To be honest, Bergara wasn’t even on my radar until the Summer of 2023. I was talking to my good friend, Scott Igert, who, along with his wife Alicia, own Michigan Gun Exchange, about a slick looking bolt rifle he bought for inventory to sell – it was a Bergara B14 HMR. I’d not heard of the brand before and he told me they were known for their barrels. If I had heard of Bergara before then, I really hadn’t paid attention and what was in front of me was a very nicely done bolt gun with a sub-Minute of Angle (MOA) guarantee.

The Bergara B14 HMR looked and felt good – nice trigger, smooth action and shouldered well. My only problem was that I knew nothing about them so I didn’t buy it and decided I better do some digging. What I found out was impressive and want to share it – by the way, I did go back and buy the rifle a few weeks later.

Corporate and Brand Structure

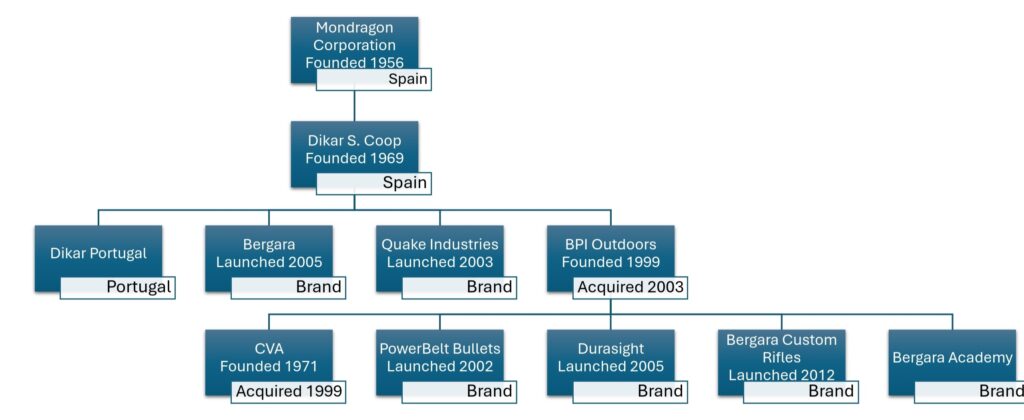

Like many arms companies these days, understanding the organizational and brand structure around Bergara took some research. Bergara is basically a brand owned by Dikar S Coop of Spain who is owned by Mondragon. Let me show you a chart to better explain this – click on the diagram to see a full size copy:

That diagram is the best I can come up with after reading Mondragon, Dikar S Coop and BPI Outdoor websites, 3rd party stories, etc. If anyone from BPI or Dikar want to email me some corrections, I’d very much welcome them.

Let’s Look At Each

- Mondragon Corporation – Books could be written about this firm and their cooperative business model – I can only summarize a tiny bit. Mondragon was founded in 1956 in Mondragon, Spain. Today, Mondragon is the seventh largest corporation in Spain (based on asset turnover) and is a worker cooperative [Click here for a ton of webpages that cover their “co-op” model in more detail]. In 2024, it had over 70,000 workers, 30,660 in the Basque Country, 29,340 in the rest of Spain and around 10,000 abroad. It has four broad categories of business – finance, industrial/equipment (I’ve seen this group mentioned three different ways – industrial, equipment and manufacturing), retail, and knowledge. To me, I think of them as a holding company with a very interesting set of management principles.

- Dikar S Coop – Is a cooperative owned by Mondragon Corporation. It’s part of the industrial/equipment group. Dikar S Coop focuses on sporting goods. It was formed by the merger of two Spanish gunmakers in 1969 Mendi S Coop (shotguns) and Jukar (muzzle loaders). Jukar was looking for access to the US market and Mendi mainly sold there. It joined Mondragon in 1991. In 2003, Dikar bought BPI Outdoors who was their largest barrel customer at that time. Today, Dikar it has over 300 people and markets in 45 countries. Note, their website links to online stores for Quake and Bergara direcly.

