The .50 Browning Machine Gun (12.7×99mm NATO) cartridge represents a singular anomaly in the history of military ordnance: a munition conceived in the frantic final months of World War I to counter primitive armor that has not only survived but thrived to become the premier heavy-engagement standard of the 21st century. This report, synthesized from the distinct yet converging perspectives of the small arms industrial analyst, the heavy-caliber engineer, and the special operations sniper, provides a definitive audit of the .50 BMG ecosystem. It explores the cartridge’s trajectory from a crude anti-tank solution to a highly sophisticated multi-mission system capable of surgical anti-personnel precision and devastating anti-materiel effects.

From an industrial standpoint, the .50 BMG is a global logistical constant. It anchors the heavy weapons capabilities of every NATO member and countless non-aligned nations, creating a manufacturing base that spans from Lake City in the United States to Raufoss in Norway, and from Pretoria in South Africa to Sao Paulo in Brazil. This ubiquity provides it with an inertia that technically superior modern cartridges, such as the.416 Barrett or.408 CheyTac, have failed to overcome. The report analyzes the global market dynamics, highlighting how manufacturers like Nammo and General Dynamics have evolved the projectile from simple lead-core ball to complex, multi-stage pyrotechnic payloads like the Mk 211 Mod 0, effectively miniaturizing autocannon lethality into a rifle-caliber package.

Technically, the cartridge is a masterclass in thermodynamic robustness. Designed by John Moses Browning and Winchester engineers, the case capacity and pressure specifications (54,000+ psi) were decades ahead of their time, allowing for the eventual transition from extruded stick propellants to high-energy double-base spherical powders. This report details the internal ballistics that allow a 45-gram projectile to remain supersonic beyond 1,500 meters, and the engineering challenges of managing the immense recoil impulse—upwards of 40 lbs of free recoil energy—through advanced muzzle brake fluid dynamics and buffer systems.

Operationally, the .50 BMG has undergone a radical doctrinal shift. For the first fifty years of its existence, it was strictly an area-suppression weapon, designed to create a “beaten zone” of fire. The Vietnam War marked a turning point, where the improvisation of USMC Gunnery Sergeant Carlos Hathcock birthed the concept of heavy-caliber sniping. This evolution culminated in the modern era of the Anti-Materiel Rifle (AMR), defined by platforms like the Barrett M82 and the McMillan Tac-50. The analysis contrasts the loose-tolerance reliability required for the M82’s semi-automatic suppression role against the micrometer-precision rigidity required for the Tac-50 to achieve world-record eliminations at distances exceeding 3,500 meters.

In conclusion, while the .50 BMG faces ballistic competition from purpose-built long-range cartridges that offer flatter trajectories and higher supersonic limits, its versatility remains unrivaled. No other small arm combines the ability to sever a radar mast, disable a light armored vehicle, and neutralize a high-value target at two kilometers with a single logistical footprint. The .50 BMG is not merely a cartridge; it is a century-old institution of heavy ordnance that continues to define the geometry of the modern battlefield.

1. Genesis of a Titan: The 13.2mm TuF and the Birth of the .50 BMG

The inception of the .50 Browning Machine Gun (BMG) cartridge was not the product of a leisurely peacetime research and development cycle, but rather a frantic, reactionary engineering effort driven by a battlefield crisis. By late 1917, the Western Front of World War I had witnessed a technological paradigm shift: the introduction of the tank and the armored aircraft. These new engines of war rendered the standard rifle-caliber machine guns of the day—such as the .30-06 Springfield, the British .303, and the French 8mm Lebel—obsolete against hardened targets. The infantryman’s rifle capability had hit a “hard” ceiling, bouncing harmlessly off the steel skins of the new mechanized age.1

1.1 The German Catalyst: 13.2mm Tank und Flieger (TuF)

The specific catalyst for the American heavy machine gun program was the Imperial German response to British armor. In 1918, Germany introduced the Mauser 13.2mm TuF (Tank und Flieger, translating to “Tank and Aircraft”). This cartridge was the world’s first dedicated anti-materiel round, designed specifically to defeat the primitive armor of Allied tanks and the engine blocks of low-flying aircraft.

The 13.2mm TuF was a massive cartridge, propelling a 795-grain (51.5 gram) hardened steel projectile at approximately 2,600 feet per second. It was capable of penetrating roughly 20-25mm of steel plate at close ranges .3 While the German Tankgewehr M1918 anti-tank rifle that fired this round was a crude, single-shot weapon that punished the shooter with brutal recoil—often breaking collarbones—the terminal ballistics of the 13.2mm projectile caught the sharp attention of Allied commanders. General John J. Pershing, commander of the American Expeditionary Force, recognized a critical capability gap: the U.S. Army lacked a weapon system that could match the German TuF’s ability to interdict armor at standoff distances.2

Pershing issued a direct requirement to the Army Ordnance Department: develop a machine gun caliber of at least 0 .50 inches (12.7mm) with a muzzle velocity of at least 2,700 feet per second (fps). The directive was clear—the US military needed a heavy projectile that could fly flat and hit hard, bridging the gap between the .30 caliber machine gun and the 37mm cannon.1

1.2 Browning and Winchester: The Engineering Scale-Up

The task of developing this new weapon system fell to the legendary gun designer John Moses Browning and the ballistics engineers at Winchester Repeating Arms Company. The initial engineering approach was deceptive in its simplicity: scale up the existing, successful .30-06 Springfield cartridge.

