My friend Scott Igert owns Michigan Gun Exchange and recently got in a bunch of out the front (OTF) automatic knives from Great Lakes Firearms and Ammunition (GLFA). This caught my attention for a couple of reasons – 1) I had never heard of GLFA. 2) The knives looked and felt decent 3) The 8″ model was only $45 at the time when Scott was introducing the model line. Well, I had to buy one right then and there to study it. At least, that would be my cover story if my wife asked.

Who is GLFA?

According to their “About Us” page – Great Lakes Firearms and Ammunition is located in Sparta, MI, and is a family owned business. They started in firearms retail in 2013 but noticed an opportunity for affordable AR rifles and started manufacturing. They now have over 30 CNC machines, do their own Cerakoting and are steadily expanding. They do not have any knife listings on their site – in general, their site is pretty light on products and details.

I’ll be honest, I did some reading on their ARs and they have mixed reviews. Some guys love their rifles and others don’t so I really can’t speak to them. The focus of this post is about the OTF knife I bought from Scott.

Opening The Box

At home, I took a hard look at the knife. It came in a box with a white label on it with a cheap sheath. It was pretty bare bones which immediately made me think it was made by somebody else – probably in China given the price point. I couldn’t think of any firms in the US being able to wholesale an OTF knife for under $45 (you can see the sticker on the box – that was what Scott was selling it for at the time).

I’m make my only real negative comment up front. It comes with a really cheap belt sheath that I would recommend replacing if you want a sheath. The stitching is light and I have zero faith in the velcro belt loop on the back.

Honestly, at the price point this sells at, this is the only thing I am going to ding them on and it’s not a big deal to get a good sheath. I’d rather they invested in the knife anyways.

