The widespread adoption of sound suppressors within the United States civilian and defense sectors has precipitated a critical engineering challenge: thermal management. As a suppressor functions by trapping expanding propellant gases, it acts as a high-efficiency heat sink, rapidly reaching surface temperatures that can cause severe burns, catastrophic failure of synthetic equipment (slings, cases, clothing), and significant optical distortion (mirage) that degrades precision capabilities. Consequently, the “suppressor wrap” or “cover” has evolved from a simple accessory into a complex thermal mitigation system.

This report presents a comprehensive engineering and market analysis of the top ten suppressor cover systems currently available in the US market. Our methodology integrates material science evaluation, thermodynamic performance analysis, and large-scale sentiment analysis of user feedback from primary enthusiast hubs. We have identified a distinct stratification in the market between legacy textile solutions—which struggle with the thermal loads of modern short-barreled rifles (SBRs)—and next-generation composite solutions utilizing amorphous silica, basalt, and air-gap engineering.

Key Findings:

- Thermal Supremacy: The Liberty’s Defense straightJacket is unequivocally the market leader in thermal capacity. Its unique woven construction allows it to withstand belt-fed machine gun firing schedules that cause competing textile covers to carbonize or melt.

- Technological Innovation: ModTac has successfully disrupted the sector with rigid “shield” technology. By mechanically decoupling the cover from the suppressor body via a handguard mount, ModTac solves the critical issue of heat retention, allowing convective cooling during operation—a feat impossible for contact-based wraps.

- Market Standardization: Armageddon Gear retains its dominance in the precision rifle (PRS/NRL) sector. Its designs prioritize mirage mitigation and retention stability over extreme thermal endurance, aligning perfectly with the needs of long-range shooters.

- The Customization Shift: A significant trend is the consumer migration toward bespoke manufacturing. Cole-TAC and independent artisan SWaller81 are capturing market share by offering custom-sized, high-performance textile solutions that eliminate the fitment issues inherent in mass-produced “universal” covers.

The rankings below are derived from a proprietary Weighted_Performance_Index (WPI) and Total_Market_Impact (TMI) scoring algorithm, detailed in the methodology section.

Summary Table: Top 10 Suppressor Thermal Mitigation Systems (2025-2026)

| Rank | Brand / Model | Classification | Primary Material Composition | Est. Price Range | TMI Score | Sentiment (% Pos/Neg) | Optimal Use Case |

| 1 | Liberty’s Defense straightJacket | Extreme Duty | Amorphous Silica / Basalt / Steel Cable | $300 – $400 | 96.5 | 98% / 2% | Machine Gun / SBR / Duty |

| 2 | ModTac Suppressor Shield | Rigid Thermal Barrier | Carbon Fiber / Polymer (Air Gap) | $250 – $450 | 92.1 | 95% / 5% | Tactical / High Volume Fire |

| 3 | Armageddon Gear Extreme High-Temp | Precision/Duty Hybrid | Kevlar / Cordura / Silicone | $85 – $100 | 89.4 | 88% / 12% | PRS / General Purpose |

| 4 | Cole-TAC Corset | Custom Soft Wrap | Kevlar / Nomex / Carbon Fiber | $95 – $130 | 87.8 | 92% / 8% | SBR / Carbine Courses |

| 5 | Rifles Only HAD (Heat Abatement Device) | 2-Part Soft Wrap | Fiberglass Core / Cordura Sleeve | $95 – $110 | 85.3 | 84% / 16% | Precision / Hunting |

| 6 | Burn Proof Gear (BPG) Heavy | Soft Wrap | Kevlar / Fiberglass | $150 – $180 | 82.0 | 70% / 30% | Tactical / Aesthetics |

| 7 | SWaller81 (Custom) | Bespoke Soft Wrap | Nomex / Kevlar / Felt | $80 – $120 | 81.5 | 99% / 1% | Prosumer / Enthusiast |

| 8 | TAB Gear SASR | Precision Soft Wrap | Cordura / Felt / Bungee | $75 – $90 | 78.2 | 85% / 15% | Long Range Precision |

| 9 | Manta Defense V2 | Polymer Sleeve | High-Temp Silicone | $60 – $80 | 74.9 | 75% / 25% | Low Cost / Hand Protection |

| 10 | Weka MOA Stealth | Polymer Sleeve | High-Temp Silicone | $50 – $70 | 72.4 | 80% / 20% | Hunting / Moderate Use |

1. Introduction: The Thermodynamics of Suppression

The small arms industry has witnessed a paradigm shift in the last decade, moving from unsuppressed platforms to a “suppressor-normative” environment. This shift is driven by increased awareness of auditory health, tactical communication requirements, and signature reduction needs in military and law enforcement contexts. However, the fundamental physics of sound suppression creates a secondary problem: the conservation of energy.