Winchester and Frankford Arsenal began by geometrically expanding the .30-06 case dimensions to accommodate a.510-inch diameter bullet. However, physics did not scale linearly. The initial prototypes failed to meet Pershing’s strict velocity requirements, achieving only 2,300 fps. The propellant technology of 1918—primarily nitrocellulose-based stick powders—struggled to push the heavy 800-grain projectiles at the desired speeds without creating dangerous chamber pressures that would rupture the brass case or damage the firearm.2

The breakthrough came from the enemy. It was the capture of German 13.2mm TuF ammunition that provided the necessary ballistic benchmark. Winchester engineers analyzed the German ballistics, dissecting the TuF rounds to understand the case volume to bore volume ratio. They adjusted their case design, increasing the powder capacity and refining the propellant loads to match the performance of the Mauser round.2 The final result was a rimless, bottlenecked cartridge with a case length of 3.91 inches (99mm) and an overall length of 5.45 inches.

A critical design decision occurred during this phase regarding the case rim. Winchester initially experimented with a rimmed cartridge, similar to the German TuF, intending it for use in an anti-tank rifle. However, General Pershing, looking forward to the need for high-volume automatic fire, insisted on a rimless design. This decision was prescient; a rimmed cartridge would have severely complicated the feeding mechanisms of belt-fed machine guns, potentially causing rim-lock and feed jams. By focusing on the machine gun role and mandating a rimless architecture, Pershing ensured the .50 BMG would function reliably in the high-speed extraction and feeding cycles of automatic weapons, securing its future versatility.2

1 .3 The Evolutionary Timeline of the .50 BMG

The development of the .50 BMG did not stop with its adoption in 1921. It has evolved through distinct phases, each characterized by technological leaps in platform and ammunition.

- 1918 (Concept): General Pershing requests a .50 caliber heavy machine gun to counter German armor, influenced by the Mauser 13.2mm TuF.

- 1921 (Adoption): The “Machine Gun, Caliber .50, M1921” enters service. The cartridge is standardized, primarily for anti-aircraft and anti-vehicle use.

- 1933 (The Ma Deuce): The M2HB (Heavy Barrel) is introduced, solving the overheating issues of earlier water-cooled or light-barrel variants. This platform becomes the universal standard for US forces.

- 1967 (The Sniping Pivot): In Vietnam, USMC Gunnery Sergeant Carlos Hathcock mounts a Unertl scope on an M2, recording a kill at 2,500 yards. This proves the cartridge’s precision potential, distinct from the machine gun’s loose tolerances.

- 1982 (The AMR Era): Ronnie Barrett designs the M82 in his garage, creating the first shoulder-fired, semi-automatic .50 BMG rifle. This democratizes heavy firepower for the infantry squad.

- 1990 (Desert Storm): The US Military purchases the M82A1 in significant numbers for EOD (Explosive Ordnance Disposal) and anti-materiel roles, validating the concept of the “Heavy Sniper.”

- 2002-2017 (The Precision Record Breakers): Canadian snipers using the bolt-action McMillan Tac-50 set successive world records (2,430m and 3,540m), utilizing match-grade ammunition to push the cartridge to its aerodynamic limits.

- 2014 (Future Tech): DARPA tests the EXACTO guided .50 caliber bullet, demonstrating the potential for smart munitions in small arms.

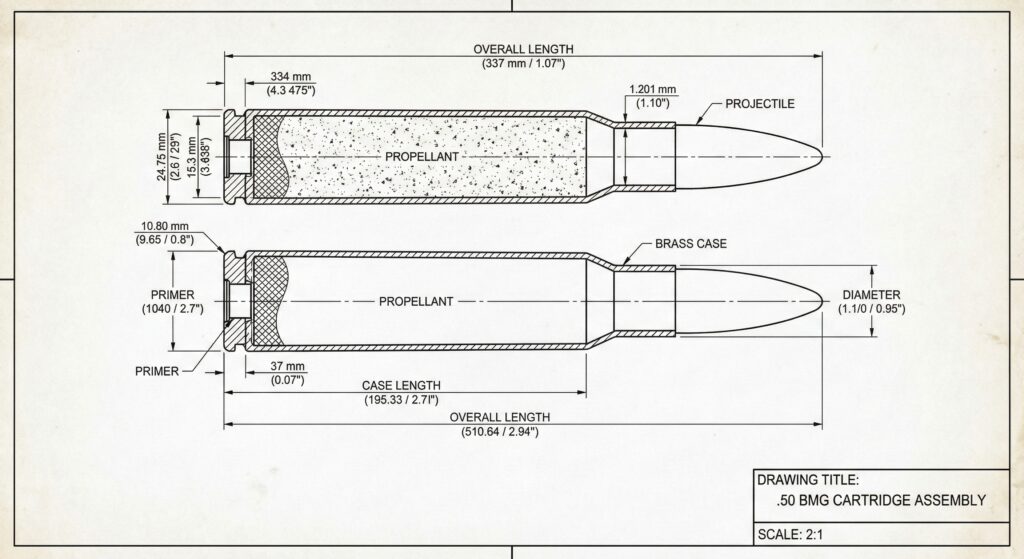

2. Internal Ballistics & Cartridge Engineering

To understand the longevity of the .50 BMG, one must analyze it not just as “big ammo,” but as a robust thermodynamic system. The cartridge case is a massive pressure vessel designed to contain a deflagration event converting solid propellant into high-pressure gas in milliseconds, managing forces that would disintegrate lesser mechanisms.

