Okay, Ronin’s Grips started making Yugo M70 grips sometime around 2004 and rapidly added models – the challenge was that I hand polished each and every one of them. It took a ton of time, handwork and was putting my carpal tunnel through the roof. Jeff Miller of HillBilly Firearms told me to abrasive blast the grips for a better grip and a heck of a lot less handwork. I was sold – I had to change something. Jeff also gave me a few tips – get a foot control to protect the seals vs. being in the cabinet with all of the grit, put transparency film on the window of the unit to make it last longer and he told me to get a “thumper” to make the grit settle.

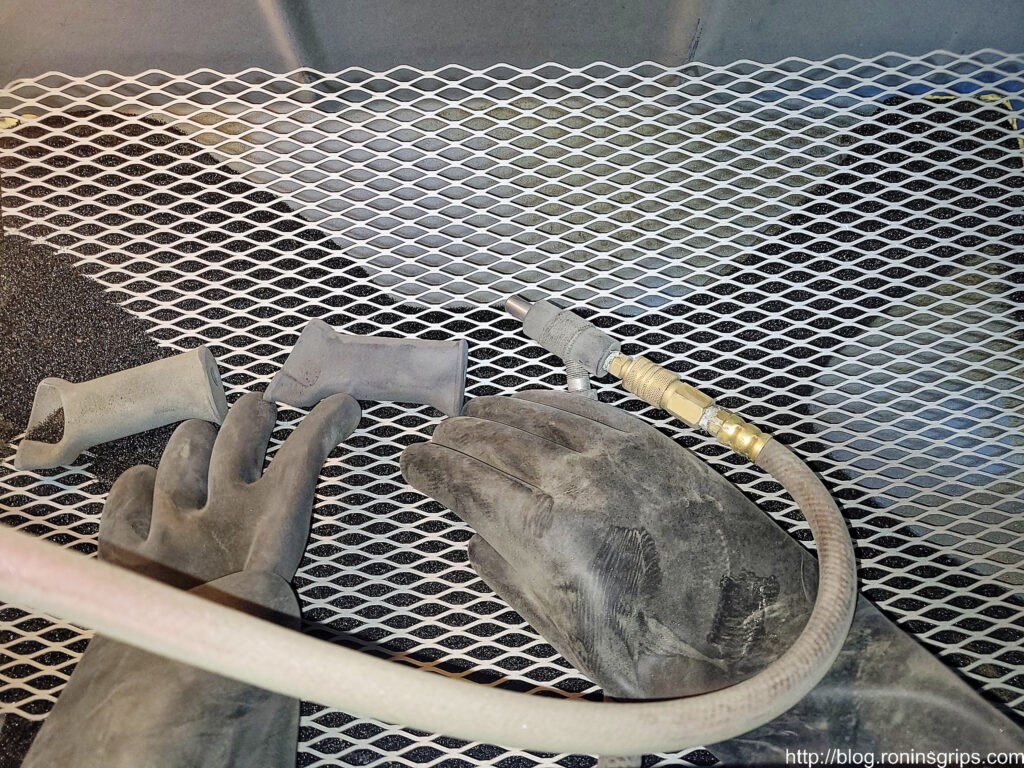

Well, way back in the day margins were super thin so I bought a large bench top abrasive blast cabinet from Cyclone Manufacturing in Dowagiac, MI – they are about an hour from my shop and I could pick it up along with the foot control, I got a box of transparency film either from Amazon or a local office supply store, but I had no idea what a “thumper” was or how important it is to productivity.

Fast forward to about a month ago. Abrasive blasting used to take me a while – blast, hit the cabinet or manually move the material around in the hopper, blast some more, whack the cabinet or move the material around … it gets old. It took me years to realize that this really sucks but blasting was so much better than polishing that I didn’t think much about it.

