The discipline of military small arms is witnessing a pivotal collision between two historically distinct capability sets: the precision-focused anti-personnel sniper system and the energy-focused anti-materiel rifle. For decades, these roles were bifurcated by the limitations of physics and materials science. Precision engagement was the domain of .30 caliber systems, while heavy payload delivery against hardened targets relied on the 12.7mm (.50 BMG) platform—a cartridge originally designed for machine guns, inherently limited in its ballistic efficiency and accuracy. However, the emergence of the “Extreme Long Range” (ELR) requirement, driven by peer-adversary overmatch in theaters such as Eastern Europe and the Pacific, has necessitated a new class of weapon system. This system, typified by the USSOCOM ELR-SR (Extreme Long Range Sniper Rifle) solicitation, seeks to fuse the sub-MOA (Minute of Angle) precision of a sniper rifle with the kinetic energy required to neutralize light vehicles and critical infrastructure at distances exceeding 2,500 meters.

This convergence is powered by a trifecta of technological advancements: the development of high-ballistic-coefficient cartridges like the .375 EnABELR and .416 Barrett, the maturation of active fire control optics that calculate complex ballistic solutions instantly, and the modular chassis designs allowing rapid caliber conversion. Yet, this mechanical renaissance faces an existential challenge from the asymmetric revolution of Unmanned Aerial Systems (UAS). The proliferation of cheap, lethal First Person View (FPV) drones offers commanders a non-line-of-sight precision strike capability that vastly outranges even the most advanced rifle, at a fraction of the training and equipment cost.

The following analysis suggests that while the ELR rifle remains a critical tool for “jam-proof” lethality in electronic warfare (EW)-saturated environments, its role is shifting. The modern sniper must evolve from a standalone marksman into a systems integrator, managing a hybrid arsenal of kinetic projectiles and loitering munitions. The cancellation of the specific USSOCOM ELR-SR solicitation in late 2024 does not signal the death of the concept, but rather a strategic pause to recalibrate the balance between the rifle and the drone in the future order of battle. This report details the technical, tactical, and industrial dimensions of this convergence, offering a definitive assessment of the sustainability of the ELR trend in the age of the algorithm.

1.0 The Strategic Context: Defining the Extreme Long Range Envelope

The definition of “long range” in the context of military small arms is a moving target, continuously pushed forward by advancements in propellant chemistry, projectile aerodynamics, and optical clarity. In the post-Cold War era, the standard for sniper effectiveness was generally capped at 1,000 meters for anti-personnel tasks using 7.62x51mm NATO, and perhaps 1,500 meters for anti-materiel tasks using the.50 BMG. However, the modern battlefield, defined by near-peer competition, has expanded this envelope significantly. Today, “Extreme Long Range” (ELR) for man-portable systems is doctrinally defined as engagement distances between 1,500 and 2,500 meters.1 This shift is not merely an incremental increase in capability; it represents a fundamental change in the tactical geometry of the infantry battlespace.

1.1 The Legacy Bifurcation: Anti-Personnel vs. Anti-Materiel

To understand the significance of the current convergence, one must first analyze the historical bifurcation of sniper roles. For the majority of the 20th and early 21st centuries, western military doctrine maintained a strict delineation between two classes of shoulder-fired precision weapons, driven largely by the limitations of the available ammunition.

The Precision Class, or Anti-Personnel (AP) role, was dominated by systems such as the M24 SWS, the M40 series, and later the Mk13. These rifles, chambered in 7.62 NATO and.300 Winchester Magnum, prioritized first-round hit probability against human-sized targets. The design philosophy focused on creating a “perfect” ballistic system where the dispersion of the shots (precision) was smaller than the vital zone of a human target (approximately 18 inches) at the weapon’s maximum effective range. However, the terminal energy of these projectiles drops precipitously past 1,200 meters. A 190-grain .300 Win Mag bullet simply lacks the mass and velocity at extended ranges to penetrate body armor, light cover, or vehicle glass, rendering it ineffective against anything other than exposed infantry.

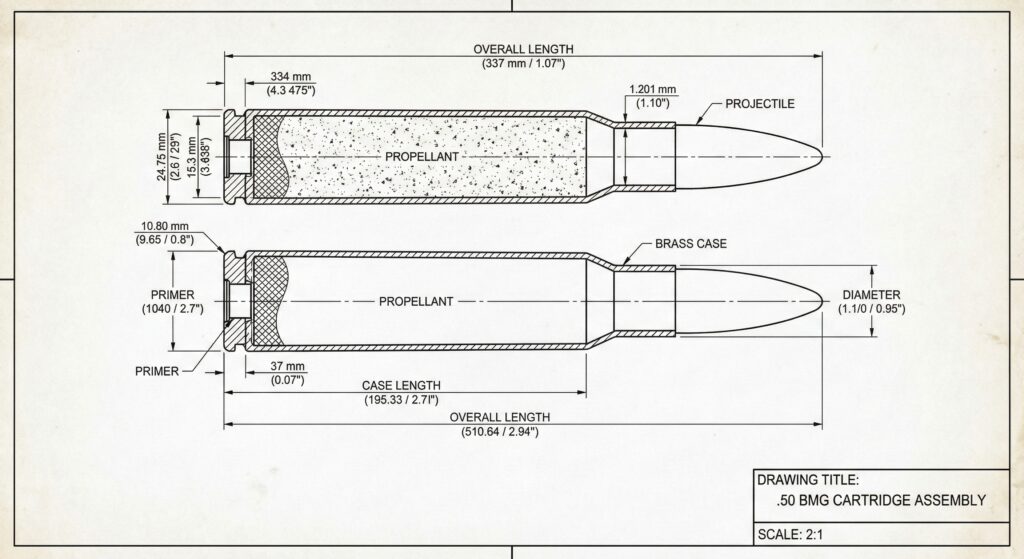

Conversely, the Payload Class, or Anti-Materiel (AM) role, was the exclusive domain of the .50 BMG (12.7x99mm). Introduced to the sniping world via the Barrett M82 in the 1980s, this platform revolutionized infantry firepower by allowing a single soldier to disable a radar dish, parked aircraft, or light armored vehicle. However, the M82/M107 is fundamentally an area-denial weapon or a “hard target interdiction” tool. The.50 BMG cartridge was designed in 1918 for the M2 Browning machine gun, intended to create a beaten zone of suppression, not to achieve pinpoint accuracy. Its standard dispersion of 3-4 MOA translates to a roughly 30-40 inch spread at 1,000 yards—far too large to reliably hit a human target.3 Furthermore, the massive reciprocating mass of the semi-automatic action creates a recoil impulse that disrupts the shooter’s sight picture, making it nearly impossible to “spot one’s own trace” and correct for environmental factors in real-time.