- Dikar Portugal – Launched in 2003 initially to produce products for Quake Industries. There are current references to them making products for Bergara, CVA and Quake.

- Bergara – the brand was launched in 2010 initially focused on barrels and introduced rifles and accessories to the US market in 2015. Within five years, Bergara sales exceeded the other brands. Note, the Dikar website is ambiguous but I think they mean within five years after the introduction to the US market. What I find interesting is their early emphasis on producing high quality barrels. They actually retained Ed Shilen, the brains behind Shilen custom barrels, to help them understand the process and methods behind quality barrels. While you may know Bergara for their rifles, they make a ton of different barrels for other big name companies.

- Quake Industries – while focused on the American market, Quake products are sold in 45 countries. They make various accessories for shooters including bags, belts, optics covers, staps/slings and more.

- BPI Outdoors – Black Powder Inc (BPI)was founded in 1999 and bought Connecticut Valley Arms (CVA) that same year. BPI Outdoors is directly owned by Dikar S Coop and isn’t surprising given Dikar’s history of muzzleloaders. As of September 2024, they employee about 75 people in Lawrenceville, Georgia.

- CVA – is the #1 brand of muzzle loader rifles in the US. In 2020, they entered the centerfire market. They did get a black eye with a barrel quality problem in 1995 and 1996 model years but that was before BPI bought them in 1999. My understanding is that Bergara makes the CVA barrels now.

- PowerBelt – is a leading brand of muzzle loader ammunition launched in 2002.

- Durasight – is a brand of sights, scope bases and rings for CVA firearms launched in 2005.

- Bergara Custom Rifles – In 2012 BPI hired retired USMC Msgt Dan Hanus. Mr. Hanus was schooled and then led the USMC’s Precision Rifle Section in Quantico, VA. He then brought in a few more builders he knew plus BPI invested in CNC machines for them to use. Their custom rifles were almost immediately adopted by a number of Georgia SWAT teams. If I had $5-6,000 + money for a comparable optic, I’d sure get in line for one of their BCR19 Heavy Tactical rifles.

- Bergara Academy – they offer long-range shooting classes in Montana and Wyoming. Small class sizes and all-inclusive pricing makes their offerings very interesting. [Read that as “I would go in a heartbeat if I could afford it!”]

Summary

You’d think “Who is Bergara?” would get a simple answer. I guess it depends on where you stop but I learned quite a bit. For example, I had no idea that Bergara started with barrels and that partly explains why my B14 HMR was so accurate. I also didn’t know about the business model set forth by Mondragon.

In short, there is a lot of experience behind Bergara not to mention capital for innovation and expansion. I also think there is a lot of good momentum pushing them forward and we will see more and more from them.

I hope this helps you out.

References

This post took some digging so I want to provide the source pages in case you are interested:

- https://www.bergara.online/en/about-us/

- https://bpioutdoors.com/about/

- https://dikarcoop.com/quienes-somos/dikar-s-coop/

- https://www.mondragon-corporation.com/

- https://www.mondragon-corporation.com/urtekotxostena/1_carta.php

- https://en.wikipedia.org/wiki/Mondragon_Corporation

- These next posts are about BPI Outdoors and Bergara in the US:

- https://gon.com/hunting/bpi-outdoors-georgia-company

- https://coffeeordie.com/book-bergara-rifles

- https://www.americanrifleman.org/content/bergara-from-blackpowder-beginnings-to-rifle-powerhouse/

- https://www.americanrifleman.org/content/bergara-storms-the-rifle-market/

- https://blog.refactortactical.com/blog/who-is-bergara/

Note, I have to buy all of my parts – nothing here was paid for by sponsors, etc. I do make a small amount if you click on an ad and buy something but that is it. You’re getting my real opinion on stuff.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, we are only paid if there is an affiliate program such as Avantlink, Impact, Amazon and eBay and only if you purchase something. If you’d like to directly contribute towards our continued reporting, please visit our funding page.