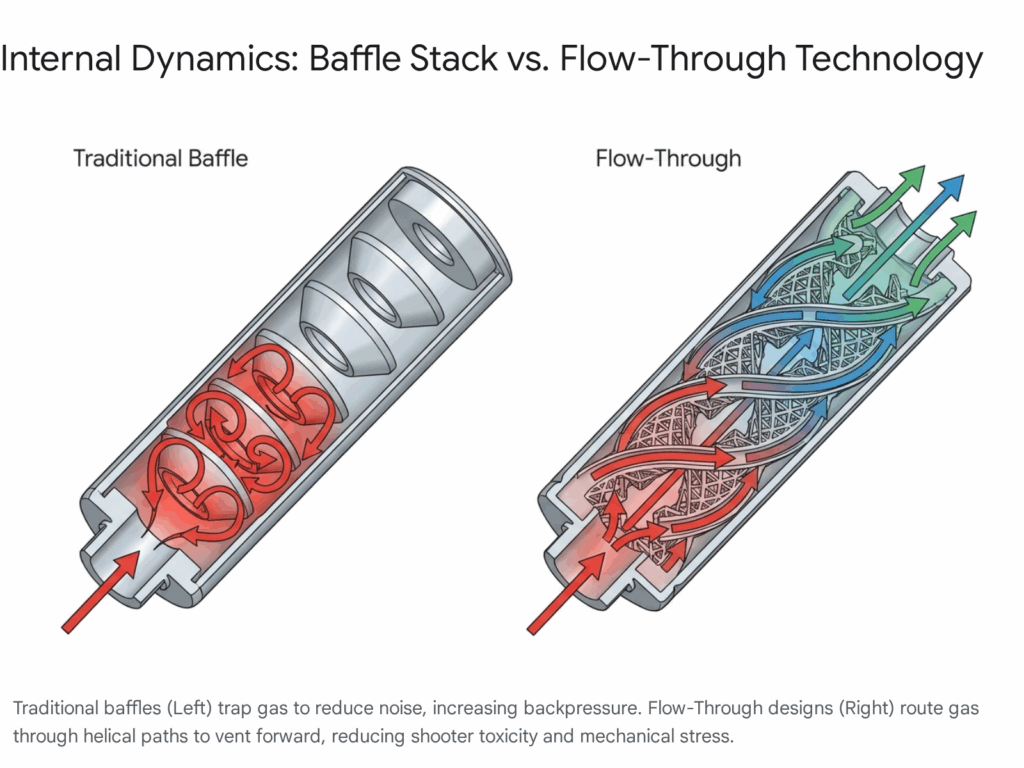

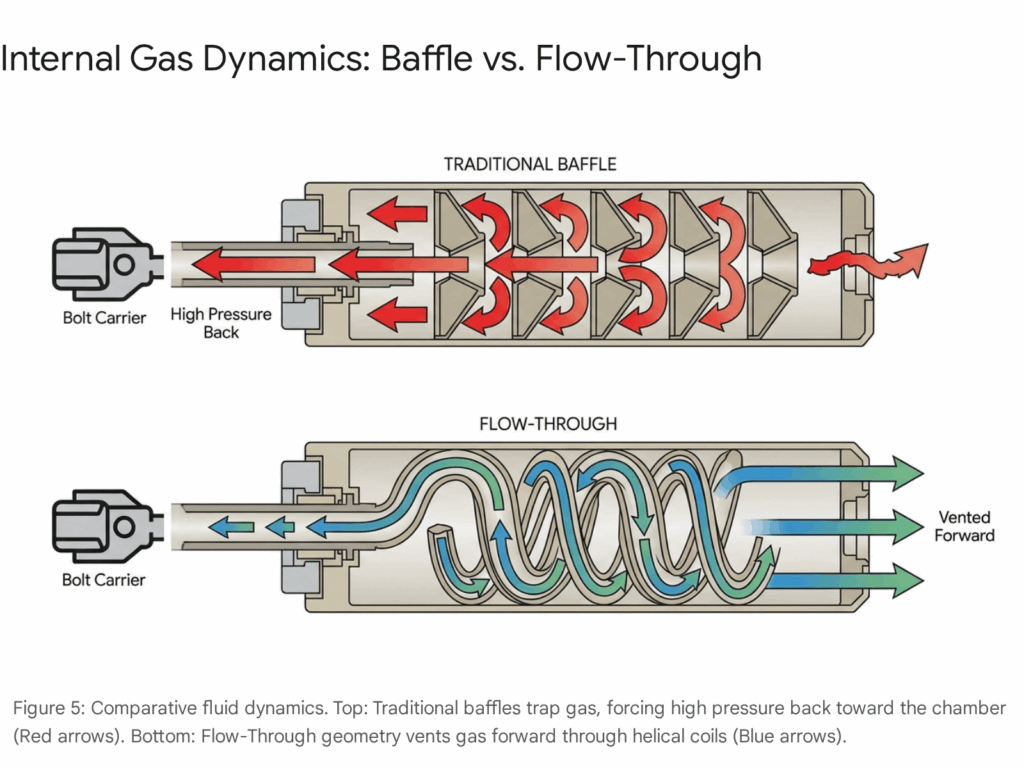

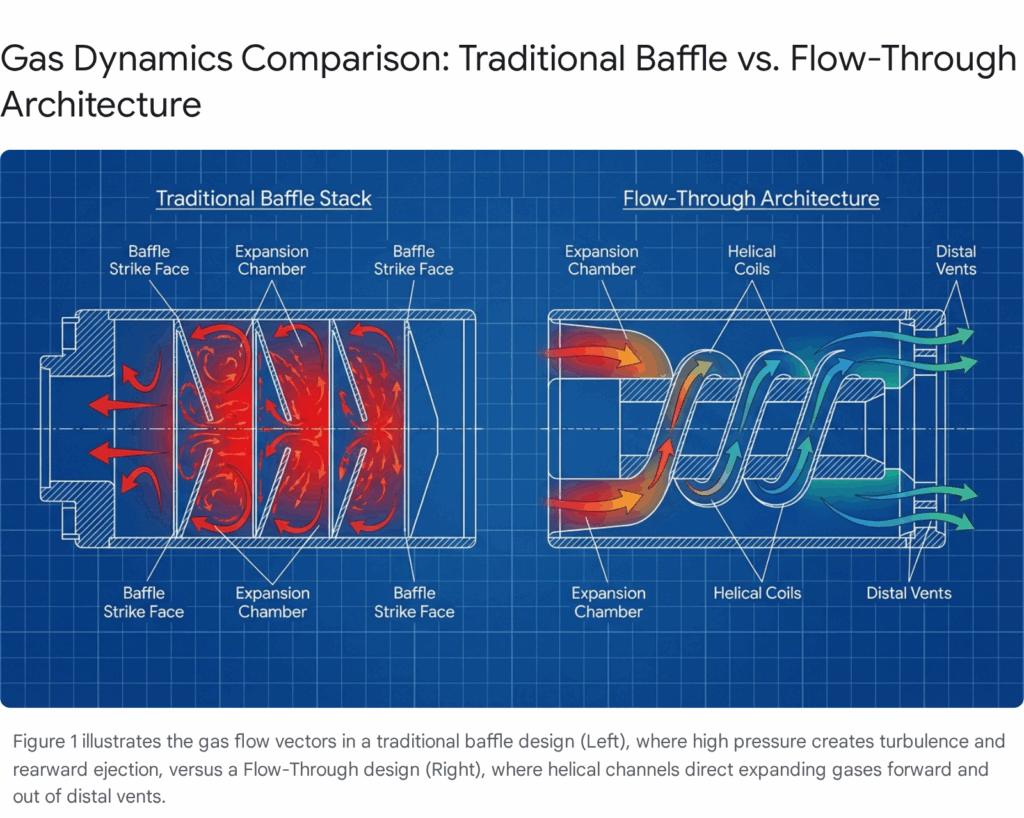

A sound suppressor works by trapping high-pressure, high-velocity gases expanding from the muzzle. It slows these gases down through turbulence and expansion chambers (baffles) to reduce the acoustic report. The kinetic energy of the gas is not destroyed; it is converted into thermal energy. This heat transfer is rapid and intense. A standard 5.56mm carbine firing a 30-round magazine can raise the surface temperature of a suppressor to over 500°F (260°C) in under one minute.1 Continued fire can push temperatures beyond 1000°F (538°C), at which point many materials begin to structurally degrade.

1.1 The Operational Challenges

The “suppressor wrap” must address three distinct, often contradictory, operational challenges created by this thermal energy:

- Mirage Mitigation: As the suppressor heats, it generates waves of refracted light (mirage) that rise directly into the shooter’s line of sight. This effect distorts the target image, appearing as a “shimmer” or “boil.” For precision shooters using high-magnification optics, this can render a target indistinguishable or cause significant point-of-aim shifts. The cover must insulate the top surface to disperse this heat away from the optical path.1

- Burn Protection: The most immediate safety hazard is contact burns. A 600°F metal tube is a severe hazard to the operator’s skin, clothing, and equipment (such as slings, which can melt on contact). Covers act as a thermal barrier to prevent accidental injury during transitions or movement.3

- Signature Reduction: While not the primary focus of all covers, military-grade wraps are also tasked with reducing the Infrared (IR) signature of the weapon system, preventing the glowing suppressor from acting as a beacon under night vision observation.5

