Well folks, I am taking the plunge into pre-charged pneumatic (PCP) air rifles. These are the airguns you see (both pistols and rifles) than have a high pressure air tank to propel the pellet. Now, I had to think long and hard about this. I live in a rural area and there aren’t any SCUBA/dive shops in my backyard to fill an intermediary air tank to then fill the rifle. I looked into high pressure air compressors (we’re talking 3-4,000 PSI here so this isn’t your average shop compressor) and the starting cost for the cheapest is about $1,100 and in the cost of the tank and the fittings and I was dead in the water.

Recently, I did more digging about hand air pumps. I had heard and read a few things about what a pain they are to work with and it turns out that is either flat out wrong or you bought a bad one. Now everyone is different. I’m 5′ 8″ and about 22o pounds plus not in that great of shape if I am to be completely hones so I paid close attention to what folks said and how they described their physical condition. Bottom line is that there are a ton of people out there using hand pumps.

So, I switched gears and started reading more about the various brands, the reviews they got, etc. From what I gathered, it came down to two pumps at the front of the pack – the Air Venturi G6 or the Hill Mk4. I then went around the forums, Amazon, Pyramyd Air and Air Depot reading comments, etc. Frankly, the Hill Mk4 gets better reviews plus it has an air dryer. Given how compressed air systems constantly produce water via condensation, I was sold. I ordered my Mk4 from Air Depot. For years, I have ordered from Pyramyd Air but Air Depot has great reviews and they had a great deal going for 10% off and free shipping when I ordered it.

Air Depot’s shipped the pump the same day via FedEx Ground and it arrived three days later. It was partially disassembled and I’d say it took about 10 minutes to put it together. I actually followed the directions and be sure to use wrenches on all fittings due to the air pressure. It comes with a small tube of silicone grease and I went ahead and lubed the shaft just to make sure it was ready – they recommend monitoring that.