1.2 The Convergence Driver: The 2,500-Meter Requirement

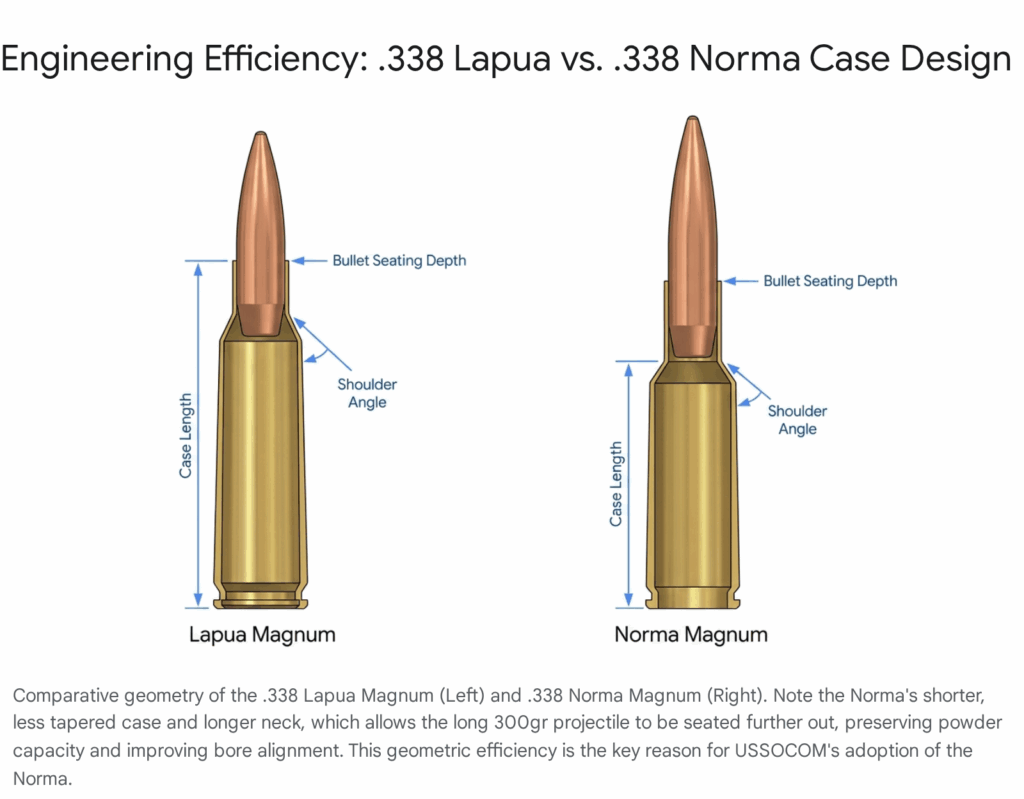

The catalyst for the current industry disruption was the identification of a distinct capability gap by United States Special Operations Command (USSOCOM). Intelligence assessments of potential near-peer adversaries, specifically Russia and China, indicated the fielding of heavy sniper systems and advanced optics capable of outranging standard NATO.338 Lapua Magnum systems. In a direct engagement, range is the primary determinant of survivability; the side that can effectively engage from further away dictates the tempo of the fight. To counter this, USSOCOM identified a requirement for a system that could deliver precision fire (defined as capable of hitting a human target) at 2,500 meters, while simultaneously retaining sufficient terminal energy to serve in an anti-materiel role.1