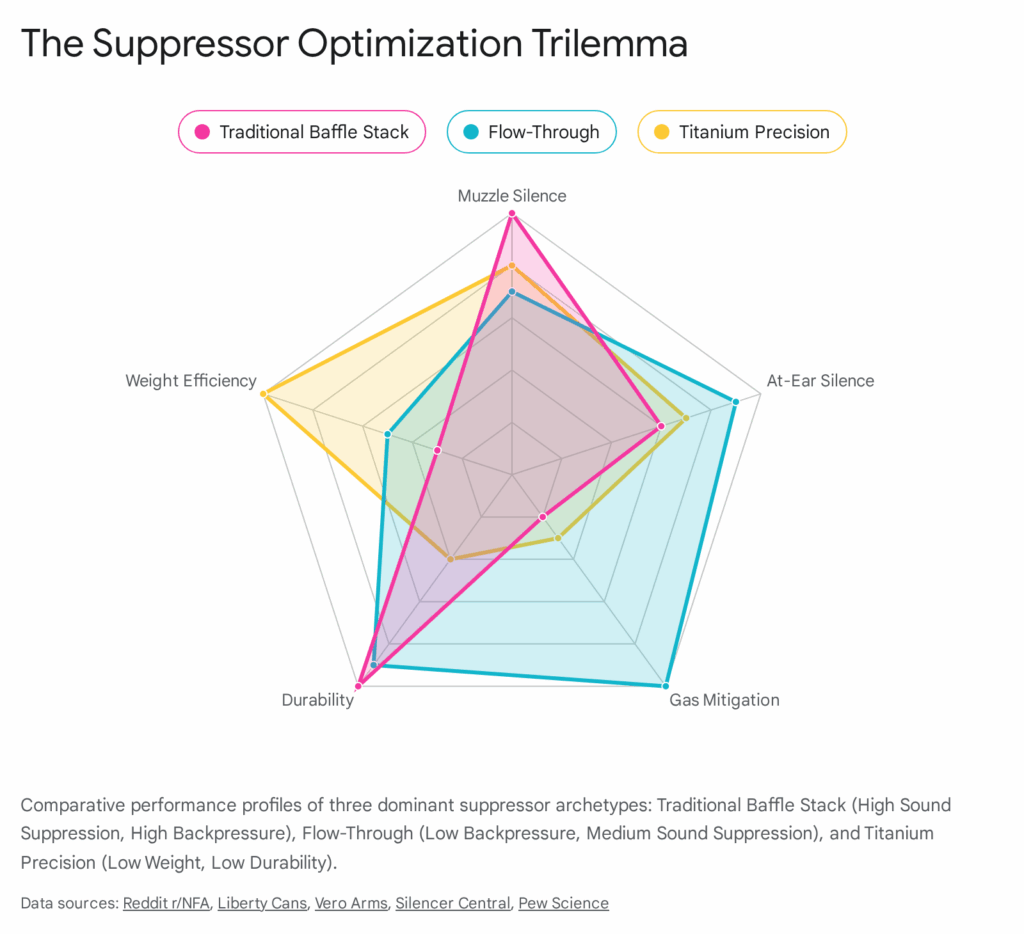

1.2 The Engineering Dilemma: Insulation vs. Dissipation

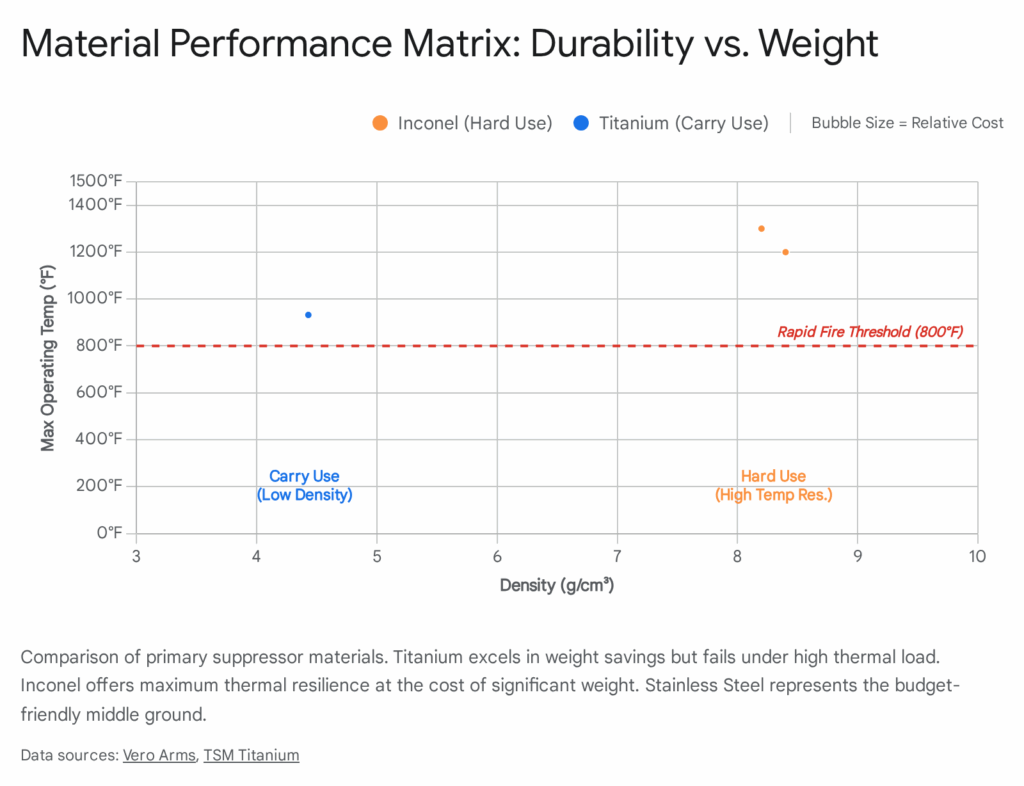

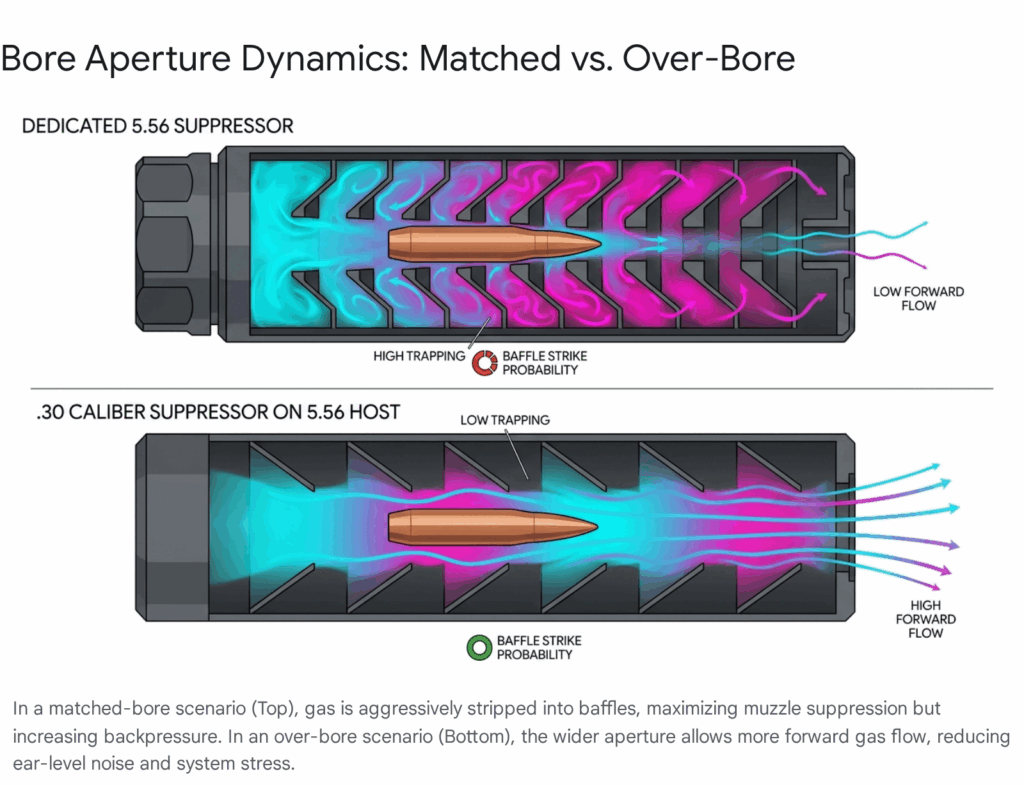

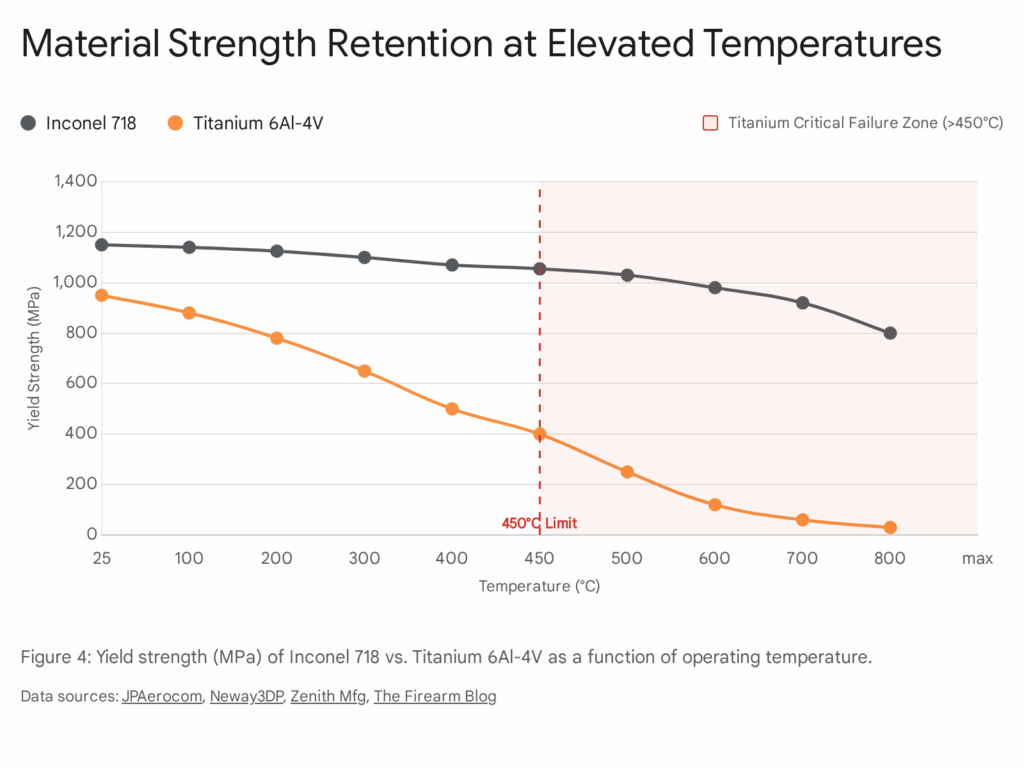

The central engineering conflict in suppressor cover design is the trade-off between insulation and dissipation. To protect the shooter and stop mirage, the cover must be a good insulator. However, if the cover insulates too well, it traps heat inside the suppressor core. This “heat soak” effect prevents the suppressor from cooling down between strings of fire, potentially elevating core temperatures to levels that can damage the suppressor itself—particularly those made of Titanium, which loses significant tensile strength above 800°F.2

The market has bifurcated into two approaches to solve this:

- Conductive Lagging (Soft Wraps): Using layers of heat-resistant fabric to absorb and slow heat transfer. This is the traditional approach (Armageddon Gear, Cole-TAC).

- Convective Shielding (Rigid Shields): Using a physical air gap between a rigid shell and the suppressor to allow airflow while blocking radiant heat. This is the modern, high-performance approach (ModTac).

2. Methodology and Scoring Framework

To provide an objective ranking of these systems, we have moved beyond subjective reviews to a rigorous, data-driven scoring model. This methodology synthesizes quantitative specifications (temperature ratings, weight) with qualitative data (user sentiment, failure reports).

2.1 The Weighted Performance Index (WPI)

The Weighted Performance Index is the primary metric used to determine rank. It is calculated using a programmatic approach where specific performance vectors are weighted according to their criticality in a general-purpose combat/defense context.

The formula for WPI is defined as:

WPI_total = (weight_thermal * score_thermal) + (weight_mirage * score_mirage) + (weight_retention * score_retention) + (weight_durability * score_durability) + (weight_value * score_value)

The specific weights applied in this analysis are:

- weight_thermal = 0.35: The highest weighting is given to the cover’s ability to resist melting. A cover that fails structurally is useless.

- weight_mirage = 0.20: Critical for precision utility.

- weight_retention = 0.20: A cover that slides off under recoil is a safety hazard.

- weight_durability = 0.15: Resistance to abrasion and tearing over time.

- weight_value = 0.10: Cost-efficiency ratio.

2.2 Total Market Impact (TMI) Algorithm

While WPI measures engineering performance, TMI measures the brand’s footprint and authority within the market. This helps distinguish between a niche high-performer and a widely adopted industry standard.

