The global small arms ammunition market is governed by a complex interplay of engineering safety margins, historical legacy, and evolving performance requirements. Within this landscape, the designations “+P” (Plus Pressure) and “+P+” (Plus P Plus) represent critical, yet often misunderstood, classifications that bridge the gap between widely circulated legacy firearm designs and the performance potential of modern propellants and metallurgy. This report provides an exhaustive industry analysis of these high-pressure ammunition types, evaluating their history, engineering specifications, operational efficacy, and economic viability in the current market.

Our research confirms that “+P” is a formal technical standard maintained by the Sporting Arms and Ammunition Manufacturers’ Institute (SAAMI), denoting a Maximum Average Pressure (MAP) approximately 10% higher than the standard specification for a specific set of cartridges. This designation serves a vital engineering function: it allows ammunition manufacturers to offer modernized performance for widely used calibers while distinguishing these loads from those intended for older, metallurgically inferior firearms. In contrast, the “+P+” designation is an informal, non-standardized nomenclature used primarily in law enforcement contracts. It indicates pressures exceeding the +P standard, often encroaching upon proof-load territories, and carries significant liability and safety implications for the end-user.

From an operational perspective, the analysis indicates that +P ammunition offers measurable benefits in specific defensive scenarios, particularly by increasing muzzle velocity to ensure reliable hollow-point expansion in short-barreled concealed carry firearms. However, this performance comes at a premium cost—typically 15-30% higher than standard training ammunition—and accelerates mechanical wear on firearm components such as recoil springs, locking lugs, and frames. The “+P+” category, while historically significant in the evolution of 9mm duty efficacy (exemplified by the Illinois State Police’s use of the 9BPLE load), is increasingly becoming an engineering relic. Modern projectile technologies now achieve superior terminal ballistics without necessitating the extreme chamber pressures that characterize +P+ loads.

Furthermore, current trends in cartridge design, such as the introduction of the .30 Super Carry and the 6mm ARC, suggest a shift away from the “+P” nomenclature. Contemporary cartridges are being engineered with high baseline pressures (50,000+ psi) from their inception, effectively “baking in” the performance that +P previously added as an aftermarket modification. While the +P designation remains essential for the continued relevance of legacy platforms like the.38 Special and 9mm Luger, the industry practice of creating “overpressure” tiers is likely to diminish for new cartridge designs. This report concludes that while +P remains a valid and valuable tool for optimizing specific legacy systems, the future of small arms ammunition lies in cartridges designed holistically for high-pressure operation, rendering the concept of “overpressure” obsolete for next-generation platforms.

1. Introduction: The Nomenclature of Power and the Official Designation List

In the precise discipline of small arms ballistics, nomenclature is not merely a labeling convention; it is a code of engineering limits, safety protocols, and performance expectations. For the industry analyst and the ballistics engineer, the terms “+P” and “+P+” signify specific deviations from established baselines. To navigate this technical landscape, one must first establish the scope of these designations and identify exactly which cartridges are governed by them.

The term “+P” strictly refers to cartridges that have been formally vetted and standardized by the Sporting Arms and Ammunition Manufacturers’ Institute (SAAMI). It is not a generic suffix that can be applied to any caliber. It is a specific engineering standard that defines a higher Maximum Average Pressure (MAP) for a cartridge that shares external dimensions with a lower-pressure parent cartridge. This distinction is critical for safety: the +P cartridge will physically fit into a firearm designed for the standard pressure version, creating a potential for catastrophic failure if the firearm’s metallurgy is insufficient.

In response to the specific inquiry regarding which rounds currently carry these designations, the list of SAAMI-recognized +P cartridges is remarkably short. Despite the vast diversity of the ammunition market, only five cartridges have an official, industry-sanctioned “+P” standard.

The Official SAAMI +P Cartridge List:

- 9mm Luger +P (9x19mm Parabellum)

- .38 Special +P

- .45 Automatic +P (commonly known as.45 ACP +P)

- .38 Super +P (Technically the modern standard for the.38 Super, distinguished from the.38 Automatic)

- .257 Roberts +P (The sole rifle cartridge in the +P registry)

Any other cartridge labeled “+P”—such as “.380 ACP +P” or “.40 S&W +P”—is strictly a marketing creation. Such labels do not correspond to any published SAAMI standard, meaning they are uncertified wildcat loads operating outside of recognized industry safety margins.

