Executive Summary

The 10th edition of the Singapore Airshow, convened in February 2026 at the Changi Exhibition Centre, serves as a definitive barometer for the evolving tactical requirements of the Indo-Pacific and global defense markets. This report provides an exhaustive analysis of the small arms news, technical developments, and industry discourse emerging from the event, which hosted over 1,000 companies from 50 countries amid a climate of heightening regional security concerns.1 The central theme of the 2026 show is the integration of traditional kinetic lethality with digital-age fire control, artificial intelligence, and networked command architectures.3

ST Engineering remains the dominant force in the regional small arms sector, utilizing the event to debut its AME (Advanced Modular Engineering) rifle family, which includes the AME-A514 assault rifle and the AME-B514 bullpup, the latter representing the “Next Generation SAR”.5 This strategic pivot signifies a move toward meeting international ergonomic preferences through AR-pattern designs while refining the high-performance bullpup configuration for specialized urban and maneuver roles.5 Technical advancements in light machine guns, specifically the Ultimax 100 Mk 9 with its new dual-feed capability, reinforce Singapore’s legacy in high-controllability suppressive fire platforms.9

In the domains of sniper and anti-materiel systems, the exhibition highlighted a shift toward modularity and the integration of loitering munitions as a complement to traditional precision rifles.8 Israeli firms, including Rafael and Israel Aerospace Industries (IAI), dominated the targeting and optics conversation with AI-enabled pods like LITENING-5 and gunfire detection systems like ThunderBullet, which integrate into decentralized tactical clouds.13 Simultaneously, Middle Eastern entities such as the EDGE Group and Caracal showcased significant progress in regional partnerships and the development of machine guns optimized for unmanned platforms, signaling a move toward autonomous lethality.17

Social media and open-source intelligence analysis reveal a professional community deeply engaged with the ergonomic shifts in the ST Engineering portfolio, alongside a Middle Eastern discourse focused on strategic self-reliance and technology transfer.7 This report concludes that the small arms industry in 2026 is defined by the “digitization of the infantryman,” where the weapon system is increasingly viewed as a sensor node within a larger multi-domain operation.5

1. The Geopolitical and Macroeconomic Backdrop of Singapore Airshow 2026

The 10th biennial Singapore Airshow serves as a critical juncture for the aerospace and defense industry, marking two decades since its inception as a standalone fixture in the global calendar.6 The 2026 event takes place against a backdrop of complex geopolitical tensions in the South China Sea and the wider Indo-Pacific rim, characterized by intensifying competition and rising military expenditures across the region.2 This environment has forced regional powers to prioritize modernizing their small arms arsenals to ensure interoperability with NATO standards while addressing the unique demands of humid, coastal, and urban environments.2

The scale of the 2026 show is reflected in its participation metrics, featuring over 1,000 exhibitors and 50,000 trade attendees from 135 countries.1 The presence of 256 VIP delegations from 90 countries underscores the show’s role as a platform for high-level military diplomacy and procurement dialogue.22 Within the exhibition halls, the “Defence and Public Security Zone” has expanded to occupy a larger percentage of total floor space, reflecting the shift toward multi-domain security solutions.9

Economically, the 2026 show arrives as the aviation industry reaches a record regional load factor of 84.4 percent, driven by a projected five billion travelers globally.3 This commercial resurgence provides the fiscal headroom for national defense organizations to pursue ambitious modernization programs.10 The show’s strategic weight is further amplified by the debut of the Royal Australian Air Force’s F-35A Lightning II, which serves as a symbol of the advanced technological alliances defining the region’s security architecture.3

2. Individual Weapons Systems: The ST Engineering AME Evolution

At the 2026 exhibition, ST Engineering’s small arms portfolio underwent its most significant transformation in a generation with the unveiling of the AME (Advanced Modular Engineering) series.5 This new family of weapons represents a dual-track strategy: embracing the globally dominant AR-pattern ergonomics while simultaneously advancing the indigenous bullpup doctrine that has defined the Singapore Armed Forces for over two decades.5

2.1 The AME-A514 and AME-A520 Conventional Platforms

The AME-A514 is a 5.56 x 45 mm NATO assault rifle that marks ST Engineering’s official entry into the high-end AR-pattern market.5 Designed for the standard infantryman, the A514 utilizes a direct gas impingement system, a choice intended to reduce overall weight and provide a smoother recoil impulse compared to piston-driven alternatives.5 To address the historical reliability concerns associated with direct impingement in humid and dusty environments, the A514 incorporates advanced material science, including a titanium nitride coated rotating bolt and corrosion-resistant coatings throughout the receiver assembly.5

The architecture of the A514 is inherently modular, featuring a full-length Picatinny rail on the upper receiver and integrated accessory interfaces on the fore-end for the mounting of day/night optics, laser pointers, and illumination systems.5 The controls are fully ambidextrous, mirroring the layout of the AR-15/M16 family to minimize the training burden for international users.5 The AME-A520 serves as the designated marksman rifle (DMR) variant of this family, featuring a 20-inch barrel and an optimized trigger group for precision engagement at extended ranges.8

2.2 The AME-B514: The Next Generation SAR Bullpup

In parallel with its conventional offerings, ST Engineering debuted the AME-B514, designated as the “Next Gen SAR”.5 This weapon is a radical evolution of the SAR 21 bullpup, utilizing a long-stroke gas piston system known for its extreme reliability in adverse conditions.7 The B514 maintains the bullpup’s inherent advantage of a full-length barrel in a compact overall package but introduces modern ergonomic features such as an adjustable buttstock and fully ambidextrous ejection and charging controls.7