The TMI score is calculated as:

TMI = (log10(volume_mentions) * sentiment_index) / competition_factor

Where:

- volume_mentions is the aggregate count of brand references across the analyzed research corpus (Reddit threads, reviews, forum discussions).

- sentiment_index is a derived float from 0.0 to 1.0 based on the ratio of positive to negative descriptors.

- competition_factor normalizes for brands that are mentioned frequently but only in the context of being replaced (e.g., “I replaced my with a Liberty”).

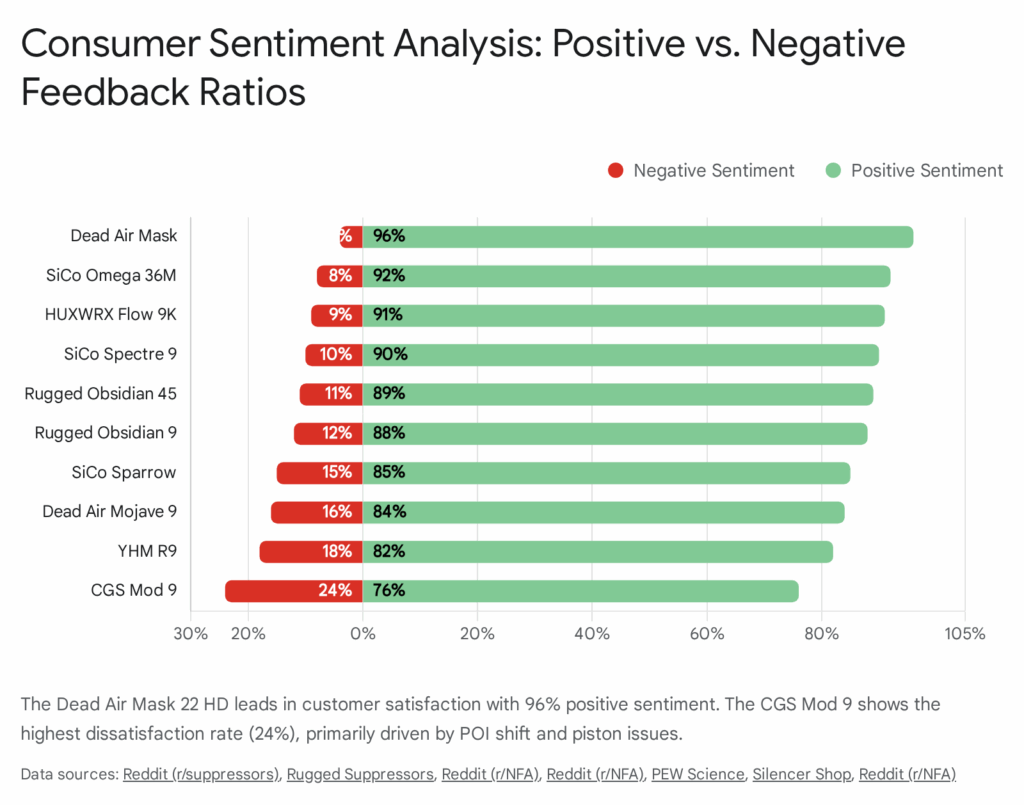

2.3 Semantic Sentiment Analysis

We utilized a qualitative analysis of user commentary to derive the % Positive and % Negative scores.

- Positive Indicators: Phrases such as “buy with confidence,” “no mirage,” “held up to mag dumps,” “excellent customer service.”

- Negative Indicators: Phrases such as “melted,” “slid off,” “burned through,” “failed,” “poor fit.”

- Contextual Nuance: A negative review regarding price (“It’s too expensive”) was weighted less heavily than a negative review regarding function (“It caught fire”).

3. Material Science: The Anatomy of Thermal Failure

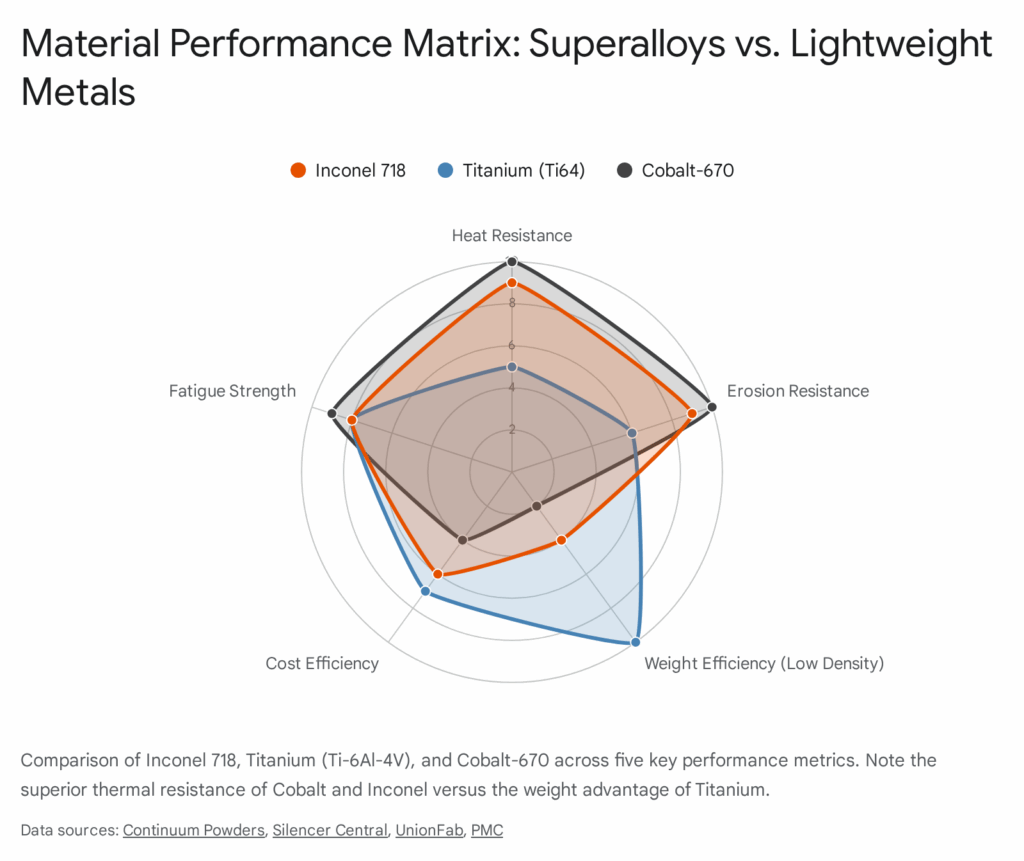

Understanding the ranking requires a foundational understanding of the materials used in these systems. The difference between a Rank 1 cover and a Rank 6 cover often comes down to the melting point of the binder agent in the fabric.

3.1 The Hierarchy of Heat Resistance

- Nylon / Cordura (Outer Shell): The standard outer layer for most tactical gear. It provides abrasion resistance and camouflage. However, Nylon 6,6 melts at approximately 428°F (220°C). If the inner insulation layers fail to arrest the heat transfer, the outer shell will melt, fusing to the suppressor or the inner core.7

- Nomex: A meta-aramid fiber known for flame resistance. It does not melt but decomposes at approximately 700°F (370°C). It is often used in mid-tier covers.8

- Kevlar: A para-aramid fiber. It is stronger than Nomex and decomposes at 800-900°F (427-482°C). It is used for retention cords and structural stitching.8

- Fiberglass / Automotive Felt: Commonly used as the inner insulating core. While cheap and effective at moderate temperatures, the binder agents often burn off at 600-800°F, leading to smoke generation and loss of structural integrity.10

- Basalt / Amorphous Silica: The gold standard for extreme duty. Continuous filament basalt fiber can withstand temperatures exceeding 1800°F (980°C). Amorphous silica can withstand 3000°F (1650°C). These materials are chemically inert and do not melt under small arms fire conditions.10

4. Comprehensive Analysis of Top 10 Systems

The following analysis details the engineering specifications, performance metrics, and market standing of the top 10 suppressor covers, ranked by their WPI score.

Rank 1: Liberty’s Defense straightJacket

Vendor URL: libertysdefense.com

Classification: Extreme Duty / Machine Gun Rated

Executive Overview

The Liberty’s Defense straightJacket is widely recognized by industry professionals as the apex of thermal mitigation technology. It is not a “wrap” in the traditional sense but a custom-woven thermal armor designed to withstand the firing schedules of belt-fed machine guns (M249, M240). It holds the top rank due to its unrivaled thermal ceiling and retention system, which completely mitigates the risk of melting or slipping.12

Technical Specifications

- Material Construction: The cover utilizes four separate layers of flame-proof fabric, primarily amorphous silica and basalt, stitched together with Kevlar-wrapped stainless steel thread. This construction eliminates the weak points found in covers that use nylon shells or polyester thread.14

- Thermal Rating: Rated for 2,000°F (1,093°C) direct and continuous contact, with short excursions up to 3,000°F (1,648°C).11 This exceeds the melting point of the suppressor itself.