The “+P+” designation, by contrast, refers to any load that exceeds the SAAMI +P pressure limit. There is no official list of +P+ cartridges because the designation itself is unrecognized by standards bodies. However, it is most commonly encountered in 9mm Luger and .38 Special, historically produced for law enforcement contracts to extract maximum stopping power from service weapons.

2. The Physics and Measurement of Ballistic Pressure

To accurately evaluate the implications of +P and +P+ ammunition, the analyst must first ground the discussion in the physics of internal ballistics. Pressure in a firearm chamber is not a static variable; it is a dynamic event, a violent spike occurring over mere milliseconds. The measurement of this event dictates the safety standards for the entire industry.

2.1 The Nature of the Pressure Curve

When the firing pin strikes the primer, it ignites the propellant. As the powder burns—deflagrates—it generates high-temperature gas that expands rapidly. This expansion creates pressure inside the cartridge case. In a closed system, this pressure would rise until the vessel burst. In a firearm, the “weakest link” is the bullet, which is pushed down the barrel, increasing the volume of the combustion chamber and eventually relieving the pressure.

The Maximum Average Pressure (MAP) is the peak of this curve. However, the total energy imparted to the bullet—and thus its velocity—is determined by the area under the pressure curve. A +P load typically uses a slightly faster-burning powder or a higher charge weight to raise the peak of this curve, increasing the total force exerted on the projectile base before it exits the muzzle.1

2.2 Units of Measurement: The Great Divergence (CUP vs. PSI)

A significant source of confusion in historical ballistic data is the unit of measurement. The history of +P is bisected by a technological shift in how pressure is recorded.

Copper Units of Pressure (CUP):

Until the mid-to-late 20th century, pressure was measured using a mechanical system known as the “Copper Crusher.” A piston actuated by chamber gas would compress a calibrated copper cylinder. The degree to which the copper was shortened was measured and cross-referenced against a tariff table to generate a CUP value.

- Limitations: This method effectively integrates force over time but is slow to react. It often misses the true instantaneous peak of the pressure spike. It is a mechanical approximation of peak force.3

Pounds Per Square Inch (PSI) / Piezoelectric:

Modern SAAMI standards utilize piezoelectric transducers. These are quartz or ceramic sensors that generate an electrical charge proportional to the stress applied to them. This provides a real-time, high-resolution graph of pressure vs. time, measured in PSI.

- Precision: This method captures the exact peak pressure, which is often higher than what the copper crusher method indicated.

The Engineering Disconnect: There is no linear mathematical formula to convert CUP to PSI. The correlation depends on the specific rise time of the pressure pulse, which varies by cartridge shape and powder burn rate. For example, in the.38 Special, the +P limit is defined as 20,000 CUP and 20,000 PSI—a rare convergence. In contrast, the.357 Magnum is 45,000 CUP but only 35,000 PSI. This non-linearity requires analysts to be extremely careful when comparing historical load data (often in CUP) with modern +P specs (in PSI).5

2.3 Global Standards: SAAMI vs. C.I.P.

The definition of “pressure” also depends on geography. The United States follows SAAMI protocols, while Europe (and many NATO specifications) follows the Commission Internationale Permanente (C.I.P.).

