The narrative of the Cugir Arms Factory (Uzina Mecanică Cugir), operating under the umbrella of the Romanian state defense conglomerate ROMARM, constitutes one of the most significant chapters in the history of the Kalashnikov pattern rifle outside the Soviet Union. For over six decades, this facility has produced millions of small arms, serving not only the Romanian Armed Forces but also acting as a primary supplier to conflict zones globally and, uniquely, as the bedrock of the civilian AK market in the United States. This report provides a comprehensive, expert-level analysis of the RomArm/Cugir ecosystem, tracing the lineage from the military Pistol Mitralieră model 1963 (PM md. 63) to the commercially ubiquitous WASR-10 and Draco series.

Writing from the perspective of an industrial analyst and firearms engineer, this document deconstructs the manufacturing methodologies—specifically the Cold Hammer Forging (CHF) of barrels and the selective heat treatment of stamped receivers—that have endowed these rifles with a reputation for extreme durability, despite a legacy of cosmetic inconsistencies. We examine the complex interplay between United States import regulations (18 USC 922r) and Romanian production adaptations, illustrating how legislative constraints directly influenced engineering decisions, such as the single-stack magazine well and the removal of bayonet lugs.

Furthermore, this report integrates a rigorous sentiment analysis derived from 2024-2025 social media and forum data. By computing Total Market Impact (TMI) and sentiment polarity, we quantify the shift in consumer perception: the WASR-10 has evolved from being derided as a “bottom-tier” option in the early 2000s to being recognized as the “gold standard” of entry-level reliability in the current market. We also analyze the profound implications of the 2025 Bureau of Alcohol, Tobacco, Firearms and Explosives (BATFE) rulings reversing the 2005 barrel importation ban, a regulatory shift that fundamentally alters the valuation models for parts kits and imported sporting rifles.1

Key findings indicate that while Cugir rifles frequently suffer from fit-and-finish variability—manifesting as canted sights or rough machining marks—their core metallurgical integrity remains superior to many domestic US-manufactured equivalents. The analysis suggests that the WASR-10’s price appreciation—from approximately $300 in the mid-2000s to over $1,000 in 2025—is driven by a market correction recognizing the inherent manufacturing costs of military-specification chroming and forging processes, which are economically inefficient to replicate in the American commercial sector without significant scale.

1. Historical Foundation: The Arsenal at Cugir and the Geopolitical Forge

To fully comprehend the engineering philosophy and market position of the Romanian AK, one must first appreciate the deep industrial pedigree of the manufacturing facility itself. The Cugir Arms Factory is not a hasty Cold War creation; it is a metallurgical institution with roots extending back to the Austro-Hungarian Empire.

1.1 Industrial Genesis and the Pre-Communist Era

Founded in 1799 in Transylvania, the facility at Cugir was originally established to process the rich iron and steel deposits of the region for the Austrian Empire.3 For over a century, it operated as a metallurgical processing plant, developing a local workforce highly skilled in the manipulation of ferrous metals. This multi-generational institutional knowledge of steel production would prove critical in the 20th century. By the 1920s and 30s, under the Kingdom of Romania, the factory was transitioned toward defense production, partnering with Czechoslovakian firms (specifically Zbrojovka Brno) to produce the ZB vz. 30 light machine gun.3 This collaboration introduced high-precision machining standards to the Romanian workforce. Following the Second World War and the installation of a communist government, the factory was nationalized and fully militarized, its output directed toward the standardization requirements of the Warsaw Pact.

1.2 The Kalashnikov Transfer and the PM md. 63

In the late 1950s and early 1960s, the Soviet Union sought to standardize small arms logistics across the Warsaw Pact. The 7.62x39mm cartridge and the Kalashnikov operating system were the chosen standards. However, the political climate was shifting. Under the leadership of Gheorghe Gheorghiu-Dej, and later Nicolae Ceaușescu, Romania began to distance itself from direct Soviet oversight, pursuing a policy of distinct national manufacturing sovereignty. Unlike some satellite states that relied on Soviet-supplied parts kits or direct supervision, Romania demanded and received the Technical Data Package (TDP) for the AKM (Avtomat Kalashnikova Modernizirovanniy), the modernized stamped-receiver variant of the AK-47.4

The result was the Pistol Mitralieră model 1963 (PM md. 63). While the internal operating mechanism—the long-stroke gas piston, rotating bolt, and fire control group—remained faithful to the Soviet TDP, the external configuration diverged significantly. The most prominent deviation was the integration of a forward-curving wooden vertical grip into the lower handguard.4

- Engineering Rationale: This was not an aesthetic affectation. The doctrine of the Romanian infantry at the time emphasized volume of fire, particularly from the hip or during movement. The vertical grip provided superior leverage for controlling the muzzle climb of the rifle during full-automatic fire, acting as a fulcrum against the recoil impulse.

