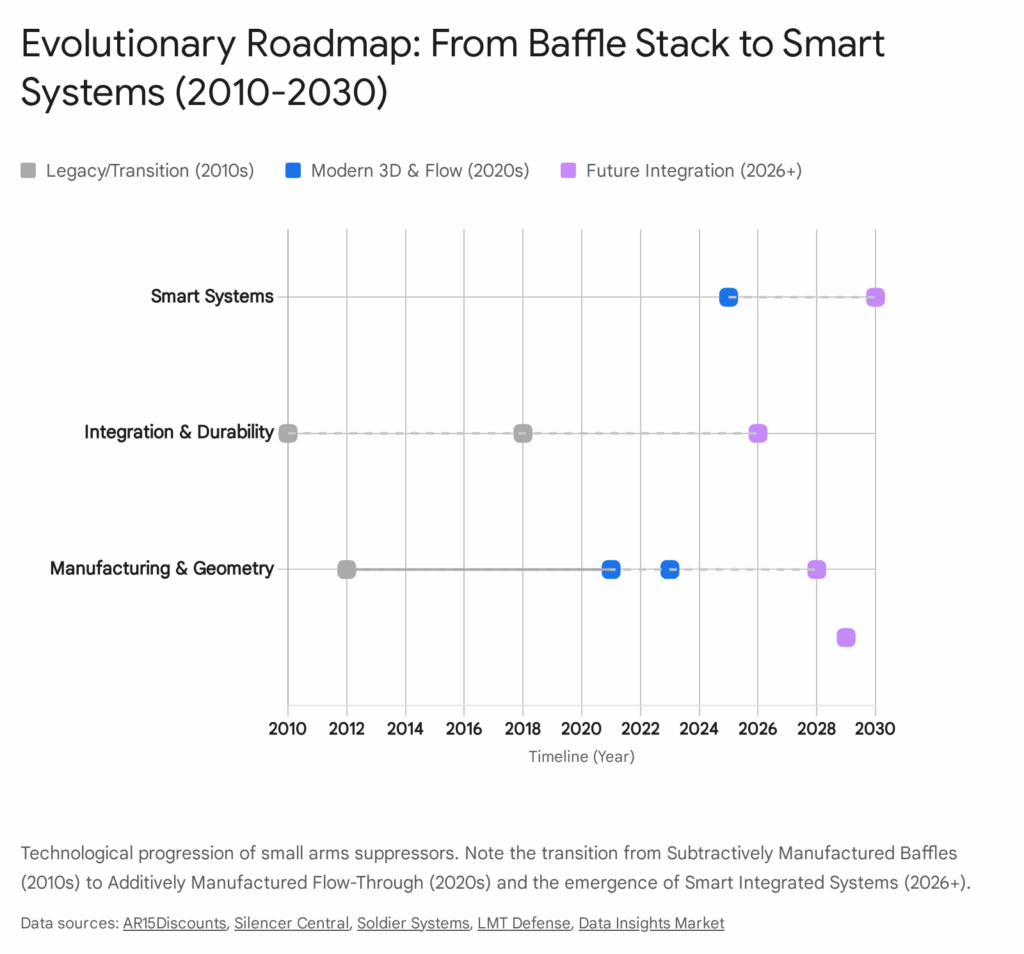

The trajectory of small arms signature reduction has fundamentally altered course in the mid-2020s, transitioning from a peripheral accessory market to a core component of advanced weapon system engineering. As we assess the technological landscape of 2025 and 2026, it becomes evident that the “silencer”—a term historically rooted in the simple mechanical trapping of gas—has evolved into a sophisticated thermodynamic engine. The modern suppressor is no longer a passive tube filled with washers; it is a complex, active system designed to manage fluid dynamics, thermal energy, and acoustic waveforms in ways that were theoretically understood but manufacturing-impossible just a decade ago.

Industry analysis confirms that the primary driver of this evolution is the operational imperative to decouple sound suppression from weapon dysfunction. For nearly a century, the addition of a suppressor meant a compromise: the operator gained acoustic stealth but accepted increased backpressure, accelerated parts wear, erratic cyclic rates, and the ingestion of toxic blowback. The “cutting-edge” designs of the current era—represented by flagship platforms from HUXWRX, Combat Application Technologies (CAT), LMT Advanced Technologies, and Silent Steel—have largely eliminated this trade-off. Through the convergence of Computational Fluid Dynamics (CFD), Additive Manufacturing (AM) of exotic superalloys, and psychoacoustic signature characterization, today’s leading suppressors enhance the host weapon’s reliability rather than degrading it.

This report provides an exhaustive analysis of the top ten attributes that define the zenith of small arms suppressor technology in 2025-2026. These attributes are not merely marketing features; they represent deep engineering solutions to the thermodynamic and fluid dynamic challenges of suppressing high-velocity projectiles. Our findings draw upon a wide array of data, including USSOCOM’s Suppressed Upper Receiver Group (SURG) solicitation requirements, independent laboratory testing standards established by PEW Science, and metallurgical studies on powder bed fusion. The analysis reveals a market that has moved beyond peak decibel reduction to prioritize holistic “shootability,” durability under machine-gun firing schedules, and the intelligent management of the entire weapon ecosystem.