- SAAMI (USA): Uses a conformal transducer. The sensor is placed around the middle of the cartridge case, measuring the expansion of the brass case wall as a proxy for internal pressure. The brass acts as a gasket or buffer between the gas and the sensor.6

- C.I.P. (Europe): Uses a drilled case method. A hole is physically drilled into the cartridge case, allowing the gas to directly contact the sensor. This measurement is typically taken closer to the case mouth (the “forward” position).7

Implication for +P: Because the C.I.P. sensor is exposed directly to gas and is located in a different part of the standing wave of pressure, C.I.P. readings are often higher than SAAMI readings for the exact same ammunition. This creates a situation where a standard European load might appear to be “+P” when measured on American equipment, or vice versa, purely due to the testing methodology. This is a critical nuance when analyzing “NATO” pressure ammunition, which is tested under C.I.P.-like protocols (EPVAT).8

3. Historical Evolution: The Metallurgical Lag

The existence of “+P” ammunition is fundamentally a solution to a historical problem: the “Metallurgical Lag.” It represents the century-long struggle to reconcile 19th-century gun design with 20th-century propellant chemistry.

3.1 The Black Powder Legacy

For centuries, black powder was the sole propellant for firearms. It is a low-explosive that deflagrates at a relatively constant subsonic rate. The pressure curve of black powder is gentle, and the maximum pressure is self-limiting by volume; one can only fit so much powder into a case. Consequently, firearms from the mid-to-late 1800s—such as the Colt Single Action Army (1873) or the early Smith & Wesson Hand Ejectors (1899)—were made of mild steels or iron, designed to contain pressures rarely exceeding 14,000 to 15,000 PSI.10

3.2 The Smokeless Revolution and the Safety Gap

The invention of smokeless powder (nitrocellulose) changed everything. It offered vastly higher energy density and burn rates. A small pinch of smokeless powder could generate pressures that would shatter a black-powder-era cylinder. However, to maintain backward compatibility, ammunition manufacturers introduced smokeless cartridges that were dimensionally identical to the old black powder rounds (e.g.,.38 Special,.45 Colt).

To prevent older guns from exploding, factories deliberately “downloaded” these smokeless rounds to mimic the low pressures of black powder. This created a Safety Gap. By the 1920s and 30s, new firearms were being built with heat-treated alloy steels capable of holding 30,000+ PSI, but they were legally and commercially shackled to ammunition loaded to 15,000 PSI to protect the owners of antique guns.12

3.3 The Mid-Century Disruption: Super Vel and the “Treasury Load”

This status quo held until the 1960s, when the gap between gun strength and ammo power became too obvious to ignore. Lee Jurras, a ballistic pioneer, founded Super Vel ammunition. Jurras recognized that modern snub-nose revolvers (like the Smith & Wesson Chiefs Special) were strong enough to handle much more than the anemic factory loads of the day.

Jurras introduced lightweight (110-grain) bullets driven at high velocities (over 1,100 fps) using high-pressure loads. These rounds offered drastic improvements in terminal performance but exceeded the industry standards of the time. This innovation forced the major manufacturers (Winchester, Remington, Federal) to respond.14

Simultaneously, the U.S. Secret Service and Treasury Department requested a high-performance load for their agents. Winchester responded with the Q4070, known as the “Treasury Load.” This was a.38 Special cartridge loaded to approximately 23,500 CUP—nearly 40% higher than the standard limit. It was essentially a.357 Magnum load in a.38 Special case, designed solely for sturdy, modern revolvers. This round is the spiritual ancestor of the modern +P and +P+ classifications.15

4. Deep Dive: The SAAMI +P Cartridges

This section provides a cartridge-by-cartridge analysis of the five official SAAMI +P designations, exploring the specific engineering context and utility of each.

4.1 9mm Luger +P (9x19mm Parabellum)