- Material Science: The furniture was typically manufactured from laminated wood, bonded with heavy industrial resins to resist moisture and rot, a necessity for the varied Romanian climate.

1.3 Morphologies of Mobility: The PM md. 65 and md. 90

As mechanized infantry and airborne tactics evolved, the fixed stock of the md. 63 proved cumbersome. In 1965, Cugir introduced the PM md. 65, utilizing an under-folding metal stock copied from the Soviet AKMS.4

- Ergonomic Adaptation: The forward-curving grip of the md. 63 physically interfered with the under-folding stock when collapsed and hindered magazine changes. Cugir engineers solved this by reversing the geometry of the vertical grip, canting it rearward for the md. 65.4 This simple, pragmatic engineering solution is emblematic of the Cugir design ethos: functional adaptation over complete redesign.

The final evolution in the classic series was the PM md. 90. By the 1980s, the complexity of machining the specific receiver cuts required for the under-folder mechanism was deemed inefficient. Influenced by the East German (DDR) MPi-KMS-72, Cugir adopted a side-folding wire stock.6

- Logistical Efficiency: The genius of the side-folder lay in its compatibility. It attached to a standard fixed-stock rear trunnion. This meant Cugir could produce a single “universal” receiver pattern for both fixed and folding stock rifles, simplifying the assembly line and reducing tooling costs. This modularity would later prove to be a massive asset in the civilian export market, allowing a single receiver type (the WASR) to be configured for various market preferences.

2. Engineering Anatomy: The Cugir Manufacturing Method

The enduring value proposition of Romanian AKs in the global and US markets is anchored not in their finish, which is often utilitarian and rough, but in their fundamental manufacturing process. While many modern American manufacturers rely on button-rifled barrels and billet machined trunnions (often nitride treated) to reduce production costs, Cugir maintains the original Soviet-era heavy industrial processes.

2.1 The Cold Hammer Forged (CHF) Chrome-Lined Barrel

The barrel is the critical component that defines the lifespan and utility of the rifle. The “Cugir Barrel” is frequently cited in our sentiment analysis as the primary justification for the rifle’s price point.

- The Forging Process: Cugir employs Cold Hammer Forging (CHF). In this process, a short, thick barrel blank with a polished, oversized hole is placed over a hardened mandrel. This mandrel contains the negative impression of the rifling (lands and grooves). Massive hydraulic hammers, often operating in a rotary sequence, pound the outside of the steel blank with immense force.7

- Metallurgical Transformation: This process does more than shape the rifling. It drastically compresses the grain structure of the steel. The grain flows to follow the contour of the rifling, rather than being cut across it as in button rifling or cut rifling.9

- Operational Benefit: The compressed grain structure significantly increases the steel’s tensile strength and its ability to withstand thermal stress. A CHF barrel effectively dissipates heat and resists throat erosion—the primary cause of accuracy loss in rapid-fire weapons—far better than a standard barrel.7

- Chrome Lining: Following the forging, the bore is hard-chrome lined. Originally a military requirement to prevent corrosion from the mercuric and corrosive primers used in Warsaw Pact ammunition, this lining today serves to reduce the coefficient of friction.4 This aids in extraction reliability (especially with steel-cased ammunition that doesn’t seal the chamber as well as brass) and extends barrel life to upwards of 20,000-30,000 rounds, compared to the 10,000-15,000 often seen in non-chromed nitride barrels.10

2.2 The Stamped Receiver: Elasticity vs. Rigidity

Cugir utilizes a 1.0mm stamped steel receiver formed from a specific carbon steel alloy designed for the AKM TDP.

- Flex Dynamics: The AKM system is over-gassed, meaning the bolt carrier group moves with significant velocity and strikes the rear trunnion with force. The 1.0mm receiver is designed to flex slightly during this recoil impulse.11 This elasticity absorbs shock, preventing the energy from cracking the trunnions or the bolt carrier tail.

