Wytwórnia Broni Jacek Popiński (WBP), a privately-owned Polish firearms manufacturer, has rapidly established itself as a dominant force in the U.S. market for imported Kalashnikov-pattern rifles. Occupying a strategic position in the premium mid-tier segment, WBP has cultivated a formidable reputation for producing firearms that exhibit exceptional quality, fit, and finish, often exceeding the standards of legacy state-run arsenals from other former Combloc nations. The company’s success is underpinned by a synthesis of modern manufacturing techniques and traditional Polish craftsmanship, further bolstered by a strategic partnership with the state-owned FB “Łucznik” Radom arsenal for critical military-grade components, such as cold hammer-forged, chrome-lined barrels.

This report finds that WBP’s U.S. market presence is facilitated by a resilient and flexible importation and distribution ecosystem involving key partners like Arms of America, Atlantic Firearms, and the U.S.-based WBP USA entity. This structure allows the company to effectively navigate complex U.S. firearms regulations, including 18 U.S.C. § 922(r), and offer a diverse portfolio of products tailored to American consumer preferences. The primary product lines available in the U.S.—the Jack rifle, the Fox rifle, and the Mini Jack/Lynx pistols—cater to a wide range of enthusiasts, from traditionalists to modern tactical shooters.

A comprehensive analysis of consumer sentiment reveals overwhelmingly positive feedback regarding WBP’s build quality, aesthetics, and reliability. The brand is consistently lauded for its straight sights, high-quality riveting, and durable finishes, placing it on par with or above more expensive competitors. While the firearms demonstrate commendable accuracy for the AK platform, a frequently noted characteristic is a tendency to be overgassed, a trait many users successfully mitigate with aftermarket components. Overall, WBP firearms represent a compelling value proposition, delivering a level of quality and refinement that justifies their price point, which sits comfortably between budget-tier options and high-end collector pieces. The company’s demonstrated responsiveness to market feedback and its continued product line expansion signal a strong growth trajectory and a lasting presence in the American firearms landscape.

The WBP Story: From Rogów, Poland to the Global Stage

Corporate Origins and Identity

Wytwórnia Broni Jacek Popiński, universally known as WBP, is an independent, privately-owned, and family-run firearms manufacturing company headquartered in the town of Rogów, Poland.1 Unlike Poland’s historic state-run military arsenal, FB “Łucznik” Radom, which has roots in the Warsaw Pact era, WBP is a relatively new entrant to the global arms market. The company’s origins are not in government contracts but in the commercial sector, having started as a business focused on refurbishing and repairing AK-pattern rifles for the domestic Polish market.4

This commercial genesis is fundamental to understanding WBP’s corporate DNA and market strategy. Without the backing of a state mandate, the company was compelled to compete on the merits of its products from its inception. Over a period of approximately ten years, WBP underwent a significant evolution, progressing from its initial role as a refurbisher to manufacturing individual firearm components to supplement its operations. This incremental growth in capability eventually culminated in the capacity to produce complete, factory-new firearms, establishing WBP as a full-scale manufacturer.4

Manufacturing Capabilities and Quality Control

Today, WBP operates a modern, fully equipped manufacturing facility that employs over 80 highly skilled personnel, including engineers, designers, and CNC machine operators.3 The company’s production philosophy is centered on a blend of “historic Polish Kalashnikov build techniques with modern 21st-century production methods,” a message that resonates strongly with consumers seeking both authenticity and precision.2 This approach is made possible by a factory floor equipped with state-of-the-art machinery.8

WBP holds all requisite licenses and certifications from the Polish Ministry of the Interior for the manufacture, storage, and trade of firearms and operates under the auspices of an Internal Control System and ISO quality standards.3 This commitment to formalized quality control is a key differentiator. The company has also invested in significant vertical integration, establishing its own barrel manufacturing division, WBP Barrel Works. This division can produce high-quality button-rifled barrels in a range of calibers, with options for either nitriding or chrome-lining surface treatments, giving WBP direct control over one of the most critical components of a firearm.10

The company’s quality control extends to rigorous testing protocols. According to company statements, each new firearm design is subjected to a 15,000-round endurance test. Furthermore, every individual rifle is reportedly test-fired 30 times before leaving the factory, a figure that far exceeds the industry average of two or three rounds and demonstrates a serious commitment to ensuring out-of-the-box functionality.4

The Symbiotic Relationship with FB “Łucznik” Radom

A crucial element of WBP’s credibility and success, particularly in the discerning U.S. market, is its nuanced and symbiotic relationship with FB Radom. While WBP is a distinct private entity, it has cultivated a close, two-way partnership with the state arsenal.4

This relationship most notably manifests in WBP’s sourcing of key military-grade components from FB Radom. For their highly popular 7.62x39mm rifles, including the Jack and Fox series, WBP utilizes barrels that are cold hammer-forged (CHF) and chrome-lined at the FB Radom factory.4 For AK enthusiasts, an FB Radom CHF barrel is a hallmark of military-grade durability and longevity, and its inclusion in WBP rifles was a masterstroke that immediately lent the new commercial brand a level of credibility it would have taken years to build independently.