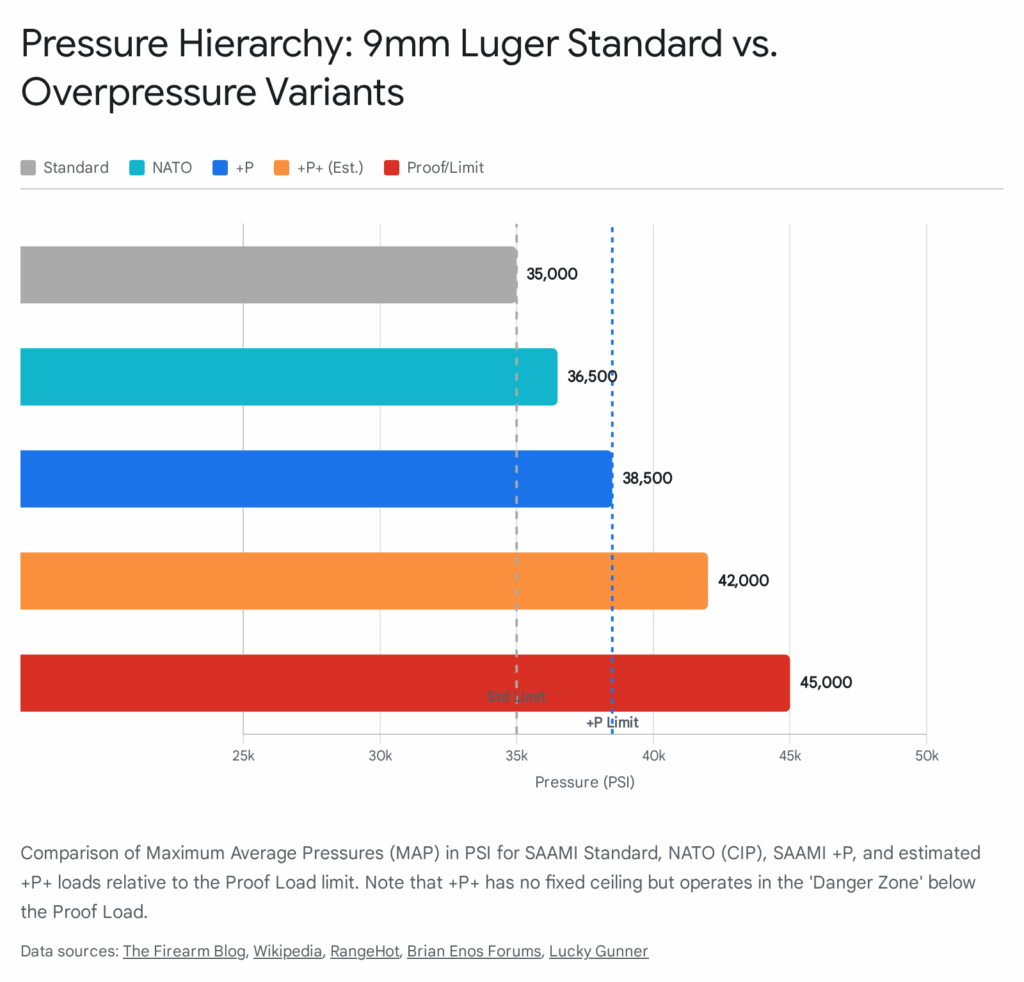

- Standard Pressure: 35,000 PSI

- +P Pressure: 38,500 PSI (+10%)

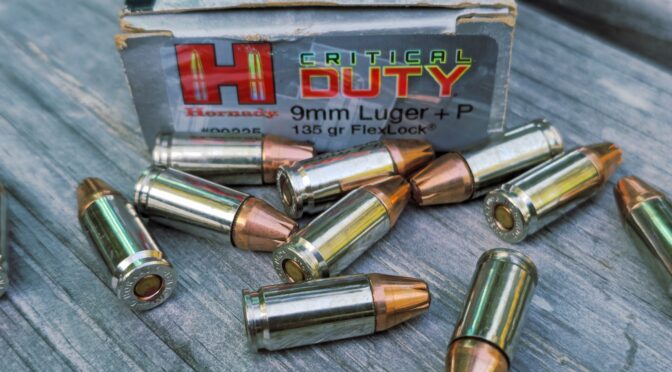

- Context: The 9mm Luger is the most ubiquitous centerfire handgun cartridge in the world. The +P designation here is vital for modern defensive use. The standard 35,000 PSI limit is a legacy of the P08 Luger toggle-lock action, which is not as robust as modern tilting-barrel designs. The 10% pressure boost in +P allows for velocities that ensure reliable expansion of hollow points through heavy clothing, particularly in short-barreled subcompacts (e.g., Glock 26, Sig P365) where velocity loss is a major concern. It also bridges the gap to NATO specification ammunition, ensuring that civilian defensive ammo cycles reliably in stiffly-sprung service pistols.16