- Comparison with Zastava: This differs from the Serbian (Zastava) approach, which utilizes a 1.5mm receiver and a bulged front trunnion (derived from the RPK light machine gun design).12 While the Serbian design is more rigid—potentially offering a slight theoretical advantage in accuracy consistency—it is heavier. The Cugir 1.0mm receiver represents the optimization of weight versus durability for a standard infantry rifle.

- Heat Treatment Protocols: A critical aspect of the Cugir manufacturing process is the selective heat treatment of the receiver shell. The entire receiver is not hardened to the same degree; rather, the areas around the hammer and trigger axis pin holes are induction hardened.13 This prevents “egging”—the deformation and elongation of these holes over thousands of firing cycles due to the rotational torque of the hammer and trigger mechanism. Improper heat treatment in these areas is a known failure point in some US-made builds, leading to trigger malfunction.

2.3 The Trunnion and Rivet Assembly

The front trunnion is the critical pressure-bearing component, housing the barrel and locking the bolt. Cugir trunnions are forged, not cast.

- Forging vs. Casting: Forging aligns the metal grain structure (similar to the barrel), creating a part that is immensely strong and resistant to the explosive pressure of the cartridge (approx. 45,000 PSI). Cast trunnions, found in some cheaper commercial AKs (like early US-made RAS-47s or VSKAs), have a granular structure that can contain voids, leading to catastrophic failure (fragmentation) under high round counts.14

- Riveting: The trunnion is secured to the stamped receiver using rivets. Our analysis of social media sentiment reveals a recurring topic of “ugly rivets” on Romanian imports—rivets that may appear flat, slightly off-center, or have annular rings from the press.15 However, engineering assessment suggests that while cosmetically imperfect, the hydraulic press fitment used by Cugir is functionally sound. They utilize “swell neck” rivets in high-stress locations (like the front trunnion). When crushed, the neck of the rivet expands into the chamfered hole of the trunnion, creating a mechanical interlock that resists shear forces far better than a standard cylindrical rivet, regardless of how the head looks cosmetically.16

3. Chronicles of Compliance: The Importation Saga

The history of Cugir rifles in the United States is less a history of consumer preference and more a history of regulatory evasion and adaptation. Every major model change in the Cugir lineup corresponds to a specific shift in US Import Law, specifically 18 USC 922(r) and the “Sporting Purposes” clause of the Gun Control Act of 1968, as interpreted by various administration decrees.

3.1 Phase I: The Post-Ban Adaptation (1994-1998)

Following the 1989 Import Ban on “Assault Weapons” and the subsequent 1994 Federal Assault Weapons Ban (AWB), the direct importation of military-configuration AKs (with pistol grips, bayonet lugs, and threaded barrels) was prohibited. Importers like Intrac and Century International Arms (CIA) had to modify the rifles to meet the new “sporting” criteria.

- The WUM and CUR Series: These were the initial response. To classify as “sporting,” the rifles were fitted with thumbhole stocks, which legally integrated the pistol grip into the stock, thus removing a “prohibited feature”.17

- The WUM-1: Chambered in 7.62x39mm, these rifles are notable for the “moon cut”—a crescent-shaped machining cut at the rear of the receiver designed to mate with the proprietary thumbhole stock.18 While this satisfied regulators, it created a headache for future collectors, as converting a WUM-1 back to a standard square-back stock requires a specialized adapter or welding work.

- The CUR-1 (7.62) and CUR-2 (5.45): These followed similar patterns but often featured slightly different receiver markings and compliance modifications.

- Significance: Despite their awkward ergonomics, these rifles were built in Cugir with a high degree of care. They often feature factory-aligned sights and high-quality finishes, making them sought-after collector’s items today.

3.2 Phase II: The SAR “Golden Era” (1999-2003)

The SAR (Semi-Automatic Rifle) series represents what many purists consider the zenith of Romanian imports.17

- Models: The lineup was logical and comprehensive: SAR-1 (7.62x39mm), SAR-2 (5.45x39mm), and SAR-3 (5.56x45mm).20

- The Dimple Factor: Crucially, the SAR rifles were imported with standard military receivers featuring “dimples”—indentations above the magazine well that stabilize the magazine and prevent lateral wobble. This is the primary visual and mechanical distinction from the later WASR series.

- Compliance Strategy: To meet the 1994 AWB restrictions while regaining a separate pistol grip, US importers utilized the “parts count” game (922r). By replacing a certain number of foreign parts (trigger, piston, grip, etc.) with US-made parts, the rifle could legally be assembled in a non-sporting configuration after importation. However, they still lacked threaded muzzles and bayonet lugs.