The rifle weighs approximately 3.5 kilograms and has been designed with a futuristic aesthetic that emphasizes user control through a distinctly sculpted pistol grip.7 The B514 is currently entering the pre-production stage, with full qualification anticipated for later in 2026.7 For specialized users, the bullpup configuration remains the preferred platform for urban operations and vehicle-mounted infantry due to its superior maneuverability in confined spaces.5

2.3 Individual Weapons Technical Specification Matrix

Description: A high-contrast matrix diagram showing technical specifications for the AME series. Text labels indicate Caliber, Action, Weight, Barrel Length, and Primary Application.

| Feature | AME-A514 | AME-B514 | AME-A520 |

| Caliber | 5.56 x 45 mm NATO | 5.56 x 45 mm NATO | 5.56 x 45 mm NATO |

| Action Type | Direct Gas Impingement | Long-Stroke Gas Piston | Direct Gas Impingement |

| Weight (Unloaded) | ~3.2 kg | 3.5 kg | ~3.8 kg |

| Barrel Length | 14 – 15 inches | 14.5 – 20 inches | 20 inches |

| Ergonomic Pattern | Conventional (AR) | Bullpup (Next Gen SAR) | Conventional (DMR) |

| Feed System | STANAG 4179 Magazine | STANAG 4179 Magazine | STANAG 4179 Magazine |

| Max Effective Range | 500 m | 500 – 800 m (varies) | 800 m |

5

3. Sub-Compact and Secondary Systems: The CPW and Handguns

The tactical landscape discussed at the Singapore Airshow 2026 also emphasized the requirement for compact personal defense and secondary weapons for specialized personnel.9 As battlefield roles become more diverse, with increased numbers of personnel operating UAVs and complex electronic systems, the need for lightweight, low-profile lethality has grown.11