The partnership is not one-sided. WBP also serves as a parts supplier to FB Radom for some of their military contracts. These WBP-made components are subject to in-house proofing by Polish government inspectors at the FB Radom facility, providing a powerful third-party validation of WBP’s own manufacturing quality and its ability to meet stringent military specifications.4 This collaboration has occasionally led to market confusion, such as with the FB Beryl rifle, which is assembled entirely at the FB Radom factory but incorporates a handful of parts supplied by WBP.14

By strategically partnering with FB Radom, WBP created a powerful brand narrative. It successfully fused the precision, aesthetic focus, and market responsiveness of a modern private enterprise with the rugged, combat-proven heritage of a legacy military arsenal. This hybrid identity has proven to be a key differentiator in the crowded AK market and a primary driver of the company’s rapid ascent.

The Transatlantic Bridge: WBP’s U.S. Import and Distribution Ecosystem

The presence of WBP firearms in the United States is the result of a multi-entity corporate and logistical framework designed to navigate complex U.S. firearms law while maximizing market responsiveness. This ecosystem involves three key players: a primary importer, a major builder and distributor, and a U.S.-based strategic entity.

The Primary Importer: Arms of America (AoA)

Arms of America, a U.S.-based firearms importer and retailer, is identified as the exclusive importer for WBP firearms and parts kits.4 AoA was instrumental in introducing the WBP brand to American consumers, initially by importing Polish parts kits and later by bringing in complete firearms.15 AoA handles the initial importation process, which often involves receiving the firearms in a “sporter” configuration with features like thumbhole stocks and single-stack magazine wells to comply with federal import restrictions.4 The company then sells a wide array of WBP models directly to consumers through its retail channels.12

The Builder and Distributor: Atlantic Firearms

Atlantic Firearms, another major U.S. retailer, functions as a key partner in the WBP ecosystem, acting as both a builder and a distributor. In many cases, Atlantic Firearms has taken complete WBP parts kits—built around the core high-quality Polish components—and assembled them into finished rifles using U.S.-made receivers, such as those from Childers Guns.18 This method allows for the creation of unique configurations while ensuring legal compliance.

Additionally, Atlantic Firearms performs the crucial “conversion” work on many of the sporterized rifles imported by AoA. This process involves modifying the firearm to its proper military-style configuration, which includes machining the magazine well to accept standard double-stack magazines, replacing the thumbhole stock, and ensuring the final product has the requisite number of U.S.-made parts to satisfy 18 U.S.C. § 922(r).4

The Strategic Enabler: WBP USA

WBP USA is a U.S.-based entity described as an “extension of the WBP family”.2 Federal Firearms License records indicate that its license is held by Velocity LLC of Duluth, Minnesota, which also operates under the trade name Atlantic Arms MFG, highlighting the close relationship between these entities.21 The stated mission of WBP USA is to offer new models that would “otherwise have been unimportable” and to help meet the growing demand in the U.S. market.2

The establishment of WBP USA represents a sophisticated strategic maneuver. This multi-entity structure is not a sign of disorganization but rather a deliberately flexible and resilient strategy. U.S. law, specifically 922r, places strict limits on the number of foreign-made parts that can be used to assemble a semi-automatic rifle. By importing parts kits or sporter rifles, the core Polish-made components enter the country legally. The final conversion and assembly are then handled by U.S.-based partners like Atlantic Firearms and WBP USA, who can strategically incorporate U.S.-made parts (such as fire control groups, pistol grips, and furniture) to achieve compliance. This division of labor creates immense flexibility, allowing the brand to offer everything from “DIY” rifles for home builders to various turnkey configurations with either Polish or American furniture.23 This ecosystem effectively insulates the brand from the complexities of import regulations and allows it to cater to multiple market segments simultaneously.