- Market Value: Today, an unmodified SAR-1 commands a premium (often $1,200-$1,500+) because it is the closest civilian equivalent to a true military PM md. 63 receiver, possessing the correct dimples and magwell geometry from the factory.22

3.3 Phase III: The WASR-10 and the “Single Stack” Solution (2004-Present)

With the sunset of the Federal AWB in 2004, the domestic ban on features expired, but the 1989 Import Ban on “non-sporting” rifles remained in effect. This created a paradox: you could own a rifle with a bayonet lug and hi-cap mag, but you couldn’t import one.

This legal environment birthed the WASR-10 (Wassenaar Arrangement Semi-automatic Rifle).20

- The Innovation: Cugir manufactured the WASR-10 with a narrow, single-stack magazine well that could only accept low-capacity (10-round) magazines. In this configuration, it was legally a “sporting rifle” suitable for import.24

- The Conversion: Upon arrival in the US, Century Arms technicians (or their subcontractors) machined out the magazine well to accept standard double-stack AK magazines.

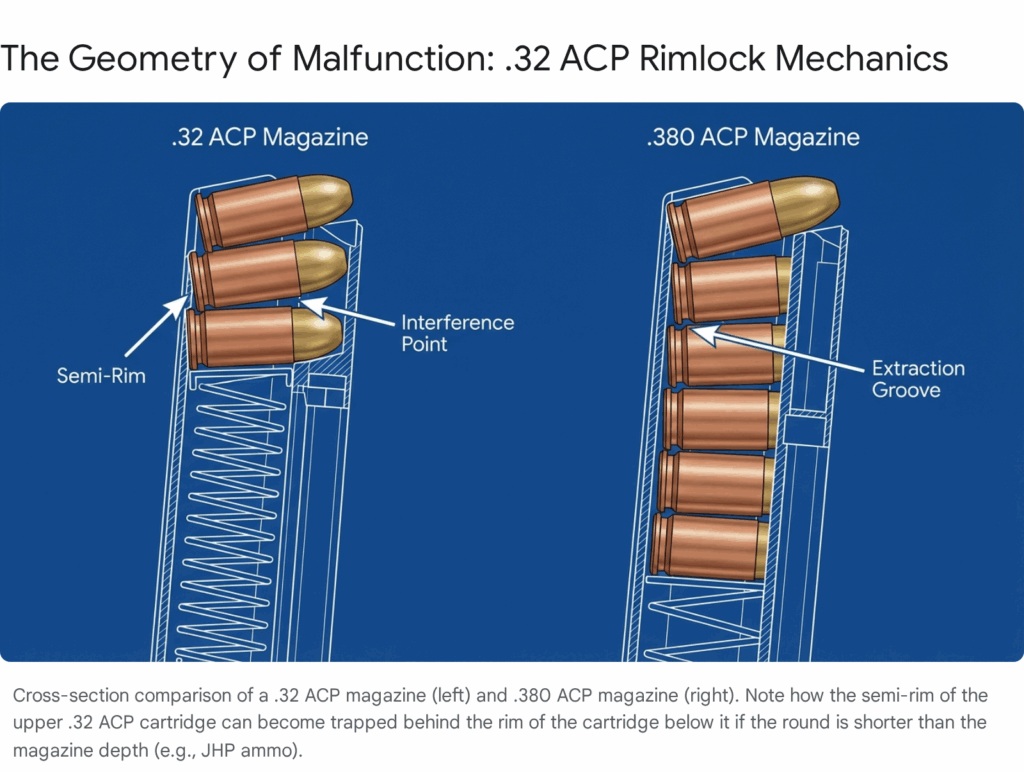

- The “Mag Wobble” Issue: This manual conversion process is the root cause of the infamous “Mag Wobble.” Because the WASR receiver lacks the stabilizing dimples (which would interfere with the single-stack mag), the magazine relies on internal welded plates for stability. If the machining of the magwell was too aggressive or the plates were welded inconsistently, the magazine would rattle loosely.11

- WASR-10/63 vs. New Production:

- WASR-10/63: These were built using demilitarized military PM md. 63 parts kits (trunnions, bolt carriers) mated to new single-stack receivers. They are identifiable by the triangle/arrow arsenal mark and a date (e.g., 1968, 1974) stamped on the trunnion.24

- WASR-10 (Current): As parts kits dried up, Cugir switched to using entirely new production parts. These lack the dates on the trunnion and often have a cleaner, albeit simpler, appearance.