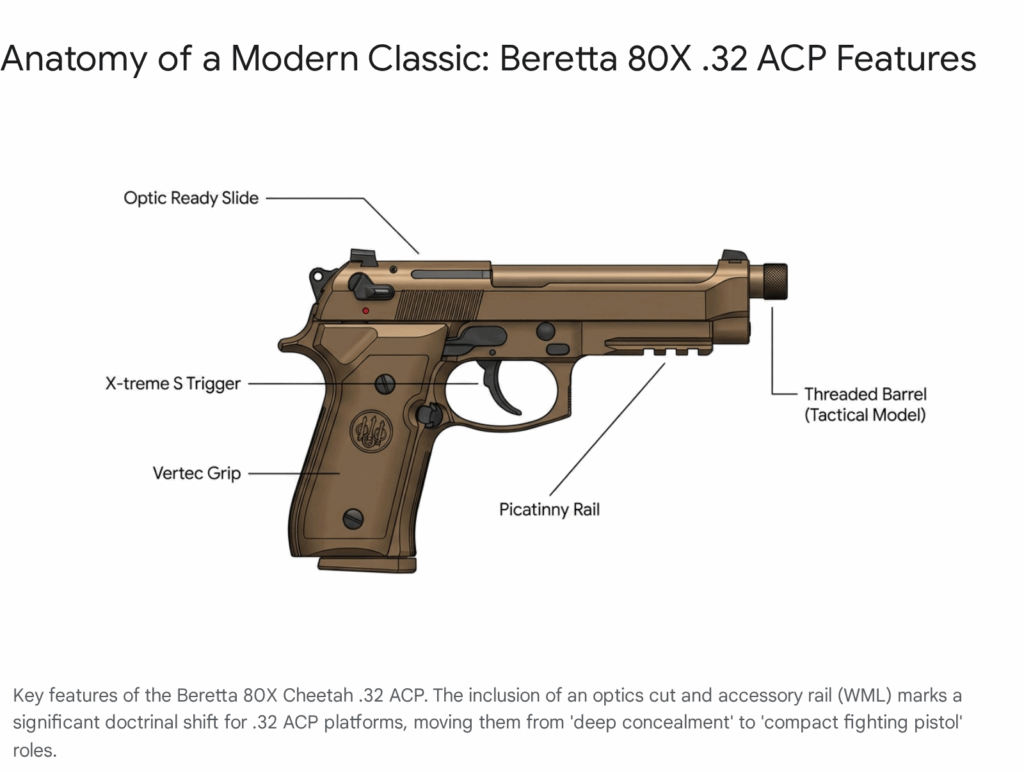

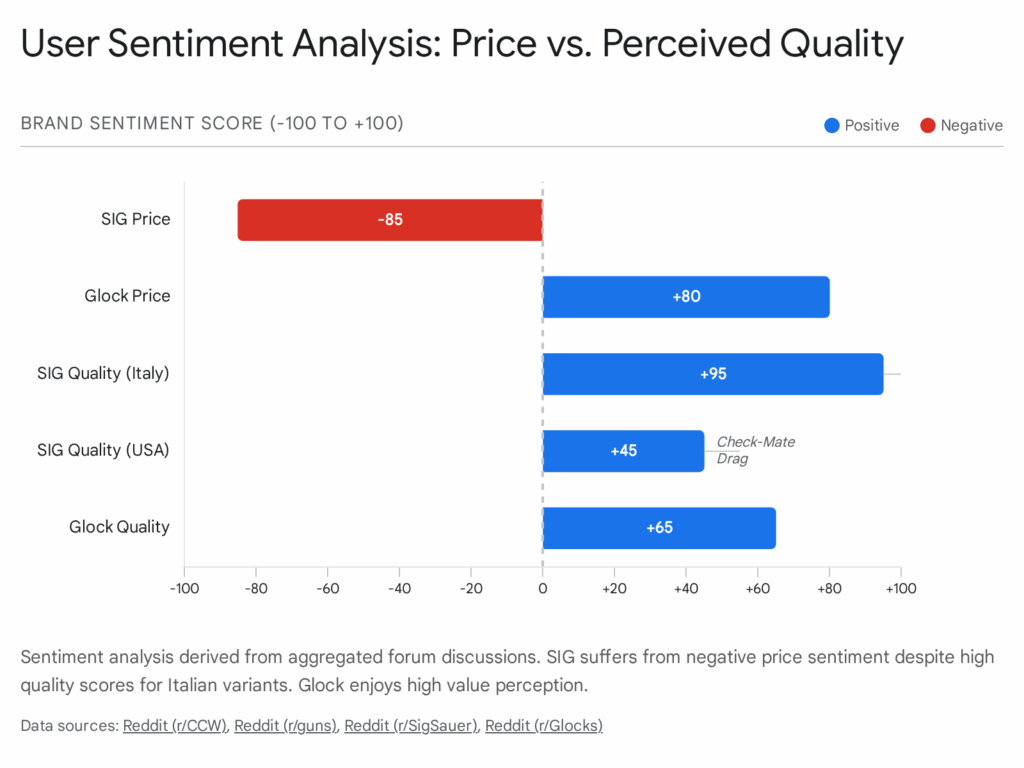

The ST Engineering Compact Personal Weapon (CPW) remains a focal point in this segment.9 The CPW is designed as a multi-caliber platform, capable of chambering various sub-caliber rounds to suit specific mission profiles.9 Its unique recoil mitigation system and compact footprint make it ideal for law enforcement, close protection, and aircrew survival roles.9 Discussions at the show also touched upon the “pistol as a primary” concept for certain urban security environments, where the ability to transition from a concealed to an active engagement stance is paramount.5 While major international handgun manufacturers like Glock or SIG Sauer were represented through various regional distributors and national pavilions, the primary technical news focused on the integration of micro-red dot optics and suppressed configurations as the new standard for professional sidearms.5

4. Suppressive Fire and Crew-Served Evolution: Ultimax 100 Mk 9

The light machine gun (LMG) remains a cornerstone of squad-level lethality, and the 2026 show provided a platform for the latest iteration of a legendary platform: the Ultimax 100 Mk 9.9 The Ultimax 100 series has historically been praised for its “constant recoil” mechanism, which allows the weapon to be fired accurately from the shoulder with minimal muzzle climb.9

4.1 The Dual-Feed Capability of the Mk 9

The most significant update for the Mk 9 variant is the introduction of a dual-feed system.9 This allows the machine gunner to utilize both 5.56mm STANAG magazines—facilitating easy ammunition sharing with riflemen—and M27 ammunition belts for sustained high-volume fire.9 This flexibility is critical for small units operating in isolated environments where logistics can be disrupted.10

Furthermore, the Mk 9 maintains its quick-change barrel system, ensuring that the weapon can stay in the fight during prolonged engagements.9 The engineering behind the Mk 9 emphasizes accuracy and ammunition conservation; by providing superior controllability, the operator can deliver effective suppressive fire with fewer rounds, extending the squad’s combat endurance.9

4.2 Heavy and Automatic Grenade Systems

Moving up the lethality scale, the 40mm Automatic Grenade Launcher (40AGL) Mk 2 and its Low Velocity variant were showcased as essential force multipliers.9 These systems are increasingly integrated into Remote Weapon Stations (RWS), such as the ST Engineering ADDER, which provides stabilized fire control for both land and naval platforms.9 The trend in 2026 is toward “intelligent” grenade systems that utilize programmable airburst ammunition to engage threats behind cover or within complex urban structures.9