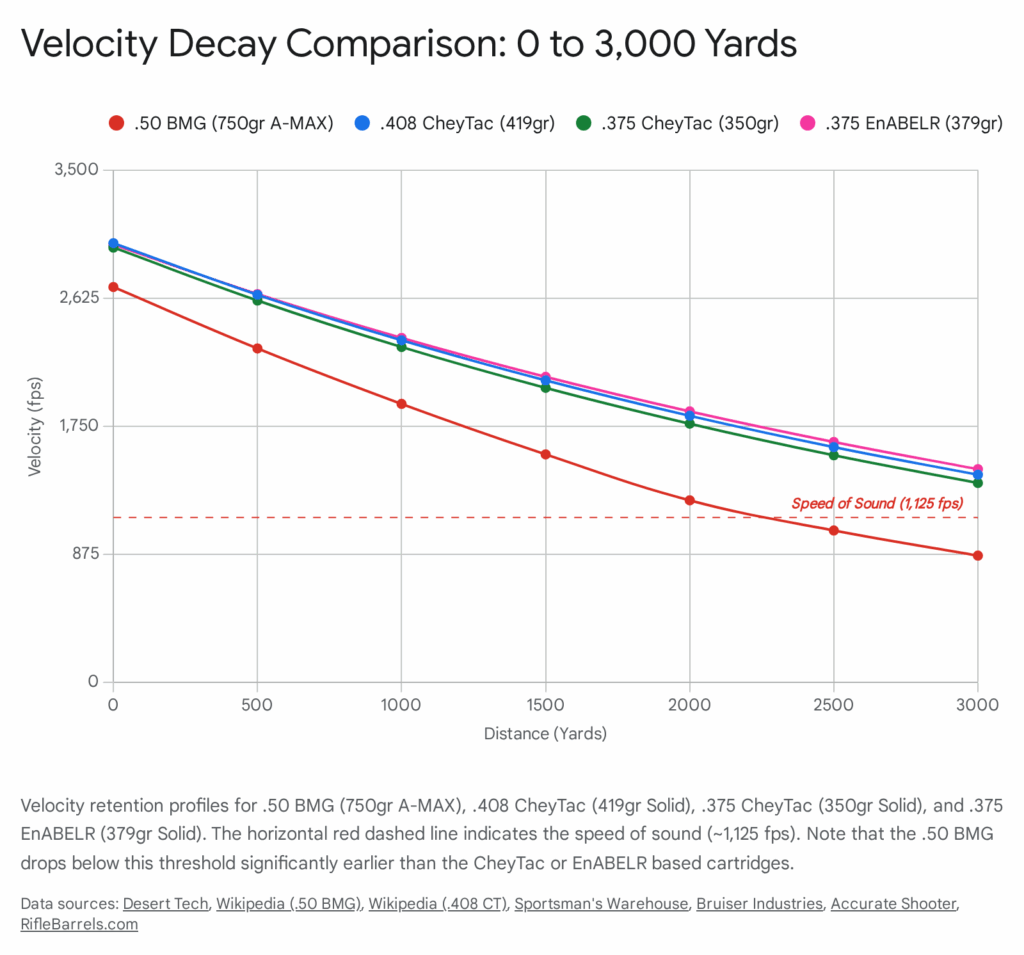

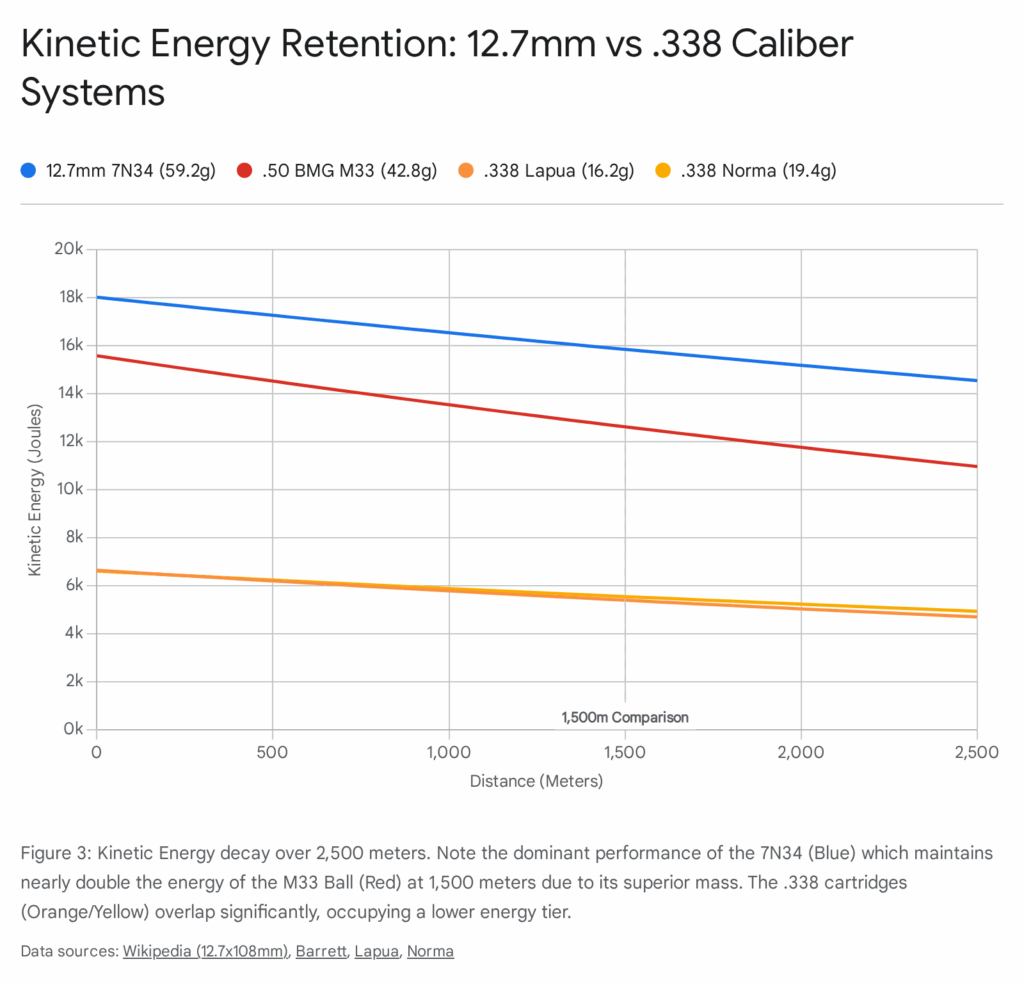

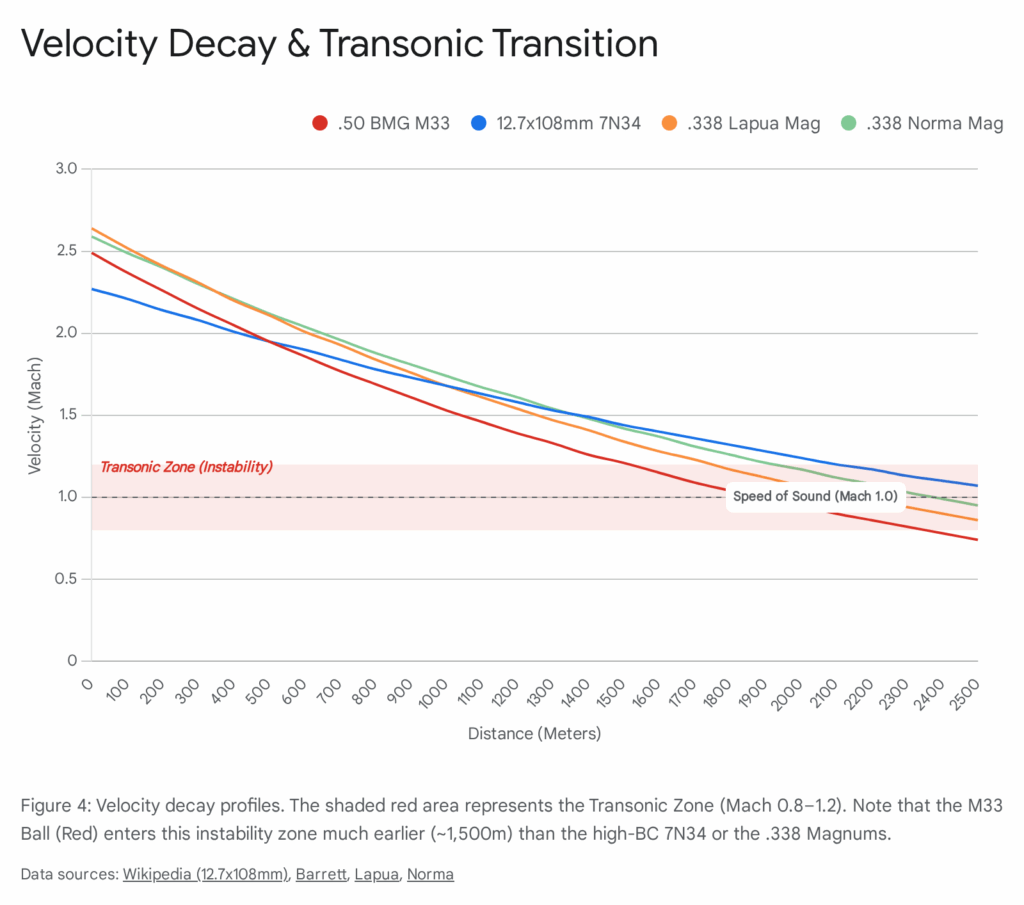

This specific range requirement—2,500 meters—is not arbitrary. It places the sniper team outside the effective engagement range of most enemy heavy machine guns (like the 12.7mm DShK or Kord), automatic grenade launchers (AGS-17), and light mortars (60mm). It effectively grants the sniper “standoff impunity” against direct-fire retaliation. However, achieving this performance rendered the legacy .50 BMG obsolete for the precision role. The aerodynamic drag of the standard .50 caliber projectile is too high, and the transition from supersonic to subsonic flight (the transonic zone) often occurs before 2,500 meters, destabilizing the bullet. This physics problem necessitated a new class of weapon: the ELR-SR.

The visualization above highlights the stark capability gap. The legacy systems force a commander to choose between range/energy (M107) and precision (M2010/Mk13). The “Convergence” zone, occupied by the new ELR-SR class, seeks to eliminate this compromise, offering a single platform that can engage a commander in a vehicle or a radar array with equal effectiveness at ranges previously reserved for indirect fire assets.

2.0 The Hardware of Convergence: Rifles and Systems Architecture

The industry response to the ELR requirement has been a decisive shift away from the semi-automatic, recoil-operated architecture that defined the anti-materiel role for the last thirty years. The inherent mechanical looseness required for a reciprocating barrel system like the M107 is antithetical to the micron-level tolerances needed for extreme long-range precision. Consequently, the new generation of ELR/AM rifles has embraced bolt-action, chassis-based systems that prioritize barrel harmonics, receiver rigidity, and modularity. The two primary exemplars of this trend are the Barrett MRADELR and the Accuracy International AX50 ELR.

2.1 The Modular Revolution: Barrett MRADELR

The Barrett MRAD (Multi-Role Adaptive Design) platform had already secured its place in the US arsenal as the Mk22 Advanced Sniper Rifle (ASR), successfully replacing the M2010, Mk13, and M107 in specific mission profiles.5 The MRADELR represents an up-scaled, reinforced evolution of this philosophy, engineered to handle the significantly higher pressures and bolt thrust of ELR cartridges.

The core innovation of the MRADELR is its user-level modularity. In previous generations of heavy weapons, converting an anti-materiel rifle to a different caliber was a depot-level task requiring specialized tools, headspace gauges, and armorers. The MRADELR allows an operator in the field to switch between .416 Barrett and .375 EnABELR in minutes using a simple Torx wrench.6 This modularity addresses a massive logistical hurdle inherent to high-performance ballistics: barrel wear. ELR cartridges are “overbore,” meaning they burn massive quantities of propellant through a relatively small bore diameter. This creates intense heat and erosion at the throat of the barrel, degrading accuracy relatively quickly compared to standard calibers.8 An easy-change barrel system transforms the barrel from a permanent component into a consumable consumable, extending the system’s service life in the field without requiring the entire weapon to be cycled back to logistics hubs.

Furthermore, the MRADELR addresses the critical human-factors engineering challenge of recoil management. The USSOCOM solicitation demanded a peak free recoil impulse of no more than 25 ft-lbs.6 This is a severe constraint given the physics involved; firing a 400+ grain projectile at 2,900 feet per second generates punishment that can cause “flinch” in the shooter, fundamentally degrading accuracy. The MRADELR utilizes a massive 3-port muzzle brake and an optimized buffer system within the stock to mitigate this. This reduction is not just for comfort; it is tactically vital. It allows the shooter to “spot their own trace”—maintaining a sight picture through the recoil to see the vapor trail of the bullet and its impact. In the ELR firing solution loop, where environmental variables are unpredictable, the ability to see the miss and correct instantly is the difference between a hit and a failure.9

2.2 The European Contender: Accuracy International AX50 ELR

Accuracy International (AI) has long been considered the gold standard for European military sniping, known for their battle-proven AW (Arctic Warfare) series. The AX50 ELR updates their legacy AW50 anti-materiel platform to meet modern precision standards, reflecting a similar design philosophy to the Barrett but with distinct engineering choices.

The AX50 ELR is built around a bonded alloy chassis integration. Unlike the stamped steel receivers of older.50 caliber designs, the AX50 ELR uses a chassis that provides a completely inert bedding surface for the action. This construction is immune to temperature and humidity shifts, ensuring that the point of impact does not wander when the rifle is subjected to the environmental extremes of modern combat zones.10