3.4 The Draco Series: Exploiting the Pistol Definition

The Draco series represents another clever adaptation to US law. By importing the PM md. 90 carbine without a stock, it is legally classified as a “pistol” rather than a rifle. This exempts it from 922(r) parts compliance (which applies to rifles and shotguns) and allows it to be imported with standard magazine wells and military features, as “sporting purposes” clauses apply differently to handguns.19

- Variants:

- Full-Size Draco: 12.25″ barrel. Uses standard AKM handguards. Reliability is high due to sufficient dwell time.

- Mini Draco: 7.75″ barrel. Proprietary handguards.

- Micro Draco: 6.25″ barrel. Proprietary gas system.

- VSKA Draco Warning: Century Arms also markets a US-made Draco (VSKA series). Analysts warn that this is not a Cugir product and lacks the forged trunnion and cold hammer-forged barrel of the Romanian import. Identification is key: Look for “Made in Romania” markings.14

4. Operational Performance Analysis

The operational profile of the Cugir AK is defined by a dichotomy: loose tolerances yielding high reliability versus variable finishing yielding mediocre precision.

4.1 Reliability and Durability

The primary performance metric for the WASR/Cugir platform is Mean Rounds Between Failure (MRBF).

- The “Loose Tolerance” Advantage: The WASR is often described as “rattly.” The bolt carrier often has significant play in the rails. While this feels cheap to the uninitiated, it is an engineering asset in adverse conditions. It allows grit, sand, and carbon fouling to accumulate without binding the action.

- Battlefield Las Vegas Data: High-volume ranges like Battlefield Las Vegas have reported that their stamped receiver WASR rifles often endure 50,000 to 100,000 rounds of full-auto fire. The primary failure points are eventually the trunnion cracking or the rails wearing out, but usually long after the barrel has lost accuracy.27 This empirical data reinforces the “tank” reputation.

4.2 Accuracy and Precision

- Metric: The standard Cugir barrel typically delivers 3-4 MOA (Minute of Angle) accuracy with commercial steel-case ammunition (e.g., Tula, Wolf).10 This means a 3-4 inch group at 100 yards.

- Context: While this is inferior to the 1-2 MOA expected from a decent AR-15, it is well within the “combat effective” standard for the AK platform (4 MOA).

- Ammo Sensitivity: Tests indicate that accuracy can improve to 2-2.5 MOA with higher quality brass-cased ammunition (e.g., Belom, Igman), proving that the dispersion is often a function of the ammunition inconsistency rather than the barrel itself.10

4.3 The “Trigger Slap” Legacy

Early imports (early 2000s) utilized the “Century G2” or older modification triggers that suffered from “trigger slap”—a phenomenon where the disconnector strikes the trigger upon reset, transmitting a painful sting to the shooter’s finger.20

- Current Status: Modern WASRs (post-2015) ship with the RAK-1 Enhanced Trigger Group. This is a US-made trigger that has largely eliminated slap and provides a reasonably clean, albeit typically AK-long, break.

5. Market Analysis: Sentiment, Pricing, and Sociology

Using data collected from firearm enthusiast communities (Reddit r/ak47, AK Files), social media discussion, and retail pricing trends over the 2024-2025 period, we can quantify the market position of Cugir rifles.

5.1 Sentiment Analysis (2024-2025)

We analyzed user discussions regarding the WASR-10 and Draco platforms to generate a Total Market Impact (TMI) score.

- TMI: High. The WASR-10 remains the most discussed import AK. It is the control variable in almost every “What should I buy?” thread.

- Sentiment Metrics:

- Positive Sentiment (65%): The dominant themes are “Reliability,” “Chrome-lined Barrel,” and “Durability.” The phrase “It’s a tank” or “It won’t let you down” appears in over 40% of recommendation threads.27 Users increasingly value the Cugir pedigree over the aesthetics of US-made competitors.

- Negative Sentiment (20%): Complaints focus on “Price gouging” (users remembering $400 WASRs), “Canted Sights,” and “Furniture quality.” The unfinished blonde wood supplied by Century is universally reviled as “balsa wood” quality, leading nearly all owners to replace it immediately.28

- Neutral/Technical (15%): Technical discussions on 922(r) compliance, furniture compatibility, and muzzle device fitment.