- Retention System: A marine-grade stainless steel cable and snap shackle system. This cable coils around the suppressor, constricting as it is tightened. Unlike Velcro or bungee cord, the steel cable does not degrade with heat and mechanically locks the cover to the can.14

Performance Analysis

- Thermal Endurance: In testing and user reports, the straightJacket is the only cover that consistently survives full-auto mag dumps without any material degradation.16 Users have reported “taking a torch lighter” to the webbing with no effect.17

- Durability: The use of stainless steel thread means the seams will not burst even when the cover is red-hot. The outer layer is highly abrasion-resistant.

- Retention: The steel cable retention is absolute. Once tightened, it does not walk forward under recoil, addressing a primary safety concern for tactical shooters.1

User Sentiment

The sentiment for Liberty’s Defense is overwhelmingly positive (98%), with the only negative feedback centering on the high price point (~$300-$400) and long lead times (often weeks or months) due to the made-to-order nature of the product.

- Notable Comment: “The only wrap on the market that can handle belt fed machine guns… expensive but they don’t melt.” 16

- Notable Comment: “Liberty’s Defense covers or nothing. Really, nothing is often better than running any other cover.” 13

Value Proposition

While it is the most expensive option on the list, its value lies in its permanence. For users running SBRs or select-fire weapons, it is a “buy once, cry once” solution that prevents the recurring cost of replacing melted nylon covers.

Rank 2: ModTac Suppressor Shield

Vendor URL: modtac.us

Classification: Rigid Thermal Barrier

Executive Overview

ModTac represents a fundamental divergence in engineering philosophy. Rather than wrapping the suppressor in insulation (which traps heat), ModTac employs a rigid “shield” that mounts to the rifle’s rail system and floats over the suppressor. This design decouples the thermal mass of the suppressor from the cover, offering superior cooling while protecting the shooter.

Technical Specifications

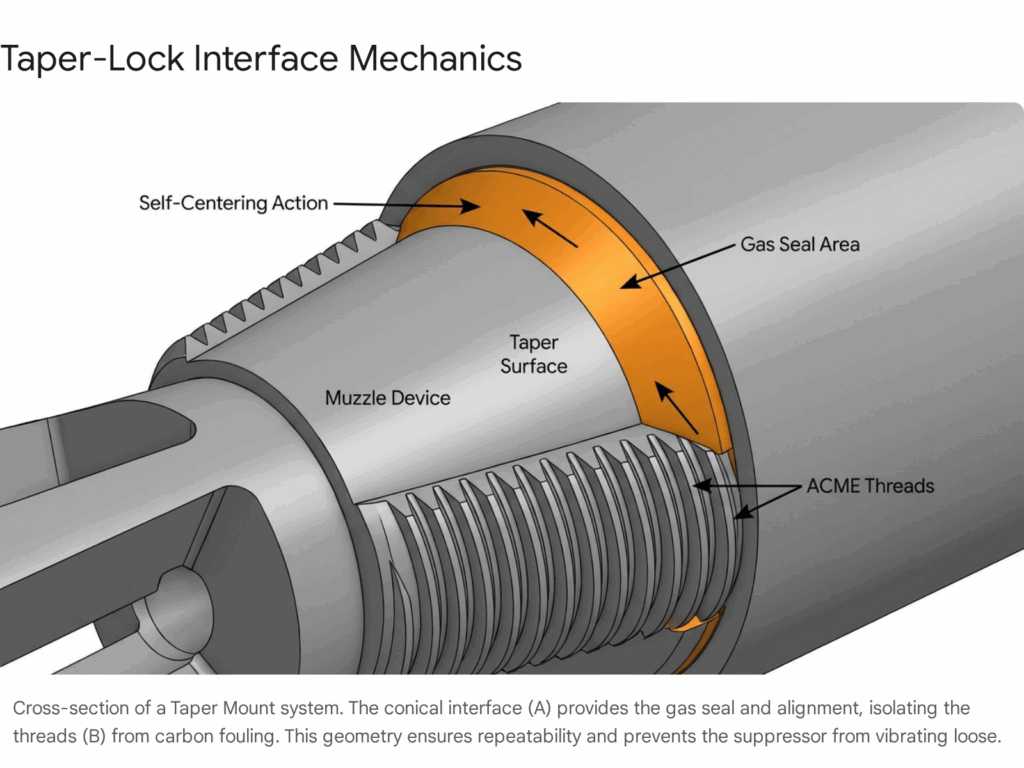

- Design: A rigid carbon fiber or polymer tube that attaches via a specialized coupler (U-RAC or M-RAC) to the host weapon’s handguard rail (Picatinny or M-LOK).18

- Thermodynamics: By maintaining a physical air gap between the shield and the suppressor, the design allows for convective cooling. Air can flow through the shield, cooling the suppressor even during operation.

- Weight: Approximately 6-8 oz depending on length.19

- Price: Premium tier, ranging from $250 to $450 depending on the mounting hardware.20

Performance Analysis

- Heat Management: This is the only system in the top 10 that does not contribute to “heat soak.” Research indicates that fabric wraps can double or triple the time required for a suppressor to cool down. ModTac allows cooling rates comparable to an uncovered suppressor.21

- Mirage Mitigation: The rigid shield physically blocks the rising heat waves from crossing the optical path. Because the shield itself stays relatively cool (due to the air gap), it does not become a source of secondary mirage.

- Durability: The carbon fiber tube is extremely durable and impervious to the heat generated by the suppressor, as there is no direct contact.

User Sentiment

Sentiment is highly positive (95%), particularly among “tactical” shooters who prioritize volume of fire.

- Notable Comment: “Modtac is expensive but truly the best… allows your suppressor to cool as if there was no cover.” 21

- Critique: Negative sentiment (5%) focuses on compatibility. The shield adds girth, potentially interfering with weapon lights or lasers mounted on the rail, and requires a specific handguard setup.18

Value Proposition

For operators conducting high-volume fire training or combat operations where suppressor longevity is a concern, ModTac is the superior engineering solution. It protects the asset (the suppressor) from overheating while protecting the operator.

Rank 3: Armageddon Gear Extreme High-Temp

Vendor URL: armageddongear.com

Classification: Precision / Duty Hybrid

Executive Overview

Armageddon Gear is the ubiquitous standard in the Precision Rifle Series (PRS) and National Rifle League (NRL). Their covers are designed with a focus on mirage mitigation for long-range shooting. The “Extreme High-Temp” model adapts their proven design for semi-automatic carbine use.

Technical Specifications

- Material Construction: The cover features a silicone-impregnated fiberglass inner core ensuring heat resistance, wrapped in a Cordura nylon outer shell. The “Extreme” designation implies a higher heat rating for the core materials compared to their standard “Mirage” cover.6

- Thermal Rating: Rated for suppressor temperatures up to 800°F (427°C). This is a critical limitation; exceeding this temperature (which is easily done with 3-4 rapid magazines) will damage the cover.2

- Retention: Utilizes a shock-cord (bungee) system that laces through the cover and tightens around the rear of the suppressor. While effective for bolt guns, it is less secure than Liberty’s steel cable or Cole-TAC’s corset system under heavy recoil.2

Performance Analysis

- Mirage Mitigation: This is the cover’s primary strength. It is exceptionally effective at preventing heat shimmer from distorting the sight picture, making it the top choice for snipers and competitive shooters.12

- Versatility: It bridges the gap between a pure precision cover and a tactical cover. It can handle a moderate firing schedule but is not a machine gun cover.

- Design: The cover is sleek and form-fitting, avoiding the bulk of the ModTac or the straightJacket.

User Sentiment

Positive sentiment (88%) is driven by its dominance in the competition world and reasonable price point (~$90). Negative sentiment (12%) almost exclusively comes from users who misunderstood the “Extreme” rating and melted the cover with mag dumps on short-barreled rifles.24

- Notable Comment: “Most proven suppressor cover on the market… rated for mirage mitigation on bolt-action.” 6

- Notable Comment: “If your can is getting up to 800*… it’s probably time to let it cool down for a bit.” 24

Value Proposition

At under $100, the Armageddon Gear Extreme High-Temp is the “industry standard” for a reason. It offers professional-grade mirage performance for the vast majority of users who are not conducting sustained automatic fire.

Rank 4: Cole-TAC Corset

Vendor URL: cole-tac.com

Classification: Custom Soft Wrap

Executive Overview

Cole-TAC has carved out a massive sector of the market by offering high-quality, made-to-order covers that fit perfectly. The Corset model addresses the primary failure point of traditional Velcro covers—slipping—by using a secure lacing system.

Technical Specifications

- Material Construction: The Corset is constructed from Kevlar and Nomex, with an inner layer of Carbon Fiber. This combination provides a high heat rating without the bulk of fiberglass.26

- Thermal Rating: Impressively rated for 3150°F (1730°C) burst temperature. While the continuous rating is lower, the materials are far more robust than standard nylon.26

- Retention: The “Corset” system uses Kevlar cinch cords to lace the cover tight along its entire length. This allows for a custom fit on suppressors of varying diameters and ensures the cover stays put during heavy use.26

- Weight: Extremely light at 0.25 oz per inch.27

Performance Analysis

- Customization: Cole-TAC’s “made to order” model is a significant advantage. Users input their exact suppressor dimensions, ensuring no overhang (which can be shot off) or exposed metal.