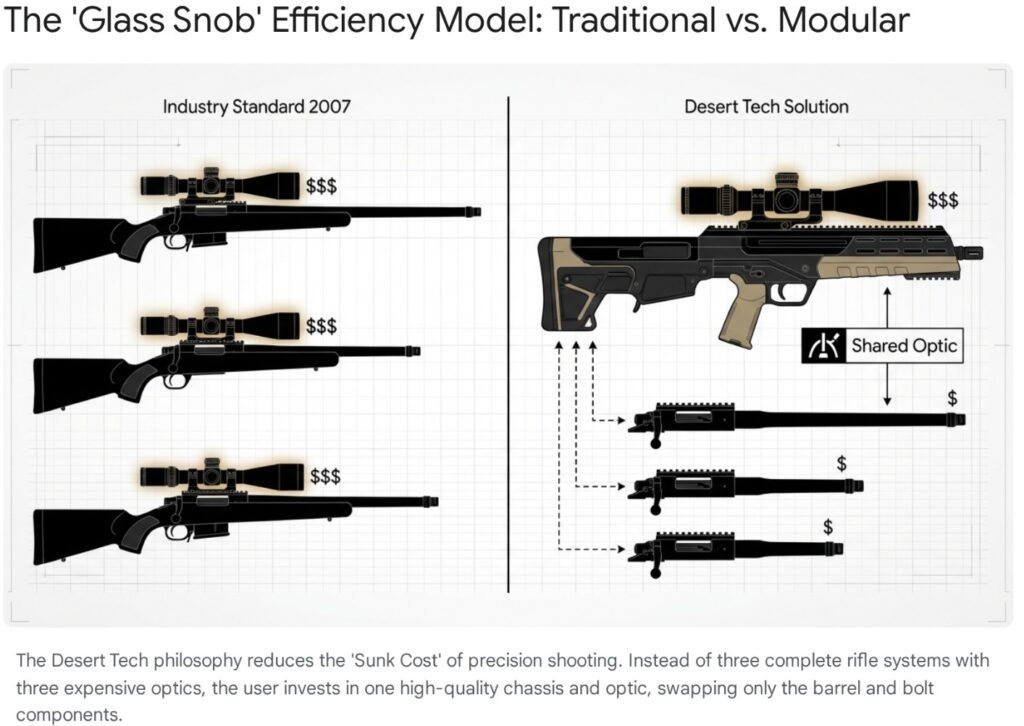

5. The Precision Tier: Sniper, DMR, and Anti-Materiel Capabilities

Precision engagement systems at the 2026 show reflected the shifting doctrine of “finding, fixing, and finishing” high-value targets at extreme stand-off ranges.11 This segment includes not only bolt-action and semi-automatic rifles but also the emerging category of tactical loitering munitions that serve as “flying anti-materiel weapons”.11

5.1 Specialized Marksman and Sniper Rifles

As noted in Section 2, the AME-A520 serves the DMR role for the standard infantry squad, bridging the gap between the rifleman and the dedicated sniper.8 In the dedicated sniper tier, regional news highlighted the Indian Army’s use of the Mauser SP66 (7.62mm NATO) and its procurement plans for approximately 600 new rifles and 200 under-barrel grenade launchers (UBGLs) to modernize its special forces and air force security units.12

Russian contexts shared at the show through defense intelligence channels also noted the delivery of upgraded SVD-M Dragunov and 12.7mm Kord-M (ASVK-M) sniper rifles to reconnaissance units, emphasizing the continued relevance of high-caliber anti-materiel systems for engaging light armored vehicles and hardened infrastructure at ranges exceeding 1,500 meters.30

5.2 Tactical Loitering Munitions as Anti-Materiel Tools

A significant disruption in the precision segment is the rise of tactical loitering munitions like the Rafael L-SPIKE 1X and 4X.13 These systems are designed to be man-portable and fully interoperable with existing SPIKE launcher architectures.15 With an operational range of up to 20 kilometers and an endurance of 30 minutes, they allow a small unit to strike adversary assets far beyond the line-of-sight of a traditional sniper or anti-materiel rifle.11 The integration of “man-in-the-loop” AI ensures that target identification is precise, reducing the risk of collateral damage in hybrid warfare environments.11

6. Ammunition and Energetics: Scaling Lethality and Sustainability

The 2026 ammunition display at the ST Engineering pavilion and within national pavilions like the German and USA Partnership Pavilions demonstrated a shift toward “lethality-on-demand” and the mitigate of environmental impact.9

6.1 Small-Caliber Innovations

ST Engineering’s family of 5.56mm rounds has been expanded to include specialized tactical variants 9:

- Extended Range (ER) 5.56mm: Optimized for longer barrels like those found on the AME-A520 and B514, providing a flatter trajectory and better energy retention at range.10

- Polymer-Cased Ammunition: Aimed at reducing the combat load of the infantryman by replacing traditional brass cases with lightweight polymers, offering up to a 30% reduction in weight for a standard 30-round magazine.10

- Lead-Free Tactical Response Ammunition: Developed for environmental compliance at training ranges without sacrificing the terminal ballistic performance required for actual combat operations.10

6.2 Specialized and Heavy Calibers

The 40mm ammunition family now includes “Low Velocity Wall Penetrating” rounds, specifically designed for urban breachers who need to neutralize threats behind interior walls or light barriers.10 In the heavy caliber segment, the.50 inch Saboted Light Armour Penetrator (SLAP) and its tracer-equipped variant (SLAP-T) remain the primary tool for defeating light armored vehicles and protected weapon emplacements.9 Furthermore, the move toward 120mm mortar systems, such as the Ground Deployed Advanced Mortar System (GDAMS), illustrates the trend of bringing heavy, high-precision indirect fire directly under the control of the tactical commander.9

6.3 Ammunition Tactical Application Matrix

| Ammunition Class | Caliber | Core Feature | Strategic Application |

| Tactical ER | 5.56 mm | Optimized Propellant | Long-range squad fire superiority |

| SLAP-T | .50 Cal | Saboted Penetrator | Anti-armor / Hardened target engagement |

| Wall Penetrator | 40 mm | Kinetic/Delayed Fuze | Urban barrier clearance |

| Programmable | 40 mm | Airburst / Time Fuze | C-UAS / Defeating defilade targets |

| Lead-Free TR | 5.56 mm | High Density Core | Training range sustainability |

7. Targeting Pods and Digital Fire Control: The “Digital-Age” Platform

The “digitization of the infantryman” was a pervasive theme throughout the 2026 trade days, with several companies showcasing how small arms are being integrated into larger C4 systems.5 The weapon is no longer a standalone kinetic tool but a node in a networked battlefield.5

7.1 LITENING-5 and Tactical Intelligence

Rafael Advanced Defense Systems highlighted the LITENING-5 targeting pod, currently integrated on 26 aircraft types across 28 air forces.13 While traditionally an aerial asset, the data generated by these pods—including advanced targeting, reconnaissance, and situational awareness—is now being streamed directly to ground-based tactical units.15 This allows for “joint terminal attack” coordination where the small arms unit on the ground can visually confirm the data being seen by air assets in real-time.15