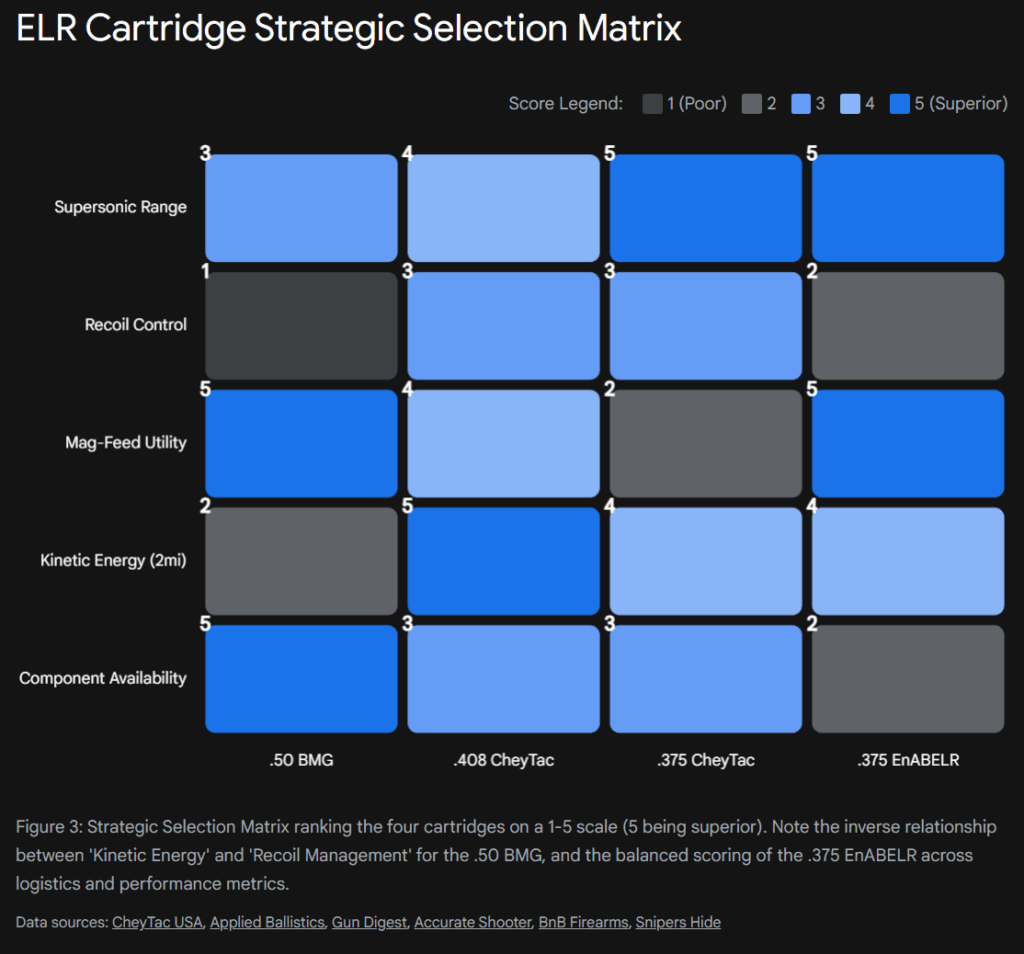

Like the Barrett, AI has fully embraced the multi-caliber reality. The AX50 ELR is designed to convert between .50 BMG, .375 CheyTac, and.408 CheyTac.11 This indicates a global industry consensus: the platform (the gun) is now distinct from the effector (the caliber). The rifle is merely a launchpad; a stable, repeatable mechanical interface for whatever cartridge offers the best ballistic coefficient for the specific mission at hand. This “caliber agnosticism” allows military units to train on a single manual of arms while tailoring their lethality package—using.50 BMG for cheap training or vehicle interdiction, and.375 CheyTac for dedicated long-range anti-personnel work.

2.3 The “System of Systems” Approach

It is crucial to understand that these platforms are no longer viewed as just “guns” in the traditional sense. They are integrated “Systems of Systems.” The USSOCOM solicitation specifies requirements not just for the rifle receiver, but for the ballistic computer, sound suppressor, and optic as a unified, cohesive package.6

The requirement for a sound suppressor capable of reducing the sound signature to 140 dB 12 is transformative for the ELR discipline. Traditionally, .50 BMG rifles were operated unsuppressed due to the immense difficulty of managing the massive volume of high-pressure gas produced by the cartridge. However, suppression is now viewed as vital for ELR operations, and not primarily for acoustic stealth. The primary tactical value of the suppressor in this context is signature management—specifically, the elimination of the muzzle blast that kicks up dust and debris. At ELR distances, the time of flight of the bullet can exceed 3 to 4 seconds. If the muzzle blast obscures the target area with dust, the shooter cannot observe the impact, rendering the follow-up shot a guess rather than a correction. By mitigating this visual signature, the suppressor closes the OODA (Observe, Orient, Decide, Act) loop for the sniper team.

Additionally, the mechanical precision requirement of 1.2 MOA at 100 yards 12 is deceptive in its apparent looseness compared to benchrest standards. In ELR shooting, a rifle that shoots 1 MOA at 100 yards often shoots better (in angular terms) at distance due to the projectile “going to sleep,” or stabilizing from its initial yaw. However, maintaining that consistency across a 2,500-meter flight path requires manufacturing tolerances in the micron range for the bolt face and chamber alignment. The “Convergence” rifle must be built with the precision of a laboratory instrument but possess the durability of a tank track.

2.4 Emerging Competitors and Global Trends

While Barrett and Accuracy International lead the conversation due to the USSOCOM solicitation, the trend is global. Sako has introduced the TRG 62, chambered in 9.5x77mm, designed specifically for the 2,000+ meter envelope.13 This indicates that European forces are mirroring the US requirement. The Sako design emphasizes cold-hammer forged barrels and an upgraded chassis to maximize shooter comfort and accuracy. Similarly, manufacturers like Desert Tech with their HTI (Hard Target Interdiction) chassis have pioneered the bullpup ELR concept, offering a shorter overall length that aids in mobility without sacrificing barrel length—a critical factor for velocity generation.14 These diverse engineering approaches all aim at the same goal: making the 2,500-meter shot a repeatable, tactical reality rather than a stunt.