Attribute 1: Computational Fluid Dynamics and Passive Flow Control Architectures

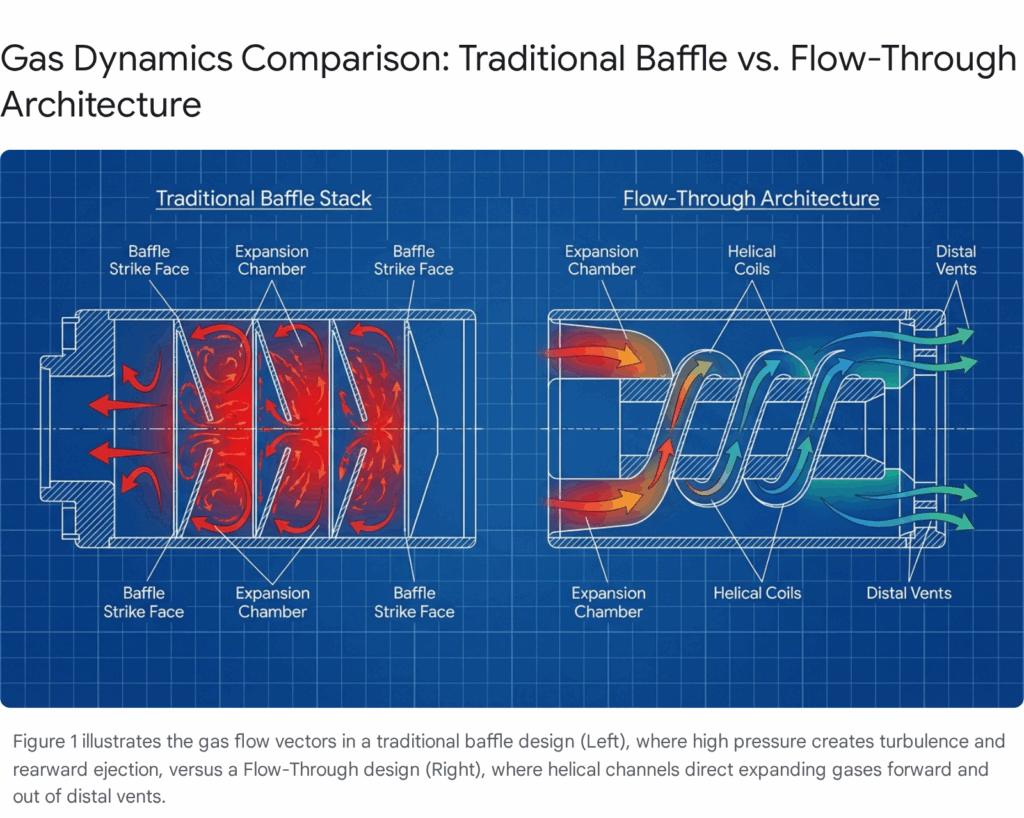

The most definitive attribute of a leading-edge suppressor in 2026 is the abandonment of the “trap and hold” philosophy in favor of advanced flow control. Traditional suppressors, often referred to as “baffle cans,” operate on a principle of occlusion. They place a series of walls (baffles) in the path of expanding gases to strip energy and trap high-pressure potential behind the projectile. While effective at reducing muzzle report, this mechanism inevitably creates a high-pressure reservoir that seeks the path of least resistance. In a gas-operated firearm like the M4 or AR-15, that path is often back down the barrel and gas tube, unlocking the bolt prematurely and flooding the receiver with superheated, toxic particulate matter.

The industry’s response has been the rapid maturation of “Flow-Through” and “Surge Bypass” architectures, designed using advanced Computational Fluid Dynamics (CFD). These systems do not trap gas; they route it. By engineering complex, tortuous pathways that maintain forward momentum, these suppressors allow the gas to expand and cool via friction and turbulence without creating the backpressure spike that disrupts weapon function.

The Physics of Flow-Through® Technology

The HUXWRX (formerly OSS) Flow-Through® technology represents the progenitor and a current apex of this design philosophy. Unlike traditional designs that rely on a stack of cones, the internal geometry of a Flow-Through suppressor resembles a jet turbine engine reversed. The core utilizes a series of helical coils and radial vents that force the expanding gas to travel a longer distance within the same linear envelope.1

As the bullet travels down the bore, the gas following it is diverted into these peripheral helical channels. This induces a high degree of rotational turbulence. According to fluid dynamics principles, this rotation increases the path length of the gas molecules, allowing for greater heat transfer to the suppressor body (cooling) and velocity reduction (quieting) before the gas exits. Crucially, the geometry is shaped to ensure that the net vector of the gas flow is always directed forward, toward the distal vents at the front of the unit.3

The engineering result is a dramatic reduction in the “Omega Metric”—a parameter used to quantify the flow restriction of a silencer.5 By minimizing flow restriction, HUXWRX designs like the FLOW 556k achieve a “zero backpressure” effect. The host weapon’s bolt carrier group velocity remains virtually identical to its unsuppressed state, eliminating the need for adjustable gas blocks, heavier buffer weights, or specialized tuning. This attribute is particularly critical for military applications where distinct weapons cannot be individually tuned for suppression in the field.4

CAT Surge Bypass©: Hybrid Pressure Management

Entering the market with a nuanced approach, Combat Application Technologies (CAT) has introduced “Surge Bypass” technology. While Flow-Through designs prioritize maximum flow rate, sometimes at the expense of low-velocity sound suppression efficiency, Surge Bypass attempts to bridge the gap between high-flow and high-suppression architectures.7

The engineering behind Surge Bypass involves a “multi-stage” internal geometry comprising “pressure vessels” and “velocity fins.” These components are fundamentally distinct from traditional baffles. The pressure vessels act as temporary accumulators that are tuned to specific pressure regimes. When a high-pressure supersonic wave enters the suppressor, the Surge Bypass system routes the peak pressure (“surge”) into these bypass channels, preventing it from overwhelming the core pathway and reflecting back down the barrel. However, unlike pure flow-through designs which can be less effective against low-pressure subsonic rounds, the Surge Bypass system retains enough dwell time to effectively strip energy from lower-velocity gases.9

This “pressure agnostic” capability allows suppressors like the CAT/ODB/A1/718 to perform exceptionally well across the spectrum of ammunition types—from high-pressure 5.56 NATO to subsonic.300 Blackout—without requiring the user to adjust the firearm or accept a significant penalty in sound reduction efficiency.10 The presence of “velocity fins” further aids in stabilizing the flow and reducing the turbulence that generates “air noise” or “hiss,” contributing to a more pleasing tonal quality.

Silent Steel Flow-IQ: Controlled Gas Rotation

Another variation of this attribute is found in the “Flow-IQ” technology from Silent Steel. This system employs a “gas rotation” concept, often described as a turbine-like structure. The geometry forces the gas into a vigorous spiral, utilizing centrifugal force to separate particulate matter and maximize the gas’s contact with the cooling surfaces of the suppressor.12

The patent details for Flow-IQ describe a “turbine-and-filter” architecture. The rotation not only cools the gas but also assists in flow stabilization, which Silent Steel claims improves shot-to-shot consistency and reduces the thermal load on the internal components during sustained fire.14 This represents a divergent evolution from the HUXWRX coil approach, focusing heavily on the thermodynamic benefits of rotational flow to manage the energy of the propellant gases.