The GLFA OTF Knife Itself

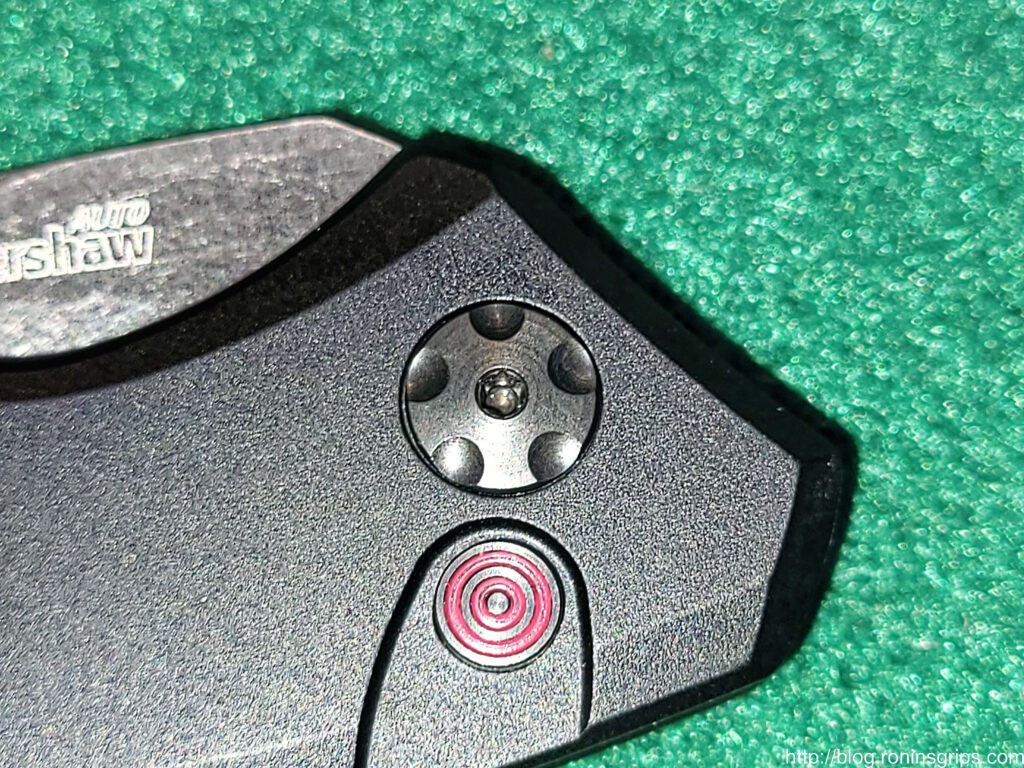

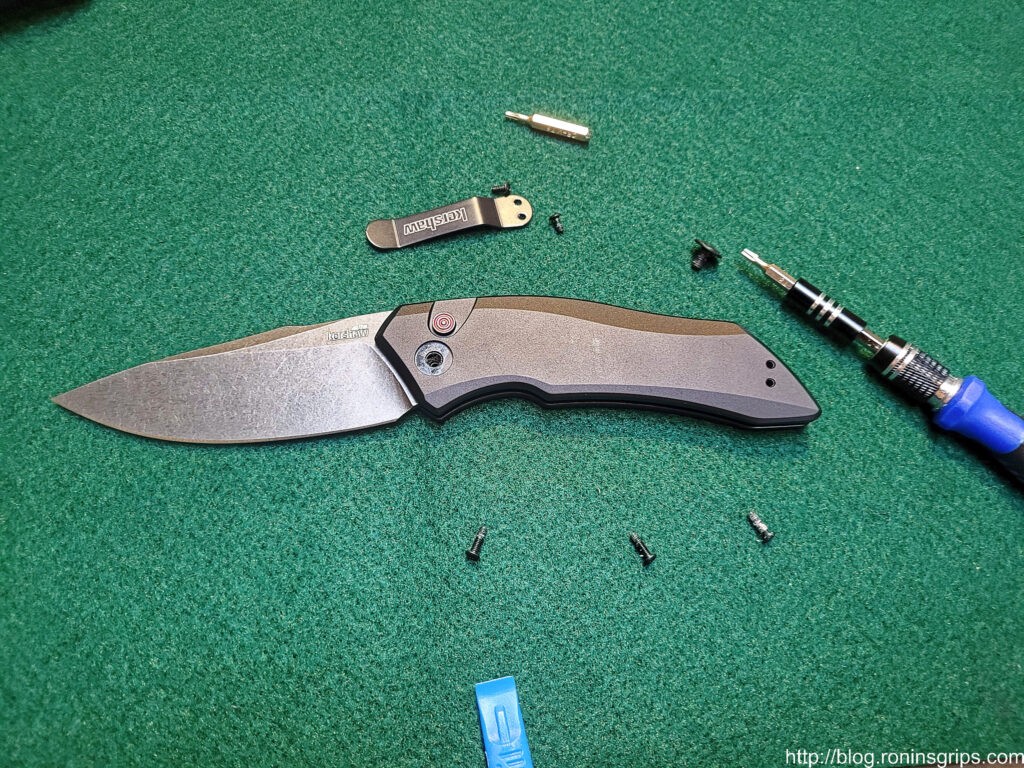

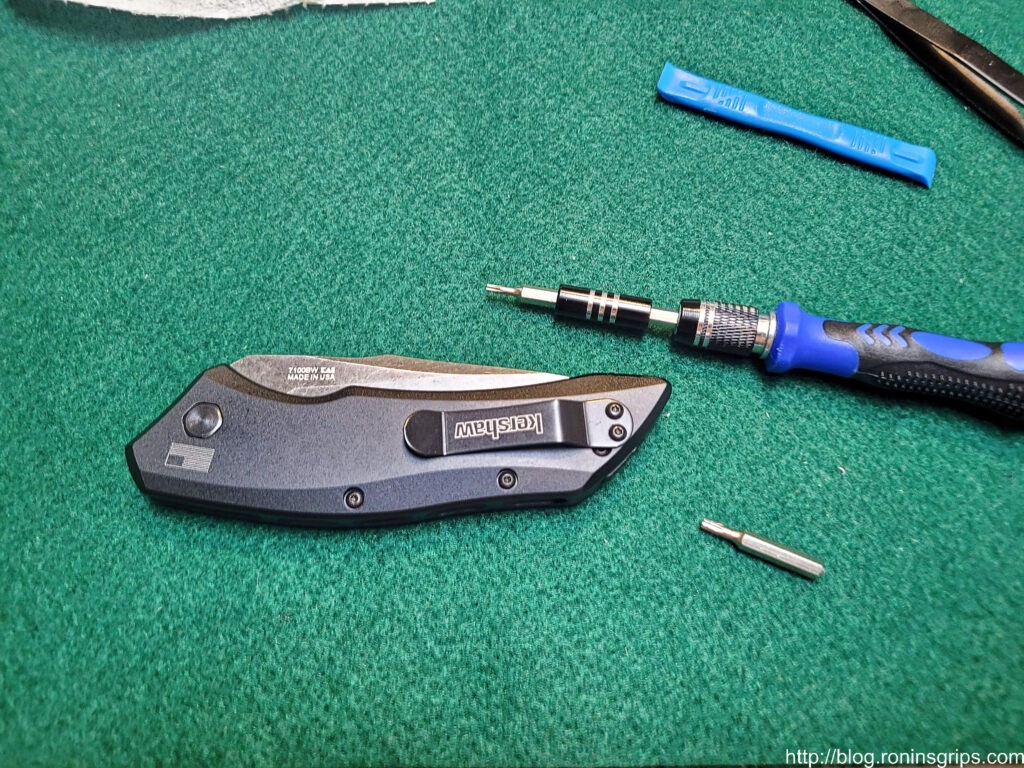

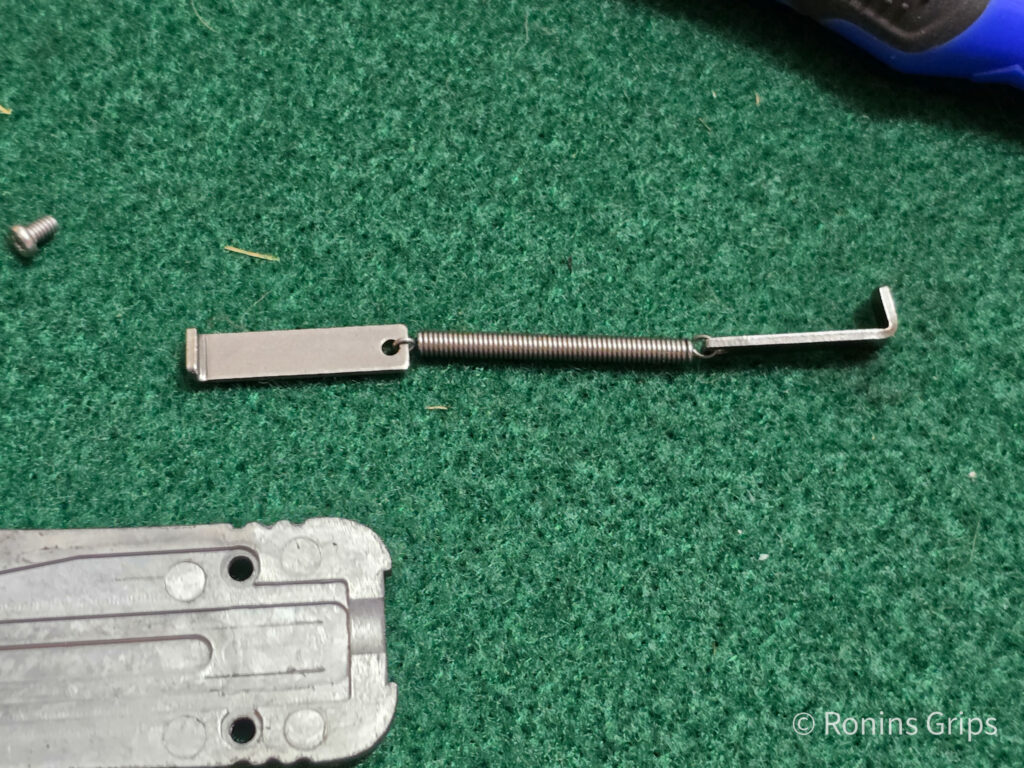

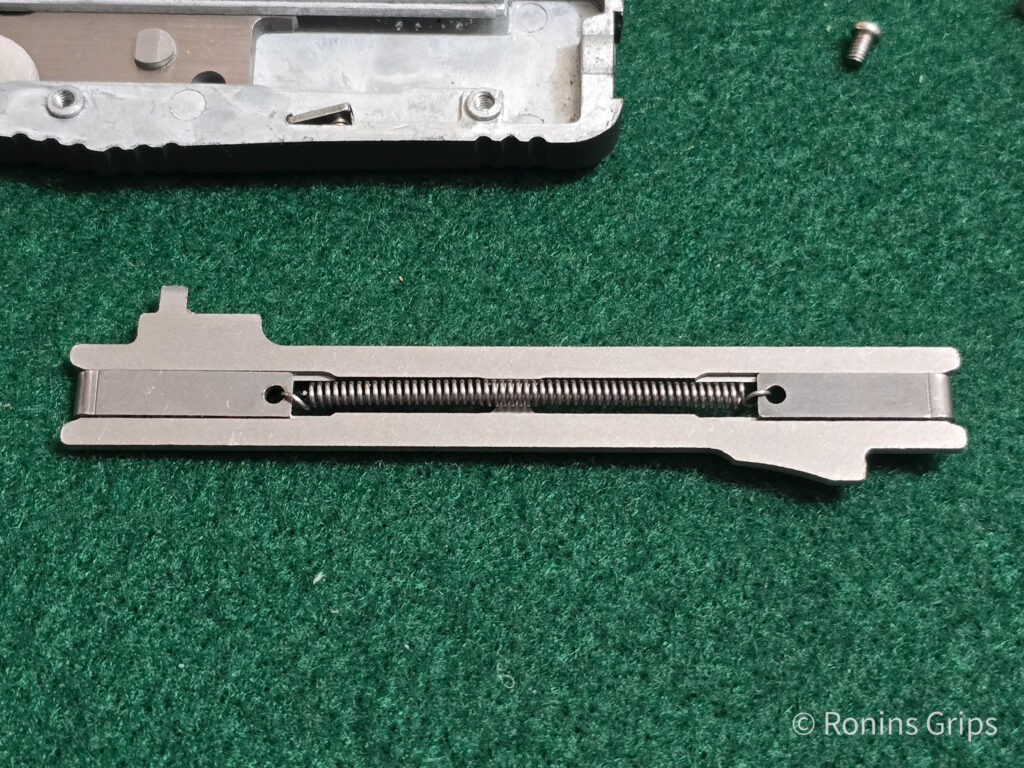

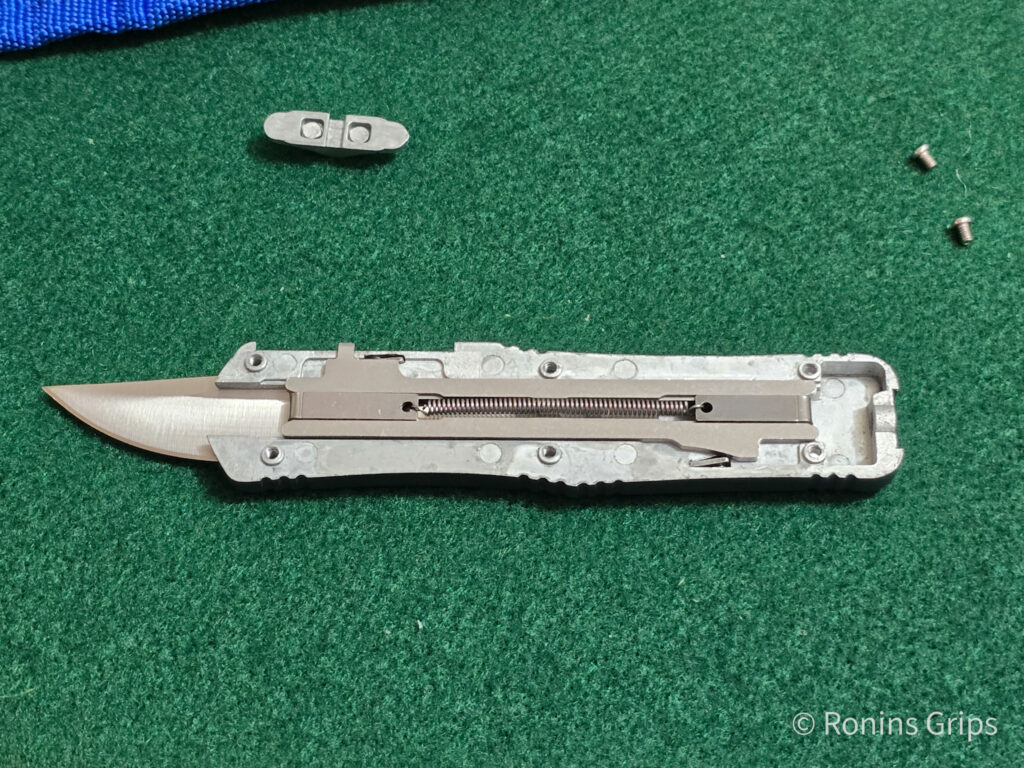

Let’s Disassemble the Knife

To open up the knife, find a nice clear flat work area. The green work matt keeps small parts from rolling or bouncing away – it’s not just a decorative background. I’ve done my fair share of searching for small parts so I try to take some precautions now. Also, take lots of photos to remember how things go back together 🙂

By the way, you may need to do this some day if your knife gets dirty and will not cycle. You’ll need to open and clean it.

To Re-Assemble

As mentioned above, the blade will be sprung. You will need to either pull the blade out to recock the spring or flick it down like a gravity knife. I did the latter out of habit to recock the spring and then everything worked fine.