2.1 Case Geometry and Volumetric Efficiency

The .50 BMG case is a masterclass in volumetric efficiency for its era. It has a water capacity of approximately 292.8 grains (18.97 cm³), a massive volume compared to the ~68 grains of a .30-06.5 This volume is necessary to house the slow-burning propellants required to accelerate heavy projectiles down long barrels (36 to 45 inches in machine guns, 29 inches in rifles) without exceeding pressure limits.

- Shoulder Angle: The cartridge features a relatively shallow shoulder angle of 15 degrees (30 degrees included angle).6 This design choice prioritizes smooth feeding in belt-fed weapons over the sharper shoulders found in modern precision cartridges (like the 35-40 degree shoulders of the.408 CheyTac or Ackley Improved rounds). While excellent for machine guns, this shallow angle can contribute to case stretching during firing, a factor that reloaders of precision bolt-action .50 BMG rifles must manage carefully to prevent case head separation.

- Pressure Limits:

- US Army (TM43-0001-27): Lists the maximum average chamber pressure at 54,923 psi (378.68 MPa), with proof pressures allowed up to 65,000 psi.5

- C.I.P. (Commission Internationale Permanente): Sets the Pmax at 3,700 bar (approx. 53,664 psi).6

- SAAMI: Interestingly, the Sporting Arms and Ammunition Manufacturers’ Institute (SAAMI) does not historically hold a specification for the .50 BMG, leaving it to military specs and CIP. The industry generally adheres to the military limits to ensure safety in the diverse range of surplus and commercial actions available.7

2.2 Propellant Evolution: The Move from Sticks to Spheres

The evolution of propellant technology has been critical in unlocking the .50 BMG’s potential and maintaining its relevance. The shift from extruded stick powders to spherical ball powders represents a major industrial transition.

IMR 5010 (The Legacy Extruded Powder):

For decades, the standard propellant for US military .50 BMG loads was IMR 5010, a single-base, extruded stick powder.

- Characteristics: It consists of small cylindrical grains. Being single-base (nitrocellulose only), it burns relatively cool, which is beneficial for barrel life in machine guns firing rapid strings.

- Handloading Status: It was reliable and provided consistent velocities for the M33 ball rounds. However, extruded powders can be difficult to meter precisely in high-speed automated loading machinery, leading to slight variances in charge weight. It became a favorite of civilian handloaders due to cheap surplus availability, though supplies have dried up in recent years.8

WC860 and WC869 (The Modern Sphericals):

Modern ammunition, particularly from manufacturers like Winchester (Olin), utilizes double-base spherical (ball) powders such as WC860 and its refined successor, WC869.

- Industrial Advantages: Ball powders flow like water. This allows for incredibly consistent charge weights on industrial loading lines, reducing the standard deviation in muzzle velocity for mass-produced ammo.

- Energy Density: They are double-base (containing nitroglycerin), which provides higher energy density. This allows for the same velocity with a slightly smaller charge volume, or higher velocities within the same case capacity.10

- Engineering Challenge: Ball powders can be harder to ignite and more temperature-sensitive than stick powders. In extreme cold, they can exhibit “hang-fires” or incomplete combustion. This required the development of hotter, more brisant primers (the #35 Arsenal Primer) to ensure reliable ignition in arctic conditions.4

- Ballistic Optimization: The St. Marks Powder division of General Dynamics developed high-energy propellants specifically to utilize the excess case capacity of the .50 BMG. By optimizing the burn speed, they can maintain peak pressure longer down the barrel, thereby increasing velocity without exceeding the Pmax limit of the receiver.10

2 .3 Barrel Dynamics: The Twist Rate Debate

A critical, often overlooked aspect of .50 BMG engineering is the rifling twist rate, which dictates the stability of the projectile.

Standard Military Twist (1:15):

The standard M2 machine gun barrel features a twist rate of 1 turn in 15 inches (1:15). This slow twist is perfectly adequate for stabilizing the standard 647-grain M33 ball projectile and the 622-grain M8 API.5 It imparts enough gyroscopic stability to prevent tumbling but not so much that it exaggerates orbital decay or “spin drift” at extreme ranges for these specific projectile lengths.

The Precision Shift (1:8 to 1:13):

As the .50 BMG transitioned to a long-range precision role, snipers began using heavier, longer, low-drag bullets.

- Civilian ELR Evolution: Civilian extreme long-range shooters often utilize solid copper monolithic projectiles. Because copper is less dense than lead, a 750-grain or 800-grain copper bullet is significantly longer than a lead-core bullet of the same weight. Length is the primary factor dictating required twist rate. Therefore, modern custom barrels often feature 1:13 or even 1:8 twist rates to stabilize these “telephone pole” projectiles.12

- The Conflict: This creates a logistical bifurcation. Military snipers are often limited to the ammunition their logistics chain provides (typically optimized for 1:15), while civilian shooters can optimize their barrel twist for specific heavy projectiles. Firing a very long monolithic solid through a standard 1:15 military barrel can result in keyholing (tumbling) and catastrophic loss of accuracy.14

3. The Projectile Ecosystem: From Ball to Raufoss

The immense versatility of the .50 BMG lies in the sheer volume of its projectile. Unlike a .30 caliber bullet, which has limited space for internal components, a .50 caliber projectile (typically 600-800 grains) acts as a capacious delivery vehicle for complex payloads. This allows for a diverse taxonomy of ammunition types.