The WBP Armory: A Detailed Analysis of U.S. Market Offerings

WBP offers a focused yet diverse portfolio of Kalashnikov-pattern firearms to the U.S. market, primarily centered around three core product families: the Fox rifle, the Jack rifle, and the Mini Jack/Lynx pistols. These models are available in multiple calibers and configurations to suit different consumer needs.

| Model Family | Available Caliber(s) | Key Distinguishing Feature | Rear Trunnion Type | Barrel (7.62×39) | Barrel (5.56/5.45) |

| WBP Fox | 7.62x39mm | Beryl-style optics rail compatibility | Beryl Pattern | FB Radom CHF Chrome-Lined | N/A |

| WBP Jack | 7.62x39mm, 5.56x45mm, 5.45x39mm | Standard AKM parts compatibility | Standard AKM Fixed | FB Radom CHF Chrome-Lined | WBP 4150 Nitrided |

| WBP Mini Jack / Lynx | 7.62x39mm, 5.56x45mm | Compact pistol/SBR platform (10″ barrel) | Underfolder (Typically) | FB Radom CHF Chrome-Lined | WBP 4150 Nitrided |

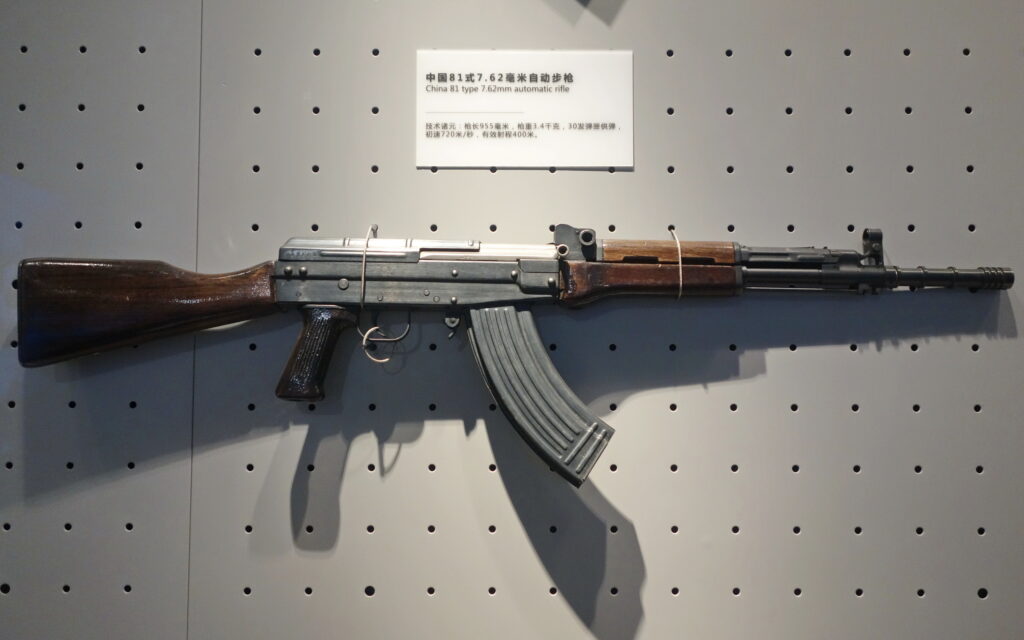

The Fox Rifle

The WBP Fox was one of the first complete WBP rifles to gain prominence in the U.S. market.4 Its defining characteristic is the use of a Beryl-style rear trunnion and rear sight block.24 This unique Polish military design allows the rifle to accept the proprietary FB Radom Beryl optic rail system, which mounts securely over the dust cover and is prized for its ability to hold zero.11 While the Fox also includes a standard side scope rail, the Beryl-ready feature appealed to enthusiasts seeking a more modern or uniquely Polish optics solution. The Fox is chambered in 7.62x39mm and is built with the highly sought-after FB Radom cold hammer-forged, chrome-lined barrel, contributing significantly to its reputation for quality and durability.13

The Jack Rifle

The Jack rifle was developed as a direct response to consumer feedback from Fox owners who desired a platform with greater aftermarket parts compatibility.11 The key difference is that the Jack utilizes a standard AKM fixed-stock rear trunnion. This seemingly small change is significant, as it makes the Jack compatible with the vast ecosystem of aftermarket AKM stocks without requiring any modification.11 This move solidified the Jack as WBP’s flagship model and the standard-bearer for a modern, high-quality AKM.