Operational Implications: Health and Visibility

The shift toward flow-control attributes has profound implications beyond simple mechanics. The reduction of backpressure is directly correlated with the reduction of toxic exposure for the operator. In traditional suppressor usage, the “gas blowback” phenomenon forces a mixture of vaporized lead, carbon, and ammonia out of the ejection port and charging handle, directly into the shooter’s breathing zone.3

Studies and user reports consistently highlight that flow-control suppressors reduce this exposure to near-unsuppressed levels. For military and law enforcement personnel conducting high-volume training or Close Quarters Battle (CQB) operations in enclosed spaces, this attribute is a matter of long-term occupational health. Furthermore, the reduction in gas blowback preserves the shooter’s visual awareness. It prevents the rapid clouding of safety eyewear and, critically, keeps the objective lenses of optics and night vision devices clear of carbon condensation, ensuring lethality is maintained throughout extended engagements.3

Attribute 2: Additive Manufacturing and Monolithic Architecture

If Computational Fluid Dynamics provides the theory for modern suppression, Additive Manufacturing (AM)—specifically Direct Metal Laser Sintering (DMLS)—provides the means. The intricate geometries required for attributes like helical coils, surge bypass channels, and internal lattice structures are physically impossible to create using traditional subtractive machining methods such as turning, milling, or drilling. Consequently, a top-tier suppressor in 2026 is almost invariably a printed component.17

The DMLS Paradigm Shift

Direct Metal Laser Sintering involves spreading a thin layer of metal powder (often 20-60 microns thick) and fusing it with a high-powered laser, layer by layer, based on a CAD model. This “growth” process liberates engineers from the constraints of tool access. An end mill cannot cut a curved tunnel inside a solid block of steel, but a laser can sinter one.

This manufacturing capability allows for “Purposely Induced Porosity” (PIP) and complex internal surface texturing. Manufacturers like PTR and HUXWRX utilize this to create internal structures that function like a sponge, increasing the surface area available for heat transfer by orders of magnitude compared to smooth machined baffles.18 The increased surface area allows the suppressor to absorb and dissipate heat more efficiently, a critical factor in managing the thermal spike of automatic fire.

Furthermore, AM facilitates the creation of “Triskelion” baffles and other non-concentric, organic shapes that disrupt sound waves more effectively than simple cones. The Dead Air “Triskelion” design, for example, uses a three-pronged geometry to shave gas off the bullet path and direct it into expansion chambers, a shape that would be prohibitively expensive or impossible to cast or machine.18

Monolithic Structural Integrity

Perhaps the most significant engineering benefit of AM is the achievement of a true “monolithic” architecture. Traditional suppressors are assemblies; they consist of an outer tube (the pressure vessel) and a stack of internal baffles, held together by welds or threaded end caps. Every weld is a Heat Affected Zone (HAZ), a region where the metal’s grain structure is altered and often weakened. Every thread is a potential point of loosening under vibration.

In a DMLS suppressor, the core, the baffles, and the outer skin are printed simultaneously as a single, continuous piece of material.2 There are no internal welds to crack and no baffle stacks to shift out of alignment. This eliminates the risk of “baffle strikes” caused by internal component failure—a catastrophic failure mode where loose baffles obstruct the bullet path.

The monolithic nature of AM suppressors also allows for weight optimization that was previously unachievable. Engineers can employ “topology optimization” algorithms to thicken the suppressor walls only where stress analysis predicts high pressure loads, while thinning them in low-stress areas. This results in suppressors like the SilencerCo Velos LBP or the HUXWRX FLOW series that offer the durability of heavy steel cans at a weight comparable to titanium units.20

Supply Chain and Powder Metallurgy

The reliability of an AM suppressor is heavily dependent on the quality of the feedstock—the metal powder. Leading manufacturers in 2026 are deeply invested in powder metallurgy, ensuring that the powders used have a perfect spherical morphology and tight particle size distribution.21 Irregular particles can lead to “porosity” or weak spots in the printed metal. Companies like Continuum Powders are at the forefront of this supply chain, providing certified powders of Inconel and Titanium that ensure the printed part has mechanical properties that meet or exceed those of wrought (forged) metal.21 The ability to trace a suppressor’s lineage back to the specific batch of atomized powder is becoming a quality control standard in the industry.

