In this step, I’ll install the bolt catch. This is the part that catches the bolt when the magazine is empty or the operator wants to lock the weapon open. In terms of risk, this step has probably caused more blemished receivers than any other. What I hope to show you is a method to minimize that.

The assembly is made up of the catch itself, a cross pin that secures it in the receiver, a spring and the bolt catch buffer. In this post, I am actually installing a Strike Industries bolt catch. I like to have a slightly larger paddle to operate the catch and Strike model is a nice size. If you ever want a giant paddle, Wilson makes one but it is just too big for my taste.

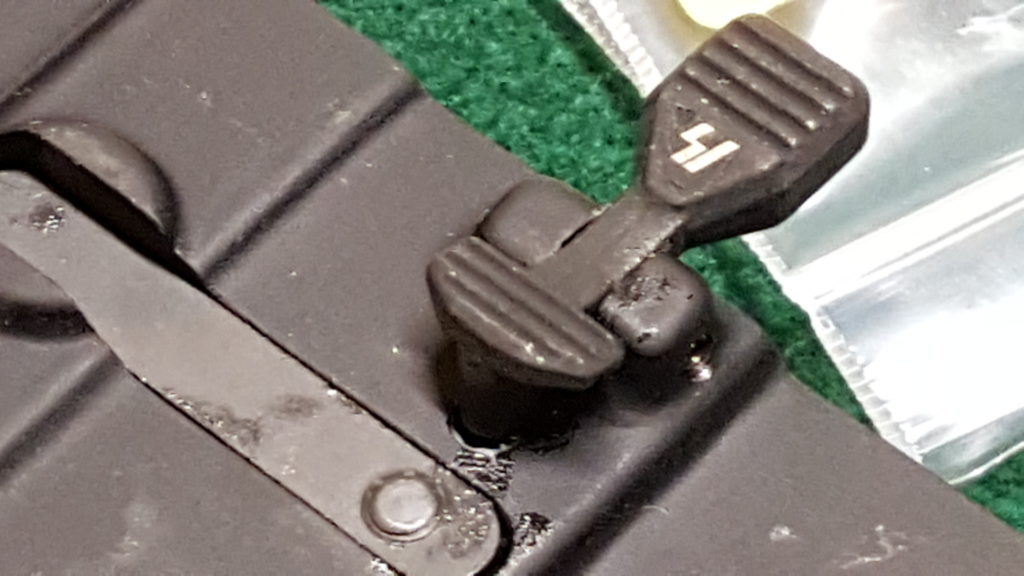

Where we are working on the receiver is right here – just above the mag catch:

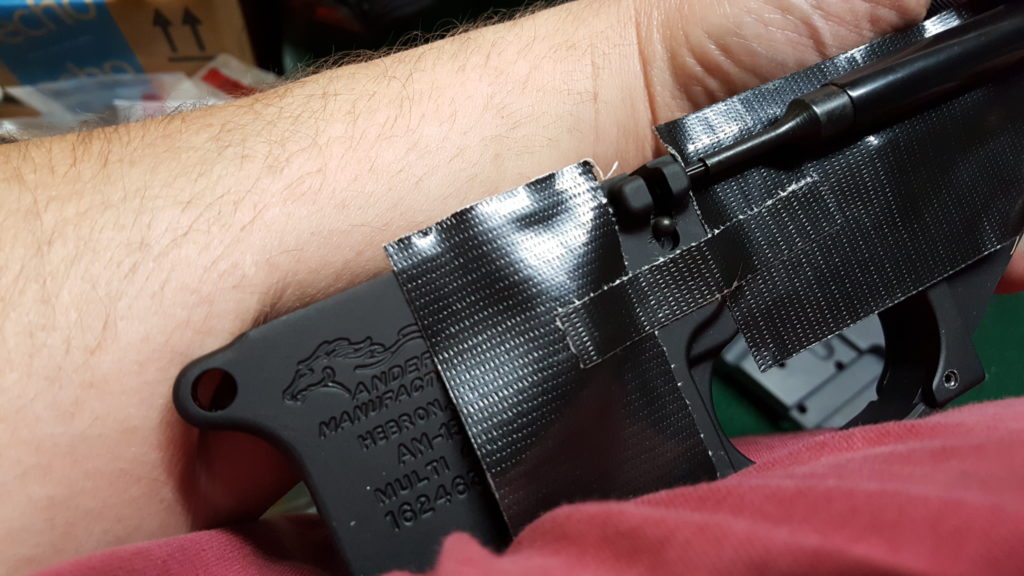

Now, this step is really risky. One slip and you will mar your receiver so take a minute and put some duct tape on just in case. I like duct tape because it is thick and sticks really well. I’ve used other types of tape in the past and it really is just cheap insurance. If you do this and what you use is up to you. You are mainly worried about the receiver, to the right of the humps/lobes where the catch is going to be installed.

Now I use three punches for this. I bought two rubber coated mag catch punches from Wheeler. They work but I wish they were longer and you still need a third to make it easy. Let me explain a bit more. The Wheeler punches are half circle designs which gives you better clearance but I still use my long Astro Pneumatics 1/8″ punch to reach down and drive the pin the rest of the way in. Like I said though, you do need three punches for this.

Ok, so first take the roll pin starter punch and install the pin on the right side part way. By getting it started you have less to try and mess with as the assembly comes together. See how the punch is right next to the receiver? You need to lightly tap this with a small hammer to drive it in while not hitting your receiver – this is why the tape is cheap insurance.

I like to put a dab of grease in the hole to hold everything gently in place. This is not a normal step and just something I do. You then insert the spring first and the buffer on top. You’ll notice with the AR design that a spring always has a detent or buffer between it and a moving surface to protect the spring.

Next, I use the roll pin punch from Wheeler to align bolt catch and hold it in place so the roll pin can be driven further in. If you do not use something to align the catch holes for the pin you will drive yourself nuts. Another option is to use a 3/32 drill bit’s smooth end to help line things up by inserting it through the front hump.

Next, you need to use the roll pin punch and a small hammer to drive the pin the rest of the way in. You can use the Wheeler block to hold the receiver or whatever works for you. Having a firm support makes it much easier. My Astro Pneumatic roll ping punches are long. My 1/8″ punch is 7″ long so I would recommend looking for something like that so you can clear the receiver when you are hammering the pin all the way in. I don’t think the Astro set I have is made any longer because I could not find it on Google to share with you. I use my Tekton punches.

See how much longer the Astro Pneumatics roll pin punch is? This lets me reach in and easily drive the roll pin in the final bit of the way. I can do the same with my Tekton gunsmith set’s punches.

See how much longer the Astro Pneumatics roll pin punch is? This lets me reach in and easily drive the roll pin in the final bit of the way. I can do the same with my Tekton gunsmith set’s punches.

With that you are done. You can function test the unit by pushing on the top paddle. You should feel the spring compress and release as you rock the catch back and forth.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, I may be paid via an affiliate program such as Avantlink, Impact, Amazon and eBay.

AR Parts Sources

There are a lot of reputable AR parts vendors online but beware of eBay and bargain basement dealers that sell airsoft parts and tell you they will stand up to firearm use – they will not. At any rate, here are my top sources of AR parts: