The GX CS4 is a very cool compressor and one of the two ways it gets the long run time is through staying properly greased. (The other is through the use of fluid coolant that I covered in a blog post about setting up and testing the unit). After 4-6 hours of compressing air with your GX CS4, you are supposed to given the top grease pot knob one full turn. How does that work and how does one refill it?

Adding Grease Every 4-6 Hours

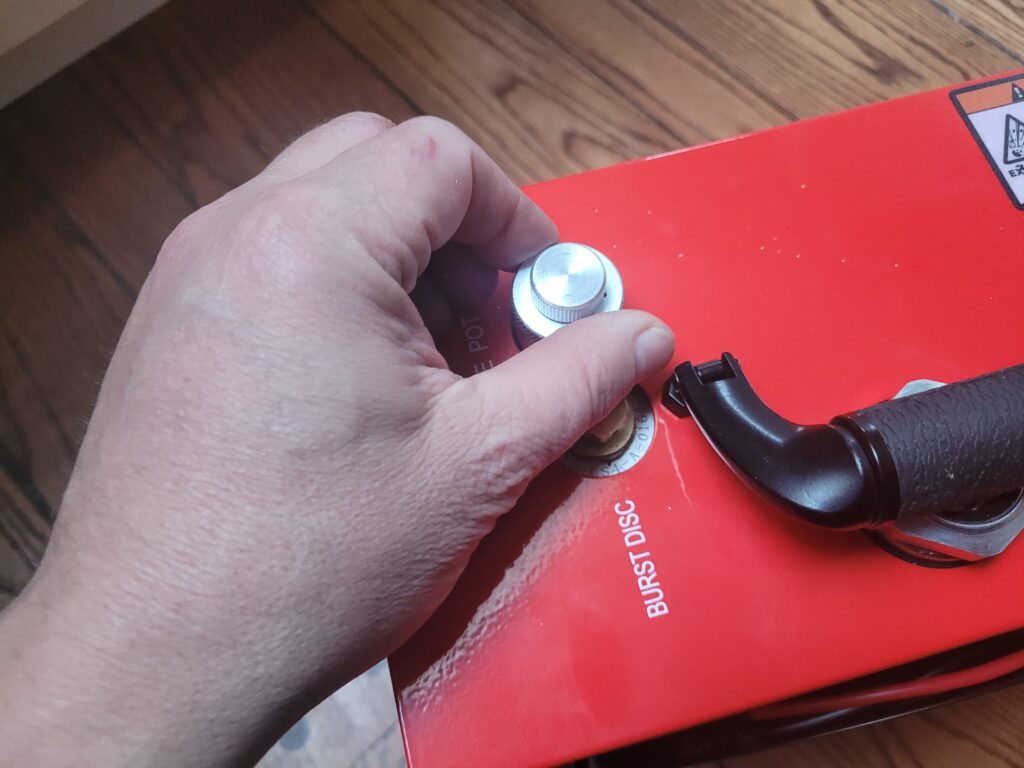

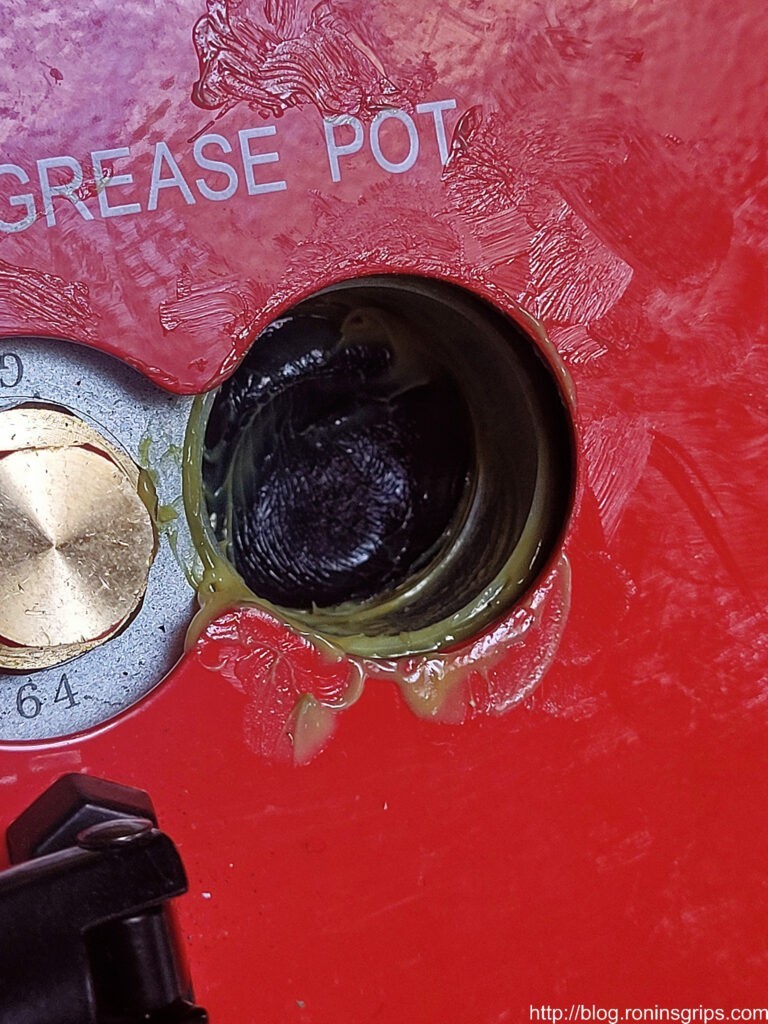

It’s simple, turn the top knob one full turn to introduce grease. You may be wondering why I even bothered adding a blog post. The reason is that when I turned the knob there was so much resistance that I thought the pot was empty – it wasn’t. What I want you to see is why there is resistance:

Refilling the Pot

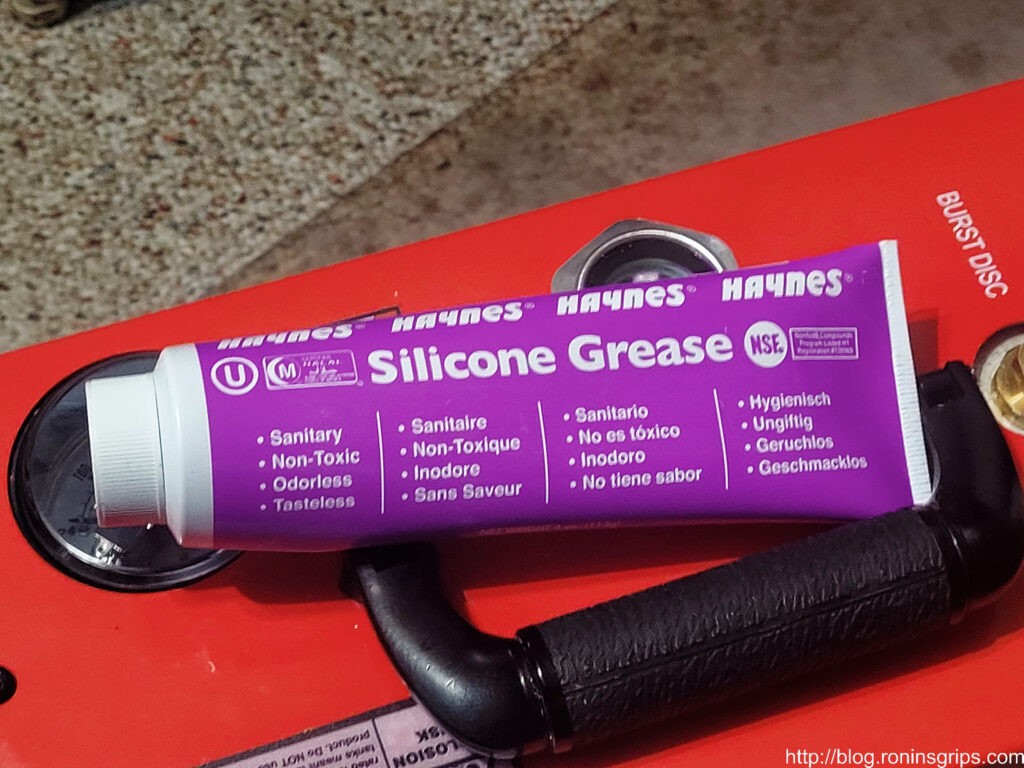

Well, I had really made a mess playing around with the grease pot and lost most of the grease in the process. I asked the Amazon seller, Ankul, what I should use and he told me to go with a general food grade grease. I asked if silicone would work because that seemed to be the composition of most, if not all, food grade greases on Amazon and he said “yes”. Based on that, I ordered a tube of the below Haynes Silicone Grease off Amazon due to it’s good reviews. The important part for you to bear in mind is to go with food grade and I assume this is to protect the seals or something.

Summary

In hindsight, it is very straight forward but I didn’t expect the flow limiter to stop the knob from turning and I didn’t know what grease to use to refill the pot so it seemed like good info to share.

I hope this helps you out.

Note, I have to buy all of my parts – nothing here was paid for by sponsors, etc. I do make a small amount if you click on an ad and buy something but that is it. You’re getting my real opinion on stuff.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, we are only paid if there is an affiliate program such as Avantlink, Impact, Amazon and eBay and only if you purchase something. If you’d like to directly contribute towards our continued reporting, please visit our funding page.