7.2 AI-Enabled Small Arms Fire Control

The AME rifle architecture was designed from the outset to host advanced optics and fire-control systems capable of range finding and ballistic computation.5 This transition is critical as the industry moves toward “intelligent” rifles that can automatically adjust aiming points for environmental factors like wind and incline.5 Companies like Israel’s Rafael presented the “Riddle Resolved” concept, an invitation-only area focused on AI-enabled intelligence and targeting systems that accelerate the detect-to-defeat cycle.13

8. Integrated Defense Ecosystems: Israeli and Middle Eastern Influence

The Singapore Airshow 2026 serves as a key gateway for Middle Eastern and Israeli defense companies to access the dynamic Asia-Pacific market.6 The influence of these two regions is particularly visible in the domain of autonomous and networked systems.11

8.1 The EDGE Group and Caracal’s Regional Strategy

The UAE-based EDGE Group and its small arms subsidiary, Caracal, have pursued a strategy of aggressive regional partnership.17 This includes co-production agreements with Indonesia’s PT Pindad for the CAR 816 assault rifle and partnerships with India’s ICOMM for localized manufacturing of various small arms.17

One of the most noteworthy developments discussed was Caracal’s work on a 12.7 x 99 mm machine gun specifically optimized for installation on unmanned air and ground vehicles (UAVs/UGVs).17 This weapon is not a traditional infantry tool but is designed to provide autonomous platforms with a “heavy” kinetic option for frontline engagements.17 This signals a Middle Eastern foresight into the “robotization” of the battlefield, where small arms must be lightweight, remotely operated, and integrated with robotic flight controllers.17

8.2 IAI and the OPAL Tactical Cloud

Israel Aerospace Industries (IAI) showcased the OPAL system, a decentralized networking layer that transforms disparate military platforms—from F-35s to ground units—into a single intelligent combat force.16 Under the OPAL framework, a ground unit equipped with a gunfire detection system like ThunderBullet can instantly share the coordinates of an enemy sniper with every other node in the network.16 This connectivity allows a ground unit to “see” through the sensors of an F-16 or an Apache helicopter, fundamentally changing how small units manage the battle space.16

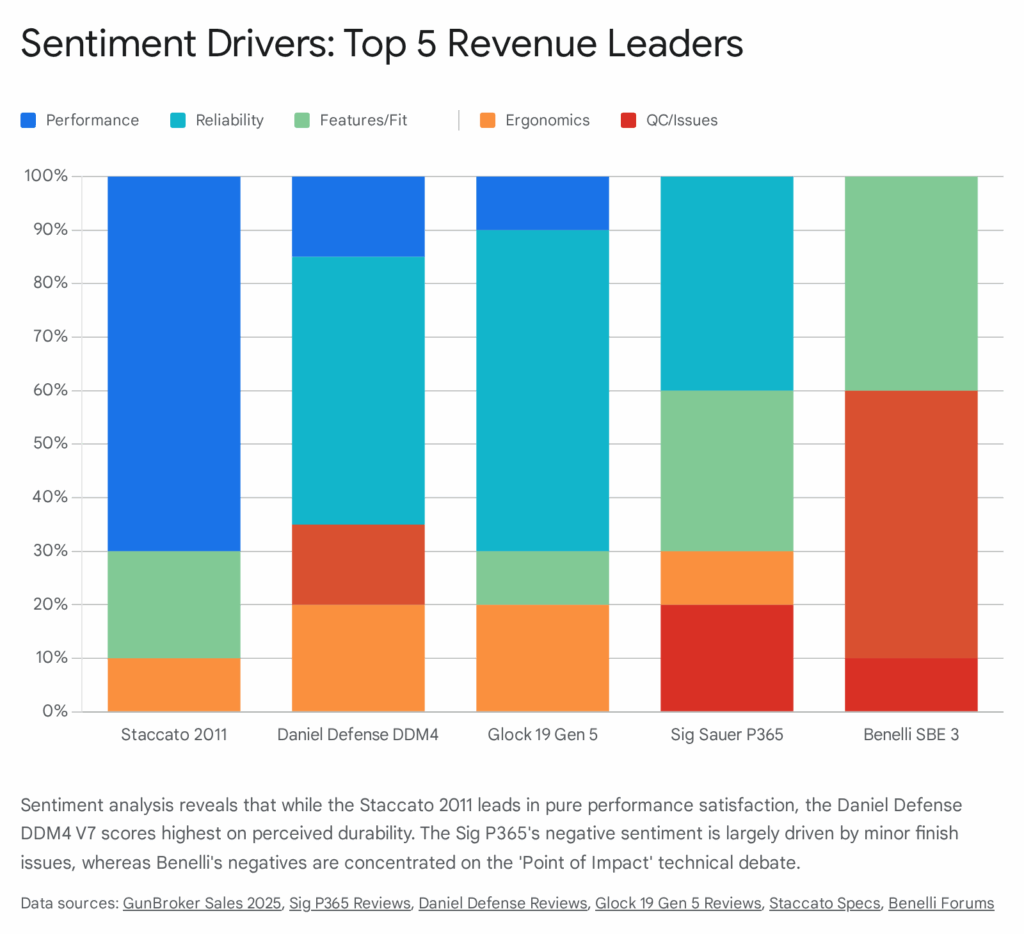

9. Social Media Review: Professional and Public Perspectives

An analysis of relevant English and Middle Eastern social media sites and forums during the week of the show reveals a community deeply engaged with the technical and aesthetic shifts presented in 2026.7