3.0 Ballistics Deep Dive: The Battle of the Coefficients

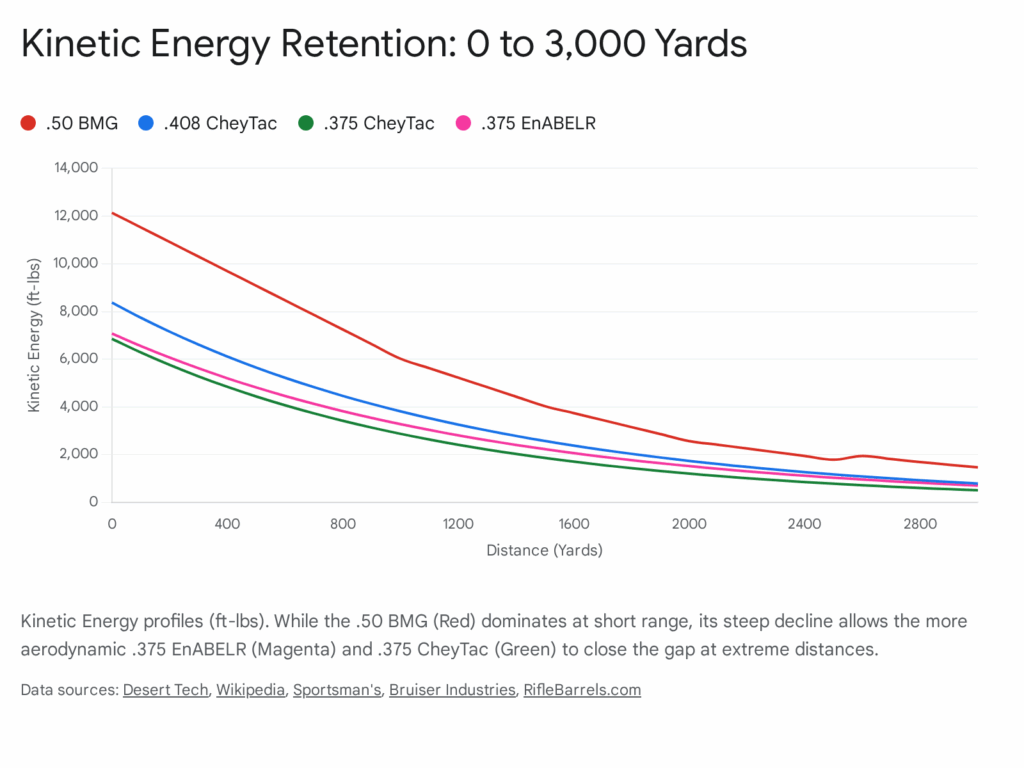

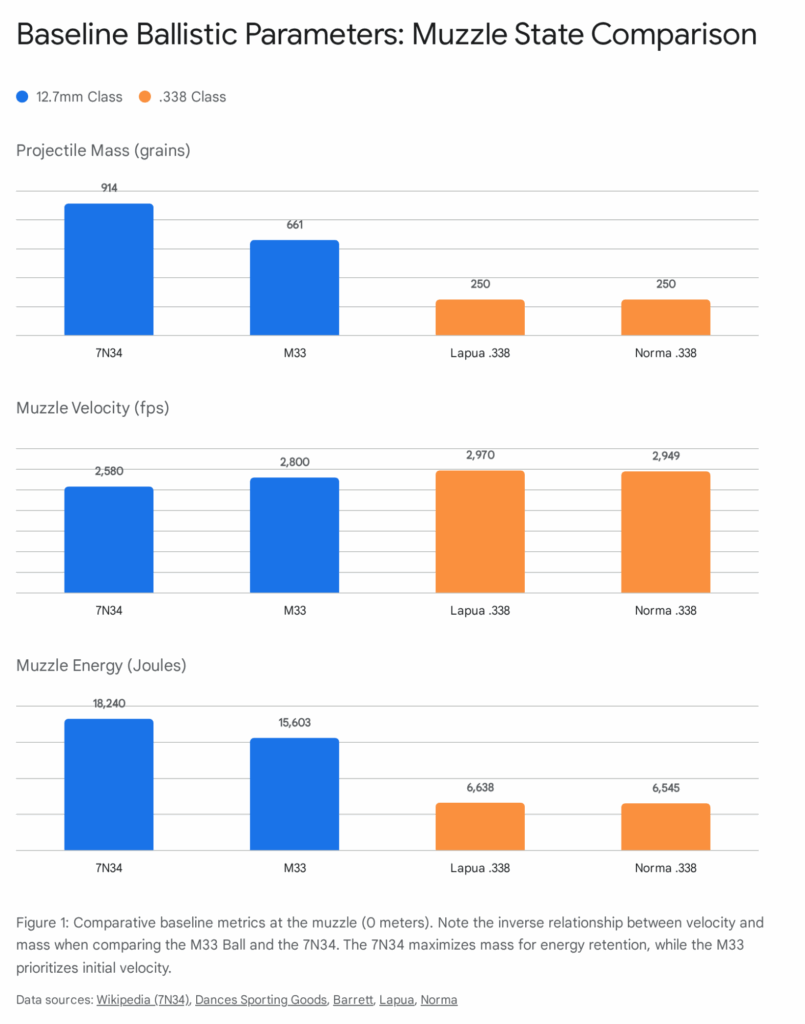

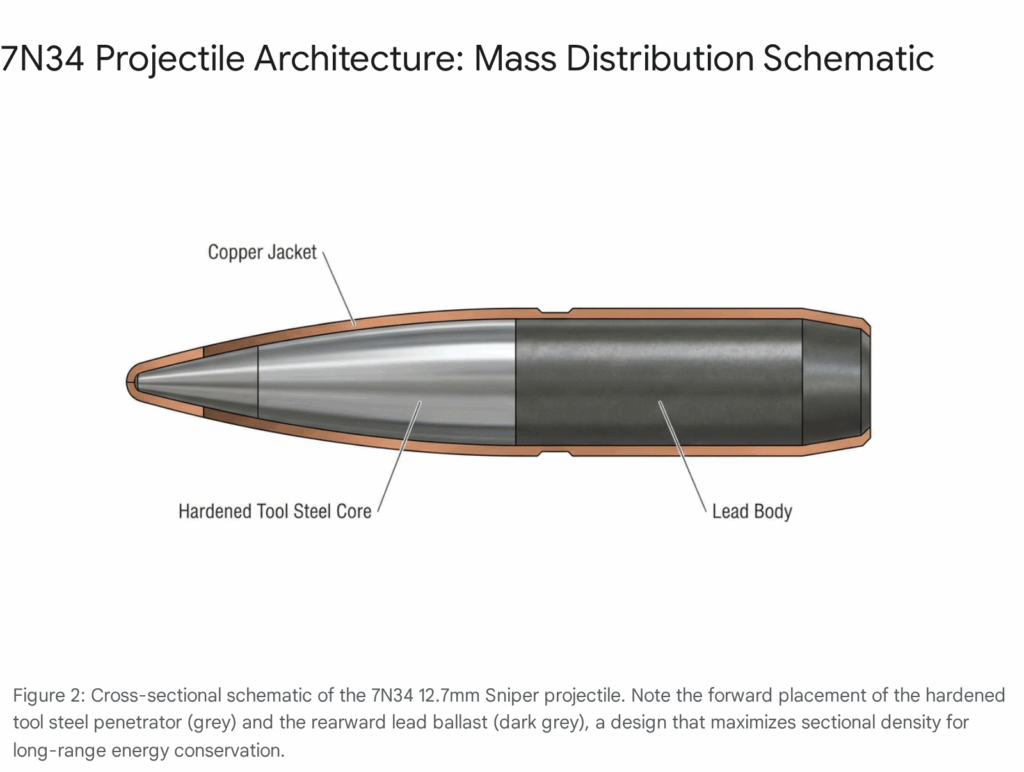

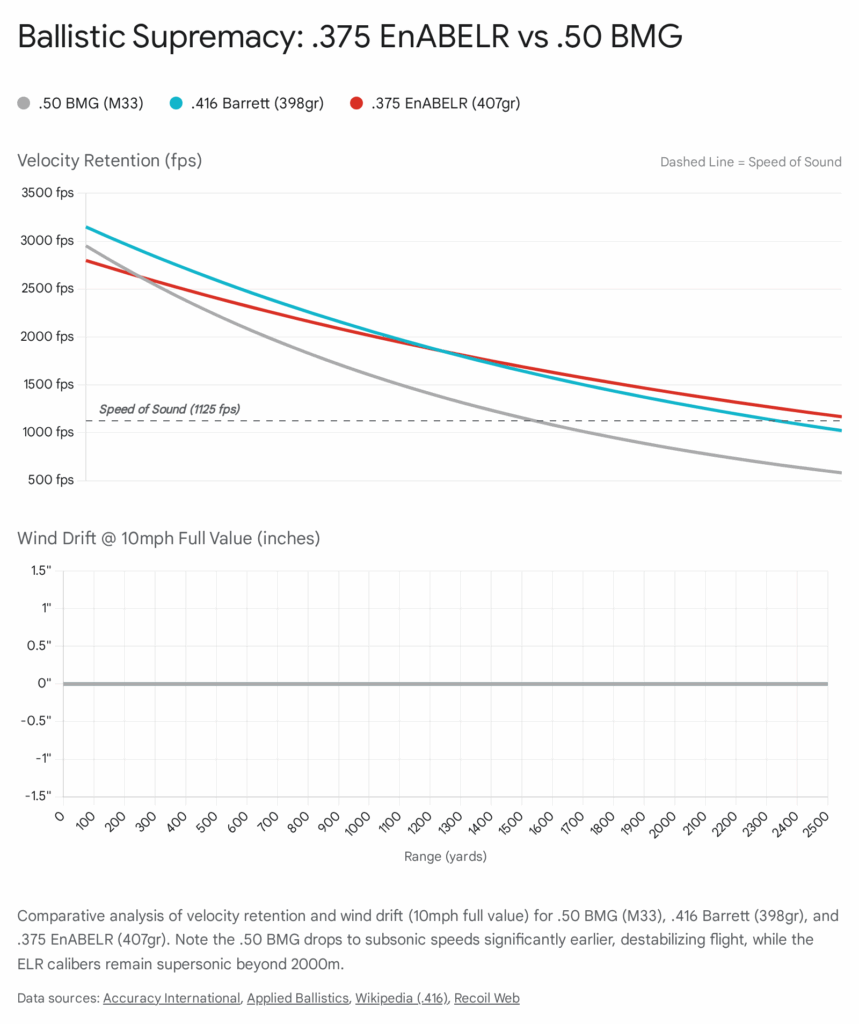

The “Convergence” is fundamentally a ballistic phenomenon. The legacy .50 BMG (12.7x99mm) dominates in raw mass (600-700 grains), but it suffers from poor aerodynamics compared to modern dedicated ELR rounds. The trend is moving decisively toward smaller diameters with longer, sleeker projectiles—specifically the .375 and .416 calibers. This shift represents a prioritization of “flying ability” (ballistic coefficient) over “smashing ability” (mass).

3.1 The Aerodynamic Advantage: Form Factor and Drag

Ballistic Coefficient (BC) is the definitive metric of a bullet’s ability to overcome air resistance and maintain velocity. In the ELR equation, a higher BC is the single most important factor for hit probability.

- .50 BMG (M33 Ball / Mk211): These rounds are blunt force trauma instruments. The M33 Ball projectile is designed for machine gun dispersion, not sniper precision. While effective at destroying engine blocks at 800 meters, these projectiles lose velocity rapidly due to drag, often dropping below the speed of sound (transonic zone) before reaching 2,000 meters. Transonic buffeting destabilizes the bullet, causing it to tumble and making accuracy unpredictable.

- .416 Barrett: This cartridge was designed specifically to solve the.50 BMG’s range problem. It stays supersonic past 2,500 yards. It typically uses a solid brass projectile (turned on a lathe, not swaged) to ensure perfect concentricity and balance. The velocity is higher (3,150 fps vs 2,800 for.50 BMG), and the drag is significantly lower.15 The.416 relies on brute force velocity to defeat drag, “outrunning” the physics of deceleration for the first 1.5 kilometers.

- .375 EnABELR: Developed by Applied Ballistics, this cartridge represents the current pinnacle of ELR engineering. It is a “balanced” cartridge, slightly shorter than the .375 CheyTac to allow for magazine feeding (a critical military requirement for rapid follow-up shots), but operates at higher pressures. The 379gr and 407gr solid copper bullets have G7 BCs exceeding 0.500.16 This high BC allows the bullet to slice through the air with minimal resistance, retaining energy and stability deep into the flight path.