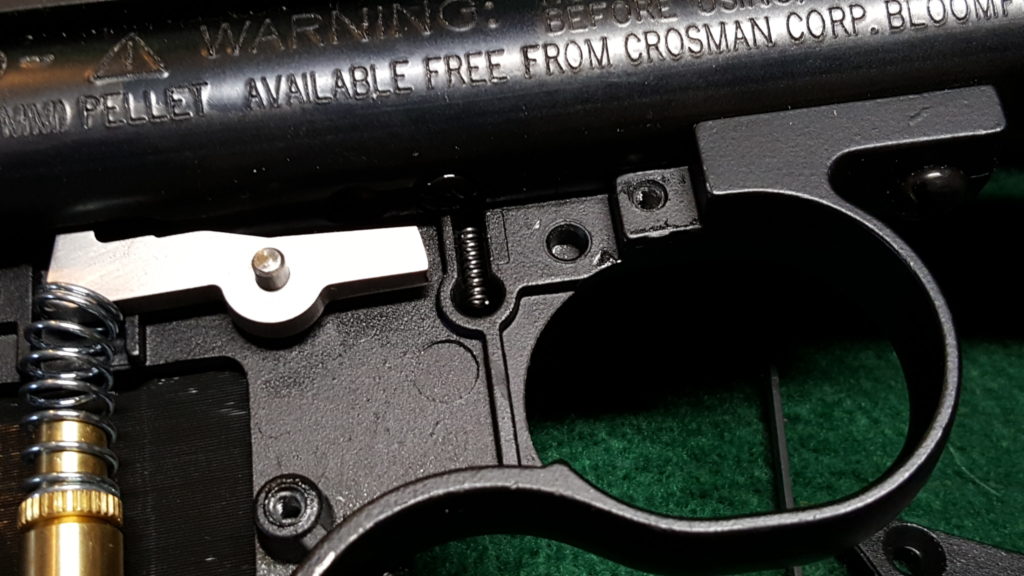

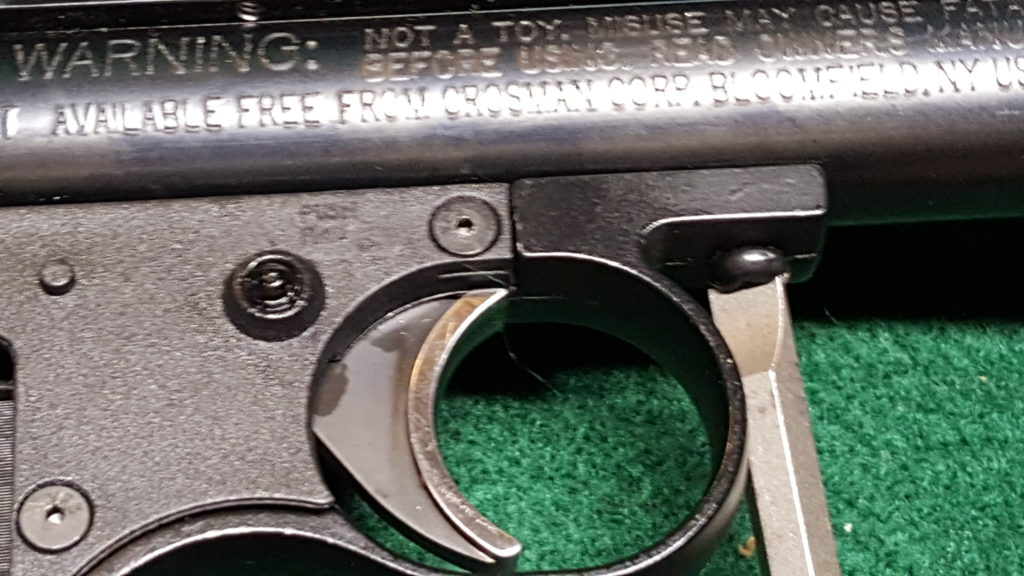

At the same time I bought the Hill, I bought a Hatsan Gladius Long bullpup in .22. I’ll write about the Gladius more later but it came with the fill probe to screw onto the Hill’s male threaded end fitting. I used wrenches to tighten things down really well, put the Gladius’ air cyliner in a cardboard box to cradle it so I could then pump air in. The hose on the Hill is really short and I suspect it is because you need to pump and pressurize that hose also before the check valve in the Gladius’ air cylinder will open and let air in.

It does take effort as you reach 200 bar (that’s 2900 PSI). The trick is to go slow and use your body weight to drive the handle down – not your arm muscles. I’d bend my knees with my arms locked and down I went. Don’t use your arms – let your weight do the work and speaking for myself, I have plenty of fat … I mean weight 🙂

Yes, it would take a real long time to fill the rifle if I let the cylinder go down to zero but the trick is to shoot a few rounds and keep the rifle in its ideal operating pressure range and refill when you get low — or shoot a few and top if off again. For example, with my Gladius, after six shots on power setting three, it then takes 30 pumps to take it back up to 200 bar – it’s not that hard – really. Why six shots? Well, the pressure was still in the green just now but towards the bottom so I topped it off and counted just to write this post.

To remove the pump from the cylinder, you unscrew a bleed valve knob on the back of the pump to relieve the pressure in the line. Do NOT try to remove the probe before the pressure is released.

The only con I have is that I wish that fill hose was a bit longer but I bet another guy would then say he wished it was shorter. The reason I’d like it longer is so I could lean my rifle against some thing and pump. I can’t do that today because the hose is too short. I’ll probably build a cradle for the rifle at some point vs. unscrewing the cylinder (and it was designed for that which is really cool by the way) and filling it.

I have a Huma regulator on order for the Gladius and will try it and write more about both the rifle and the regulator down the road. The purpose of this post is to recommend the Hill Mk4 pump and to clearly tell you that a hand pump absolutely can get you started in the world of PCP airguns. In fact, I’m kind of embarrassed that I held off due to hearsay until now and want to clear up the misinformation – a pump can definitely get you started. In fact, I do plan on getting a compressor some day but I am in no rush now.

January 25, 2018 Update: The pump is still going strong. I have topped off my Gladius at least 30-40 times – I try to keep the pressure between 160-190 bar – every time the 10 round mag is empty or running low, I top the gun off and add pellets. I just did a bit of preventive maintenance and applied silicone grease to the shaft of the pump and the fill probe. I am still very happy and recommend this pump.

September 24, 2018 Update: Still no problems. I can’t begin to guess how many times I have topped off my Gladius now. I did grease the shaft again just to be safe. I also keep a very light film on the fill probe and keep the probe wrapped in a plastic bag when not in use to keep dirt off it. I shoot two magazines (20 rounds) and then top off. It’s as simple as that.

February 10, 2020 Update: Had one of the O-rings on the fill tube fail and had to replace it a few months ago. Am keeping the probe and pump shaft lubricated with silicone grease.

6/29/2020 Update: Still very happy with the Hill. We now have replacement fill-probe O-rings and caps to keep your fill probe clean. Click here to learn more.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, we are only paid if there is an affiliate program such as Avantlink, Impact, Amazon and eBay and only if you purchase something. If you’d like to directly contribute towards our continued reporting, please visit our funding page.