9.1 English-Language Professional Discourse

On sites such as The Firearm Blog (TFB), the debate centered on the ST Engineering AME-B514 bullpup.7 Analysts and enthusiasts were quick to note the futuristic aesthetic and the removal of the enclosed pistol grip seen in earlier prototypes, with many praising the addition of an adjustable stock to a bullpup design.7 However, some skepticism remained regarding the global shift back toward conventional rifles, with users noting that “another bullpup that no one wants” reflects a tension between specialized doctrine and market demand.7 The AME-A514 was generally viewed as a pragmatic move by ST Engineering to offer a “standardized” solution for the international market that prioritizes training commonality over the compact length of the bullpup.5

9.2 Middle Eastern Forum Sentiment

Middle Eastern forums like Defense-Arab reflected a broader strategic interest, focusing on the multibillion-dollar contracts and the geopolitical implications of the show.18 Discussions regarding Raytheon’s $170 million contract for Maverick missiles and the competition between the Eurofighter and American F/A-18 for regional requirements provided the context in which Middle Eastern small arms partnerships are viewed.19 There is a visible pride in the success of the EDGE Group’s localized production strategies, with participants viewing these partnerships as a means to achieve strategic autonomy from traditional Western suppliers.17

9.3 Sentiment and Discussion Distribution Matrix

Description: A matrix showing the density and sentiment of social media discussions. Axis labels indicate “Technical Detail” vs “Strategic Impact.” Text labels for specific platforms: TFB, Reddit, Defense-Arab, LinkedIn.

| Platform / Community | Primary Theme | Sentiment Index | Market Insight |

| X / Twitter (Military) | RAAF F-35A Debut | High Excitement | Focus on advanced aircraft; small arms secondary. |

| The Firearm Blog | AME-B514 Ergonomics | Polarized | Bullpup vs Conventional debate; praise for weight. |

| Defense-Arab | UAE/Indo Partnerships | High Approval | Strategic value of tech transfer and regional hubs. |

| LinkedIn (Defense) | AI & C-UAS Trends | Professional/Serious | Shift toward “Detect-to-Defeat” workflows. |

| Reddit (/r/military) | US Commitmnet to APAC | Analytical | Questions on US isolationism vs regional alliances. |

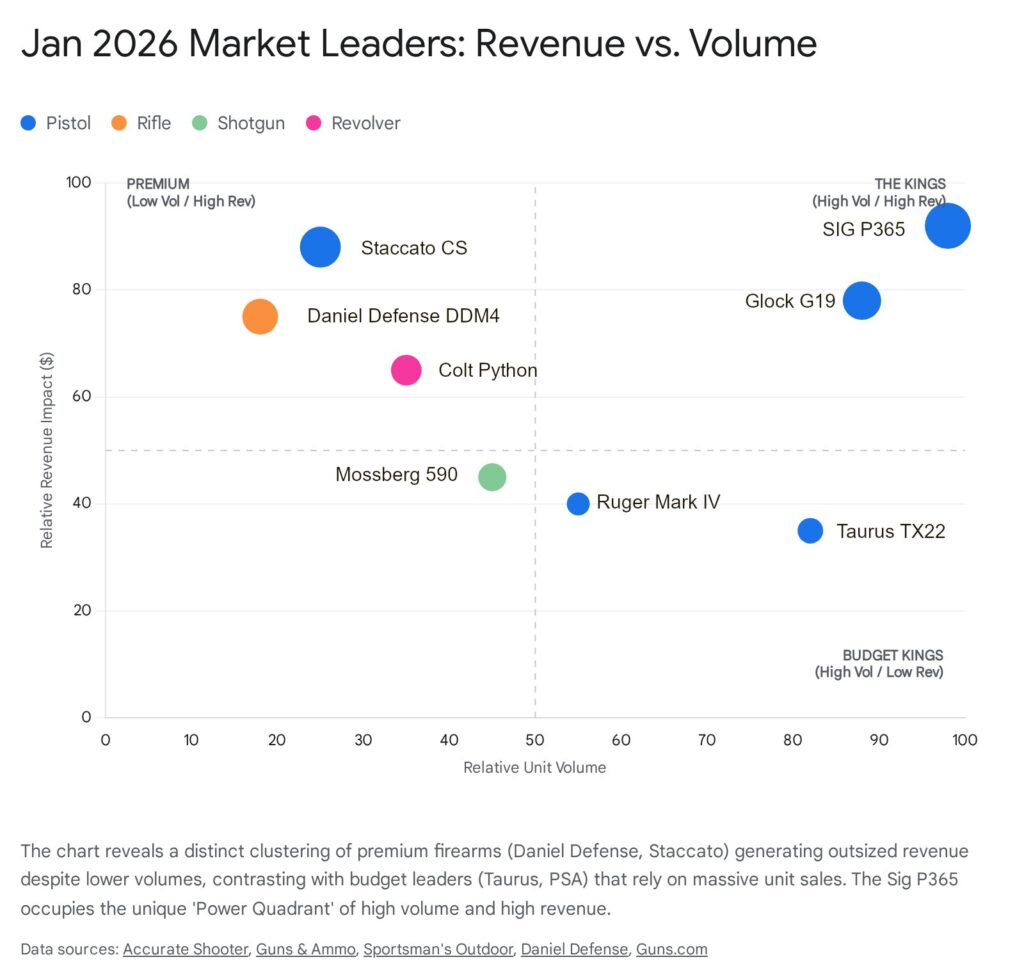

10. Market Forecast and Industry Trajectories

The data gathered during the Singapore Airshow 2026 points toward three dominant trajectories for the small arms industry over the next five-year cycle.5