Attribute 3: Advanced High-Temperature Superalloys

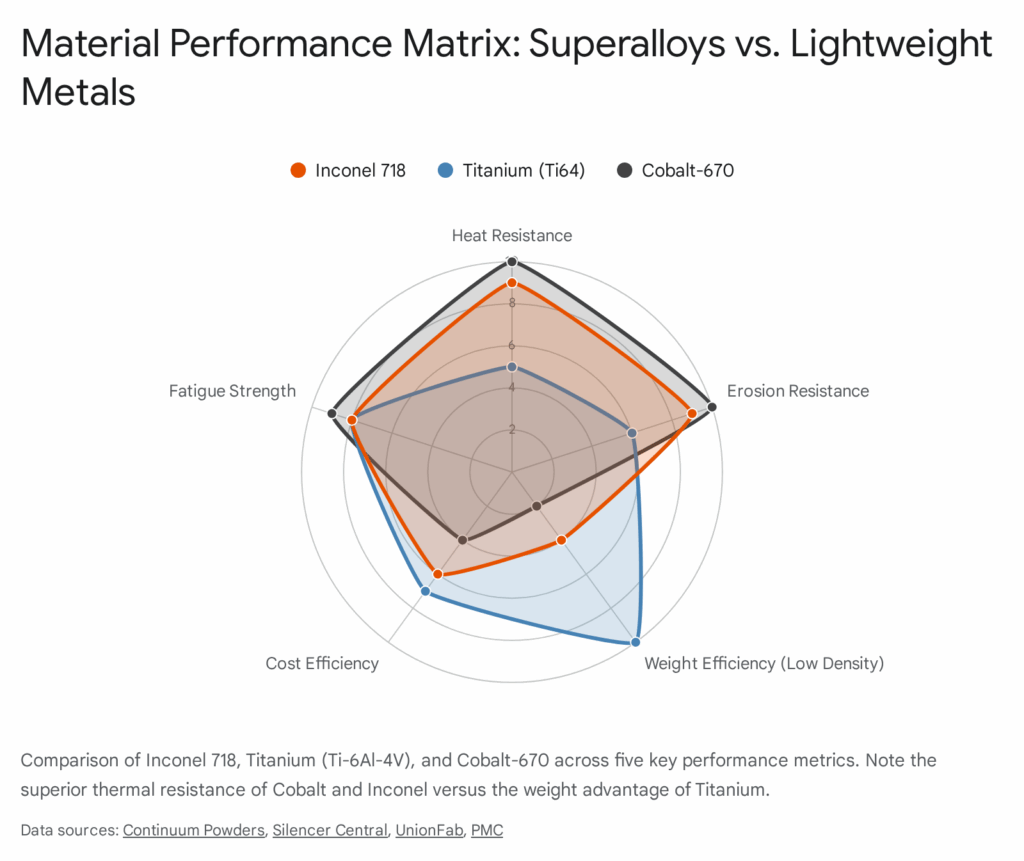

The material science of suppressors has migrated from standard firearm steels (like 4140 or 17-4 PH stainless) to the exotic superalloys of the aerospace and gas turbine industries. The operating environment of a suppressor on a short-barreled machine gun is one of the most hostile on earth, combining extreme pressure (10,000+ psi), thermal shock (0° to 1500°F in seconds), and particulate erosion. To survive this, 2026’s top designs utilize materials like Inconel 718, Cobalt-670, and Haynes 282.

Inconel 718: The Workhorse of War

Inconel 718, a precipitation-hardenable nickel-chromium alloy, remains the gold standard for “hard-use” suppressors.17 Its defining characteristic is its yield strength retention at elevated temperatures. While stainless steel loses a significant portion of its strength above 800°F, Inconel 718 retains its integrity up to 1300°F.24

This thermal stability is crucial for preventing the “ballooning” or bursting of suppressors under the firing schedules mandated by SOCOM SURG trials. Additionally, Inconel forms a stable, passive oxide layer when heated, which protects the metal from further chemical attack by the corrosive byproducts of gunpowder combustion (ammonia, sulfur, etc.).26

Cobalt-670 and Erosion Resistance

For the most critical areas of the suppressor—specifically the “blast baffle” which takes the direct impact of the supersonic gas jet—engineers are increasingly turning to Cobalt-based alloys like Cobalt-670 (often referred to generically as Stellite).19

Cobalt alloys possess exceptional resistance to “erosion” or “ablation.” In a suppressor, the high-velocity stream of unburnt powder particles acts like a sandblaster, physically wearing away the metal of the first baffle. Over time, this erosion opens up the bore aperture, reducing sound performance. Cobalt-670 is significantly harder and more resistant to this abrasive wear than Inconel, extending the service life of the suppressor significantly.28 While heavier and more expensive, its use in the blast chamber is a hallmark of premium durability.

Haynes 282: The Printable Superalloy

A newer entrant gaining traction in 2025 is Haynes 282. This alloy was specifically developed for high-temperature structural applications in gas turbines and is particularly well-suited for Additive Manufacturing. Unlike some superalloys which are prone to “strain-age cracking” during the rapid heating and cooling cycles of 3D printing, Haynes 282 possesses excellent weldability and fabricability.30

This allows for the printing of thinner, more intricate features without the risk of micro-cracking during production. Manufacturers using Haynes 282 can produce suppressors that rival the durability of Inconel 718 but with potentially lower weight or more complex internal geometries.32

Titanium and the “Sparking” Trade-off

Titanium (Ti-6Al-4V) remains a popular choice for “hunter” or “precision” suppressors due to its incredible strength-to-weight ratio—roughly 40% lighter than steel.23 However, in a combat or rapid-fire context, Titanium has a fatal flaw: it is reactive. Above 800°F, titanium begins to react with oxygen and nitrogen, becoming brittle. Worse, the erosion particles from titanium ignite, creating a shower of white sparks downrange.33

For this reason, cutting-edge tactical suppressors in 2026 often employ a Hybrid Material Architecture. Designs like the SilencerCo Velos LBP utilize a 3D-printed Inconel 625 core (to handle the heat and erosion) welded to 17-4 stainless steel mounting modules (for thread durability).20 Other manufacturers are experimenting with “bimetallic” printing, transitioning from Inconel in the blast chamber to Titanium in the distal baffles to save weight without sacrificing durability, although this process remains technologically challenging.34

Attribute 4: Psychoacoustic Engineering and Signature Characterization

For decades, the suppression industry operated on a single, flawed metric: peak decibel (dB) reduction. A suppressor was considered “good” if it lowered the peak sound pressure level (SPL) measured 1 meter to the left of the muzzle. By 2026, this simplistic view has been replaced by Signature Characterization, a discipline that accounts for the complexity of human auditory perception and the physics of sound waves.

The PEW Science Standard

The rise of PEW Science and its “Suppression Rating™” has revolutionized how suppressors are evaluated. This independent standard has forced manufacturers to engineer for the entire waveform, not just the peak amplitude.35 The research demonstrates that “peak dB” does not correlate linearly with hearing damage risk. A short, high-intensity impulse might register a lower peak dB than a longer, lower-intensity wave, yet cause more damage to the inner ear cilia due to the total energy delivered (dose).

Leading 2026 designs are engineered to optimize the PEW Science Suppression Rating, which synthesizes peak pressure, impulse duration, and wave frequency into a single “damage risk” metric.36 This has led to the prioritization of “at-ear” performance.

At-Ear vs. At-Muzzle Dynamics

A critical insight driving modern design is the decoupling of “muzzle sound” (what the enemy hears) from “ear sound” (what the shooter hears).

- The Port Pop Phenomenon: On a gas-operated rifle, a significant portion of the noise reaching the shooter’s ear comes from the ejection port (“port pop”), not the muzzle. High-backpressure suppressors increase the bolt velocity, causing the action to open while bore pressure is still high. This vents a loud “pop” right next to the shooter’s ear.

- The Flow-Through Advantage: Low-backpressure suppressors like the HUXWRX FLOW 556k reduce this port pop significantly. Even if they are technically louder at the muzzle than a restrictive baffle can, they are often much quieter at the shooter’s ear because they delay the unlocking of the bolt and reduce the pressure in the receiver.1

Frequency and Tone

Beyond damage risk, “tone” has become a sellable attribute. High-flow suppressors typically produce a “boomy” low-frequency signature, as opposed to the sharp, high-pitched “hiss” or “crack” of traditional high-pressure cans.10 Low-frequency sounds are generally perceived as more pleasant and less startling by the human ear.

CAT’s Surge Bypass technology specifically targets “high-frequency suppression” to optimize this tonal quality, utilizing its velocity fins to smooth out the turbulent flow that generates high-pitch noise.7 This “psychoacoustic optimization” aims to make the shooting experience less fatiguing, allowing for better communication and situational awareness.