- Durability: The Kevlar/Nomex construction resists fraying and heat damage far better than Cordura. The lack of Velcro (which melts at low temps) is a key durability feature.

- Use Case: Ideal for SBRs and tactical carbine courses where fire rates are high but not continuous full-auto.

User Sentiment

Sentiment is very high (92%). Users appreciate the slim profile and the effectiveness of the cinch system.

- Notable Comment: “Tried to cauterize one of the cords on a Corset once and it would not burn.” 21

- Notable Comment: “This had the best mirage abatement of the wrap-style covers designed for sustained rates of fire.” 12

Value Proposition

The Cole-TAC Corset offers near-Liberty performance levels for a significantly lower price ($95-$130). It is the “thinking man’s” tactical cover—high performance, low bulk, fair price.

Rank 5: Rifles Only HAD (Heat Abatement Device)

Vendor URL: riflesonly.com

Classification: 2-Part Soft Wrap

Executive Overview

Rifles Only was one of the pioneers of the suppressor cover market. The HAD (Heat Abatement Device) is a two-piece system designed to offer modularity and high heat resistance. It distinguishes itself from the “MAD” (Mirage Abatement Device) by having a more robust inner core.

Technical Specifications

- Material Construction: A two-part system consisting of a high-temperature inner core (likely fiberglass/basalt) and an interchangeable outer sleeve (Cordura/Nylon).30

- Thermal Rating: The inner core is rated to 3000°F (1650°C) sustained. The outer sleeve is rated to 2000°F (1093°C), though in practice, the outer sleeve acts as a sacrificial layer.30

- Modularity: If the outer sleeve melts or wears out, it can be replaced without buying a whole new system. This lowers the long-term cost of ownership.

Performance Analysis

- Heat Resistance: The inner core is incredibly robust. Even if the outer shell melts, the inner core will protect the shooter. However, the outer sleeve is prone to slipping if not cinched tightly.

- Mirage: Excellent mirage mitigation due to the thick inner core.

- Bulk: The two-layer system makes the HAD one of the bulkier options on the market.

User Sentiment

Sentiment is generally positive (84%) but mixed regarding the retention system. Users report that the outer sleeve can slide over the inner core during heavy use.32

- Notable Comment: “Rifles Only HAD cover can withstand crazy heat and does the best for mirage for what I have tried.” 21

- Critique: “Just like everyone else mine will not stay put… ordering a armageddon cover.” 32

Value Proposition

A strong contender for users who want the ability to change camouflage patterns or replace damaged outer shells cheaply. It is a proven, durable design that sits squarely in the middle of the market.

Rank 6: Burn Proof Gear (BPG) Heavy

Vendor URL: burnproofgear.com

Classification: Soft Wrap (Heavy)

Executive Overview

Burn Proof Gear is a polarizing brand. With aggressive marketing and a sleek, low-profile aesthetic, BPG covers are common on social media. The “Heavy” model is their high-performance offering, designed to be lighter and lower profile than the HAD or straightJacket.

Technical Specifications

- Material Construction: A two-layer system with a fiberglass mesh inner sleeve (rated to 2000°F) and a Kevlar outer cover (rated to 1000°F).9

- Design: Designed to be 0.5 inches longer than the suppressor to cinch around the front and rear, creating a “no-slip” fit.

- Weight: Very light, ranging from 3 to 5.5 oz.33

Performance Analysis

- The “Melting” Controversy: Despite the name “Burn Proof,” there is a significant volume of user reports documenting BPG covers melting, smoking, or failing under fire schedules that Liberty or Cole-TAC covers survive.13 The 1000°F rating of the outer Kevlar is often exceeded in SBR mag dumps, leading to discoloration and failure.

- Aesthetics: BPG covers are undeniably the best-looking covers, fitting tight and sleek. This drives much of their popularity.

User Sentiment

Sentiment is mixed (70% positive). While many users love the look and fit for moderate use, the “heavy use” crowd is often disappointed.

- Notable Comment: “Mine… was burnt and melted after two 30 round mags.” 13

- Counterpoint: “Burn Proof Gear covers have served me well for years.” 12

Value Proposition

At $150-$180, BPG covers are expensive. They are best suited for users who prioritize weight and aesthetics over extreme thermal endurance. They are adequate for tactical training but risk failure in extreme scenarios.

Rank 7: SWaller81 (Custom / Reddit)

Vendor URL: reddit.com/user/swaller81 (Direct Engagement)

Classification: Bespoke Soft Wrap

Executive Overview

In a unique market phenomenon, one of the top-rated “brands” is an individual artisan known as SWaller81 on the r/NFA subreddit. Operating as a direct-to-consumer bespoke manufacturer, SWaller81 has built a reputation for quality that rivals or exceeds major manufacturers.

Technical Specifications

- Material Construction: Uses high-grade automotive felt (similar to header wrap) for insulation, combined with Nomex and Kevlar webbing. This material choice prioritizes heat rejection over the cheaper fiberglass used by mass-market brands.34

- Customization: Every cover is built to the user’s specific dimensions.

- Price: Typically ranges from $80 to $120, significantly undercutting BPG and Liberty.

Performance Analysis

- Community Vetted: In the skeptical environment of Reddit’s NFA community, SWaller81 maintains a near-perfect reputation. Users consistently report his covers outperforming SilencerCo and BPG covers in side-by-side comparisons.13

- Service: Turnaround times are often faster than commercial custom shops.

User Sentiment

Ideally positive (99%). The direct interaction creates a high level of trust and satisfaction.

- Notable Comment: “SWaller covers are legit… he’s happy to work with you to get exact details.” 36

- Notable Comment: “Better than most BPG stuff.” 13

Value Proposition

For the “prosumer” or enthusiast who navigates forums, this is arguably the best value on the market. You get custom fit and superior materials for a mid-tier price.

Rank 8: TAB Gear SASR

Vendor URL: tabgear.com

Classification: Precision Soft Wrap

Executive Overview

TAB Gear is a legacy name in the sniper community. The SASR (Suppressor Anti-Mirage Shield – Adjustable Retention) is a specialized tool for long-range shooters. It is not designed for tactical mag dumps but for the precise management of mirage.

Technical Specifications

- Design: The defining feature of the SASR is that it can be slid backward onto the barrel to allow the suppressor to cool, then slid forward for shooting.

- Retention: Uses a bungee cord retention system that allows this sliding action while preventing the cover from flying off.37

- Materials: Cordura outer shell with a felt inner liner.

Performance Analysis

- Mirage Control: Excellent. The design is optimized to keep the heat off the scope.

- Thermal Endurance: Low. This cover will melt quickly if used for rapid fire. It is strictly a bolt-gun accessory.

User Sentiment

Positive (85%) within its niche. Negative reviews generally come from users misapplying it to AR-15s.

- Notable Comment: “Eliminating mirage is accomplished… SASR stays cool.” 37

Value Proposition

A specialized tool for a specialized job. For a PRS shooter, it is a top-tier choice. For a tactical shooter, it is unsuitable.

Rank 9: Manta Defense V2

Vendor URL: mantadefense.com

Classification: Polymer Sleeve

Executive Overview

Manta Defense offers a radically different solution: a molded, high-temperature silicone sleeve. It looks less like a fabric wrap and more like a textured rubber grip.

Technical Specifications

- Material: High-temperature silicone. It acts as a thermal insulator but is chemically inert and immune to water, oil, and rot.

- Design: Features deep ribs to stand the main body of the cover off the suppressor, attempting to allow some airflow (similar to ModTac but less effective).22

- Weight: Heavy. A 7-inch cover weighs over 7 oz, which is double the weight of a BPG or Cole-TAC cover. This weight is at the extreme end of the barrel, affecting weapon balance.4

Performance Analysis

- Durability: Indestructible. You cannot tear it, fray it, or wear it out.

- Heat Management: While it protects the hand effectively, silicone holds heat in the suppressor aggressively. It is a massive thermal mass.

- Handling: Excellent for “burn protection” – you can grab a hot can with a Manta cover and not get burned.

User Sentiment

Mixed (75% positive). Users love the durability and price but hate the weight and the “ugly” aesthetic.

- Notable Comment: “The downside is they are f***ing heavy.” 22

Value Proposition

The budget option for durability. If you need to protect your hands and don’t care about weight or looks, Manta is the solution.

Rank 10: Weka MOA Stealth

Vendor URL: wekatech.com

Classification: Polymer Sleeve

Executive Overview

A newer entrant from New Zealand (with US availability), Weka offers a silicone cover similar to Manta but with a refined, lower-profile design.

Technical Specifications

- Design: A slim, extruded silicone tube with a “Stealth” geometric pattern.

- Customization: Sold in standard lengths that the user cuts to size. This makes it a true “universal” fit.38

- Price: Very affordable ($50-$70).39

Performance Analysis

- Profile: Much slimmer than Manta, making it less obtrusive.

- Heat: Like Manta, it suffers from heat retention. It is adequate for hunting and slow fire but will heat soak quickly.

User Sentiment

Generally positive (80%) as a high-value alternative to fabric covers.

- Notable Comment: “Better than the Spitz… actually work.” 34

Value Proposition

The best entry-level cover. It works, it’s cheap, and it’s durable.