The Jack line is offered in all three major Kalashnikov calibers: 7.62x39mm, 5.56x45mm/.223 Rem, and 5.45x39mm.1 A critical distinction exists in the barrels used across the product line. The 7.62x39mm Jack rifles continue to feature the military-grade FB Radom CHF chrome-lined barrel, a major selling point.11 However, the 5.56mm and 5.45x39mm models are equipped with barrels manufactured in-house by WBP. These are high-quality 4150 steel barrels with a black nitride finish for corrosion resistance and longevity, but they are not cold hammer-forged or chrome-lined.30 All Jack rifles feature desirable collectible elements, including factory serial numbers on most major parts and the iconic Polish Eagle crest on the left side of the rear sight block.11

The Mini Jack & Lynx Pistols

The Mini Jack and Lynx models represent WBP’s entry into the popular AK pistol market.35 These firearms feature a compact form factor with 10-inch barrels and are available in both 7.62x39mm and 5.56x45mm.1 They are marketed as highly flexible platforms and are often imported with an underfolder-style rear trunnion pre-installed. This makes them ideal hosts for conversion into Short-Barreled Rifles (SBRs) upon receiving the required NFA tax stamp, as the most difficult part of the conversion is already complete.35 Mirroring the rifle line, the 7.62x39mm Mini Jack is equipped with a 10-inch FB Radom CHF chrome-lined barrel, a premium feature for a pistol, while the 5.56mm version uses a WBP-made nitrided barrel.37

Key Technical Variations: Milled vs. Stamped Receivers

While the majority of WBP’s firearms are based on the traditional stamped sheet metal receiver of the AKM, the company also produces variants with receivers machined from a solid block of steel. These milled receiver models, such as the Milled Mini Jack, offer consumers an alternative that is perceived by many to be more durable and rigid, albeit at the cost of increased weight compared to their stamped counterparts.16 This diversification allows WBP to cater to different segments of the AK community.

Voice of the Market: Consumer Sentiment and Performance Analysis

An extensive analysis of consumer reviews, forum discussions, and video content reveals a clear and consistent market perception of WBP firearms. The brand enjoys a remarkably positive reputation, particularly concerning build quality, while also having well-documented performance characteristics that potential buyers should be aware of.

Overall Quality: Fit, Finish, and Construction

This is unequivocally WBP’s strongest attribute in the eyes of the consumer. Across hundreds of reviews, the sentiment regarding fit, finish, and overall construction is overwhelmingly positive. The firearms are consistently described with superlatives such as “excellent,” “superb,” “top notch,” “gorgeous,” and even “museum quality”.12

Specific points of praise frequently include:

- Riveting: The rivet work is consistently noted as clean, well-pressed, and professional, a key indicator of a properly assembled AK.24

- Straightness: WBP rifles have earned a strong reputation for having perfectly straight sights and gas blocks, a stark contrast to the “canted sights” that have plagued other imported AKs for years.25

- Finish: The deep, rich black painted finish is praised for its aesthetic appeal and durability, and is considered far superior to the parkerized finishes found on competitors like the Romanian WASR.12

- Furniture: The Polish laminate wood furniture is frequently highlighted as beautiful, well-fitted, and a major contributor to the rifle’s premium feel.11

Performance Metrics: Accuracy, Reliability, and Known Issues

- Reliability: In line with the Kalashnikov platform’s reputation, WBP firearms are regarded as exceptionally reliable. Reviewers report flawless function through hundreds, and in some cases thousands, of rounds using a wide variety of ammunition and magazines from different countries of origin.41

- Accuracy: For a non-free-floated, piston-driven rifle, the accuracy of WBP products is considered very good. Multiple independent tests and user reports show the rifles are capable of producing groups of approximately 2 Minutes of Angle (MOA) at 100 yards.46 This performance is a notable improvement over the historical 3-5 MOA expectation for a standard AKM.40 Accuracy can be further improved with the use of high-quality commercial ammunition.46 While isolated reports of poor accuracy exist, they appear to be outliers rather than the norm.48

- Known Issue: Overgassing: The most frequently cited and widely acknowledged performance characteristic of WBP rifles is that they are significantly overgassed from the factory, an issue that appears more pronounced on the 5.56mm models.30 This means the gas system directs more force than necessary to the bolt carrier, resulting in a sharper recoil impulse and more violent ejection of spent casings.

- Community Solution: KNS Piston: The enthusiast community has widely adopted the KNS Precision Adjustable Gas Piston as the go-to solution for the overgassing issue. Numerous owners report that installing this aftermarket component allows them to tune the gas system, resulting in a much softer-shooting and flatter-recoiling rifle.30

The widespread acknowledgment of the overgassing issue does not appear to detract from WBP’s positive brand perception. Because the core build quality is so high, consumers view the overgassing not as an irreparable defect, but as a tunable performance characteristic. The existence of a simple, effective aftermarket solution transforms the “flaw” into an opportunity for personalization. This dynamic creates a class of highly invested owners who have “perfected” their rifles, often leading to even stronger brand advocacy.