4.2.38 Special +P

- Standard Pressure: 17,000 PSI

- +P Pressure: 20,000 PSI (+17.6%)

- Context: This is the most critical +P designation in the industry. The standard.38 Special is severely hobbled by its black powder origins (originally ~14,000 PSI). A standard pressure.38 Special often fails to expand modern hollow points reliably, acting more like a solid projectile. The +P rating raises the pressure to 20,000 PSI, which is still low by modern standards (compare to 9mm at 35,000), but significant enough to drive a 125-grain or 135-grain bullet to effective velocities (~950-1000 fps). The “FBI Load”—a 158-grain Lead Semi-Wadcutter Hollow Point (LSWCHP) +P—remains the benchmark for terminal effectiveness in snub-nose revolvers.18

4.3.45 Automatic +P (.45 ACP)

- Standard Pressure: 21,000 PSI

- +P Pressure: 23,000 PSI (+9.5%)

- Context: The.45 ACP is naturally a low-pressure cartridge, designed in 1904 to duplicate the ballistics of.45 Colt black powder loads. Its large case volume and heavy bullet (230 grain) mean it does not need high pressure to achieve its baseline performance. The +P designation is less critical here than in 9mm or.38 Special. It is primarily used to boost the velocity of lighter (185-grain or 200-grain) projectiles to flatten trajectory and increase kinetic energy for law enforcement applications. However, the heavy recoil penalty of.45 ACP +P often outweighs the marginal terminal gains, making it less popular than its 9mm counterpart.3

4.4.38 Super +P

- Standard Pressure: N/A (See Note)

- +P Pressure: 36,500 PSI

- Context: This cartridge is a semantic anomaly. The.38 Super was introduced in 1929 as a high-pressure loading of the older.38 ACP (which was limited to 26,500 PSI). Dimensionally, the cases are identical. To prevent shooters from loading the hot new rounds into old, weak Colt M1900 pistols, the industry eventually added the “+P” suffix to the name of the cartridge itself. Thus, there is no “Standard.38 Super”—the cartridge is officially named “.38 Super +P” or “.38 Super Automatic +P”. It is a favorite in competitive shooting (IPSC/USPSA) because its high pressure allows it to generate the gas volume necessary to work compensators efficiently.21

4.5.257 Roberts +P

- Standard Pressure: 54,000 PSI

- +P Pressure: 58,000 PSI (+7.4%)

- Context: The only rifle cartridge on the list. The.257 Roberts was a wildcat based on the 7x57mm Mauser. When Remington standardized it, they chose a very low pressure limit (54,000 PSI) out of fear that the rounds would be used in converted, weaker Spanish Mauser actions or rolling blocks. This stifled the cartridge’s potential. Decades later, a +P standard was introduced (58,000 PSI) to allow the round to perform as originally intended in modern bolt-action rifles like the Winchester Model 70 and Ruger M77. This brings it closer to the.25-06 in performance.22

5. The Twilight Zone: +P+ and Non-Standard Overpressure

Beyond the regulated world of SAAMI lies the domain of +P+. This designation denotes a load that exceeds the +P standard. It is critical to understand that SAAMI does not recognize, regulate, or test +P+ ammunition. It is a “use at your own risk” category.

5.1 The Law Enforcement Origins

The +P+ designation emerged largely from the demands of American law enforcement in the 1980s. Agencies transitioning to 9mm pistols (the “Wonder Nine” era) were skeptical of the 9mm’s stopping power compared to their old.357 Magnums. To secure contracts, manufacturers like Federal and Winchester created “Law Enforcement Only” loads that pushed the 9mm envelope.