Attribute 5: Flash Mitigation and Spectral Signature Management

In a peer-near conflict environment, staying hidden is as much about the electromagnetic spectrum as it is about acoustics. With the ubiquitous proliferation of Gen-3 Night Vision Goggles (NVGs) and thermal imaging sights, a suppressor must effectively mask the visual and infrared signatures of the weapon.

The Science of Flash

Muzzle flash is caused by two distinct events:

- Primary Flash: The glowing propellant gases exiting the muzzle.

- Secondary Flash: The re-ignition of unburnt powder and combustible gases (like hydrogen and carbon monoxide) when they mix with oxygen in the atmosphere. This is the large “fireball” often seen in unsuppressed fire.

Traditional suppressors can sometimes worsen secondary flash. By trapping gas, they can act as a combustion chamber where these gases mix and ignite upon exit. 2026’s leading designs combat this with integrated Flash Hider End Caps.

GeoFlash™ and Cap Geometry

Geometries like HUXWRX’s “GeoFlash™” cap or Dead Air’s flash hider front caps utilize complex tine structures or contoured apertures.2 These shapes serve to mechanically disrupt the gas bubble as it exits the suppressor. By inducing turbulence at the exit point, they prevent the formation of the coherent gas-air mixture required for secondary ignition.

This is a standard feature on duty-grade suppressors in 2026. The ability to swap end caps allows a user to prioritize length (flat cap) or signature reduction (flash hider cap) depending on the mission profile.40

Infrared (IR) Bloom and Surface Roughness

A fascinating second-order effect of Additive Manufacturing is the impact of internal surface roughness on IR signature. The rough, sintered surface of a 3D-printed suppressor creates a massive surface area. While this aids cooling, it also creates thousands of micro-cavities that can trap unburnt powder.

- Sparking: Titanium suppressors are particularly prone to “sparking,” where small particles of titanium erode and ignite, creating streaks visible under NVGs. This “sparking” can give away a position even if the muzzle flash is suppressed.

- The Inconel Solution: Top-tier tactical suppressors minimize this by using Inconel or Cobalt linings in the blast chamber, which do not spark. Additionally, specialized high-temperature coatings (like Cerakote C-Series or DLC) are used to mask the thermal signature and prevent the external tube from reflecting IR light.4

Attribute 6: Advanced Mounting Systems: Taper and Torque

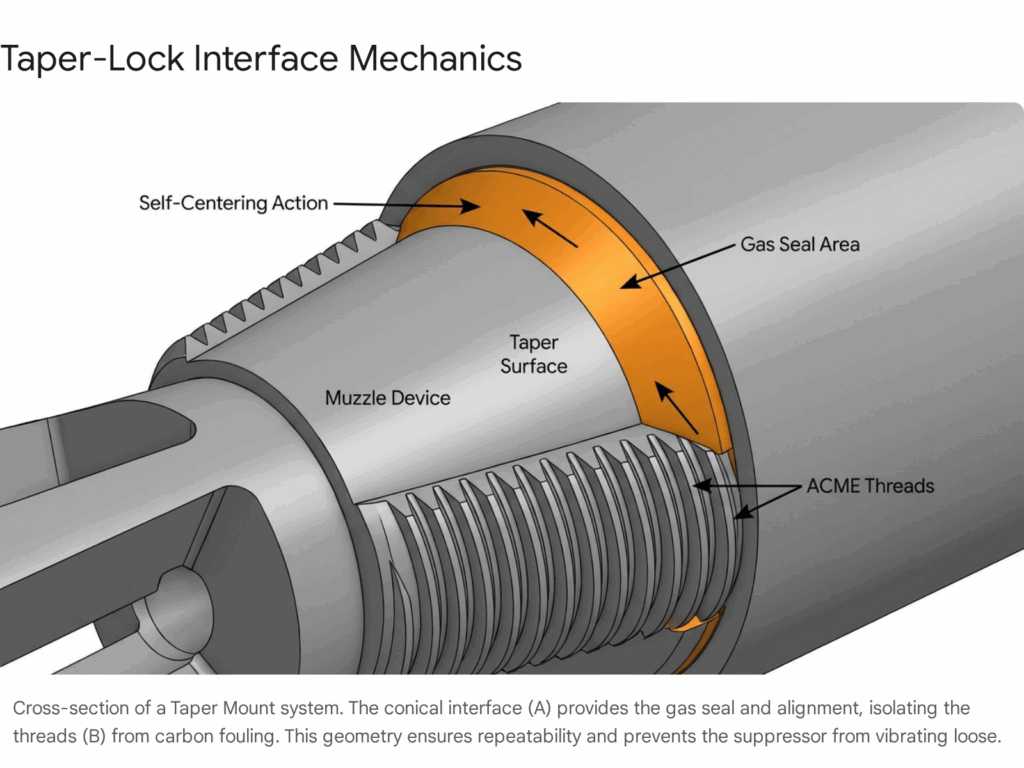

The interface between the suppressor and the barrel is the Achilles’ heel of the system. A loose suppressor leads to a “baffle strike”—where the bullet clips the internal geometry, destroying the unit. The era of simple Direct Thread (90-degree shoulder) interfaces is ending, replaced by the mechanical superiority of Taper Mounts.

The Physics of the Taper

A Taper Mount utilizes a male cone on the muzzle device and a female cone inside the suppressor. When tightened, these two surfaces mate with a friction fit that is far superior to a flat shoulder.41

- Concentricity: The taper naturally self-centers the suppressor. Even if the threads are slightly loose, the taper ensures the bore of the suppressor is perfectly aligned with the bore of the barrel.43

- Gas Seal: The large contact area of the taper creates a gas-tight seal that prevents carbon fouling from reaching the threads. This is critical for preventing “carbon lock,” where the suppressor becomes fused to the mount.43

- Vibration Resistance: The friction of the taper resists the vibrational forces that tend to unscrew direct-thread suppressors during firing. It requires less torque to secure and more torque to break free.45

Left-Hand (LH) Thread Pitch and “Torque Lock”

A subtle but vital innovation is the adoption of Left-Hand (LH) threads for the suppressor-to-mount connection.

- The Problem: Standard muzzle devices are threaded Right-Hand (RH) onto the barrel. If the suppressor is also RH threaded onto the mount, unscrewing a stuck suppressor can accidentally unscrew the mount from the barrel, leaving the mount stuck inside the can.