3.2 Terminal Energy vs. Hit Probability

The debate between Anti-Materiel and ELR often centers on terminal energy. Can a. 375 EnABELR disable a truck engine at 2,000 meters as effectively as a.50 BMG?

- The Energy Equation: Kinetic energy is defined by the equation E=1/2(mv)^2. While the.50 BMG possesses significantly more mass (m), the.375 and.416 rely on velocity (v). Because velocity is squared in the equation, retaining speed at range is the most efficient way to deliver energy. A.50 BMG might start with 13,000 ft-lbs of energy, but drag robs it of that energy quickly. A.416 Barrett starts with less mass but keeps its speed, often delivering more energy at 2,500 meters than the.50 BMG simply because it hasn’t slowed down as much.

- The Hit Probability Force Multiplier: Energy is irrelevant if the bullet misses the target. The .375 EnABELR has significantly less wind drift than the .50 BMG. At 2,000 meters, a 5 mph crosswind might push a .50 BMG bullet 10 feet off target. The .375 might only move 6 feet. This 40% reduction in wind deflection acts as a massive force multiplier for hit probability.17 In a tactical scenario, the ability to put a round into the engine block with the first shot is far more valuable than the theoretical ability to smash it with a round that misses by three meters.

3.3 Ammunition Logistics and Patrol Considerations

The shift to these specialized calibers introduces a complex logistical dimension. .50 BMG is ubiquitous; it can be sourced from machine gun belts in nearly any theater of operation. .375 EnABELR and .416 Barrett are niche, “match-grade” munitions that must be specifically procured and transported.

From a patrol weight perspective, the new calibers offer a slight advantage. The ammunition is lighter and smaller than .50 BMG, allowing a sniper team to carry more rounds for the same weight burden. However, the cost is significantly higher. Standard M33 Bal l.50 BMG can be procured for a few dollars per round; match-grade .375 EnABELR or .416 Barrett ammunition commands a premium, often exceeding $10-$15 per shot.18 This cost differential relegates these systems to “surgeon’s tools”—weapons used for specific, high-value tasks rather than general suppressive fire. The “Convergence” rifle is not a machine gun replacement; it is a force multiplier for precision effects.

4.0 The Optical Revolution: From Glass to Fire Control

If the rifle provides the mechanical potential for ELR hits, the optic provides the practical capability to realize that potential under combat stress. The most significant trend in this sector is the transition from passive optical sights—pure glass and metal—to active, digital Fire Control Systems (FCS) that integrate sensing and computing directly into the aiming process.

4.1 The “Disturbed Reticle” Concept

Traditional sniping involves a cognitive process known as “holdover.” The shooter measures the range to the target, consults a data card (DOPE – Data On Previous Engagement) to find the bullet drop, measures the wind, and then physically holds the crosshair above and to the side of the target using the reticle’s stadia lines (mil-dots). This process is slow, cognitively demanding, and highly prone to error, especially under the physiological stress of combat.

New systems like the Vortex XM-157 NGSW-FC 20 and the Steiner M7Xi IFS 22 utilize a technology known as the “disturbed reticle” or “active reticle,” derived from aviation HUDs and tank fire control systems.

The workflow is radically simplified:

- Lase: The shooter presses a button on the scope or rifle to fire the integrated Laser Rangefinder (LRF) at the target.

- Compute: Onboard sensors immediately measure environmental variables (temperature, barometric pressure, humidity, inclination/cant). A ballistic solver chip (often running Applied Ballistics software) calculates the exact firing solution in milliseconds.

- Display: The optic projects a digital aim point (a red dot) onto the shooter’s field of view, overlaid on the analog image. The shooter simply places the digital dot on the target and pulls the trigger.

This technology democratizes ELR accuracy. It allows a moderately trained soldier to achieve first-round hits that previously required a master sniper’s intuition and years of training. By offloading the math to the computer, the shooter can focus on the art of wind reading and timing.

4.2 The Thermal Fusion Advantage

Daylight optics are insufficient for modern 24-hour combat operations. The integration of clip-on thermal imagers has extended the sniper’s reach into the infrared spectrum, but the specific type of thermal technology matters immensely for ELR.

- Cooled vs. Uncooled: Standard thermal sights used by infantry (uncooled microbolometers) are rugged and cheap but struggle to resolve detail at long range. They detect heat differences but often produce a “blob” at 2,000 meters. Cooled thermal sights, such as the Teledyne FLIR HISS-XLR, use a cryogenic cooler to lower the sensor temperature to extremely low levels. This vastly increases sensitivity, allowing for the detection of minute temperature differences.

- Trace Detection: The “killer app” of cooled thermal for snipers is the ability to see bullet trace—the heat generated by the friction of the bullet pushing through the air. In a cooled thermal sight, this appears as a distinct streak. This capability transforms night sniping from “guessing” where the bullet went to “tracking” it like a tracer round, allowing for instant corrections even in total darkness.23 The HISS-XLR allows detection of man-sized targets out to 2,000 meters, matching the effective range of the new rifle calibers and ensuring the optic does not become the limiting factor in the weapon system.23

4.3 The Vulnerability of Smart Scopes

Despite their undeniable advantages, the reliance on active optics introduces new failure points that terrify traditionalists.

- Battery Dependence: A dead battery turns a disturbed reticle into a paperweight (though most have etched glass backups, the advanced features are lost).

- Electronic Signature: Active rangefinders emit laser energy that can be detected by enemy Laser Warning Receivers (LWR) on tanks or vehicles, instantly revealing the sniper’s position. Furthermore, Bluetooth connections (used to sync wind meters like Kestrels to the scope) emit RF signatures that can be intercepted, triangulated, or jammed by sophisticated EW assets.22

This vulnerability drives a counter-trend: the continued dominance of “pure” analog optics like the Zero Compromise Optic (ZCO) and Tangent Theta among top-tier units. These scopes offer mechanical perfection, superior light transmission, and absolute reliability without the electronic liability. They are preferred by teams operating in high-EW threat environments where emitting any signal is a death sentence.25 The choice between “Smart” and “Pure” optics is now a mission-dependent tactical decision.

4.4 The Digital Ecosystem: Ballistic Solvers

Beyond the scope itself, the modern sniper relies on a networked ecosystem of data. Devices like the Wilcox RAPTAR-S represent the externalization of the fire control brain. The RAPTAR-S is a rail-mounted module containing a laser rangefinder, infrared illuminator, and ballistic computer.27 It can communicate wirelessly with a Kestrel weather meter to pull real-time wind data and then display the firing solution on the shooter’s scope or a separate screen. This modularity allows the shooter to upgrade the computer without replacing the optic, preserving the investment in high-quality glass while keeping pace with Moore’s Law.

5.0 The Drone Disruption: Cooperation or Competition?

The most critical question facing the small arms industry is not about calibers, rifling twist rates, or optical coatings. It is a question of relevance. The proliferation of small, cheap, highly lethal Unmanned Aerial Systems (UAS) has fundamentally altered the risk/reward calculus of long-range engagement, challenging the very existence of the ELR sniper role.

5.1 The FPV “Sniper”: A Disruptive Competitor

First Person View (FPV) drones, weaponized with RPG warheads or blocks of plastic explosive, have emerged as a direct competitor to the sniper rifle for the mission of long-range precision elimination.

- Range Superiority: An FPV drone can strike targets at 10km to 20km.28 The absolute best ELR rifle is limited to approximately 2.5km. The drone offers nearly an order of magnitude greater standoff distance.

- Lethality Superiority: An FPV carries a shaped charge capable of destroying a main battle tank or collapsing a bunker. A .416 Barrett or .375 EnABELR can, at best, damage the optics, sensors, or tracks of a tank, or kill the crew if they are unbuttoned. The drone brings anti-tank lethality to the individual soldier level.

- Cost Efficiency: A military-grade FPV setup, even with upgrades, costs under $1,000 per unit. An ELR-SR system (Rifle + Optic + Suppressor + Ammo + Ballistics Computer) exceeds $25,000, with match-grade ammunition costing $15 per shot.28 The economic argument overwhelmingly favors the drone for one-way missions.

- Operator Safety: The drone pilot operates from a bunker, basement, or vehicle kilometers away, effectively immune to direct return fire. The sniper must have Line of Sight (LOS) to the target, meaning the target also has a line of sight to the sniper. This exposes the human asset to counter-fire, detection, and suppression.