The most famous example is the Federal 9BPLE (9mm 115-grain JHP +P+). Adopted by agencies like the Illinois State Police and the Border Patrol, this round was loaded to pressures estimated between 38,500 and 42,000 PSI.24 It drove a standard cup-and-core bullet at 1,300+ fps. The high velocity caused violent fragmentation and reliable expansion even with the primitive bullet technology of the time. The Illinois State Police reported excellent street results, cementing the +P+ legend.26

5.2 Engineering Risks of +P+

Because there is no upper ceiling defined by SAAMI for +P+, a cartridge marked +P+ could technically be loaded to proof-load levels (45,000+ PSI for 9mm). This creates severe risks:

- Case Head Separation: The unsupported area of the case web (common in Glock chambers) can bulge or rupture (“Glock smile”), venting 40,000 PSI gas into the magazine well and the shooter’s hands.27

- Slide Velocity: Excessive pressure drives the slide rearward at velocities the recoil spring cannot manage. This leads to the slide hammering the frame stops, causing peening, cracking of locking blocks, or shearing of barrel lugs.

- Timing Issues: The slide may move faster than the magazine spring can lift the next round, causing bolt-over-base malfunctions.28

Consequently, almost every major firearm manufacturer (Glock, HK, Sig Sauer, Smith & Wesson) explicitly states in their manuals that the use of +P+ ammunition voids the warranty. They cannot warranty a product against a standard that does not exist.29

6. Related High-Pressure Standards and Modern Developments

The concept of “+P” is increasingly being challenged by global standardization and modern cartridge design philosophies that abandon the “downloaded baseline.”

6.1 The NATO vs. SAAMI Confusion

A frequent point of confusion is the relationship between civilian 9mm +P and 9mm NATO ammunition. 9mm NATO is governed by EPVAT (Electronic Pressure Velocity and Action Time) standards, which are closely aligned with C.I.P. protocols.

- 9mm NATO Pressure: Approximately 36,500 PSI (as measured by C.I.P. methods).

- Comparison: This places 9mm NATO squarely between SAAMI Standard (35,000 PSI) and SAAMI +P (38,500 PSI).

- Verdict: 9mm NATO is effectively a “mild +P” load. It is perfectly safe to use in any modern firearm rated for +P ammunition. The “NATO” stamp is essentially a military quality control and dimensional standard, but in terms of pressure, it is a known quantity.9

6.2 Modern Cartridges “Born Hot”

The +P designation is a relic of upgrading old cartridges. New cartridges designed in the 21st century do not use this system. They are designed for high pressures from day one.

- 30 Super Carry: Introduced by Federal in 2022, this cartridge has a standard SAAMI MAP of 52,000 PSI. There is no “30 Super Carry +P” because the baseline is already set at the metallurgical limit of modern handgun actions. It operates at rifle-like pressures to deliver 9mm performance in a smaller diameter.31

- 6mm ARC: A modern rifle cartridge optimized for the AR-15 platform, standardized at 52,000 PSI.33

- 5.7x28mm FN: Another high-pressure micro-caliber (approx 50,000 PSI).

This trend suggests that the “+P” nomenclature will eventually die out with the legacy cartridges it supports. Future firearm systems will simply be rated for 50,000+ PSI as the new normal.

7. Engineering Impact on Firearms: Metallurgy and Wear

Can +P be used in normal firearms? The answer lies in the specific metallurgy of the gun in question.

7.1 Barrel Steels: 4140 vs. 4150

Modern firearm barrels and actions are typically machined from Chromoly Steel, specifically AISI grades 4140 and 4150.

- AISI 4140: (~0.40% Carbon). The industry workhorse for civilian firearms. It offers an excellent balance of toughness and tensile strength (approx 95,000 – 100,000+ PSI yield strength after heat treat).

- AISI 4150: (~0.50% Carbon). Often used in “Mil-Spec” barrels (e.g., M4 carbines). The higher carbon content allows for greater hardness and better resistance to heat erosion during rapid fire.34

Both steels are more than capable of containing the static pressure of a +P load (38,500 PSI). The barrel will not burst. The “Hoop Stress” generated by +P is well within the elastic limit of these alloys.

7.2 The Weak Link: Fatigue and Moving Parts

The danger of +P is not a single catastrophic explosion, but accelerated fatigue.

- Bolt Thrust: Pressure exerts force backward on the breech face. In a locked-breech pistol, this force is transmitted through the locking lugs or locking block. Repeated stress cycles at +P levels can cause microscopic stress fractures to propagate faster than at standard pressures.