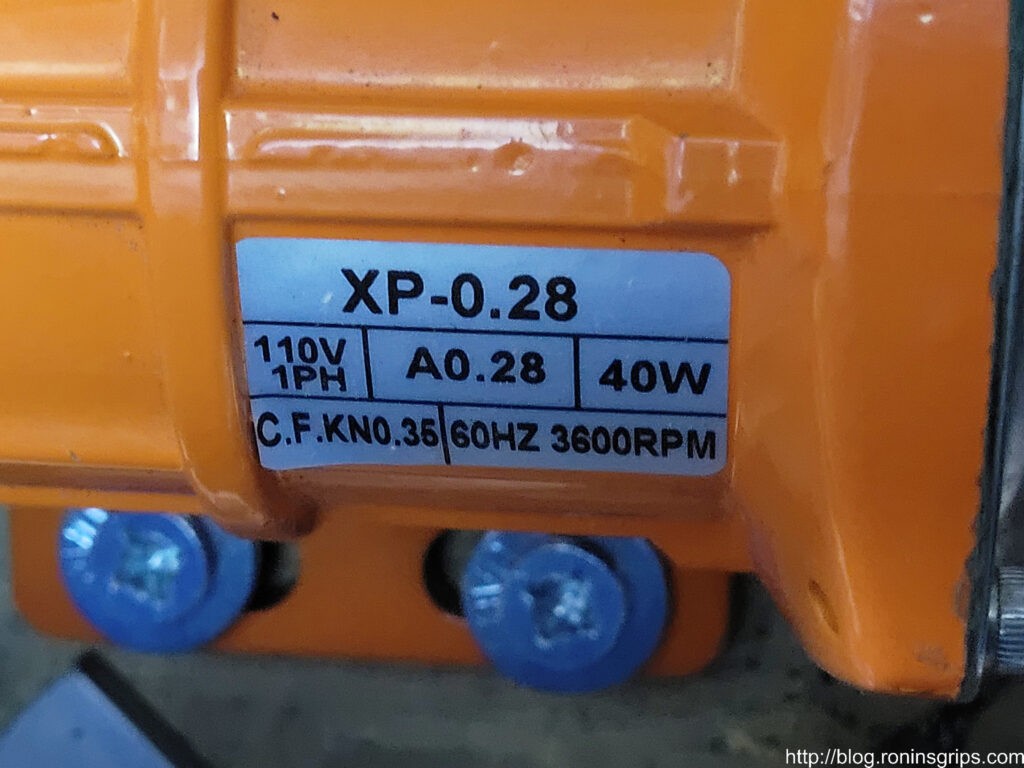

So, a “thumper” is basically and industrial vibrator (insert joke here) that uses an electric motor in a housing with off center weights on the shaft that then vibrate like crazy when the motor runs. I guess you could call it the power of Amazon but one day I was scrolling through Amazon and a suggested item came up – a concrete vibrator – and it looked like a small motor in a housing. I had 25 Galil grips I was going to blast and all of a sudden I remembered Jeff’s advice.

Okay, the power of a vibrator with a blast cabinet is that the vibrations cause the grit to shake down to the lowest point constantly. You can blast and blast and blast. The unit was $118 with free delivery and I figured I would give it a try.

It shipped from the importer, not Amazon, and showed up a few days later – it was pretty quick as I recall. The unit was very well made other than my needing to tape up a plastic junction box on the power cord that was a little cracked and I needed to attach a 120 volt plug – it was one phase and they said about 40 watts so nothing special. The machine label says – 110V, 1 phase, 40 watts, 3600 RPM – the little thing totally kicks butt and was only $49.

I didn’t put it on the blaster right away because I wasn’t really sure how violent it would be and I am glad I didn’t – it vibrates like you would not believe – there is nothing subtle about it – and I immediately realized two things – 1) I was going to mount it on the free standing tool bench and not the plastic blast cabinet walls or it would eventually shake loose and 2) I needed a variable speed control to tone it down some.

Try #1

Okay, so sometimes you just have to poke fun at yourself – or at least I do. I marked the bolt holes on the 3/4″ plywood bench top and mounted the vibrator. I then plugged the power cord from the vibrator into the speed controller, the controller into a surge strip and turned it on at full speed.

I wish I had a before photo or a video of what happened next but I don’t. Every single thing on that table started vibrating right off of it. Yeah, all the grit went to the bottom on the blast table but the blast table was headed to the edge of the bench too. Whoa! I hit the off switch.

Try #2

I simply took some strips of plywood and added a cradle around the legs to limit travel. That worked. Time to try blasting some stuff.

Actually Blasting

Folks, it is night and day different – stunningly different. Because I don’t have to stop and whack the side of the baster or reach in and move grit around, I’d bet I’m getting work done 2-3 times faster. A bench top blaster doesn’t have a very deep bottom so without a thumper, I spent a lot of time moving grit over to the pick ,up.

Another fun lesson learned. Over the years, I’ve developed the habit of putting my chin on the plexiglass as I focused on doing the work. Don’t do that. I put my chin down on the vibrating plexiglass and it felt like someone was playing the tambourine with my teeth 🙂

In Conclusion

This is one time I can honestly tell you that I have one regret – I should have done this years and years ago. Wow. It was worth it! I’ve used vibrator and speed controller both extensively for a little over a month and it’s a great combo. I don’t use the slowest speed but I am closer to the low end on the dial than I am the fastest speed.

Note, I got lucky with my first purchase. I really wasn’t sure what size to buy but the 40 watt unit has worked great. I can’t imagine anyone needing a bigger unit for a blast cabinet. These generic industrial vibrators have all kinds of uses including for the movement of powders, grains, rock, etc. so they sell bigger and more powerful ones as well.

I’d highly recommend this to anyone who has a ton of blasting to do and is getting tired of having to stop and manually move grit around.

Note, I have to buy all of my parts – nothing here was paid for by sponsors, etc. I do make a small amount if you click on an ad and buy something but that is it. You’re getting my real opinion on stuff.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, I may be paid via an affiliate program such as Avantlink, Impact, Amazon and eBay.