3.1 Standard Munitions: The Logistics Backbone

- M33 Ball: The ubiquitous “general purpose” round found in ammo cans across the globe. It utilizes a 661-grain projectile with a mild steel core inside a copper jacket, with a lead point filler. It is designed for anti-personnel use and light unarmored targets. While not armor-piercing by designation, the sheer mass and velocity allow it to penetrate significant material, such as concrete blocks or heavy timber, simply through kinetic energy.5

- M17 Tracer: Identified by a red/brown tip (or sometimes orange for the M10 variant). This round contains a pyrotechnic charge in the base that burns for approximately 2,000+ yards, allowing gunners to “walk” fire onto targets. In sniper applications, tracers are rarely used due to the trajectory mismatch with ball ammo—as the tracer compound burns off, the bullet’s mass changes in flight—and the risk of revealing the shooter’s position.4

3.2 The Armor Piercing Lineage (AP, API, API-T)

- M2 AP (Black Tip): The WWII-era standard. It utilizes a hardened manganese-molybdenum steel core (approx. 0.42 inches in diameter). It can penetrate roughly 0.75 inches (19mm) of face-hardened armor at 500 meters. This round is highly prized by surplus collectors for its penetration capability.17

- M8 API (Silver Tip): Armor-Piercing Incendiary. This replaced the M2 as the standard combat round. It combines the hardened steel core of the M2 with an incendiary composition (IM-11) in the nose, located in front of the core. Upon impact, the jacket peels back, compressing and igniting the incendiary mix. This flash is designed to ignite fuel tanks or hydraulic lines while the core continues to penetrate the armor. It is the standard “combat mix” component in M2 belts (typically 4 M8s to 1 M20).5

- M20 API-T (Red/Grey Tip): This is effectively an M8 API with a tracer element added to the base. It allows the gunner to see the trajectory while delivering armor-piercing and incendiary effects. It produces a red trace visible out to 1,800 yards.17

3 .3 The Game Changer: Saboted Light Armor Penetrator (SLAP)

In the 1980s, the US Marine Corps sought to extend the anti-armor capability of the M2HB without adopting a new weapon system (like a 20mm cannon). The result was the M903 SLAP (Saboted Light Armor Penetrator).

- Design Physics: The M903 fires a sub-caliber .30 inch (7.62mm) tungsten penetrator wrapped in a .50 caliber plastic (Ultem) sabot. By reducing the projectile mass to ~355 grains while using the full propellant load of a .50 BMG case, the muzzle velocity skyrockets to over 4,000 fps (1,219 m/s).5

- Performance: This velocity allows for an incredibly flat trajectory and vastly increased kinetic energy at the point of impact. The tungsten penetrator can defeat 0.75 inches (19mm) of high-hardness armor at 1,500 meters—three times the effective range of M2 AP against the same target. This allows an M2 gunner to engage light APCs (Armored Personnel Carriers) that would otherwise be immune to .50 caliber fire.20

- Critical Warning: SLAP rounds should never be fired through a muzzle brake (like on an M82 or M107). The plastic sabot is designed to separate immediately upon exiting the muzzle. If it catches a baffle in the muzzle brake, it can cause catastrophic failure of the weapon and severe injury to the shooter. SLAP is strictly for M2 machine guns with open muzzles or flash hiders.21

3.4 The Crown Jewel: Nammo Raufoss Mk 211 Mod 0

The Mk 211 Mod 0, developed by Nammo Raufoss AS in Norway, is widely considered the pinnacle of .50 BMG lethality. It is a “Multipurpose” (MP) round, identified by a green tip with a white or grey ring.5

Internal Anatomy & Mechanism:

The Raufoss is an engineering marvel that fits a complex ignition train into a 12.7mm shell. Unlike traditional explosive rounds that use a mechanical fuze (which is complex, expensive, and prone to failure at small scales), the Mk 211 uses a pyrotechnic ignition train initiated by the shock of impact.22

- Impact: The round strikes the target.

- Incendiary/Explosive Initiation: The nose contains an incendiary and high-explosive mix (RDX and Comp A). The shock of impact compresses this mix against the penetrator, initiating detonation.

- Penetration: A tungsten carbide core sits behind the explosive charge. It punches through the armor of the target.

- Zirconium After-Effect: Zirconium powder is included in the composition. As the round penetrates, the zirconium ignites, creating a shower of burning particles.24

Terminal Effect:

Upon impact, the round detonates, blasting a hole in the outer skin of the target (e.g., a helicopter fuselage or light vehicle door). The tungsten core continues through the armor, while the zirconium and explosive charge follow through the hole, creating a “shotgun effect” of high-velocity fragments and fire inside the vehicle. It effectively replicates the damage of a 20mm cannon shell in a .50 caliber package, providing “anti-materiel” capability that far exceeds simple kinetic energy.22

4. The Machine Gun Era: M2 to Present

The .50 BMG was born for the machine gun, and the Browning M2 remains its primary platform. The genius of John Browning’s design lies in its scalability and robustness.

4.1 The M2HB “Ma Deuce”

The M2 is a recoil-operated, air-cooled machine gun.

