I’ve used presses for many years and have watched them bend stuff and or even shoot stuff across a room. One of the scariest sounds I used to hear was the “BANG” when an AK barrel pin would finally let go and come out. My point is that with a press, you are working with tons of pressure — literally. If you have a 20 ton press, that means you could apply somewhere around 40,000 tons of pressure.

Presses are pretty simple really – you have a frame made of steel with an adjustable shelf and a hydraulic bottle jack. As you pump the jack, the ram assembly is pushed/pressed down and applies pressure on whatever you have underneath. The shelf is open in the middle and arbor plates, or some metal plates are used in the middle to hold the work when pressure is applied.

The problem is that many of the press plates supplied with presses are not up to the task. I bent the plates that came with with my press — they were basically two pieces of thick U channel mystery metal that couldn’t handle the load. Now some guys have reported their cast iron press plates shattering under load and causing injury.

As part of purchasing my SWAG press brake, they told me the unit must be fully supported underneath or it would bend. As my press plates were history and I just had 1/2″ bar stock that I would stack to work on stuff, I knew I needed to invest in better plates. SWAG offers quality 50-A572 steel plate in a number of sizes both 1″ and 1.5″ thick. Their pricing is surprisingly good too. I ordered a 12x12x1.5 set direct from them knowing I would need to but down one side a bit to get it into my press. Note, you must go to SWAG’s website to get this particular size – due to the size of my press, I need 12″ for front to back.

A few days later a couple of heavy Priority Mail boxes arrived with one plate in each.

I looked at the plates and did some thinking – I planned the cut it such that my most likely used opening would be available. I then used my PowerMax 45 plasma cutter to cut the plate. The 1.5″ thick piece was way past the unit’s limit. I went real slow from one side, turned it over and then did the other. I then did some grinding to clean it up.

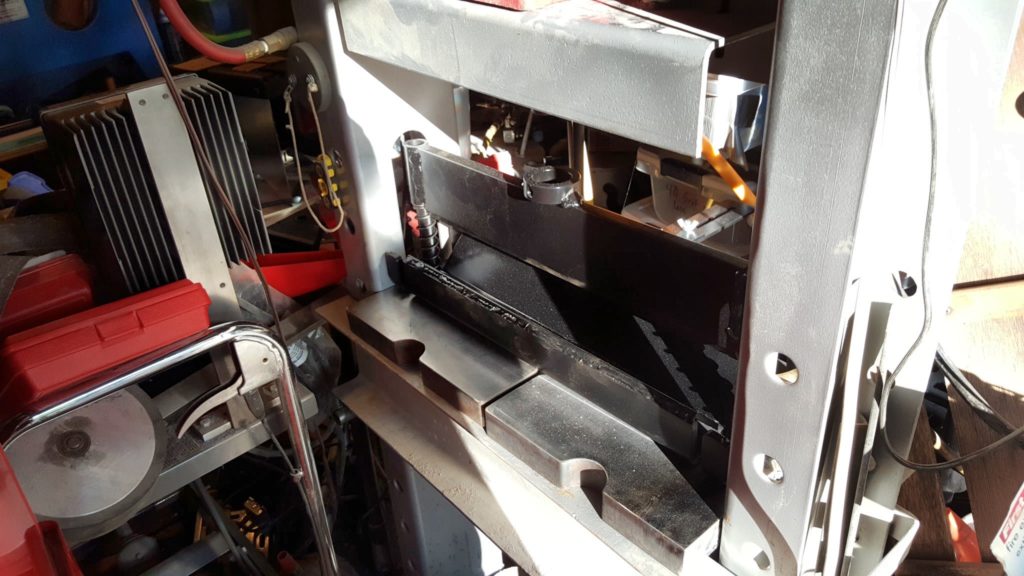

Here’s the SWAG brake sitting on the plates.

Nothing is permanently attached. The press and the plates can be pulled out if I need to do any work that requires a different configuration.

The following two plates are smaller but you can get them off Amazon:

The next post will be about installing the air over pneumatic bottle jack.

6/2/2019 Update: These plates are awesome. I have put some tremendous pressure on them when pressing parts using a 20 ton air over hydraulic bottle hack and they have not given at all. They are well worth it.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, I may be paid via an affiliate program such as Avantlink, Impact, Amazon and eBay.