Value Proposition: Price-to-Quality Ratio

WBP firearms typically retail in the $1,000 to $1,500 price range, placing them squarely in the premium mid-tier of the imported AK market.11 The consensus among consumers is that this price is not only fair but represents an excellent value given the high level of quality. The rifles are seen as a significant and worthwhile upgrade over budget-tier AKs for a modest price increase, and they are considered competitive with, or superior to, offerings from Zastava and Arsenal in terms of fit, finish, and features.27

Consumer Sentiment Analysis Summary Table

| Model | Price/Value Sentiment | Quality/Finish Sentiment | Accuracy Sentiment | Reliability & Key Issues Sentiment |

| WBP Jack (7.62×39) | Very Positive. Considered an excellent value for a high-quality import with an FB Radom barrel. | Overwhelmingly Positive. Praised for flawless finish, straight sights, and beautiful wood. Benchmark for quality. | Good to Very Good. Generally capable of ~2 MOA. Outperforms typical AK expectations. Some outlier reports of poor accuracy exist. | Excellent. Flawless reliability reported. Standard AK overgassing is present but generally considered manageable. |

| WBP Jack (5.56×45) | Positive. Good value for a 5.56 AK, though lack of CHF barrel is noted. | Overwhelmingly Positive. Same high standards of fit, finish, and construction as the 7.62 model. | Good. Capable of good accuracy, but can be ammo-sensitive. Nitride barrel is noted as accurate. | Excellent Reliability. Prone to being significantly overgassed; KNS piston is a very common and recommended upgrade. |

| WBP Jack (5.45×39) | Positive. Considered one of the best available options for a new 5.45 rifle, but value is tied to the high cost and limited availability of 5.45×39 ammo. | Overwhelmingly Positive. Consistently high praise for fit, finish, and overall build quality. | Very Good. Reports of ~2 MOA or better with surplus and commercial ammo. | Excellent Reliability. No significant issues reported. Functions flawlessly with various magazines. |

| WBP Fox (7.62×39) | Positive. Price is seen as fair for a premium AKM with unique features and an FB Radom barrel. | Overwhelmingly Positive. Often described as “gorgeous” and “too pretty to shoot.” Finish and wood are highly praised. | Very Good. Considered remarkably accurate and reliable. | Excellent Reliability. Some reports of being overgassed, but less frequently than the 5.56 models. |

| WBP Mini Jack (7.62×39) | Very Positive. Excellent value for a high-quality AK pistol with an FB Radom CHF barrel and SBR-ready trunnion. | Overwhelmingly Positive. Described as having outstanding quality, smooth action, and beautiful finish. | Not a primary focus of reviews, but generally considered good for its format. | Excellent Reliability. No significant issues reported. Praised as a smooth-shooting pistol. |

| WBP Mini Jack (5.56×45) | Positive. Considered a top choice for a compact 5.56 AK pistol due to standard parts compatibility and quality. | Overwhelmingly Positive. Finish and build quality are consistently highlighted as fantastic. | Good for a short-barreled platform. | Excellent Reliability. Like the Jack rifle, it is known to be significantly overgassed and benefits greatly from a KNS piston. |

The Polish Contender: Competitive Positioning and Outlook

WBP has successfully carved out a distinct and highly competitive niche in the U.S. imported AK market. By strategically combining the most desirable attributes of its rivals while avoiding their primary weaknesses, WBP has positioned its products as a “best all-arounder” choice for the modern firearms enthusiast.

WBP Jack vs. Zastava ZPAP M70 (Serbia)

The Zastava ZPAP M70 is one of WBP’s closest competitors. The M70’s strengths lie in its rugged, “built-like-a-tank” construction, which features a heavier 1.5mm stamped receiver and a bulged front trunnion derived from the RPK light machine gun.52 However, this durability comes with drawbacks: the M70 is significantly heavier, its barrel is not chrome-lined, and it uses a proprietary “Yugo” pattern of furniture, which severely limits aftermarket stock and handguard options.27

In contrast, the WBP Jack is lighter, adheres to the standard AKM pattern for maximum aftermarket parts compatibility, and its 7.62x39mm variant features a chrome-lined FB Radom barrel.42 Consumers consistently rate the WBP’s fit and finish as superior to the Zastava’s.27 The choice for a consumer often boils down to a preference for the Zastava’s raw durability versus the WBP’s refinement, lighter weight, and vastly superior customizability.