This disparity is likely the primary driver behind USSOCOM’s decision to “pause” the ELR-SR program in late 2024 in favor of “other priorities”—a euphemism for loitering munitions and UAS development.2 Strategic planners are asking a hard question: Why spend millions developing a rifle to hit a target at 2,500m when a Switchblade 300 or a generic FPV can do it more reliably, from further away, and with less risk to the operator?

5.2 The Resilience of the Rifle: The “Jam-Proof” Argument

However, the narrative of “drones replacing snipers” is critically flawed due to one massive vulnerability inherent to unmanned systems: Electronic Warfare (EW).

In the high-intensity conflict of Ukraine, Russian EW assets regularly jam the command links (C2) and GPS signals of FPV drones, rendering them useless over vast swathes of the front. “Drone denial” zones are becoming common, where the electromagnetic spectrum is so saturated with noise that no remote-controlled vehicle can operate.31

In these GPS-denied, spectrum-saturated environments, the sniper rifle remains the ultimate “dumb” weapon. It cannot be jammed. It cannot be spoofed. It requires no satellite link and no radio frequency handshake. Once the bullet leaves the barrel, physics is the only master. The projectile is an autonomous delivery system that is immune to hacking. Therefore, the ELR rifle is transitioning from a primary engagement tool to a strategic fallback capability—a “break glass in case of jamming” asset that ensures lethality can still be delivered when the digital world goes dark.

5.3 Convergence of Operations: The Sniper-Drone Team

The sustainable trend, therefore, is not replacement, but integration. The most effective modern sniper teams are adopting drones not just as targets, but as essential tools in their workflow.

- The Drone Spotter: Traditionally, a spotter used a high-magnification spotting scope to observe the target and “walk” the shooter’s rounds onto it. This required the spotter to be physically located next to the shooter, doubling the signature of the firing position. Now, teams utilize small reconnaissance drones (like the Black Hornet 4) to identify targets and observe the fall of shot from a forward, orthogonal perspective.33 This “detached spotter” allows the sniper to remain deeper in concealment, observing the drone feed on a tablet or HUD, while the drone risks exposure closer to the target.

- Kinetic Counter-UAS: Snipers are increasingly tasked with shooting down enemy drones. The extreme accuracy of ELR systems, combined with smart optics that can track moving targets and calculate leads, makes the sniper a viable, low-cost localized air defense asset against slow-moving observation drones. Using a $10 bullet to down a $5,000 observation drone is a highly favorable cost-exchange ratio.35

6.0 Tactical Realities: Lessons from the Ukrainian Front

The ongoing war in Ukraine serves as the primary testing ground for these theories, providing a grim but valuable dataset on the utility of ELR systems in modern high-intensity conflict. The conflict has validated the utility of both ELR rifles and drones, but in distinct operational phases.

- Static Phases: In stabilized trench lines and static defensive positions, snipers equipped with.338 Lapua and.50 caliber rifles dominate the “no-man’s land.” The ability to reach out to 2,000 meters forces the enemy to keep their heads down, restricting their movement and situational awareness. In this environment, the psychological impact of the sniper is paramount.

- Maneuver Phases: During rapid assaults and fluid maneuvers, FPV drones provide the “flying artillery” that snipers cannot match in volume or destructive power. The speed of the drone allows it to chase down fleeing vehicles or strike troops hiding in defilade (behind cover) where a direct-fire rifle cannot reach.

- The “Snipex Alligator” Phenomenon: A unique development in Ukraine is the fielding of indigenous 14.5mm anti-materiel rifles, such as the Snipex Alligator. These massive weapons, firing the heavy machine gun cartridge of the BTR series, are used to engage BMPs, parked aircraft, and even hover-capable helicopters. This validates the “anti-materiel” convergence theory—there is a tangible, urgent need for man-portable heavy caliber fire that can disable light armor, a task that standard sniper rifles cannot achieve.37

7.0 Electronic Warfare and Signature Management

The survival of the ELR sniper in a drone-saturated battlefield depends entirely on signature management. The “shoot and scoot” tactics of the past are being refined into an art form of multispectral camouflage.

7.1 The Acoustic and Thermal Signature

Every shot fired by a .416 or .50 caliber rifle creates a massive acoustic and thermal event.

- Acoustic: The supersonic crack of the bullet is audible for kilometers. Acoustic detection systems (like the Boomerang) can triangulate the shooter’s position instantly based on the shockwave.

- Thermal: The muzzle flash and the heated barrel are beacons to thermal sensors on overhead drones.

This reality reinforces the requirement for suppression. A suppressor does not make the shot silent, but it diffuses the gas, reducing the thermal bloom and confusing the acoustic triangulation algorithms. Furthermore, snipers are adopting “thermal blankets” and specialized hides to mask their body heat from drone thermals. The contest is no longer just shooter vs. target; it is shooter vs. sensor grid.

7.2 The Rifle as an EW-Proof Asset

The table below illustrates the strategic trade-off that defines the current procurement landscape. While the FPV drone is superior in cost and range, its vulnerability to EW makes it unreliable against a sophisticated adversary. The ELR rifle acts as the insurance policy.

| Feature | ELR Rifle System | FPV Drone | Javelin Missile |

| Unit Cost | High ($25k System) | Very Low ($500 – $1k) | Extreme ($175k+) |

| Cost Per Shot | Low ($15/round) | Medium ($500/unit) | High ($175k/shot) |

| Max Range | ~2.5 km | 10 – 20 km | 4 km |

| EW Vulnerability | None (Zero) | High (Jamming/Spoofing) | Low (IR Seeker) |

| LOS Requirement | Yes (Direct Line of Sight) | No (Indirect/NLOS) | Yes (for lock-on) |

| Lethality | Precision/Anti-Personnel | Anti-Tank/Anti-Bunker | Heavy Anti-Tank |

| Training Load | High (Expert Skill) | Moderate (Pilot Skill) | Low (Fire & Forget) |

Table 1: Strategic comparison of engagement modalities. The ELR Rifle’s key advantage is its immunity to Electronic Warfare. 28

8.0 Future Outlook: Is the Trend Sustainable?

The trend of merging ELR and Anti-Materiel capabilities is sustainable, but it will likely remain a niche Special Operations capability rather than a general infantry standard. We are witnessing the maturation of the “Hunter-Killer” cell concept.

8.1 The “Peak Rifle” Theory

We may be approaching the practical limit of man-portable ballistics. To achieve effective range significantly beyond the .375 EnABELR’s capabilities, one needs more propellant and a larger case capacity. This necessitates a heavier rifle to manage the recoil and a longer barrel to burn the powder. A 40-pound rifle is no longer a sniper weapon; it is a crew-served weapon. The physics of recoil management on a man-portable platform limits the energy ceiling. We have likely reached “Peak Rifle.” Future gains will come from ammunition consistency (manufacturing tolerances), computational optics (making the hits easier), and materials science (lighter barrels), not from bigger calibers.

8.2 The Hybrid Force Structure

The “Tactical World” will not move entirely to drones, nor will it stay with rifles. Instead, we will see a tiered structure of lethality:

- Tier 1 (Kinetic – The ELR Sniper): Expert teams equipped with.375/.416 systems for High Value Target (HVT) elimination in high-EW environments, or where collateral damage concerns prohibit the use of explosive drones.

- Tier 2 (Loitering – The Squad): Squad-level integration of Switchblade-style munitions for Non-Line-of-Sight (NLOS) engagement of light armor, bunkers, and defilade targets.

- Tier 3 (Commodity – The Mass): Mass deployment of cheap FPVs for harassment, attrition, and fixing the enemy in place.

The cancellation of the ELR-SR program is likely a pause to rewrite the requirements to better fit this tiered ecosystem, ensuring that the rifle purchased today complements, rather than competes with, the drone of tomorrow.

9.0 Conclusion

The convergence of Extreme Long Range sniper rifles and anti-materiel systems is a technological reality, exemplified by the .416 Barrett and .375 EnABELR. These systems have successfully bridged the gap between the precision of the.338 Lapua and the payload of the .50 BMG, offering a unified platform for the modern marksman. However, this convergence has collided with the asymmetric revolution of drone warfare, which offers superior range and lethality at a fraction of the cost.

While drones dominate the headlines and the budget sheets, they lack the reliability of kinetic fire in contested electromagnetic spectrums. The future of small arms is not in competing with drones for range—a battle the rifle has already lost—but in integrating with them for command and control. The ELR sniper of 2030 will not just be a marksman; they will be a ballistic systems manager, orchestrating a suite of kinetic and unmanned assets to deliver lethality at the edge of physics. The rifle remains indispensable as the ultimate “backup plan” for when the datalinks fail, but it is no longer the only tool in the long-range box.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, we are only paid if there is an affiliate program such as Avantlink, Impact, Amazon and eBay and only if you purchase something. If you’d like to directly contribute towards our continued reporting, please visit our funding page.