First, the “AR-standardization” of the global market will continue to accelerate, as evidenced by ST Engineering’s decision to develop the A514 alongside their bullpup line.5 Manufacturers that can provide a “familiar” ergonomic platform with high-end material science will likely dominate the export markets.5 Second, the integration of AI-driven fire control is moving from a luxury add-on to a baseline requirement.11 Weapons that are not “digitally ready” will become obsolete as militaries increasingly rely on networked sensor fusion.5

Finally, the Middle East and Southeast Asia are shifting from being purely “buyers” to “makers” through strategic partnerships and co-production hubs.17 The success of EDGE/Caracal in Indonesia and India serves as a blueprint for other emerging defense economies seeking to secure their own tactical supply chains while leveraging international technology.17

11. Conclusion

The Singapore Airshow 2026 has definitively shown that the small arms industry is in the midst of a digital renaissance. While the kinetic foundations of the assault rifle, machine gun, and sniper system remain constant, the systems that surround and direct that kinetic energy have been revolutionized by artificial intelligence, advanced energetics, and decentralized tactical networks.5

ST Engineering’s AME family represents a sophisticated response to a bifurcated market—one that demands the compact efficiency of the bullpup and the ergonomic familiarity of the AR platform.5 Simultaneously, the emergence of tactical loitering munitions and AI-enabled gunfire detection has blurred the lines between the individual marksman and the larger C4I infrastructure.11 For the small arms industry analyst, the 2026 show confirms that success in the next decade will be determined not just by the quality of the barrel and the action, but by the weapon’s ability to exist as a digital node within a multi-domain, networked battle space.

Appendix: Methodology

The findings in this report were compiled by a Senior Small Arms Industry Analyst through a multi-stage intelligence gathering and verification process conducted during the Singapore Airshow 2026.

The primary research layer involved on-site technical reviews of weapons and ammunition at the ST Engineering pavilion and various national pavilions, with specific attention paid to the “Defence and Public Security Zone”.9 Secondary data was gathered through official press releases from global leaders such as Rafael, IAI, MBDA, and Saab, as well as high-level interviews with military leadership including Singapore’s Chief of Air Force.13

Sentiment and market discourse were analyzed via open-source intelligence (OSINT) techniques, monitoring English-language specialist media (The Firearm Blog, EDR Magazine) and Middle Eastern defense forums (Defense-Arab) to identify professional and public perceptions.5 All technical data was cross-referenced against manufacturer catalogs and verified through multiple defense journalism channels to ensure the highest degree of accuracy in this strategic report.7

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, we are only paid if there is an affiliate program such as Avantlink, Impact, Amazon and eBay and only if you purchase something. If you’d like to directly contribute towards our continued reporting, please visit our funding page.

Works cited

- Singapore Airshow 2026 Exhibitors & Attendees Lists, accessed February 3, 2026, https://www.expocaptive.com/singapore-airshow-exhibitors-list/

- Singapore’s aviation showcase to reflect region’s defence uncertainties and growth ambitions | DD News, accessed February 3, 2026, https://ddnews.gov.in/en/singapores-aviation-showcase-to-reflect-regions-defence-uncertainties-and-growth-ambitions/

- Singapore Airshow 2026 expects larger turnout than previous edition: Organiser, accessed February 3, 2026, https://www.straitstimes.com/singapore/transport/singapore-airshow-2026-expected-to-see-larger-turnout-than-previous-edition-organiser

- Singapore’s aviation showcase to reflect region’s defence uncertainties and growth ambitions, Lifestyle News – AsiaOne, accessed February 3, 2026, https://www.asiaone.com/lifestyle/singapores-aviation-showcase-reflect-regions-defence-uncertainties-and-growth-ambitions

- Singapore Airshow 2026 – ST Engineering presents the AME‑A514 …, accessed February 3, 2026, https://www.edrmagazine.eu/singapore-airshow-2026-next-generation-firepower-st-engineering-presents-the-ame-a514-assault-rifle

- Singapore Airshow 2026 Marks 10th Edition with New Frontiers in Aviation and Space, accessed February 3, 2026, https://www.singaporeairshow.com/others/singapore-airshow-newsroom/2025/singapore-airshow-2026-marks-10th-edition-with-new-frontiers-in-aviation-and-space

- DSEI 2025: Hands On With ST Engineering’s New Bullpup – the AME-B514, accessed February 3, 2026, https://www.thefirearmblog.com/blog/dsei-2025-hands-on-with-st-engineering-s-new-bullpup-the-ame-b514-44822788

- ST Engineering AR Rifles Showcased – Asian Defence Journal, accessed February 3, 2026, https://adj.com.my/2025/11/13/st-engineering-ar-rifles-showcased/

- [Airshow 2026 Highlights] ST Engineering’s full listing of exhibits at …, accessed February 3, 2026, https://www.stengg.com/en/singapore-airshow-2026/all-exhibits/

- Singapore Airshow 2026 Shaping the Aerospace Landscape as Asia-Pacific Drives Global Growth, accessed February 3, 2026, https://www.asiapacificsecuritymagazine.com/singapore-airshow-2026-shaping-the-aerospace-landscape-as-asia-pacific-drives-global-growth/

- ST Engineering Unveils EagleStrike Loitering Munition at Singapore Airshow 2026, Redefining Tactical Warfare in the Indo-Pacific – Defence Security Asia, accessed February 3, 2026, https://defencesecurityasia.com/en/st-engineering-eaglestrike-loitering-munition-singapore-airshow-2026/