WBP vs. Cugir WASR-10 (Romania)

For decades, the Romanian WASR-10 has been the benchmark for an affordable, entry-level imported AK. It is known for its legendary reliability but is equally infamous for its rough-and-ready construction, which can include canted sights, rough tool marks, and a poor finish.4 WBP positions itself as a definitive step up. For a moderately higher price, the consumer receives a firearm that is universally regarded as superior in every aesthetic and quality control metric. The WBP Jack is the rifle for a buyer who wants a refined, high-quality firearm out of the box, whereas the WASR is the choice for a user seeking a functional “beater” rifle on a tighter budget.24

WBP vs. FB Radom Beryl (Poland)

The comparison with the FB Radom Beryl is one of commercial quality versus military pedigree. The Beryl is a semi-automatic version of the actual service rifle of the Polish Armed Forces, giving it immense collector appeal and historical significance.55 However, it has proprietary features, such as its unique optics rail system and furniture. The WBP Jack, conversely, is a commercial rifle that is more faithful to the classic AKM pattern, offering greater flexibility for customization. The WBP Fox serves as a bridge between the two, offering the Beryl’s unique optic mounting capability on an AKM-style platform.25 The decision between them often hinges on whether the buyer prioritizes military authenticity and collectibility (Beryl) or modern AKM performance and customizability (WBP).

By occupying this middle ground, WBP has created a product that is more refined than a WASR, more customizable than a Zastava, and more accessible than a Beryl or a high-end Arsenal. This balanced approach makes it a frequent and highly confident recommendation for a consumer’s first high-quality AK rifle.

Conclusion: The Future of WBP in America

Wytwórnia Broni Jacek Popiński has, in a remarkably short period, transitioned from a relative unknown to a benchmark for quality in the U.S. imported AK market. The company has successfully built a powerful brand identity founded on demonstrable quality, superior aesthetics, and the intelligent leveraging of strategic partnerships. Consumer sentiment is overwhelmingly positive, cementing WBP’s reputation as a manufacturer that delivers a premium product at a competitive price point.

The company’s trajectory indicates a keen understanding of the American market and a commitment to long-term growth. The evolution from the Beryl-railed Fox to the standard-pattern Jack demonstrated a willingness to listen and respond directly to consumer feedback. The establishment of a sophisticated, multi-layered U.S. distribution and compliance network via WBP USA and its partners signals a deep and lasting investment in its most important export market.

Looking forward, WBP shows no signs of complacency. The recent unveiling of a WBP-manufactured AR-15 at the IWA 2025 trade show is a clear signal of the company’s future ambitions.58 This strategic expansion suggests that WBP intends to leverage the stellar reputation it has meticulously built in the AK community to compete in the even larger and more lucrative AR-15 market. This move marks a new chapter for the Polish firm, positioning it not just as a Kalashnikov specialist, but as a diversified and formidable player on the global firearms stage.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, we are only paid if there is an affiliate program such as Avantlink, Impact, Amazon and eBay and only if you purchase something. If you’d like to directly contribute towards our continued reporting, please visit our funding page.

Works cited

- WBP Rogów, accessed August 6, 2025, https://www.wbprogow.com/

- Our Mission – WBP USA, accessed August 6, 2025, https://wbpusa.com/our-mission

- About us | WBP Rogów, accessed August 6, 2025, https://www.wbprogow.com/?page_id=606

- WBP: New Polish AKs With Humble Beginnings – Gun Digest, accessed August 6, 2025, https://gundigest.com/gun-reviews/military-firearms-reviews/wbp-new-polish-aks-with-humble-beginnings

- WBP Rogów – Polski producent karabinków AKM i akcesoriów – Gatshop, accessed August 6, 2025, https://gatshop.pl/brand/12-wbp-rogow

- WBP wholesale – B2B Safety Agency, s.r.o. – Rigad, accessed August 6, 2025, https://b2b.rigad.com/wbp

- WBP USA, accessed August 6, 2025, https://wbpusa.com/

- What does the WBP AK-47 Factory Look Like? | AK-47 Manufacturer | Rogow, Poland : r/ForgottenWeapons – Reddit, accessed August 6, 2025, https://www.reddit.com/r/ForgottenWeapons/comments/1lvm5am/what_does_the_wbp_ak47_factory_look_like_ak47/

- WBP Rogów – New Jager, accessed August 6, 2025, https://nuovajager.it/en/product–category/armeria/armi-lunghe/wbp-rogow/

- Barrel works | WBP Rogów, accessed August 6, 2025, https://wbpbarrels.com/

- Are Polish AK-47s Worth the Money? The WBP Jack Review – YouTube, accessed August 6, 2025, https://www.youtube.com/watch?v=ECneImQIXoQ

- WBP 762SC Jack Rifle – 7.62×39 – Arms of America, accessed August 6, 2025, https://armsofamerica.com/wbp-762sc-jack-rifle-7-62×39/

- Polish WBP Fox Rifle Review – You Asked – They Delivered – YouTube, accessed August 6, 2025, https://www.youtube.com/watch?v=vIevB82npH0