- The Solution: Leading systems (like HUXWRX and newer CAT models) use LH threads for the suppressor body. As the suppressor is tightened (counter-clockwise), the torque is transferred to the mount in a “tightening” direction (clockwise) relative to the barrel.46 This “Torque Lock” effect ensures that the mount stays on the gun and the suppressor comes off when intended.2

Attribute 7: Universal Modularity and “HUB” Architecture

In the past, buying a suppressor meant marrying a brand’s proprietary mounting ecosystem. If you bought a SilencerCo can, you had to use ASR mounts. If you bought Dead Air, you used KeyMo. In 2026, the market has converged on an open-source standard known as HUB Architecture.

The 1.375×24 TPI Standard

The “HUB” is simply a standardized thread pitch (1.375×24 threads per inch) cut into the rear of the suppressor tube. This attribute allows for universal compatibility.

- Ecosystem Agnosticism: A user can purchase a CAT ODB suppressor (known for its Surge Bypass tech) but mount it using a Rearden Atlas adapter (known for its lightweight taper system). This decouples the “suppressor choice” from the “mount choice,” empowering the consumer.41

- Mission Adaptability: The HUB standard allows a single suppressor to serve multiple roles. It can be fitted with a Direct Thread adapter for a precision bolt gun, a QD brake for a tactical rifle, or a 3-Lug mount for a submachine gun, all in seconds.49

Serviceability vs. Sealed Design

While the mounting interface is modular, the core of 2026’s best suppressors is increasingly sealed (non-user serviceable). The monolithic strength of a printed core outweighs the benefit of being able to disassemble the unit for cleaning. Cleaning is now accomplished via chemical “dipping” or ultrasonic baths, which is made possible by the corrosion resistance of Inconel and Titanium.51 The one exception to this trend is the end cap; users demand replaceable front caps to repair minor damage without scrapping the serialized part.52

Attribute 8: Duty-Cycle Durability and Thermal Management

“Full-Auto Rated” was once a vague marketing claim. In 2026, durability is quantified by adherence to rigorous military standards, specifically the USSOCOM Suppressed Upper Receiver Group (SURG) testing protocols.

The SURG Standard

The SURG durability test is widely regarded as the “torture test” benchmark. It requires the suppressor to withstand:

- The Firing Schedule: Six cycles of 240 rounds fired continuously.

- The Thermal Load: The suppressor reaches temperatures exceeding 1200°F, glowing cherry red. It is then allowed to cool, and the cycle repeats.

- The Criteria: To pass, the suppressor must not fail structurally (burst) or degrade in sound suppression performance or accuracy (shift in point of impact).53

Suppressors like the LMT ION 30 and HUXWRX Flow series are engineered specifically to meet this standard.56 The use of Inconel 718 and monolithic construction is the primary enabler of this performance.

Convection Cooling

Thermal management is another area where Flow-Through designs excel. Traditional baffle cans act as heat sinks; they trap hot gas and hold the heat, taking a long time to cool down. Flow-Through suppressors act as heat exchangers. By constantly venting gas out the front, they create a convective cooling effect. As fresh air is pulled through the system (or simply by the ejection of hot gas), the unit cools faster than a sealed baffle can. This reduces the “thermal soak” time and extends the life of the materials.3

Attribute 9: Digital Integration and Smart Systems

We are witnessing the digitalization of the suppressor. In high-end military and fleet applications, the “dumb” metal tube is becoming a “smart” node in the weapon network.

The LMT PAL Smart Counter

Systems like the LMT “PAL” Smart Counter represent this frontier. These devices integrate accelerometers, thermal sensors, and RFID tags into the weapon system (often the suppressor mount or grip).

- Data Logging: The system records the exact number of rounds fired, distinguishing between live fire and dry fire.58

- Thermal History: It tracks the thermal stress the barrel and suppressor have been subjected to. A suppressor that has fired 10,000 rounds in slow fire is in very different condition than one that fired 10,000 rounds in full-auto dumps.

- Predictive Maintenance: The software analyzes this data to predict the remaining service life of the barrel and suppressor, alerting armorers when a part needs inspection or replacement before it fails in the field.59

While currently a premium feature for defense contracts, this technology provides the data-driven lifecycle management required for modern logistics.

Attribute 10: Integrated First Round Pop (FRP) Mitigation

A tactical suppressor must be quiet from the very first shot. However, the physics of combustion often leads to “First Round Pop” (FRP)—a significantly louder report on the first shot caused by the detonation of oxygen-rich air trapped inside the cool suppressor.

Engineering the FRP Solution

In the past, operators mitigated FRP by adding water, gel, or grease (“shooting wet”) to the suppressor to displace the oxygen.62 This was messy and temporary. The leading designs of 2026 solve FRP geometrically.

- Venturi Venting: Advanced flow-through designs utilize the Venturi effect to purge the suppressor of air the instant the bullet enters the blast chamber. By accelerating the gas flow, they create a pressure drop that evacuates the oxygen before it can mix with the unburnt powder and detonate.64

- Chamber Tuning: The “Surge Bypass” vessels in CAT suppressors are specifically tuned to accommodate the initial high-pressure spike of the cold bore shot. This ensures that the acoustic signature of the first round is virtually indistinguishable from subsequent shots, maintaining the element of surprise.7

Conclusion: The Horizon of 2030

As we look toward 2030, the trajectory of small arms suppressor technology points toward a total fusion of manufacturing and physics. The era of the “can”—a simple accessory threaded onto a barrel—is ending. It is being replaced by the Integrated Signature Reduction System.

The best suppressor of 2026 is defined not by a single metric, but by its systemic harmony. It flows gas to preserve the host weapon; it utilizes additive manufacturing to achieve geometries that defy conventional machining; it employs superalloys to outlast the barrel it is mounted on; and it integrates with the digital battlespace. The convergence of these ten attributes—from Computational Fluid Dynamics to Smart Counter integration—represents the maturity of an industry that has moved from simple noise reduction to comprehensive signature dominance.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, we are only paid if there is an affiliate program such as Avantlink, Impact, Amazon and eBay and only if you purchase something. If you’d like to directly contribute towards our continued reporting, please visit our funding page.