- Carpenter 158 Steel: This is why high-pressure bolts (like in the AR-15) are often made of Carpenter 158, a proprietary case-hardening steel. It provides a super-hard outer surface for wear resistance while maintaining a softer, ductile core to absorb the shock of the bolt thrust without snapping.36

7.3 Recoil Dynamics and Spring Rates

In semi-automatic pistols, +P ammunition increases the slide velocity. If the slide moves too fast, it acts as a battering ram against the frame.

- Solution: Heavier recoil springs. For example, a standard 1911 Government model (.45 ACP) uses a 16lb recoil spring. When shooting a steady diet of +P, it is standard engineering practice to upgrade to an 18.5lb or 20lb spring. This absorbs the extra energy, preventing frame battering, but may cause the gun to malfunction (failure to eject) if the user switches back to light target ammo.38

8. Operational Performance: Terminal Ballistics

The ultimate question for the user is: “What do I get for the extra pressure?” The answer is primarily Velocity, which drives Reliability.

8.1 The Velocity Threshold

Hollow point bullets rely on fluid dynamics to expand. Fluid enters the nose cavity, creating hydraulic pressure that peels back the copper jacket. Every bullet design has a “velocity threshold” below which this hydraulic pressure is insufficient to expand the bullet.

- The Short Barrel Problem: A 9mm bullet designed to expand at 1,100 fps (from a 4-inch barrel) might only travel at 1,000 fps from a 3-inch subcompact barrel (like a Sig P365). At this lower speed, it may fail to expand.

- The +P Solution: By using +P ammunition, the shooter can regain that lost 50-100 fps. This pushes the bullet back above its expansion threshold, ensuring it performs as designed even from a deep-concealment pistol.39

8.2 Barrier Penetration

In law enforcement, bullets must often pass through barriers (auto glass, heavy denim, plywood) before hitting the target. Higher velocity (and thus higher kinetic energy) aids in barrier defeat. The extra energy helps the bullet retain its structural integrity and momentum after the initial impact with the barrier.40

9. Market and Economic Analysis

9.1 Cost vs. Benefit

The market for +P ammunition is heavily segmented.

- Standard Training Ammo (FMJ): High volume, low margin. ~$0.25 – $0.30 per round.

- Defensive Ammo (+P JHP): Low volume, high margin. ~$1.20 – $1.80 per round.41

Is it worth the price?

- For Training: No. The slight difference in recoil is not worth the 400-500% price hike. Standard pressure ammo is sufficient for marksmanship practice.

- For Defense: Yes. The cost of the ammunition is negligible compared to the value of reliability in a life-threatening scenario. The premium price pays for the high-tech bonded bullet (Gold Dot, HST), nickel-plated brass (for corrosion resistance and slick feeding), and low-flash propellants, not just the extra pressure.

10. Future Trajectory: Is +P Obsolete?

The practice of creating +P variants is a specific solution to the problem of legacy firearms. As we move further into the 21st century, the need for this bifurcation is waning.

10.1 The End of “Downloading”

New cartridges like the .30 Super Carry (52,000 PSI) and 6mm ARC (52,000 PSI) demonstrate the new industry philosophy. Engineers are no longer constrained by 1870s metallurgy. They are setting the baseline pressure at the upper limits of modern materials. There will never be a “30 Super Carry +P” because the standard load is already maximized.31

10.2 The Persistence of Legacy

However, the +P designation will never disappear as long as the 9mm Luger,.38 Special, and.45 ACP remain popular. There are simply too many billions of rounds of these calibers in circulation, and too many millions of older firearms that require the lower pressure standard. +P will remain the necessary bridge, allowing a 1911 to function as a modern defensive tool while keeping a 1940s service pistol safe from destruction.

11. Conclusion

The landscape of +P and +P+ ammunition is a testament to the firearm industry’s ability to innovate within the rigid constraints of history and safety.