- Headspace and Timing: Historically, the M2 required operators to manually set headspace and timing using a gauge every time the barrel was changed. If done incorrectly, the gun could fail to fire or explode. This was a significant training burden and a point of failure in combat stress.16

- The QCB Upgrade: Modern variants, like the M2A1, feature a Quick Change Barrel (QCB) system with fixed headspace and timing. This engineering update modernized the century-old design, removing the need for gauges and allowing for barrel swaps in seconds, significantly increasing sustained fire capability.

4.2 The Failed M85

It is worth noting the failures to replace the M2. The M85 machine gun, designed for use inside the cramped turrets of the M60 Patton tank, attempted to reduce the receiver length. However, it was plagued by reliability issues and complex maintenance requirements. It serves as a cautionary tale: the sheer length of the .50 BMG cartridge dictates a certain receiver geometry. Compressing the action (as the M85 tried to do) reduces the operating margin for feeding and extraction, leading to jams. The M2’s massive receiver is not a flaw; it is a requirement for reliability with such a large cartridge.18

5. The Birth of Long Range Sniping: Vietnam to Falklands

The transition of the .50 BMG from a machine gun cartridge to a sniper cartridge is a story of field improvisation driving doctrine.

5.1 The Unlikely Pioneer: Carlos Hathcock

During the Vietnam War, the .50 BMG was strictly a heavy machine gun round. However, USMC Gunnery Sergeant Carlos Hathcock recognized the inherent ballistic potential of the heavy projectile. In a famous instance of field improvisation, Hathcock mounted an 8-power Unertl telescopic sight (bracketed with his own custom-fabricated mount) onto an M2 Browning Machine Gun used in single-shot mode.25

In February 1967, Hathcock used this “jury-rigged” system to engage a Viet Cong guerilla transporting weapons on a bicycle. The range was approximately 2,286 meters (2,500 yards). Hathcock fired, knocking the rider off the bike. This shot stood as the longest confirmed sniper kill in history for over 35 years.26

Insight: Hathcock’s success proved that the cartridge was capable of extreme long-range (ELR) precision, even if the platform (a loose-tolerance machine gun) was not designed for it. The sheer mass of the bullet allowed it to buck the wind and retain lethality far beyond the range of the standard 7.62mm sniper rifles of the day. This event planted the seed for the development of a purpose-built .50 caliber rifle.

5.2 The Forgotten Progenitor: The RAI 500

While Barrett gets the glory, the Research Armament Industries (RAI) Model 500 was the true grandfather of the American .50 caliber sniper rifle. Designed by Jerry Haskins in 1981-1982, the RAI 500 was a bolt-action rifle specifically built to meet a US military requirement for long-range interdiction.

- Design: It was a minimalist design, featuring a breakdown capability for transport and a massive muzzle brake. It was used by US Marines in Beirut and Grenada in small numbers.28

- Legacy: Although RAI eventually folded, the design principles of the Model 500—a dedicated single-shot or bolt-action platform with a free-floating barrel—directly influenced subsequent designs like the McMillan Tac-50. Haskins proved that a man-portable rifle could harness the .50 BMG’s power effectively .30

6. The Anti-Materiel Revolution: The Barrett Era

6.1 The Barrett M82 (Light Fifty)

In the early 1980s, Ronnie Barrett, a photographer with no formal engineering training, designed a semi-automatic, shoulder-fired .50 BMG rifle in his garage. His design, the M82, used a short-recoil operation.

- Mechanism: When fired, the barrel and bolt recoil backward together for a short distance (about an inch) inside the receiver. This movement absorbs a massive amount of the recoil energy. The bolt then unlocks, and the barrel returns to battery while the bolt continues rearward to eject the spent case.

- Recoil Mitigation: This system, combined with the iconic “arrowhead” muzzle brake, reduced the felt recoil to manageable levels—comparable to a 12-gauge shotgun. This allowed for rapid follow-up shots, a critical capability for engaging convoys or multiple targets .32

- Adoption: The M82 (later standardized as the M107) saw its first major combat use in Operation Desert Storm (1990-1991). The US Marine Corps and Army purchased hundreds to deal with Iraqi light armor and unexploded ordnance (EOD). It revolutionized the role of the sniper, giving them “anti-materiel” capability—the ability to destroy hardware, not just personnel .32

6.2 Accuracy Limitations

While the M82 provided immense firepower, it had a flaw: accuracy. The recoiling barrel meant that the barrel moved before the bullet left the muzzle (microscopically) and never returned to the exact same position for the next shot. The M82 is generally considered a 2.5 – 3 MOA (Minute of Angle) rifle. It is precise enough to hit a truck engine at 1,500 meters, but often lacks the consistency to hit a human target at that range .35

7. The Precision Era: Tac-50 & Records

For pure anti-personnel sniping at extreme ranges, the moving barrel of the M82 was unacceptable. This led to the adoption of rigid, bolt-action platforms.

7.1 The McMillan Tac-50

The McMillan Tac-50 is a bolt-action rifle with a heavy, match-grade, free-floating barrel and a specialized stock.

- Rigidity: Because the barrel is fixed and the action is manually operated, there are fewer moving parts to disrupt the harmonics of the shot.

- Accuracy: With match-grade ammunition, the Tac-50 is capable of 0.5 MOA accuracy. This is the difference between hitting a truck and hitting a helmet at a mile .36

- The Records: It was with a Tac-50 that Canadian snipers shattered Hathcock’s record.