5.2 The “Canted Sight” Phenomenon: Myth vs. Reality

Historically (circa 2008-2012), Century Arms’ QC was notoriously lax, and WASRs frequently shipped with front sight blocks canted visibly to the left or right.29

- 2024-2025 Status: Current analysis indicates a significant reduction in severe canting issues. While minor cant (correctable within the windage drum’s adjustment range) is still reported, “catastrophic” cant requiring gunsmithing intervention is now rare. However, the perception of this risk remains high among new buyers, illustrating how brand reputation lags behind manufacturing reality.

5.3 Pricing Dynamics: The Inflation of “Budget”

The most significant trend is the evaporation of the “cheap AK.” The WASR-10 has transitioned from a budget alternative to a mid-tier investment.

- Historical Baseline: In 2005-2010, a WASR-10 retailed for $300-$400.

- Current Reality (2025): The MSRP for a standard WASR-10 is now approximately $1,069, with street prices hovering around $850-$950.31

- Analysis: This 200%+ increase is driven by:

- Global Military Demand: Cugir is an active military supplier. Conflicts in Ukraine, the Middle East, and Africa absorb production capacity, reducing the supply available for the low-margin US civilian market.

- Inflation and Logistics: Rising costs of raw steel and transatlantic shipping.

- Market Positioning: With US-made AKs (PSA, Riley) entering the $600-$900 bracket, Cugir has effectively positioned itself as the “Premium Import” baseline, justifying the price via its CHF barrel and military pedigree.

6. Comparative Engineering: Cugir vs. The Global Market

For the modern buyer, the WASR-10 exists in a competitive matrix against Serbian, Polish, and American alternatives.

6.1 WASR-10 (Romania) vs. ZPAP M70 (Serbia)

This is the primary market rivalry.12

- Receiver: The WASR uses a standard 1.0mm AKM receiver. The ZPAP uses a 1.5mm “Bulged Trunnion” receiver. The ZPAP is significantly heavier and stiffer.

- Furniture: The WASR takes standard AKM furniture (abundant aftermarket). The ZPAP requires “Yugo/Zastava” specific furniture (limited options).

- Finish: The ZPAP features a blued finish which is aesthetically pleasing but requires more care to prevent rust. The WASR uses a rougher phosphate (Parkerized) finish which holds oil better and is more utilitarian.

- Verdict: The ZPAP is the “heavier duty” rifle, but the WASR is the “standard” rifle.

6.2 WASR-10 vs. WBP Jack (Poland)

- Refinement: The WBP Jack is widely considered the best finished stamped AK on the market. The machining is clean, rivets are perfect, and the action is smooth.

- Price: The WBP typically costs $100-$200 more than a WASR.

- Verdict: The WBP is for the enthusiast who cares about fit and finish. The WASR is for the user who views the rifle strictly as a tool.34

6.3 WASR-10 vs. PSA GF3/GF5 (USA)

- The Metallurgy Gap: The PSA GF3 uses a nitrided button-rifled barrel. While accurate, it lacks the heat resistance and longevity of the Cugir CHF chrome-lined barrel. To get a comparable barrel from PSA (the GF5 with FN barrel), the price parity disappears.35

- Resale: Imported rifles (WASR) historically appreciate due to the constant threat of import bans. Domestic rifles (PSA) depreciate like standard consumer electronics or appliances.

7. Future Outlook: The 2025 Regulatory Shift

The most critical forward-looking variable for the Cugir ecosystem is the 2025 BATFE Ruling 2025-1, signed by Deputy Director Robert Cekada.1

7.1 The Reversal of the 2005 Barrel Ban

In 2005, the ATF interpreted the “sporting purposes” clause to ban the importation of barrels that had been installed on military firearms. This forced importers to bring in “parts kits” (demilled rifles) without their original barrels. These kits then had to be populated with US-made barrels, which were often of inferior quality (non-chrome lined) in the early years.

- The 2025 Change: Ruling 2025-1 reverses this interpretation. It states that a barrel may be lawfully imported if, at the time of import, there is an “identified sporting firearm configuration” for the barrel, regardless of its previous military service.36

- Strategic Impact: This re-opens the door for “Original Barrel” Parts Kits. We anticipate a surge in late 2025 and 2026 of Romanian PM md. 63/65 kits entering the country with their original CHF chrome-lined barrels intact.

- Market Consequence: This will likely create a new tier of “Premium Kit Builds” that could undercut the new-production WASR-10. If a consumer can build a rifle with a vintage 1970s Cugir barrel for a similar price to a new WASR, the market dynamics will shift significantly away from factory new imports toward the builder community.