Sources Used

- The Best 9mm Suppressors for 2025: Top Picks for Pistols and PCCs – AR15Discounts, accessed January 1, 2026, https://ar15discounts.com/the-best-9mm-suppressors-for-2025-top-picks-for-pistols-and-pccs/

- FLOW 556k – Huxwrx, accessed January 1, 2026, https://huxwrx.com/flow-556k/

- Flow-Through Suppressors: The Future of Suppressed?, accessed January 1, 2026, https://libertycans.net/2025/07/14/flow-throughsuppressor/

- HUXWRX FLOW 556K FLASH CAP SUPPRESSOR WITH FLASH HIDER (FDE), accessed January 1, 2026, https://modernwarriors.com/product/hux-flow-556k-fh-kit-fde

- I have a weird observation here, flow through suppressor has more recoil than traditional? : r/NFA – Reddit, accessed January 1, 2026, https://www.reddit.com/r/NFA/comments/1d2xkeh/i_have_a_weird_observation_here_flow_through/

- New Suppressors for 2025 | An Official Journal Of The NRA – Shooting Illustrated, accessed January 1, 2026, https://www.shootingillustrated.com/content/new-suppressors-for-2025/

- CAT WB 718 Suppressor | Specter CAT Inconel 5.56 Silencer, accessed January 1, 2026, https://www.silencershop.com/cat-wb-718.html

- Flow-Through Silencers vs. Conventional Baffle Silencers on …, accessed January 1, 2026, https://pewscience.com/sound-signature-reviews-free/sss-6-124-research-supplement-flow-through-forward-flux-surge-bypass-conventional-300-blk-rifle-silencers

- Technology – Specters Cat, accessed January 1, 2026, https://specterscat.com/technology/

- What is the quietest Low Back Pressure 5.56 Silencer? – PEW Science, accessed January 1, 2026, https://pewscience.com/sound-signature-reviews-free/sss-6-169-research-supplement-low-back-pressure-556-silencers

- Flow-Through, Forward Flux, SURGE BYPASS, and Conventional – with subsonic 300 BLK : r/NFA – Reddit, accessed January 1, 2026, https://www.reddit.com/r/NFA/comments/16sm0ct/flowthrough_forward_flux_surge_bypass_and/

- Silent Steel USA’s FLOW-IQ Gas-Rotation Suppressor Technology Patented, accessed January 1, 2026, https://www.thefirearmblog.com/blog/silent-steels-flow-iq-gas-rotation-suppressor-technology-patented-44824378

- New: Silent Steel USA Streamer Suppressor Family | An NRA Shooting Sports Journal, accessed January 1, 2026, https://www.ssusa.org/content/new-silent-steel-usa-streamer-suppressor-family/

- Silent Steel USA Launches Innovative FLOW-IQ Technology Across Its Suppressor Lineup, accessed January 1, 2026, https://www.alm.com/press_release/alm-intelligence-updates-verdictsearch/?s-news-16750207-2025-12-03-silent-steel-usa-launches-innovative-flow-iq-technology

- Silent Steel FLOW-IQ: For a New Era in Suppressor Performance – UN12 Magazine, accessed January 1, 2026, https://un12magazine.com/silent-steel-flow-iq-tech-suppressor-performance/

- Ultra-Low Backpressure Suppressors: Complete Guide | Capitol Armory, accessed January 1, 2026, https://www.capitolarmory.com/articles/benefits-of-no-backpressure-suppressors-guide

- PRESS RELEASE: Faxon Firearms to Unveil Cutting-Edge Suppressor Lineup at SHOT Show 2025, accessed January 1, 2026, https://faxonfirearms.com/blog/press-release-faxon-firearms-to-unveil-cuttingedge-suppressor-lineup-at-shot-show-2025/

- 3D-Printing: A Modern Method to Suppressor Design – Silencer Central, accessed January 1, 2026, https://www.silencercentral.com/blog/3d-printing-a-modern-method-to-suppressor-design/

- How BANISH Suppressors use Additive Manufacturing – Silencer Central, accessed January 1, 2026, https://www.silencercentral.com/blog/how-banish-suppressors-use-additive-manufacturing/

- 3D Printed Suppressors: The Velos – SilencerCo, accessed January 1, 2026, https://silencerco.com/blog/3d-printed-suppressors-velos

- Additively Manufactured Suppressors: A Powder Metallurgy Perspective, accessed January 1, 2026, https://www.continuumpowders.com/material-considerations-for-additive-manufactured-suppressors-a-powder-metallurgy-perspective/

- Critical Material Properties For Additive Manufactured Suppressors | Continuum Powders, accessed January 1, 2026, https://www.continuumpowders.com/critical-material-properties-for-additive-manufactured-suppressors/

- Inconel vs Titanium: What Suppressor Is Right for You? – Silencer Central, accessed January 1, 2026, https://www.silencercentral.com/blog/inconel-vs-titanium-what-suppressor-is-right-for-you/

- Inconel 718: A Workhorse Material for Additive Manufacturing – Protolabs, accessed January 1, 2026, https://www.protolabs.com/resources/blog/inconel-718-a-workhorse-material-for-additive-manufacturing/

- Inconel vs. Titanium vs. Stainless Steel[+Full Alloy Comparison Chart] – Unionfab, accessed January 1, 2026, https://www.unionfab.com/blog/2025/05/inconel-vs-titanium-vs-stainless-steel

- 3D Printed Suppressors | Sniper’s Hide Forum, accessed January 1, 2026, https://www.snipershide.com/shooting/threads/3d-printed-suppressors.6875054/

- Cobalt 6 vs Inconel : r/suppressors – Reddit, accessed January 1, 2026, https://www.reddit.com/r/suppressors/comments/1m6kl0h/cobalt_6_vs_inconel/

- Wear Resistance Comparison Research of High-Alloy Protective Coatings for Power Industry Prepared by Means of CMT Cladding – MDPI, accessed January 1, 2026, https://www.mdpi.com/2076-3417/12/9/4568

- Effect of Initial Temperature on the Microstructure and Properties of Stellite-6/Inconel 718 Functional Gradient Materials Formed by Laser Metal Deposition – PMC – PubMed Central, accessed January 1, 2026, https://pmc.ncbi.nlm.nih.gov/articles/PMC8269723/

- 3D Printed Suppressors: A Revolution in the Firearms Industry – Silencer Shop, accessed January 1, 2026, https://www.silencershop.com/blog/3d-printed-suppressor

- Nickel Alloys for Industrial 3D Printing – EOS GmbH, accessed January 1, 2026, https://www.eos.info/metal-solutions/metal-materials/nickel-alloys