Sources Used

- USSOCOM Seeks Extreme Long Range-Sniper Rifle System | Soldier Systems Daily, accessed January 8, 2026, https://soldiersystems.net/2023/12/29/ussocom-seeks-extreme-long-range-sniper-rifle-capability/

- Extreme Long Range-Sniper Rifle 2 – HigherGov, accessed January 8, 2026, https://www.highergov.com/contract-opportunity/extreme-long-range-sniper-rifle-elrsrssn-r-9a6b2/

- The Unmatched Legacy of the M200 Intervention® | CheyTac, accessed January 8, 2026, https://cheytac.com/the-unmatched-legacy-of-the-m200-intervention/

- USSOCOM ELR-SR (Extreme Long Range-Sniper Rifle) Solicitation – The Firearm Blog, accessed January 8, 2026, https://www.thefirearmblog.com/blog/2024/01/02/ussocom-elr-sr-solicitation/

- The Best Sniper Rifles In Action Today – Outdoor Life, accessed January 8, 2026, https://www.outdoorlife.com/guns/best-sniper-rifles/

- USSOCOM ELR-SR | Sniper’s Hide Forum, accessed January 8, 2026, https://www.snipershide.com/shooting/threads/ussocom-elr-sr.7202407/

- Barrett MRAD ELR Barrel Conversion Kit .416 Barrett 36″ Heavy Barrel – Natchez, accessed January 8, 2026, https://www.natchezss.com/barrett-mrad-elr-barrel-conversion-kit-416-barrett-36-heavy-barrel

- Cheytac barrel life ? How many rounds ? | Shooters’ Forum, accessed January 8, 2026, https://forum.accurateshooter.com/threads/cheytac-barrel-life-how-many-rounds.4054085/

- New Barrett MRAD ELR? | Sniper’s Hide Forum, accessed January 8, 2026, https://www.snipershide.com/shooting/threads/new-barrett-mrad-elr.7193849/

- Accuracy International – AX ELR Black – Mile High Shooting Accessories, accessed January 8, 2026, https://www.milehighshooting.com/accuracy-international-ax-elr-black/

- Accuracy International AX50 ELR – EuroOptic.com, accessed January 8, 2026, https://www.eurooptic.com/accuracy-international-ax50-elr

- ELR-SR tender: USSOCOM is looking for a new sniper rifle for extreme ranges. What is in the list of requirements? | all4shooters, accessed January 8, 2026, https://www.all4shooters.com/en/shooting/pro-zone/elr-sr-ussocom-is-looking-for-a-new-sniper-rifle/

- Sako’s Newest, Finest, Finnish Long Range Sniper Rifle: The TRG 62 | EnforceTac 2025, accessed January 8, 2026, https://www.youtube.com/watch?v=uIKXfHLvN4g

- Best big bore cartridge and platform to choose? 375 CT, 408 CT, 416 Barrett and 50 BMG | Long Range Only, accessed January 8, 2026, https://www.longrangeonly.com/forum/threads/best-big-bore-cartridge-and-platform-to-choose-375-ct-408-ct-416-barrett-and-50-bmg.7192/

- .416 Barrett – Wikipedia, accessed January 8, 2026, https://en.wikipedia.org/wiki/.416_Barrett

- Shooting ELR: Applied Ballistics EnABELR – Bruiser Industries, accessed January 8, 2026, https://bruiserindustries.com/shooting-elr-applied-ballistics-enabelr/

- Applied Ballistics Offers Turnkey Solution for ELR Game – Accurate Shooter Bulletin, accessed January 8, 2026, https://bulletin.accurateshooter.com/2019/04/applied-ballistics-offers-turnkey-solution-for-elr-game/

- 375 Cheytac Ammo for Sale – MidwayUSA, accessed January 8, 2026, https://www.midwayusa.com/375-cheytac/br?cid=23882

- 416 Barrett Ammo Prices – Black Basin Outdoors, accessed January 8, 2026, https://blackbasin.com/ammo-prices/416-barrett/

- Vortex M157 — World’s Most Versatile Military Optic – YouTube, accessed January 8, 2026, https://www.youtube.com/watch?v=t9ErFg-AFCY

- The US Military’s New Smart Optic that Aims For You. The XM-157 – YouTube, accessed January 8, 2026, https://www.youtube.com/watch?v=f5YWXrZdNpA

- Steiner M7Xi IFS 4-28×56 – MSR 2 – Camera Land NY, accessed January 8, 2026, https://cameralandny.com/shop/steiner-m7xi-ifs-4-28×56-msr-2/7cc5cd50-0095-0137-3596-00163ecd2826?variation=1901648

- ThermoSight® HISS-XLR | Defense.flir.com, accessed January 8, 2026, https://defense.flir.com/defense-products/thermosight-hiss-xlr/

- ThermoSight® HISS-XLR | Navtech, accessed January 8, 2026, https://navtech.com.tr/wp-content/uploads/2024/09/Teledyne-FLIR-ThermoSight-HISS-XLR-Datasheet.pdf

- Alpha Class Long Range Scope Review, Part 1 – Dark Lord of Optics – Locals, accessed January 8, 2026, https://darklordofoptics.locals.com/post/3076448/alpha-class-long-range-scope-review-part-1

- Zero Compromise Optics’ ZC420 MPCT1 Scope Review – Sniper’s Hide, accessed January 8, 2026, https://www.snipershide.com/precision-rifle/bigjimfishs-review-of-the-zero-compromise-optics-zc420-mpct1/

- RAPTAR S – Wilcox Industries, accessed January 8, 2026, https://wilcoxind.com/products/combat-systems/fire-control-systems/product_combat_raptar-s

- MCU Insights, vol. 16, no. 4 – Marine Corps University, accessed January 8, 2026, https://www.usmcu.edu/Outreach/Marine-Corps-University-Press/MES-Publications/MES-Insights/MCU-Insights-vol-16-no-4/

- MRADELR Barrel Conversion Kit, .416 BARRETT, accessed January 8, 2026, https://store.barrett.net/p-13301-mradelr-barrel-conversion-kit-416-barrett.aspx

- Search For Barrett .50 Caliber Sniper Rifle Replacement Halted By SOCOM – The War Zone, accessed January 8, 2026, https://www.twz.com/news-features/search-for-barrett-50-caliber-sniper-rifle-replacement-halted-by-socom

- A Thousand Snipers in the Sky: The New War in Ukraine | Drones now cause about 70 percent of deaths and injuries, commanders say : r/Futurology – Reddit, accessed January 8, 2026, https://www.reddit.com/r/Futurology/comments/1j9lrvu/a_thousand_snipers_in_the_sky_the_new_war_in/

- Russian Offensive Campaign Assessment | SEP–NOV 2025 | ISW, accessed January 8, 2026, https://understandingwar.org/research/russia-ukraine/russian-offensive-campaign-assessment-updates/

- Adapting the Combat Training Centers for the Drone Battlefield – Small Wars Journal, accessed January 8, 2026, https://smallwarsjournal.com/2026/01/08/adapting-the-combat-training-centers-for-the-drone-battlefield/

- Black Hornet® 4 PRS | Defense.flir.com, accessed January 8, 2026, https://defense.flir.com/defense-products/black-hornet-4-prs/

- The Army has a novel solution to its drone problem: Shoot them with tanks – Task & Purpose, accessed January 8, 2026, https://taskandpurpose.com/news/army-tank-manual-drones/

- In Ukraine, long guns become desperate defenses against small drones, accessed January 8, 2026, https://www.defensenews.com/global/europe/2024/12/11/in-ukraine-long-guns-become-desperate-defenses-against-small-drones/

- Ukrainian sniper sets world record with AI-assisted kill shot, accessed January 8, 2026, https://tvpworld.com/88386736/ukrainian-sniper-sets-world-record-with-ai-assisted-kill-shot

- The Ukrainian “Ghost” Sniper Just SHATTERED the World Record! – YouTube, accessed January 8, 2026, https://www.youtube.com/watch?v=s8v66Oi56d8&vl=en

- The Rise of Tiny FPV Drones in Warfare: How They’re Used – Dronelife, accessed January 8, 2026, https://dronelife.com/2024/05/31/the-rise-of-tiny-fpv-drones-in-warfare-how-theyre-used/

- How Much Do Switchblade Drones Cost? | HireDronePilot, accessed January 8, 2026, https://hiredronepilot.uk/blog/switchblade-drone-cost