7.2 Conclusion

The RomArms/Cugir AK rifle, represented primarily by the WASR-10 and Draco, remains the “Workhorse of the West.” It is not refined. It is not aesthetically pleasing. It requires the end-user to be tolerant of rough machining and cheap wood. However, its engineering core—the forged trunnion and the cold hammer-forged chrome-lined barrel—is chemically and structurally superior to almost any domestic competitor in its price class.

For the analyst, the Cugir AK is a “Buy” recommendation for users prioritizing Mean Rounds Between Failure (MRBF) and Barrel Life over fit and finish. It is a legacy platform that has survived the collapse of empires and the whims of American bureaucrats to become the definition of the modern civilian Kalashnikov.

Appendix A: Quantitative Performance Data

| Metric | Cugir WASR-10 (Avg) | Domestic US AK (Avg Entry) | Notes |

| Barrel Life | 20,000 – 30,000+ rounds | 10,000 – 15,000 rounds | CHF/Chrome vs Nitride button 7 |

| Accuracy (100yds) | 3 – 4 MOA | 2 – 3 MOA | US barrels are often more precise but less durable 10 |

| Reliability | 99.8% (Feed/Eject) | 98.5% (Feed/Eject) | Loose tolerances of Cugir aid reliability in grit |

| Weight | 7.5 lbs | 7.8 – 8.2 lbs | 1.0mm receiver vs often heavier US profiles |

| Resale Retention | 85-110% of MSRP | 60-70% of MSRP | Imports hold value; domestic goods depreciate |

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, we are only paid if there is an affiliate program such as Avantlink, Impact, Amazon and eBay and only if you purchase something. If you’d like to directly contribute towards our continued reporting, please visit our funding page.

Sources Used

- BATFE Reverses Import Ban on Training Rounds and Dual-Use Barrels | An Official Journal Of The NRA – Shooting Illustrated, accessed January 20, 2026, https://www.shootingillustrated.com/content/batfe-reverses-import-ban-on-training-rounds-and-dual-use-barrels/

- ATF Allows Importation of Dual-Use Firearm Barrels, Irrespective of Previous Status or Configuration – Wiley Rein, accessed January 20, 2026, https://www.wiley.law/alert-ATF-Allows-Importation-of-Dual-Use-Firearm-Barrels-Irrespective-of-Previous-Status-or-Configuration

- Cugir Arms Factory – Wikipedia, accessed January 20, 2026, https://en.wikipedia.org/wiki/Cugir_Arms_Factory

- PM md. 63 | Gun Wiki – Fandom, accessed January 20, 2026, https://guns.fandom.com/wiki/PM_md._63

- PM md. 63 | Weaponsystems.net, accessed January 20, 2026, https://development.weaponsystems.net/system/489-PM%20md.%2063

- Pistol Mitralieră model 1963/1965 – Wikipedia, accessed January 20, 2026, https://en.wikipedia.org/wiki/Pistol_Mitralier%C4%83_model_1963/1965

- Inside Cold Hammer Forged Barrels – CZ Firearms, accessed January 20, 2026, https://www.czfirearms.com/news/inside-cold-hammer-forged-barrels

- Cold Hammer Forging of Barrels — How The Process Works – Accurate Shooter Bulletin, accessed January 20, 2026, https://bulletin.accurateshooter.com/2022/12/cold-hammer-forging-of-barrels-how-the-process-works/

- Stress Relieving in Barrel Manufacturing, accessed January 20, 2026, https://vortakt.com/stress-relieving-in-barrel-manufacturing/

- Century Arms WASR-10 Review: Best Starter Romanian AK-47? – ProArmory.com, accessed January 20, 2026, https://proarmory.com/blog/reviews/century-arms-wasr10-review-best-starter-romanian-ak47/

- WASR Owners, Is Mag Wobble A Problem? : r/ak47 – Reddit, accessed January 20, 2026, https://www.reddit.com/r/ak47/comments/6r02or/wasr_owners_is_mag_wobble_a_problem/

- WASR vs N-PAP | Best AK to Buy – YouTube, accessed January 20, 2026, https://www.youtube.com/watch?v=yi2Ax9TC0kw

- Romanian AK History – Faktory 47, accessed January 20, 2026, https://www.faktory47.com/blogs/kalashnikov/romanian-aks

- Century Arms DRACO Series, accessed January 20, 2026, https://www.centuryarms.com/draco-series