- New Suppressors for 2025 – Firearms News, accessed January 1, 2026, https://www.firearmsnews.com/editorial/new-suppressors-for-2025/532987

- Shhhh…New Suppressors from SHOT Show 2025 – Athlon Outdoors, accessed January 1, 2026, https://athlonoutdoors.com/article/new-suppressors-from-shot-show-2025/

- High-precision 3D Printed Suppressor with 2Create & 2Create Plus – 2oneLab, accessed January 1, 2026, https://2onelab.com/newsandmore/blog/3d-printed-suppressor/

- Stealth Additive Works Tisha AR15 SBR Suppressor Test – PEW Science, accessed January 1, 2026, https://pewscience.com/sound-signature-reviews-free/sss-6-209-saw-tisha-mk18-556

- SSS.5 – Suppression Rating – PEW Science, accessed January 1, 2026, https://pewscience.com/silencer-sound-standard-suppression-rating

- PEW Science & What to Know Before Buying a Suppressor – AR Build Junkie, accessed January 1, 2026, https://www.arbuildjunkie.com/pew-science-what-to-know-before-buying-a-suppressor/

- HUXWRX FLOW 556k 5.56 AR15 SBR Suppressor Test — PEW …, accessed January 1, 2026, https://pewscience.com/sound-signature-reviews-free/sss-6-83-huxwrx-flow-556k

- Comparing Huxwrx and CAT suppressors : r/NFA – Reddit, accessed January 1, 2026, https://www.reddit.com/r/NFA/comments/1ls8wh5/comparing_huxwrx_and_cat_suppressors/

- Front Caps – Suppressor Accessories – Silencer Shop, accessed January 1, 2026, https://www.silencershop.com/gun-accessories/suppressor-accessories/front-caps.html

- Suppressor Mounting Systems Guide, accessed January 1, 2026, https://stealthadditive.com/wp-content/uploads/2025/04/Stealth-Additive-Works-Mounting-Systems-2.0.pdf

- Any cons to suppressor mounts that utilize a taper locking system? : r/NFA – Reddit, accessed January 1, 2026, https://www.reddit.com/r/NFA/comments/9rr61g/any_cons_to_suppressor_mounts_that_utilize_a/

- Suppressors | Tapered Mounting System – YouTube, accessed January 1, 2026, https://www.youtube.com/shorts/zftWu30ZBbs

- Carbon Locking and Suppressor Hardware Upkeep – True Shot Ammo, accessed January 1, 2026, https://trueshotammo.com/blogs/true-shot-academy/carbon-locking-and-suppressor-hardware-upkeep

- Taper Mount Archives – Griffin Armament, accessed January 1, 2026, https://griffinarmament.com/product-category/silencer-accessories/muzzle-devices/taper-mount/

- Left Hand Thread: Benefits? : r/NFA – Reddit, accessed January 1, 2026, https://www.reddit.com/r/NFA/comments/10gxvy3/left_hand_thread_benefits/

- Suppressor Mounting Systems Explained – Guns.com, accessed January 1, 2026, https://www.guns.com/news/2025/05/21/suppressor-mounting-systems-explained

- CAT/ODB – Specters Cat, accessed January 1, 2026, https://specterscat.com/product/cat-odb/

- Modular Suppressors Explained and 5 Benefits – Silencer Shop, accessed January 1, 2026, https://www.silencershop.com/blog/modular-suppressor

- Quick Detach vs Direct Thread Suppressors – Silencer Shop, accessed January 1, 2026, https://www.silencershop.com/blog/quick-detach-vs-direct-thread-suppressor

- Technology – Huxwrx, accessed January 1, 2026, https://huxwrx.com/technology

- CHOOSING A SUPPRESSOR – MATERIAL & CONSTRUCTION, accessed January 1, 2026, https://griffinarmament.com/choosing-a-suppressor-material-construction/

- SUREFIRE SOCOM FAST-ATTACH® SOUND SUPPRESSOR SYSTEM – Scopelist.com, accessed January 1, 2026, https://www.scopelist.com/PDF/surefire-sf-bsd-manuals.pdf

- Suppressed Upper Receiver Group Testing Methods, accessed January 1, 2026, https://ndia.dtic.mil/wp-content/uploads/2017/armament/McGee19422.pdf

- First Look – USSOCOM’s New Suppressed Upper Receiver Group (SURG) from SIG SAUER, accessed January 1, 2026, https://soldiersystems.net/2018/08/02/first-look-socoms-new-suppressed-upper-receiver-group-from-sig-sauer/

- GoldenWebb Demonstrates a New Suppressor Durability Standard with the LMT ION 30, accessed January 1, 2026, https://soldiersystems.net/2025/08/18/goldenwebb-demonstrates-a-new-suppressor-durability-standard-with-the-lmt-ion-30/

- Article Feature | Soldier Systems-GoldenWebb Demonstrates a New Suppressor Durability Standard with the LMT-AT ION 30, accessed January 1, 2026, https://lmt-at.com/soldier-systems-feature-goldenwebb-suppressor-durability-standard/

- [TFB GUNFEST] LMT’s Shot Counter Grip Module For Military And LE – The Firearm Blog, accessed January 1, 2026, https://www.thefirearmblog.com/blog/2021/01/18/lmts-shot-counter-grip/

- LMT Advanced Technologies Partners with Delivered by Silencer Central for Seamless Suppressor Fulfillment, accessed January 1, 2026, https://lmt-at.com/lmt-advanced-technologies-partners-with-delivered-by-silencer-central-for-seamless-suppressor-fulfillment/

- PAL Smart Counter – LMT Advanced Technologies, accessed January 1, 2026, https://lmt-at.com/product/pal-smart-counter/

- PAL – The world’s most secure and reliable smart counter for firearms, accessed January 1, 2026, https://lmt-at.com/pal-the-worlds-most-secure-and-reliable-smart-counter-for-firearms/

- What is First Round Pop? Everything You Need to Know – Silencer Shop, accessed January 1, 2026, https://www.silencershop.com/blog/what-is-first-round-pop

- Why PopStop and why does FRP (First Round Pop) matter? – Discreet Ballistics, accessed January 1, 2026, https://discreetballistics.com/popstop-frp-first-round-pop-matter/

- First Round Pop: What It Is and Why We Care – Silencer Central, accessed January 1, 2026, https://www.silencercentral.com/blog/first-round-pop-what-it-is-and-why-we-care/