

Ok, so after measuring the rifle, I ordered the US Peacekeeper case and it fits like a glove. Often you have slop at the ends but here the butt and muzzle go right up to the cushioned ends.

The case is rather discrete and very well made in terms of materials, zippers and stitching. Inside the outer pocket is MOLLE straps for securing pourches and accessories. To hold the magazines, I opted for a three cell pouch made for AR magazines – you can get two of the AK-V 35 round magazines in each and just barely close the flap.

That’s It For Now

I will try to get this to the range at some point and will report back when I do. I hope you found these posts useful.

This is a four part series on the PSA AK-V 9pmm:

- Part One: Good Reviews Really Raised My Interest After PSA Fixed the Initial Problems

- Part Two: First Thoughts Out Of The Box (tons of photos)

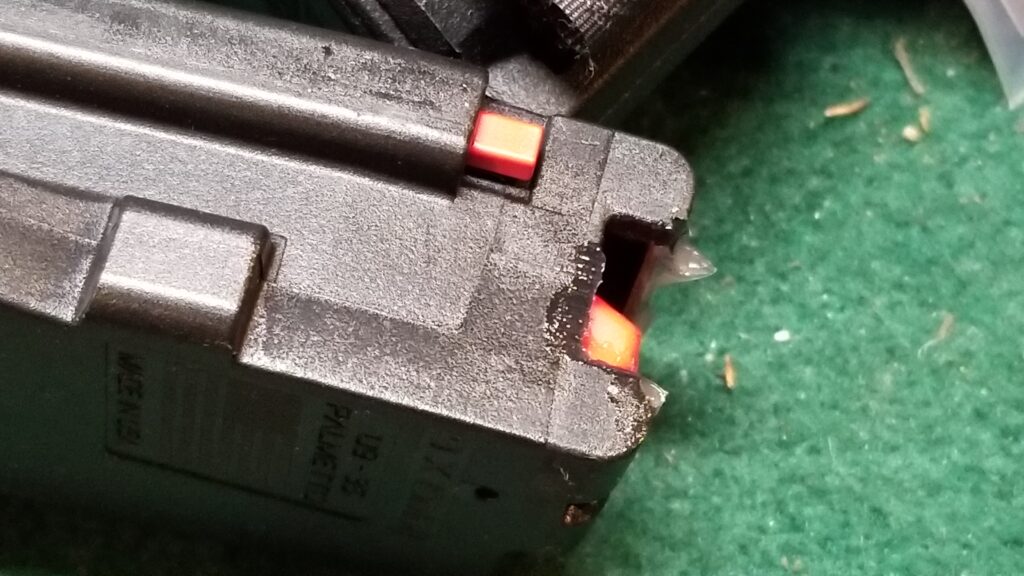

- Part Three: Changing the Brace, Adding a Red Dot and Installing a Quick Takedown Pin For the Dust Cover

- Part Four: Lubricating the AK-V and a 28″ US Peacekeeper Carrying Case

Note, I have to buy all of my parts – nothing here was paid for by sponsors, etc. I do make a small amount if you click on an ad and buy something but that is it. You’re getting my real opinion on stuff.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, we are only paid if there is an affiliate program such as Avantlink, Impact, Amazon and eBay and only if you purchase something. If you’d like to directly contribute towards our continued reporting, please visit our funding page.

PSA AK Webstore Links

Interested in an American made AK? Consider Palmetto State Armory (PSA) as a source. Click on the following links for the associated webstore categories for AK-related rifles, pistols and parts at PSA:

- PSA AK-74 – PSA, just released their 5.45×39 rifle

- PSA AK-47 GF4

- AK-V (their Vityaz-inspired wicked 9mm) – [click here for my blog posts on the one I bought and converted] – this includes accessories

- Accessories including magazines, handguards, grips, triggers and more

- They are also selling individual parts such as springs, barrels, bolt carriers, furniture sets, repair kits and more