For some reason, I never really got into the Saigas when they were the hot conversion ticket. I guess it was because I was mainly working on rifles and had a Vepr 12. At any rate, when I heard from Paul Popov that SDS was importing a Saiga-12 clone known as the Lynx 12 from China where it was made in the same factory that made the Type 56 AKs. Even better, it did not need the conversion and the street price was about $499, I contacted Scott Igert, my friend who owns Modern Antique Firearms in Benton Harbor, MI, to order me one.

| Palmetto State Armory has SDS Lynx 12 gauge shotguns for sale – click here to go to their order page. |

In short order the shotgun arrived and then promptly sat idle as I was busy with a ton of other projects. Scott nudged me along to take a look as he was curious about the Lynx 12 also as were clients of his. That prompted me to get my act in gear and take a close look at the shotgun by taking it apart to install a bunch of modifications I had planned.

The first step was to give it a careful external exam. The Lynx had a nice heavy uniform dark parkerized finish – probably a manganese “park” given the color. There was some type of preservative on it that had the most interesting smell. I have no way to describe it other that to say it did not smell like the typical cosmoline-ish anti-corrosion coatings I was used to. Note, parkerization does not prevent rust but what it does do is create a textured surface that oil, preservatives or even weapons finishes can “grab” hold of an stay in place. For example, when I build an AK, I have found that abrasive blasting, followed by manganese parkerization and then Norrell’s Molyresin is a remarkably durable finishing process. By the way, I have a post on how to do make and apply your own manganese parkerization.

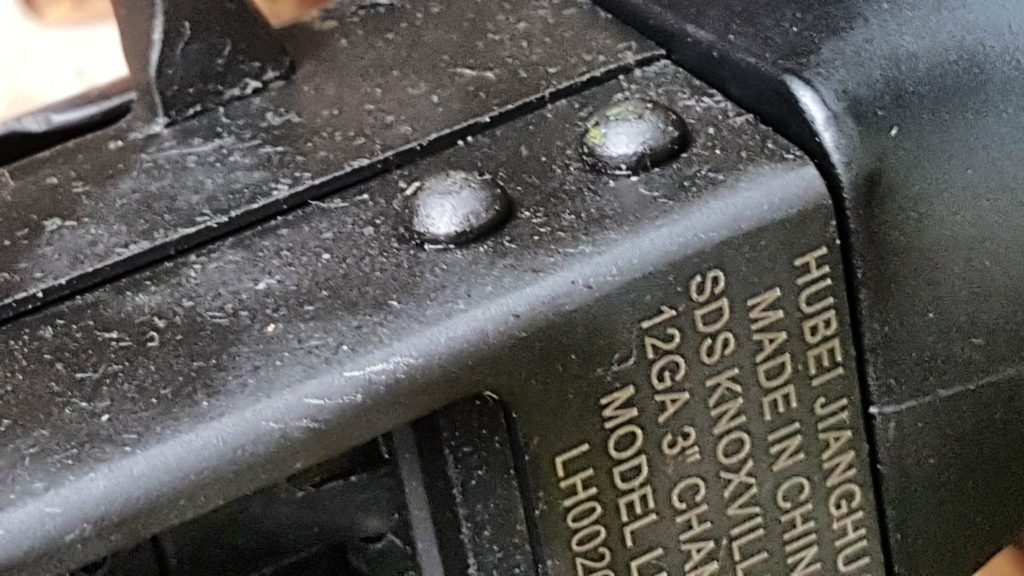

The rivets were pretty good – in a few cases the domes were flatter than others, which is me nit picking, but they all were sitting nice and snug against the sheet metal. Rivets are pretty amazing and result in strong attachments of the forged trunnions to the sheet metal as long as they are formed properly and the Lynx’s rivets are solid.

I found it interesting that the front trunnion sits on top of the sheet metal receiver. The fitment was pretty good.

There were reports of early models having sharp edges but I did not see any. All edges and the parkerized finish were well done.

I did notice that the rear stock screw as a bit chewed up by whomever installed the rear stock. Normally you see this when someone uses a screw driver blade that is too small. Not too bad and since I planned on replacing the rear stock, I really wasn’t worried about it.