- 2002: Rob Furlong (PPCLI) achieved a kill at 2,430 meters (2,657 yards) in Afghanistan .37

- 2017: An unnamed JTF2 operative achieved a kill at a staggering 3,540 meters (3,871 yards) in Iraq, engaging an ISIS fighter. The bullet flight time was approximately 10 seconds. This shot effectively redefined the maximum effective range of small arms fire .36

7.2 The “Food” for the Rifles: Match Grade Ammunition

While the M2 machine gun is content with mass-produced M33 ball, a sniper rifle is only as good as its ammo.

- M1022 Long Range Sniper Ammunition: Developed specifically for the M107 and Tac-50, this round features a projectile with a green coating (no tip color). It is optimized for accuracy, using a specialized bullet that is trajectory-matched to the Mk 211 Raufoss but without the expensive explosive payload. It is designed to remain supersonic out to 1,600 meters.5

- Hornady A-MAX: The gold standard for civilian and law enforcement precision. The 750-grain A-MAX features an aluminum tip (to prevent deformation in the magazine and standardize the meplat) and an ultra-high ballistic coefficient (G1: 1.050). This bullet is capable of staying stable through the transonic zone, a critical factor for hits beyond 2,000 yards.40

- Lead vs. Copper: There is a growing shift toward solid copper (monolithic) projectiles, such as those from Barnes or Cutting Edge Bullets.

- Pros: Perfect concentricity (lathe-turned), better penetration on hard targets.

- Cons: Lower density than lead means the bullet must be longer to achieve the same weight. This requires faster twist rates (1:13 or 1:9) than standard military barrels (1:15), leading to stabilization issues in legacy rifles.42

8. Ballistic Rivals & The Future of Heavy Caliber

Despite its dominance, the .50 BMG is inherently an inefficient cartridge for pure long-range trajectory. Its large diameter creates significant drag, and its velocity (approx. 2,800 fps) is relatively modest compared to modern magnums.

8.1 The Challengers:.416 Barrett and.408 CheyTac

To surpass the .50 BMG, engineers looked to “neck down” the case to fire a smaller, more aerodynamic bullet at higher speeds.

- .416 Barrett: Developed by Chris Barrett (Ronnie’s son), this cartridge uses a shortened .50 BMG case necked down to.416 caliber.

- Advantage: It fires a solid brass bullet at ~3,150 fps. The projectile stays supersonic well past 2,500 yards, whereas the .50 BMG often goes transonic (and thus unstable) around 1,600-1,800 yards. This makes hitting targets at 2,000+ yards significantly easier.44

- Legal/Logistics: It was also designed to be legal in jurisdictions (like California) where .50 BMG is banned.46

- .408 CheyTac: A purpose-built cartridge that sits between .338 Lapua and .50 BMG. It offers a ballistic coefficient superior to both, maintaining supersonic flight to nearly 2,200 meters. However, it lacks the anti-materiel payload capability of the .50 BMG.47

The Verdict: While the.416 and.408 are superior ballistically for hitting paper or personnel at 2 miles, they cannot match the .50 BMG’s payload. You cannot fit a meaningful explosive/incendiary charge into a.408 or.416 bullet. Therefore, military forces retain the .50 BMG for its ability to destroy trucks and radar dishes, while specialized sniper teams may adopt the smaller calibers for pure anti-personnel work.

8.2 Future Tech: EXACTO

The Defense Advanced Research Projects Agency (DARPA) initiated the EXACTO (Extreme Accuracy Tasked Ordnance) program to develop a self-steering .50 caliber bullet.

- Mechanism: The bullet utilizes optical sensors and aero-actuation (tiny fins) to adjust its path in flight, correcting for wind and target movement.

- Status: Successful live-fire tests were conducted in 2014/2015, showing the bullet turning in mid-air to hit moving targets. However, the program has since gone quiet, likely transitioning to classified operational testing or shelved due to cost.48

9. Global Industry & Manufacturing Base

The .50 BMG is not just a US asset; it is a global standard.

- USA: Olin Winchester (operating the Lake City Army Ammunition Plant) is the primary supplier for the US military, producing millions of M33, M8, and M20 rounds annually .50

- Europe: Nammo (Norway/Finland) is the undisputed leader in high-performance specialty rounds like the Mk 211. Their Raufoss facility is the sole source for genuine Mk 211 technology.

- France: Nexter (now KNDS France) produces 12.7mm ammunition for the Leclerc tank’s coaxial machine gun and the new Griffon and Serval armored vehicles, which utilize remote weapon stations (RWS) optimized for heavy machine gun fire. The interplay between vehicle stability and ammunition consistency is critical for these RWS platforms.51

- South Africa: PMP (Pretoria Metal Pressings), a division of Denel, is a major Southern Hemisphere producer. They supply the SANDF and export widely. PMP is known for high-quality brass and reliable standard ball/tracer variants that function well in the harsh African environment.53

- UK: Manroy Engineering creates the heavy machine guns and supports the ammunition supply chain for British forces, ensuring that the “General Purpose Machine Gun” (GPMG) concept is backed by heavy .50 cal capability where needed.55

Supply Chain Insight: The reliance on specific high-tech components (like the tungsten carbide cores for SLAP/Raufoss and the energetic materials for the Raufoss tips) creates a specialized supply chain that is harder to scale than standard ball ammo. In a major peer-to-peer conflict, the consumption of these “silver bullets” would likely outstrip production capacity rapidly, forcing a reversion to standard API.