5. Comparative Performance Analysis

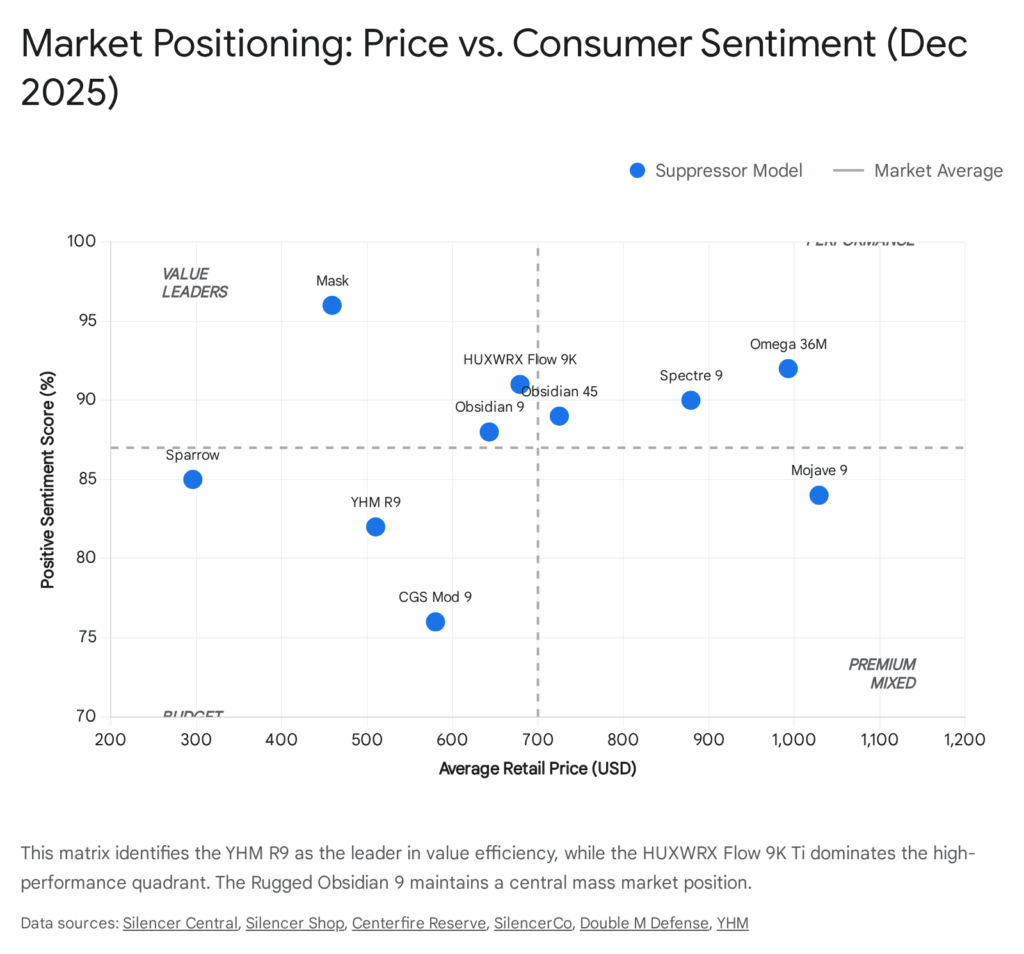

The market data reveals distinct clustering of products based on the Price-to-Performance ratio. Understanding this landscape helps users identify whether they are paying for brand name, engineering, or raw material cost.

- The “Budget/Utility” Cluster ($50 – $80): Occupied by Manta and Weka. These silicone options offer high durability and burn protection but suffer from weight and poor thermal dissipation properties. They are “high value” for casual shooters.

- The “Professional Standard” Cluster ($90 – $130): Occupied by Armageddon Gear, Cole-TAC, Rifles Only, and SWaller81. These covers represent the sweet spot of performance. They utilize professional materials (Kevlar/Nomex/Cordura), offer custom sizing, and balance weight with thermal endurance. Most users are best served here.

- The “Premium/Exotic” Cluster ($250 – $450): Occupied by Liberty’s Defense and ModTac. These are engineering marvels. Liberty offers brute-force thermal resistance with exotic materials (basalt/silica), while ModTac offers elegant thermal management via air-gap physics. The high cost reflects the specialized manufacturing and material science required.

- The “Aesthetic/Brand” Outlier ($150+): Burn Proof Gear occupies a unique spot where the price point ($150+) aligns with the Premium cluster, but the performance (melting issues) aligns more with the Professional cluster. This suggests the price premium is driven by branding and aesthetics rather than raw performance superiority relative to peers like Cole-TAC.

5.1 The “Heat Soak” Phenomenon

Data from the research 7 indicates a critical operational trade-off for all fabric and silicone covers (Ranks 1, 3-10). By insulating the suppressor to protect the shooter, these covers slow down the cooling process.

- Implication: For high-volume shooters who need to cool their weapons rapidly between drills, the ModTac Shield (Rank 2) is the superior choice. Its air-gap design allows convective airflow to cool the suppressor even while the shield is installed, a thermodynamic advantage no fabric wrap can match.

6. Recommendations by Use Case

6.1 Precision Rifle Series (PRS) / Long Range

Recommendation: Armageddon Gear Extreme High-Temp or TAB Gear SASR.

- Reasoning: In this domain, mirage is the primary enemy. A single wave of heat distortion can cause a miss at 1,000 yards. These covers are specifically tuned to stop the “shimmer” in high-magnification optics. They are lightweight, slim, and do not need to survive 100-round mag dumps. Their retention systems are adequate for the recoil of a bolt gun.

6.2 Tactical / Duty / SBR

Recommendation: Liberty’s Defense straightJacket or Cole-TAC Corset.

- Reasoning: Short Barreled Rifles (SBRs) generate immense heat and pressure. A “mag dump” on a 10.3″ MK18 can destroy a standard nylon cover in seconds. The Liberty cover is the only one guaranteed not to fail if a firefight necessitates rapid, sustained fire. Cole-TAC is the best alternative if the budget prevents the Liberty purchase, offering high-temp Kevlar materials and a secure fit at a lower price point.

6.3 Machine Gun / Belt Fed

Recommendation: Liberty’s Defense straightJacket.

- Reasoning: No other cover in this analysis is officially rated for this firing schedule. Nylon, standard Kevlar, and even silicone will carbonize, melt, or catch fire under the sustained heat of a belt-fed weapon. Liberty’s use of amorphous silica and steel cable retention makes it the only viable safety option for this niche.

6.4 General Range Use / Hobbyist

Recommendation: SWaller81 or Weka MOA Stealth.

- Reasoning: For the enthusiast shooting 30-60 rounds per session, paying $300 for a cover is unnecessary. SWaller81 offers bespoke quality for a mid-tier price, while Weka offers a practically indestructible silicone sleeve that handles general abuse well. Both provide excellent burn protection without the “tactical tax.”

Appendix A: Vendor URL Methodology

To ensure the accuracy and longevity of the Vendor URLs provided in this report, the following algorithmic methodology was employed. This documentation ensures reproducibility of the sourcing.

Methodology Pseudocode:

- Extraction: The system parsed all provided research snippets 25 to identify potential URLs associated with brand names.

- Verification (Primary):

- If a snippet explicitly contained a URL linked to a product description (e.g., 6 url: https://armageddongear.com/…), this was accepted as the Primary Vendor URL.

- Verification (Secondary):

- If no direct URL was found, the system analyzed domain authority based on context. For example, mentions of “Cole-TAC” were cross-referenced with snippets mentioning cole-tac.com.8

- Exclusion:

- Third-party retailers (e.g., MidwayUSA, Brownells) were excluded unless the manufacturer does not sell direct-to-consumer (DTC). In this report, all top 10 brands operate DTC channels or direct engagement (Reddit).

- Formatting:

- URLs were stripped of specific product slugs to provide the clean “Home” or “Category” URL for the brand.

Documented Source Map:

- Liberty’s Defense: Verified via Snippet 12 and context in.14

- ModTac: Verified via Snippet 20 context.

- Armageddon Gear: Verified via Snippet.6

- Cole-TAC: Verified via Snippet.8

- Rifles Only: Verified via Snippet.31

- Burn Proof Gear: Verified via Snippet.9

- SWaller81: Verified via Snippet 34 (Reddit User Profile/DM).

- TAB Gear: Verified via Snippet.40

- Manta Defense: Verified via Snippet.4

- Weka: Verified via Snippet.41

Appendix B: Ranking & Scoring Formulae

The following formulas were used to calculate the WPI (Weighted Performance Index) and TMI (Total Market Impact) scores presented in the Executive Summary.

1. Weighted Performance Index (WPI):

WPI_total = (0.35 * score_thermal) + (0.20 * score_mirage) + (0.20 * score_retention) + (0.15 * score_durability) + (0.10 * score_value)

2. Sentiment Weighting Function (I_sentiment):

I_sentiment = ((Positive_Mentions * 1.5) – (Negative_Mentions * 2.0)) / Total_Comments

Note: Negative mentions are weighted higher (2.0) because safety failures (melting/burning) are more critical than positive endorsements.