- Is WBP Making Beryl Type AKs For FB-Radom? – YouTube, accessed August 6, 2025, https://www.youtube.com/watch?v=AktKCQEr7a8

- Who Is WBP? Q&A With The Makers Of The Polish Lynx & Fox Imports – YouTube, accessed August 6, 2025, https://www.youtube.com/watch?v=TRthn7fb8tk

- WBP Firearm Products – Arms of America, accessed August 6, 2025, https://armsofamerica.com/wytwornia-broni-jacek-popi-ski-wbp/

- WBP Headspaced and Parts Kits | Arms of America, accessed August 6, 2025, https://armsofamerica.com/wbp/

- Intro & First Impressions – Polish WBP CG1 AK Part 1 – YouTube, accessed August 6, 2025, https://www.youtube.com/watch?v=Ylj9WEmjlJA

- Atlantic’s WBP Beryl Style AK Rifle – Review & FB Radom Archer Comparison – YouTube, accessed August 6, 2025, https://www.youtube.com/watch?v=rYjgJViYiHA

- You Asked For It! WBP & WBP USA DELIVERED! The JACK 5.56 100 SERIES! – YouTube, accessed August 6, 2025, https://www.youtube.com/watch?v=NLXHqsJ8PTo

- Atlantic Arms Mfg / Wbp Us / Wbp Usa / Wbp Customs, 6315 RICE LAKE RD, DULUTH, MN | FFLs.com, accessed August 6, 2025, https://www.ffls.com/ffl/341137086f04466/velocity-llc

- WBP USA’s 7.62 100 Series JACK RIFLE is a GAME CHANGER! – YouTube, accessed August 6, 2025, https://www.youtube.com/watch?v=7rfwdRy3lUc

- WBP Jack DIY – 7.62×39 – Arms of America, accessed August 6, 2025, https://armsofamerica.com/wbp-jack-diy-7-62×39/

- WBP Fox: An AKM With Some Polish Flair – Gun Digest, accessed August 6, 2025, https://gundigest.com/gun-reviews/military-firearms-reviews/wbp-fox-an-akm-with-some-polish-flair

- WBP Jack Rifle 762SR – 7.62×39 *ETA: TBD* – Arms of America, accessed August 6, 2025, https://armsofamerica.com/wbp-jack-rifle—7.62×39-sr-eta-q1-2023-/

- WBP Fox AK47 Rifle – 7.62×39 – Arms of America, accessed August 6, 2025, https://armsofamerica.com/wbp-fox-ak47-rifle-7-62×39/

- [rifle] WBP 762SC Jack Rifle $1299.99 : r/gundeals – Reddit, accessed August 6, 2025, https://www.reddit.com/r/gundeals/comments/rhzm1k/rifle_wbp_762sc_jack_rifle_129999/

- 7.62×39 Rifles – WBP USA, accessed August 6, 2025, https://wbpusa.com/firearms/wbp-usa-rifles/7-62×39-rifles

- WBP USA Rifles, accessed August 6, 2025, https://wbpusa.com/firearms/wbp-usa-rifles

- [Rifle] WBP Jack AK47 Rifle-556SR $1,299 °in stock : r/gundeals – Reddit, accessed August 6, 2025, https://www.reddit.com/r/gundeals/comments/xkoskq/rifle_wbp_jack_ak47_rifle556sr_1299_in_stock/

- WBP 545SR Jack Rifle – 5.45×39 – Arms of America, accessed August 6, 2025, https://armsofamerica.com/wbp-545sr-jack-rifle-5-45×39/

- WBP Jack Rifle – Model 556SC – Arms of America, accessed August 6, 2025, https://armsofamerica.com/wbp-jack-rifle-model-556sc/

- WBP Jack 556SR Rifle – 5.56/.223 Cal – Arms of America, accessed August 6, 2025, https://armsofamerica.com/wbp-jack-rifle-556-223-cal/

- WBP 545SR Jack -AK74 Rifle, accessed August 6, 2025, https://wbpusa.com/firearms/wbp-545sr-jack-ak74-rifle

- New Polish Import, WBP Lynx Classic AK47 Pistol Preview – YouTube, accessed August 6, 2025, https://www.youtube.com/watch?v=bjmI6l6yEZw

- WBP Mini Jack 7.62 SBR : r/NFA – Reddit, accessed August 6, 2025, https://www.reddit.com/r/NFA/comments/wibiva/wbp_mini_jack_762_sbr/

- WBP Polish Mini AK47 Pistol | Arms of America, accessed August 6, 2025, https://armsofamerica.com/wbp-polish-mini-jack-ak47-7-62×39-pistol/