Conclusion

The .50 BMG cartridge has defied the typical lifecycle of military technology. Born from the desperate need to punch through WWI tanks, it has reinvented itself as the hammer of the modern infantry commander. Its unique volume allows it to be a “Jack of All Trades”—a machine gun round that suppresses area targets, an anti-materiel round that burns vehicles, and a sniper round that eliminates high-value targets at 2,000 meters.

While ballistically superior cartridges like the.416 Barrett challenge its dominance in the ultra-long-range precision niche, they lack the payload capacity to replace it in the heavy logistics role. As long as there are light armored vehicles to stop and insurgents hiding behind concrete walls, the “Ma Deuce” and its thunderous cartridge will remain the final word in squad-level firepower. The .50 BMG is not just a caliber; it is a century-old institution of heavy ordnance that continues to write history with every trigger pull.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, we are only paid if there is an affiliate program such as Avantlink, Impact, Amazon and eBay and only if you purchase something. If you’d like to directly contribute towards our continued reporting, please visit our funding page.

Sources Used

- John Browning & .50 BMG History: America’s Heavy Slugger for Over 100 Years – Guns.com, accessed January 8, 2026, https://www.guns.com/news/browning-50-bmg-cal-bullet-history

- M2 Browning | Military Wiki – Fandom, accessed January 8, 2026, https://military-history.fandom.com/wiki/M2_Browning

- Biggest Bullets | Rock Island Auction, accessed January 8, 2026, https://www.rockislandauction.com/riac-blog/biggest-bullet

- History of 50 BMG Ammo – Reddit, accessed January 8, 2026, https://www.reddit.com/r/ammo/comments/ueeyox/history_of_50_bmg_ammo/

- .50 BMG – Wikipedia, accessed January 8, 2026, https://en.wikipedia.org/wiki/ .50_BMG

- 50 Browning – C.I.P., accessed January 8, 2026, https://bobp.cip-bobp.org/uploads/tdcc/tab-i/50-browning-en.pdf

- Is there a SAAMI 50 BMG spec? | Sniper’s Hide Forum, accessed January 8, 2026, https://www.snipershide.com/shooting/threads/is-there-a-saami-50-bmg-spec.6956523/

- 50 bmg loads – amax 750gr with wc860 | Sniper’s Hide Forum, accessed January 8, 2026, https://www.snipershide.com/shooting/threads/50-bmg-loads-amax-750gr-with-wc860.7237968/

- Anyone load 50 BMG? | Sniper’s Hide Forum, accessed January 8, 2026, https://www.snipershide.com/shooting/threads/anyone-load-50-bmg.6449034/

- .50 Cal Advanced Propellants, accessed January 8, 2026, https://ndia.dtic.mil/wp-content/uploads/2011/smallarms/WednesdayAmmo12322Howard.pdf

- Ball vs Stick powder for 223 2022 – Shooters’ Forum, accessed January 8, 2026, https://forum.accurateshooter.com/threads/ball-vs-stick-powder-for-223-2022.4072842/

- DA50 .50 BMG 1:8 or 1:15 twist? | Canadian Gun Nutz, accessed January 8, 2026, https://www.canadiangunnutz.com/forum/threads/da50-50-bmg-1-8-or-1-15-twist.1713649/

- Calibers and Twist Rates – Lilja Precision Rifle Barrels, accessed January 8, 2026, https://riflebarrels.com/calibers-and-twist-rates/

- Rifle Barrel Twist Rates – E. Arthur Brown Company, accessed January 8, 2026, https://eabco.com/blog/rifle-barrel-twist-rates/

- How To Find the Ideal Twist Rate for Your Rifle – The Everyday Marksman, accessed January 8, 2026, https://www.everydaymarksman.co/equipment/rifling-twist-rate/

- M2 Browning – Wikipedia, accessed January 8, 2026, https://en.wikipedia.org/wiki/M2_Browning

- AP-I or AP for M2 machine gun? : r/Warthunder – Reddit, accessed January 8, 2026, https://www.reddit.com/r/Warthunder/comments/243oto/api_or_ap_for_m2_machine_gun/

- .50 Caliber Round | Military.com, accessed January 8, 2026, https://www.military.com/equipment/50-caliber-round

- Saboted light armor penetrator – Wikipedia, accessed January 8, 2026, https://en.wikipedia.org/wiki/Saboted_light_armor_penetrator

- M903 Caliber .50 Saboted Light Armor Penetrator (SLAP), M962 Saboted Light Armor Penetrator Tracer (SLAPT), accessed January 8, 2026, https://man.fas.org/dod-101/sys/land/slap.htm

- Which .50 load is better at long range in terms of metal penetration and accuracy? M2 AP, M8 API, M20 APIT, M903 SLAP or M962 SLAP-T? – Long Shots, accessed January 8, 2026, https://longshots.quora.com/Which-50-load-is-better-at-long-range-in-terms-of-metal-penetration-and-accuracy-M2-AP-M8-API-M20-APIT-M903-SLAP-or

- Raufoss Mk 211 – Wikipedia, accessed January 8, 2026, https://en.wikipedia.org/wiki/Raufoss_Mk_211

- Multipurpose Ammunition – Developing the Impossible – YouTube, accessed January 8, 2026, https://www.youtube.com/watch?v=kODcUp1cr4s

- File:Raufoss Mk.211.png – Wikimedia Commons, accessed January 8, 2026, https://commons.wikimedia.org/wiki/File:Raufoss_Mk.211.png

- Voting From the Rooftops – Section One: The Capability of the 50 Caliber Sniper Rifle, accessed January 8, 2026, https://vpc.org/publications/voting-from-the-rooftops/voting-from-the-rooftops-section-one-the-capability-of-the-50-caliber-sniper-rifle/

- How the 50 Cal Changed Marksmanship Forever | Coffee or Die, accessed January 8, 2026, https://www.coffeeordie.com/article/50-cal

- .50 BMG – Ammunition Store, accessed January 8, 2026, https://ammunitionstore.com/content/50%20BMG.pdf

- accessed January 8, 2026, https://guns.fandom.com/wiki/RAI_Model_500#:~:text=5%20See%20also-,History,Grenada%2C%20Panama%2C%20and%20Iraq.