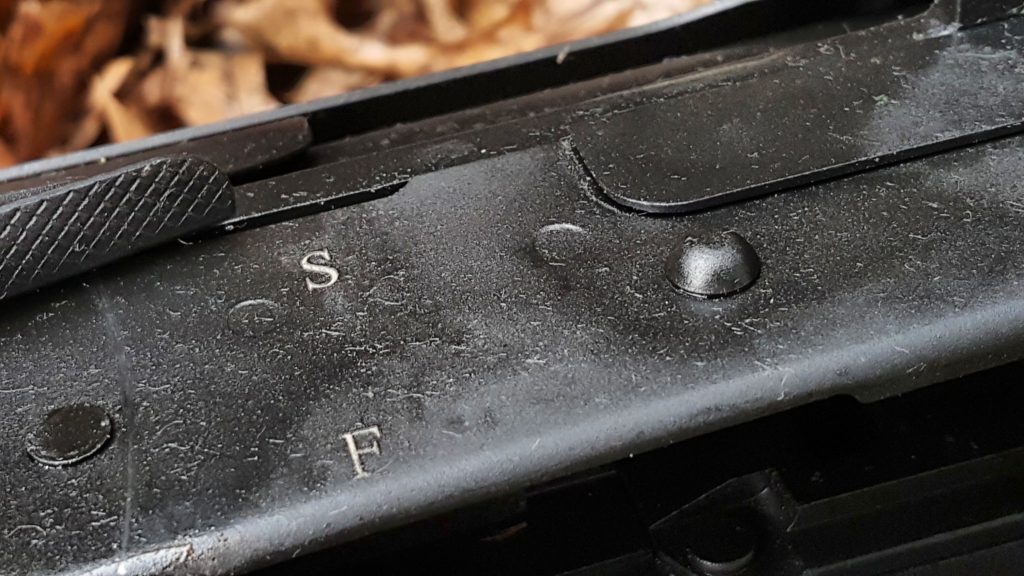

The selector lever was noticeably loose. On most AK rifles, it takes a bit of effort to move the lever between the safe and fire positions. The lever on the Lynx moves very easily. I’ll bend the lever slightly or use a center punch to increase the depth of the detent. Again, not a big worry.

Because the shotgun is brand new and the fire control group and the inside of the receiver are all parkerized, the action was pretty rough. This was to be expected – the parts need to wear in. I knew from experience that cleaning and better lubrication would help.

The muzzle cover was easy to remove and threaded nicely. It is threaded to use Saiga chokes and brakes.

The dust cover has an additional retainer spring and pin that you do not see on most AKMs to hold the dust cover in place. Notice the attention to detail that the retaining button is shaped to allow the dust cover to clear it better.

A nicely done optics side rail is already installed and begging to be used.

It’s a good thing that is there because I really think you will want to run a red dot either via a scope mount or on a front rail. The Lynx’s sights are to the front and rear of the gas tube. The rear has a dovetail and can be drifted with a pin punch to the left or right. The front sight is threaded and can be adjusted up or down. They definitely are functional but I don’t care for them at all to be perfectly honest.

The gas regulator is pretty slick and how has four settings for you to choose from. The SDS website describes the settings thusly:

…smallest dot = basically no gas, no rounds will usually cycle when the regulator is on this position. Next smallest dot = “00” buckshot, high velocity rounds and slugs. Next to largest dot = all things in between your results and field testing will be required to see what your individual shotgun will run in this setting. Largest dot = birdshot and other lower powered ammunition.

You’ll notice it has an AK-74 looking buttstock but it is actually hollow and very light. It’s nicely formed and installed but the net result is that the shotgun is light overall but very front-heavy. I planned to replace the buttstock, grip and forearm from the start and I will describe what was one and why in future posts in this series.

It uses Saiga magazines also. One five round mag comes with the shotgun and SDS now sells 10 round magazines also that you can readily find. It’s actually harder to find spare five round SDS-brand magazines right now than the 10 round units.

By the way, if you are interested about how it shoots, I haven’t had a chance to take it out yet. In researching the shotgun and how durable it was, I talked to Paul Popov and he has 350 rounds through his with no signs of trouble. I also talked to Justin McMillion at JMAC Customs and they have put through about 500 rounds also with no problems showing up. Here is a great overview video from Justin and his wife Ashley:

To sum it all up, I was pretty impressed with my initial just out of the box assessment. I’m certainly not done though as I bought the Lynx specifically to customize and blog about. The custom Lynx 12 blog series will have two more posts – one about disassembly and then one with the customizations I made.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, I may be paid via an affiliate program such as Avantlink, Impact, Amazon and eBay.