- Equipment of the Indian Army’s Infantry soldier | ADU MEDIA – Aviation Defence Universe, accessed February 3, 2026, https://www.aviation-defence-universe.com/equipment-of-the-indian-army/

- Rafael to Present Integrated Air, Space and Air Defense Solutions at …, accessed February 3, 2026, https://www.israeldefense.co.il/en/node/67689

- Singapore Airshow 2026 – IAI, accessed February 3, 2026, https://www.iai.co.il/trade-shows/singapore-airshow-2026

- RAFAEL to Showcase Integrated Air, Space, Intelligence and Air Defense Capabilities at Singapore Airshow 2026 – European Security & Defence – Euro-sd, accessed February 3, 2026, https://euro-sd.com/2026/02/news/48990/rafael-to-showcase-integrated-air-space-intelligence-and-air-defense-capabilities-at-singapore-airshow-2026/

- OPAL: Transforming Military Fleets into a Unified Combat Network – IAI, accessed February 3, 2026, https://www.iai.co.il/news-media/iai-action/opal

- Inside EDGE – Caracal, small arms from the UAE – EDR Magazine, accessed February 3, 2026, https://www.edrmagazine.eu/caracal-small-arms-from-the-uae

- انطلاق مرتقب لمعرض سنغافورة الدولي للطيران 2026 بمشاركة عالمية واسعة – Defensehere, accessed February 3, 2026, https://defensehere.com/ar/%D8%A7%D9%86%D8%B7%D9%84%D8%A7%D9%82-%D9%85%D8%B1%D8%AA%D9%82%D8%A8-%D9%84%D9%85%D8%B9%D8%B1%D8%B6-%D8%B3%D9%86%D8%BA%D8%A7%D9%81%D9%88%D8%B1%D8%A9-%D8%A7%D9%84%D8%AF%D9%88%D9%84%D9%8A-%D9%84%D9%84%D8%B7%D9%8A%D8%B1%D8%A7%D9%86/

- الإمارات تطلب صورايخ مافريك لمهاجمة الأهداف السريعة والمناورة – أخبار الدفاع العربي, accessed February 3, 2026, https://defense-arab.com/news/805/

- Singapore modernising aircraft, defence systems with ‘game-changers’: Air force chief, accessed February 3, 2026, https://www.channelnewsasia.com/singapore/modernising-aircraft-defence-systems-game-changers-chief-air-force-5900456

- Singapore Airshow Newsroom – Singapore Airshow 2026, accessed February 3, 2026, https://www.singaporeairshow.com/media/singapore-airshow-newsroom

- About the Show – Singapore Airshow 2026, accessed February 3, 2026, https://www.singaporeairshow.com/the-show/about-singapore-airshow

- Singapore Airshow 2026 – MBDA, accessed February 3, 2026, https://www.mbda-systems.com/singapore-airshow-2026

- Tourism News-, accessed February 3, 2026, http://en246398.hotels168.com/news-1.html

- Singapore Airshow 2026 to thrill audiences with spectacular line-up of international flying displays, accessed February 3, 2026, https://www.singaporeairshow.com/others/singapore-airshow-newsroom/2026/singapore-airshow-2026-to-thrill-audiences-with-spectacular-line-up-of-international-flying-displays

- [Airshow 2026 Highlights] ST Engineering’s full listing of exhibits at Singapore Airshow 2026, accessed February 3, 2026, https://www.stengg.com/en/singapore-airshow-2026/exhibits-listing/

- ST Engineering debuts its largest cargo drone at Singapore Airshow 2026, accessed February 3, 2026, https://www.businesstimes.com.sg/companies-markets/st-engineering-debuts-its-largest-cargo-drone-singapore-airshow-2026

- RAFAEL to Showcase a Broad Array of Capabilities at Singapore Air Show 2026, accessed February 3, 2026, https://www.rafael.co.il/news/rafael-to-showcase-a-broad-array-of-capabilities-at-singapore-air-show-2026/

- Request For Information (RFI) – Request For Proposal(RFP) | Aviation Defense Universe, accessed February 3, 2026, https://www.aviation-defence-universe.com/rfirfp/

- Russian Southern District reconnaissance unit receives ASVK-M and SVD-M sniper rifles, accessed February 3, 2026, https://defensehere.com/en/russian-southern-district-reconnaissance-unit-receives-asvk-m-and-svd-m-sniper-rifles/

- Singapore Airshow 2026 – Kallman Worldwide, Inc., accessed February 3, 2026, https://www.kallman.com/show/singapore-airshow-2026/

- Ondas Unifies Autonomous Combat Systems under New Defense and Security Unit, accessed February 3, 2026, https://www.ainonline.com/aviation-news/defense/2026-01-31/ondas-unifies-autonomous-combat-systems-under-new-defense-and

- سلاح الجو الالماني سيشتري 90 طائرة يوروفايتر لتحل مكان التورنادو – أخبار الدفاع العربي, accessed February 3, 2026, https://defense-arab.com/news/40511/

- MBDA, Excellence at your side | MBDA, accessed February 3, 2026, https://www.mbda-systems.com/

- Saab at Singapore Airshow 2026, accessed February 3, 2026, https://www.saab.com/markets/singapore/press_releases/saab-at-singapore-airshow-2026

- MBDA at SINGAPORE AIRSHOW 2026: showcasing innovation & commitment, accessed February 3, 2026, https://www.mbda-systems.com/mbda-singapore-airshow-2026-showcasing-innovation-commitment