Note, a knife like this needs to break in / wear in as parts get smoother with use. If you need to lubricate it, use a dry lube and not oil. For example, Dupont’s Dry Film Lubricant spray.

Who made the knife?

Whomever built this knew what they were doing and had masws production capabilities to drive the price down. From my perspective, there was no way GLFA could produce a decent OTF knife like this, at such a low price point and still have time to make their rifles. Clearly they were OEM’ing them from someone. As mentioned earlier, I was almost certain it was a Chinese company.

I did some digging based on the four relatively unique design elements that I figured would be rare to see combined – the shape of the handle, profile of the blade, the distinctive successively larger lightening holes in the blade and the glass breaker tip.

I used Google Images and some industry trade sites I know of and narrowed it down to the most likely candidate who does OEM knife work including OTF knives: Yangjiang Honglin Industrial Co., Ltd of Guangdong, China. They claim to have been in business for more than 10 years, have over 20,000 square meters of manufacturing, over 10 production lines and several Chinese quality certifications. They can build a knifefrom the point of raw materials to finished goods.

Could I be wrong about the manufacturer? Yes, but nobody else had all of those design elements present in the photos of sample products I saw.

So, they are a legit knife maker and that then makes my best guess that the knife steel is the Chinese 8CR13MOV which is a perfect decent/average stainless alloy. The average hardness of 8CR13MOV is 58-60 HRC but that’s an industry average and no guarantee of what the Chinese company actually did.

In short, they did a decent job designing and building the knife. I doubt they used junk steel and it’s what you’d find in many sub $40 retail Chinese import blades from Kershaw and others.

By the way, this is not a negative post about GLFA. I was curious as to who made this. Finding and importing quality products takes effort and money.

Summary

For the price, you can’t beat the GLFA OTF knife. You can afford to buy one, use it, enjoy it and not worry about it getting lost or damaged. Speaking for myself, the more expensive a knife gets, the more inclined I am to baby it than use it. I’ll use this GLFA and not worry about it and I’m saying that in a good way.

If you are interested, you can order this and other models from Scott’s website or visit his Michigan Gun Exchange store in Saint Joseph, MI.

I hope this helps you out.

Note, I have to buy all of my parts – nothing here was paid for by sponsors, etc. I do make a small amount if you click on an ad and buy something but that is it. You’re getting my real opinion on stuff.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, we are only paid if there is an affiliate program such as Avantlink, Impact, Amazon and eBay and only if you purchase something. If you’d like to directly contribute towards our continued reporting, please visit our funding page.