- WBP Polish Mini AK47 Pistol | Arms of America, accessed August 6, 2025, https://armsofamerica.com/wbp-5.56/.223-polish-mini-jack-ak-pistol-mj556sr/

- New Polish WBP Mini Jack Pistol, Now With 100% More Milled Receiver Goodness!, accessed August 6, 2025, https://www.youtube.com/watch?v=BFcQVXLGq-Q

- WBP Fox Tabletop Review and Field Strip – YouTube, accessed August 6, 2025, https://www.youtube.com/watch?v=chYYyU9RD_Y

- WBP Fox AKM Review – YouTube, accessed August 6, 2025, https://www.youtube.com/watch?v=vtgGB9GwtK0

- [Rifle] AK47 WBP Jack Rifle – $949 plus $30 shipping maybe tax : r/gundeals – Reddit, accessed August 6, 2025, https://www.reddit.com/r/gundeals/comments/185yp8l/rifle_ak47_wbp_jack_rifle_949_plus_30_shipping/

- I just purchased a WBP AKM and I’m worried. : r/guns – Reddit, accessed August 6, 2025, https://www.reddit.com/r/guns/comments/1j4dkcp/i_just_purchased_a_wbp_akm_and_im_worried/

- WBP Mini Jack 5.56 AK | First Shots – “AK Flamethrower” – YouTube, accessed August 6, 2025, https://www.youtube.com/watch?v=CAkFaPyMHVg

- WBP Polish Jack 100 545 rifle : r/AK74 – Reddit, accessed August 6, 2025, https://www.reddit.com/r/AK74/comments/1i00ut5/wbp_polish_jack_100_545_rifle/

- WPB Jack: NATO-Made Poison Bullet Launcher – Recoil Magazine, accessed August 6, 2025, https://www.recoilweb.com/wpb-jack-nato-made-poison-bullet-launcher-183073.html

- Informational post regarding WBP Jack 556SR accuracy with various ammo. Posting here because I got banned from another sub lmao – Reddit, accessed August 6, 2025, https://www.reddit.com/r/tacticalgear/comments/12ilo0a/informational_post_regarding_wbp_jack_556sr/

- [Rifle] WBP Jack 556SR rifle – $1000 + Shipping : r/gundeals – Reddit, accessed August 6, 2025, https://www.reddit.com/r/gundeals/comments/1ae9zgh/rifle_wbp_jack_556sr_rifle_1000_shipping/

- WBP AK-47 Classic Straight Pull Rifle 7.62×39, FULL REVIEW, would YOU have one?, accessed August 6, 2025, https://www.youtube.com/watch?v=TKjln0Vpg5Q&pp=0gcJCfwAo7VqN5tD

- For those of you who held off getting a WBP during Black Friday, you’re missing out. 556 Mini Jack. : r/guns – Reddit, accessed August 6, 2025, https://www.reddit.com/r/guns/comments/187o14y/for_those_of_you_who_held_off_getting_a_wbp/

- [Rifle] WBP Fox AKM 7.62×39 Sporter Rifle w/ FB Radom … – Reddit, accessed August 6, 2025, https://www.reddit.com/r/gundeals/comments/m2zkb3/rifle_wbp_fox_akm_762x39_sporter_rifle_w_fb_radom/

- WBP Jack or M70 ZPAP? : r/CAguns – Reddit, accessed August 6, 2025, https://www.reddit.com/r/CAguns/comments/129954h/wbp_jack_or_m70_zpap/

- Zastava M70 vs. AK-47: Key Differences – AR15Discounts, accessed August 6, 2025, https://ar15discounts.com/zastava-m70-vs-ak-47-key-differences/

- Why the WBP 545SR Jack AK-74 Rifle is a Game-Changer – YouTube, accessed August 6, 2025, https://www.youtube.com/watch?v=kJP7a_f6XBk

- FB Beryl – Wikipedia, accessed August 6, 2025, https://en.wikipedia.org/wiki/FB_Beryl

- WBP vs FB RADOM : r/AK74 – Reddit, accessed August 6, 2025, https://www.reddit.com/r/AK74/comments/1dpwjov/wbp_vs_fb_radom/

- [Rifle] FB Radom – Beryl Rifle – 7.62×39 $1499.99 : r/gundeals – Reddit, accessed August 6, 2025, https://www.reddit.com/r/gundeals/comments/snnzii/rifle_fb_radom_beryl_rifle_762x39_149999/

- AK-47 Manufacturer WBP is Making an AR-15! | IWA 2025 – YouTube, accessed August 6, 2025, https://www.youtube.com/watch?v=CtSOpq883NA