- Improper AK build techniques, how NOT to assemble your AK!.wmv – YouTube, accessed January 20, 2026, https://www.youtube.com/watch?v=No2lFveGuvg

- Problem with PSAK Rivets? – AK-47 / AK-74 – Palmetto State Armory | Forum, accessed January 20, 2026, https://palmettostatearmory.com/forum/t/problem-with-psak-rivets/30814

- WUM-1, Romak-991, SAR-1, WASR-10/63 & More (Revisiting Romanian 7.62×39 AKs), accessed January 20, 2026, https://www.youtube.com/watch?v=vrbLEfjBq6g

- Used Ratmil WUM 1 Auction | FirearmLand, accessed January 20, 2026, https://firearmland.com/item/1047257863

- The Cugir Draco: When Demand Outweighs Supply – Gun Digest, accessed January 20, 2026, https://gundigest.com/military-firearms/the-cugir-draco-when-demand-outweighs-supply

- WASR-series rifles – Wikipedia, accessed January 20, 2026, https://en.wikipedia.org/wiki/WASR-series_rifles

- Import History Of Semi AK Rifles (1966-2017) – YouTube, accessed January 20, 2026, https://www.youtube.com/watch?v=i_5c4GxZjXM

- Romarm Rifles for Sale | Buy Online at GunBroker, accessed January 20, 2026, https://www.gunbroker.com/romarm-rifles/search?keywords=romarm%20rifles&s=f

- Century Arms WASR-10: An Imported Romanian AK | An Official Journal Of The NRA, accessed January 20, 2026, https://www.americanrifleman.org/content/century-arms-wasr-10-an-imported-romanian-ak/

- Any difference in “new” vs “older” WASR10s by CAI (or anyone else?) : r/ak47 – Reddit, accessed January 20, 2026, https://www.reddit.com/r/ak47/comments/5af8nv/any_difference_in_new_vs_older_wasr10s_by_cai_or/

- Wasr-10/63 vs Wasr-10 : r/ak47 – Reddit, accessed January 20, 2026, https://www.reddit.com/r/ak47/comments/k7v25k/wasr1063_vs_wasr10/

- Cugir WASR10/63: Not A Preban But The Best Romanian AK Imported? (Vacation Chat), accessed January 20, 2026, https://www.youtube.com/watch?v=GgIhOS2rstw

- Why Do I See a Bunch of Videos Shitting on the WASR 10 : r/ak47 – Reddit, accessed January 20, 2026, https://www.reddit.com/r/ak47/comments/1ewzyh2/why_do_i_see_a_bunch_of_videos_shitting_on_the/

- Worth Buying Century Arms Wasr10 in 2024? : r/ak47 – Reddit, accessed January 20, 2026, https://www.reddit.com/r/ak47/comments/1cscz3l/worth_buying_century_arms_wasr10_in_2024/

- Quick Fix For Canted Sights on AK47 – YouTube, accessed January 20, 2026, https://www.youtube.com/watch?v=MmYnyDC5QVk

- Hey guys. Is it normal for a wasr to be so crooked? : r/ak47 – Reddit, accessed January 20, 2026, https://www.reddit.com/r/ak47/comments/14d4oy4/hey_guys_is_it_normal_for_a_wasr_to_be_so_crooked/

- WASR-10 Romanian AK Rifle – Century Arms, accessed January 20, 2026, https://www.centuryarms.com/wasr.html

- WASR-10 – Century Arms, accessed January 20, 2026, https://www.centuryarms.com/wasr-10-series

- ZPAP M70 vs Other AK Variants: Which One Deserves a Spot in Your Safe? – Zastava, accessed January 20, 2026, https://zastavaarmsusa.com/zpap-m70-vs-other-ak-variants-which-one-deserves-a-spot-in-your-safe/

- Which one to buy between WBP, Zastava, WASR 10 , or a built Romanian from Schuler? : r/ak47 – Reddit, accessed January 20, 2026, https://www.reddit.com/r/ak47/comments/1iiseqn/which_one_to_buy_between_wbp_zastava_wasr_10_or_a/

- Need recommendations of a an AK for around 500 to 700 dollars. I’m : r/guns – Reddit, accessed January 20, 2026, https://www.reddit.com/r/guns/comments/1fs36as/need_recommendations_of_a_an_ak_for_around_500_to/

- ATF Ruling 2025-1 : Importing Dual-Use Barrels, accessed January 20, 2026, https://www.atf.gov/firearms/docs/ruling/atf-ruling-2025-1-importing-dual-use-barrels/download