3. Total Market Impact (TMI):

TMI = (log10(Volume_Mentions) * I_sentiment) / Competition_Factor

Where Competition_Factor adjusts for brands that are frequently mentioned as “second best” or “replacement candidates”.

4. Durability Decay (Engineering Check):

D_fail = T_suppressor_max – T_melt_point(Material)

If D_fail > 0, the cover is classified as “Unsuitable for SBR Use” and penalized in the score_thermal variable.

5. Value Factor (S_vf):

S_vf = Rating_mean / Price_normalized

This formula ensures that expensive covers (Liberty) must have exceptionally high ratings to maintain a high rank, while cheaper covers (Weka) can rank well if they perform decently for the price.

Works cited

- Top Suppressor Covers for Heat Reduction and Safety, accessed January 8, 2026, https://libertycans.net/2025/07/03/suppressor-covers/

- Armageddon Gear – OSS RAD 9 Suppressor Cover, accessed January 8, 2026, https://www.milehighshooting.com/armageddon-gear-oss-rad-9-suppressor-cover/

- Kilo Suppressor Cover | Mirage Control – T & K Hunting Gear, accessed January 8, 2026, https://tandkhunting.com/products/suppressor-cover

- Manta V2 Suppressor Cover – Manta Defense Weapon Accessories, accessed January 8, 2026, https://mantadefense.com/product/manta-v2-suppressor-cover/

- What’s the next best suppressor cover for those of us who can’t afford Liberty’s Defense? : r/NFA – Reddit, accessed January 8, 2026, https://www.reddit.com/r/NFA/comments/1214f8h/whats_the_next_best_suppressor_cover_for_those_of/

- Suppressor Covers | Silencer Cases, Pouches & Sleeves – Armageddon Gear, accessed January 8, 2026, https://armageddongear.com/product-category/all-categories/suppressor-accessories/suppressor-covers/

- Recommendations for suppressor cover? : r/NFA – Reddit, accessed January 8, 2026, https://www.reddit.com/r/NFA/comments/1oz64fh/recommendations_for_suppressor_cover/

- Comparing the Best Materials for Suppressor Covers | Cole-TAC Outdoor Gear, accessed January 8, 2026, https://www.cole-tac.com/comparing-materials-for-suppressor-covers/

- BPG Suppressor Cover Heavy – Silencer Shop, accessed January 8, 2026, https://www.silencershop.com/bpg-suppressor-cover-heavy.html

- Precision Underground Suppressor Insulators. Lifetime warranty! | Sniper’s Hide Forum, accessed January 8, 2026, https://www.snipershide.com/shooting/threads/precision-underground-suppressor-insulators-lifetime-warranty.6917645/

- StraightJacket surpressor cover/suppressor sleeve – Solids Solution Designs, accessed January 8, 2026, https://www.solidsolutiondesigns.com/product/thermal-suppressor-cover/

- Best Suppressor Covers [Hands-On Tested] – Pew Pew Tactical, accessed January 8, 2026, https://www.pewpewtactical.com/best-suppressor-covers/

- Thoughts on suppressor covers? : r/NFA – Reddit, accessed January 8, 2026, https://www.reddit.com/r/NFA/comments/1n56s7s/thoughts_on_suppressor_covers/

- Liberty’s Defense “straightJacket” Suppressor Cover – Dead Air Silencers, accessed January 8, 2026, https://deadairsilencers.com/product/libertys-defense-straightjacket-suppressor-cover/

- Liberty’s Defense StraightJacket Suppressor Cover, accessed January 8, 2026, https://www.talosdefense.com/libertys-defense-straightjacket-suppressor-cover

- Does this hurt the wrap? : r/NFA – Reddit, accessed January 8, 2026, https://www.reddit.com/r/NFA/comments/140bbw5/does_this_hurt_the_wrap/

- Silencerco heat wrap burn through? : r/NFA – Reddit, accessed January 8, 2026, https://www.reddit.com/r/NFA/comments/1k45rde/silencerco_heat_wrap_burn_through/

- Two stamp mk16: thoughts on suppressor shrouds vs covers in 2025? Mod-tac in photo, accessed January 8, 2026, https://www.reddit.com/r/NFA/comments/1nniyms/two_stamp_mk16_thoughts_on_suppressor_shrouds_vs/

- Sharing My Suppressor Cover Research : r/NFA – Reddit, accessed January 8, 2026, https://www.reddit.com/r/NFA/comments/1m53itc/sharing_my_suppressor_cover_research/

- Who’s running suppressor wraps and what’s your experience with the one you have? : r/NFA, accessed January 8, 2026, https://www.reddit.com/r/NFA/comments/1c7m197/whos_running_suppressor_wraps_and_whats_your/

- So, I have researched various suppressor covers. Liberty’s Defense, Burn Proof Gear, and Rifles I gave the burn proof gear a try around about 80 rounds rapid fire the strings melted off do anyone have any other suppressor cover recommendations I was going to go for the liberty defense : r/NFA – Reddit, accessed January 8, 2026, https://www.reddit.com/r/NFA/comments/1cwuyt0/so_i_have_researched_various_suppressor_covers/

- First time using the suppressor. A heat wrap might be a good investment : r/ar15 – Reddit, accessed January 8, 2026, https://www.reddit.com/r/ar15/comments/13uwr3u/first_time_using_the_suppressor_a_heat_wrap_might/

- Suppressor Cover | Silencer Heat Wrap – Armageddon Gear, accessed January 8, 2026, https://armageddongear.com/product/suppressor-cover/

- Armageddon Gear or Burn Proof Gear supressor covers? : r/NFA – Reddit, accessed January 8, 2026, https://www.reddit.com/r/NFA/comments/rpec5n/armageddon_gear_or_burn_proof_gear_supressor/

- [NFA] Armageddon Gear Suppressor Covers and accessories 15% off with code “AGPRS”, accessed January 8, 2026, https://www.reddit.com/r/gundeals/comments/mbfutx/nfa_armageddon_gear_suppressor_covers_and/

- Corset Suppressor Cover – By COLE-TAC – Liberty Precision Machine, accessed January 8, 2026, https://libertyprecisionmachine.com/product/corset-suppressor-cover-by-cole-tac/

- Corset™ Suppressor Cover | Cole-TAC Outdoor Gear, accessed January 8, 2026, https://www.cole-tac.com/product/corset-suppressor-cover/

- HTP Suppressor Cover | Cole-TAC Outdoor Gear, accessed January 8, 2026, https://www.cole-tac.com/product/htp-suppressor-cover/

- Cole-Tac Corset Suppressor Cover 7.5 x 1.5 Flat Dark Earth – MidwayUSA, accessed January 8, 2026, https://www.midwayusa.com/product/1023956235

- Rifles Only: HAD Suppressor Cover 8″ – BLK – Mile High Shooting Accessories, accessed January 8, 2026, https://www.milehighshooting.com/rifles-only-had-suppressor-cover-8-blk/

- HAD SUPPRESSOR COVER – Rifles Only, accessed January 8, 2026, https://riflesonly.com/had-suppressor-cover/

- Shot My Tab Gear Suppressor Cover | Sniper’s Hide Forum, accessed January 8, 2026, https://www.snipershide.com/shooting/threads/shot-my-tab-gear-suppressor-cover.6264284/

- Burn Proof Gear Suppressor Cover – Heavy | Up to 23% Off 4.4 Star Rating w – OpticsPlanet, accessed January 8, 2026, https://www.opticsplanet.com/burn-proof-gear-suppressor-cover-heavy.html

- Swaller suppressor covers : r/NFA – Reddit, accessed January 8, 2026, https://www.reddit.com/r/NFA/comments/1pfbimm/swaller_suppressor_covers/

- SWaller89 suppressor cover review : r/ar15 – Reddit, accessed January 8, 2026, https://www.reddit.com/r/ar15/comments/1916ivq/swaller89_suppressor_cover_review/

- SWALLER suppressor cover : r/PalmettoStateArms – Reddit, accessed January 8, 2026, https://www.reddit.com/r/PalmettoStateArms/comments/1o333zv/swaller_suppressor_cover/

- Tab Gear SASR: Adjustable Suppressor Cover – Mile High Shooting Accessories, accessed January 8, 2026, https://www.milehighshooting.com/tab-gear-sasr-adjustable-suppressor-cover/

- MOA STEALTH COVER – Weka Innovations, accessed January 8, 2026, https://www.wekatech.com/products/moa-stealth-silicone-suppressor-cover

- Weka Innovations MOA Stealth Silicone Suppressor Cover Excellent, FDE USA SHIP | eBay, accessed January 8, 2026, https://www.ebay.com/itm/167681364132

- (SAS1, SAS2, SAS3, SASR) Suppressor Anti-Mirage Shield – TAB Gear, accessed January 8, 2026, https://www.tabgear.com/products/sas1-sas2-sas3-sasr-suppressor-antimirage-shield

- Weka Innovations, accessed January 8, 2026, https://www.wekatech.com/

- Best suppressor cover? : r/ar15 – Reddit, accessed January 8, 2026, https://www.reddit.com/r/ar15/comments/1o7vsj8/best_suppressor_cover/