- RAI Model 500 – Gun Wiki | Fandom, accessed January 8, 2026, https://guns.fandom.com/wiki/RAI_Model_500

- J. Haskins Rifle Company “Bicentennial” Rifle – Revivaler, accessed January 8, 2026, https://revivaler.com/j-haskins-rifle-company-bicentennial-rifle/

- Haskins Rifle – Wikipedia, accessed January 8, 2026, https://en.wikipedia.org/wiki/Haskins_Rifle

- M82: Deadly in Desert Storm | Rock Island Auction, accessed January 8, 2026, https://www.rockislandauction.com/riac-blog/m82-deadly-in-desert-storm

- Barrett: 40 Years Of .50-Caliber Authority | An Official Journal Of The NRA, accessed January 8, 2026, https://www.americanrifleman.org/content/barrett-40-years-of-50-caliber-authority/

- Barrett M82 – Gun Wiki | Fandom, accessed January 8, 2026, https://guns.fandom.com/wiki/Barrett_M82

- Barrett VS Mcmillan – GunBroker, accessed January 8, 2026, https://support.gunbroker.com/hc/en-us/community/posts/32635706922395-Barrett-VS-Mcmillan

- McMillan TAC-50 – Wikipedia, accessed January 8, 2026, https://en.wikipedia.org/wiki/McMillan_TAC-50

- McMillan TAC-50: A True AMR/Anti-Personnel Sniper Rifle – Gun Digest, accessed January 8, 2026, https://gundigest.com/article/mcmillan-tac-50-a-true-amr-anti-personnel-sniper-rifle

- Deconstructing a Sniper’s Record-Breaking Kill-Shot, accessed January 8, 2026, https://thesnipermind.com/blog/deconstructing-a-sniper-s-record-breaking-kill-shot.html

- XM1022 Long-Range Sniper Ammunition: Army Program Report – Studylib, accessed January 8, 2026, https://studylib.net/doc/10866837/xm1022-long-range-sniper-ammunition

- DTM Ammo .50BMG 750gr A-MAX Premium Match – Desert Tech, accessed January 8, 2026, https://deserttech.com/dtm-ammo-50bmg-750gr.html

- 50 Cal .510 750 gr A‑MAX® ‑ Hornady Manufacturing, Inc, accessed January 8, 2026, https://www.hornady.com/bullets/rifle/50-cal-510-750-gr-a-max#!/

- Copper Ammunition vs Lead – Remington, accessed January 8, 2026, https://www.remington.com/big-green-blog/copper-ammunition-vs-lead.html

- Solid copper bullets vs. traditional lead core bullets, accessed January 8, 2026, https://cuttingedgebullets.com/pages/copper-vs-lead-bullets

- .416 Barrett – Wikipedia, accessed January 8, 2026, https://en.wikipedia.org/wiki/.416_Barrett

- Going the Distance – Shooting Times, accessed January 8, 2026, https://www.shootingtimes.com/editorial/ammunition_st_goingthedistance_20001/100044

- Why does the military opt for the Barrett .416 instead of the larger 50 caliber? – Quora, accessed January 8, 2026, https://www.quora.com/Why-does-the-military-opt-for-the-Barrett-416-instead-of-the-larger-50-caliber

- Everything You Need To Know About .408 CheyTac – Gun Digest, accessed January 8, 2026, https://gundigest.com/gear-ammo/ammunition/408-cheytac

- EXACTO – Grokipedia, accessed January 8, 2026, https://grokipedia.com/page/EXACTO

- EXACTO – Wikipedia, accessed January 8, 2026, https://en.wikipedia.org/wiki/EXACTO

- North America Small Caliber Ammunition Market Outlook to 2030 – Ken Research, accessed January 8, 2026, https://www.kenresearch.com/industry-reports/north-america-small-caliber-ammunition-market

- ARX®30 | KNDS Group, accessed January 8, 2026, https://knds.com/en/products/systems/arx-30

- VBMR Griffon – Wikipedia, accessed January 8, 2026, https://en.wikipedia.org/wiki/VBMR_Griffon

- Pretoria Metal Pressings – Wikipedia, accessed January 8, 2026, https://en.wikipedia.org/wiki/Pretoria_Metal_Pressings

- Denel PMP to boost ammunition production as it eyes R1bn/y turnover – Engineering News, accessed January 8, 2026, https://www.engineeringnews.co.za/article/denel-pmp-to-boost-ammunition-production-as-it-eyes-r1bny-turnover-2014-06-17

- Manroy M2 HMG QCB – AmmoTerra, accessed January 8, 2026, https://ammoterra.com/product/manroy-m2-hmg-qcb