- Engineering Validity: The +P designation is a legitimate, highly regulated engineering standard that provides a quantified and safe performance boost (approx. 10%) for modern firearms. It is the preferred choice for defensive applications in 9mm,.38 Special, and.45 ACP, particularly for compact firearms where velocity loss is a liability.

- The Danger Zone: The +P+ designation is a non-standardized contractual artifact. While historically effective (e.g., the 9BPLE), it carries significant risks of accelerated wear and catastrophic failure in unsupported chambers. It should be avoided by the general public unless the firearm is explicitly rated for such pressures by the manufacturer—a rarity.

- Obsolescence: While vital for legacy calibers, the concept of +P is obsolete for new designs. The future of small arms ballistics belongs to cartridges like the.30 Super Carry, which normalize 50,000+ PSI pressures as the standard, rendering the need for an “overpressure” suffix a footnote of the 20th century.

For the professional analyst and the end-user, the guidance is clear: Embrace +P for duty and defense in modern firearms to ensure expansion reliability. Treat +P+ with extreme caution. And recognize that the future of ballistics is not about “hotter” loads, but smarter, high-pressure cartridge design from the ground up.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, we are only paid if there is an affiliate program such as Avantlink, Impact, Amazon and eBay and only if you purchase something. If you’d like to directly contribute towards our continued reporting, please visit our funding page.

Works cited

- American National Standard Voluntary Industry Performance Standards for Pressure and Velocity of Centerfire Rifle Ammunition for the Use of Commercial Manufacturers – SAAMI, accessed December 25, 2025, https://saami.org/wp-content/uploads/2018/01/206.pdf

- American National Standard Voluntary Industry Performance Standards for Pressure and Velocity of Rimfire Sporting Ammunition for the Use of Commercial Manufacturers – SAAMI, accessed December 25, 2025, https://saami.org/wp-content/uploads/2018/01/Z299-1_ANSI-SAAMI_Rimfire.pdf

- SAAMI Pressures: Data From The Current SAAM Specs (2004) Please Note That Some Are in Psi and Some Cup – Scribd, accessed December 25, 2025, https://www.scribd.com/document/639201414/Untitled

- Ammunition Pressure Testing – Guns and Ammo, accessed December 25, 2025, https://www.gunsandammo.com/editorial/ammunition-pressure-testing/458750

- Cartridge Pressure Standards, accessed December 25, 2025, http://kwk.us/pressures.html

- Ways to Measure Pressure | The Ballistic Assistant, accessed December 25, 2025, https://www.theballisticassistant.com/ways-to-measure-pressure/

- Small arms ammunition pressure testing – Wikipedia, accessed December 25, 2025, https://en.wikipedia.org/wiki/Small_arms_ammunition_pressure_testing

- New to Grendel – Why the QL difference between SAAMI and CIP?, accessed December 25, 2025, https://www.65grendel.com/forum/forum/-6-5-grendel-discussion-forums/-6-5-grendel-ammunition-reloading/11854-new-to-grendel-why-the-ql-difference-between-saami-and-cip

- 9mm Luger Vs. 9mm Nato – 9mm/38 Caliber – Brian Enos’s Forums… Maku mozo!, accessed December 25, 2025, https://forums.brianenos.com/topic/22682-9mm-luger-vs-9mm-nato/

- Black and Smokeless Powders – National Academies of Sciences, Engineering, and Medicine, accessed December 25, 2025, https://www.nationalacademies.org/read/6289/chapter/3

- The History of Propellants – The Ballistic Assistant, accessed December 25, 2025, https://www.theballisticassistant.com/the-history-of-propellants/

- Smokeless powder – Wikipedia, accessed December 25, 2025, https://en.wikipedia.org/wiki/Smokeless_powder

- The Transition from Black Powder to Smokeless Powder: How It Changed Firearms Forever, accessed December 25, 2025, https://inside.safariland.com/blog/the-transition-from-black-powder-to-smokeless-powder-how-it-changed-firearms-forever/

- The 38 Special +P+ Treasury Load – Shooting Times, accessed December 25, 2025, https://www.shootingtimes.com/editorial/38-special-treasury-load/389102

- Ammo Evolution: .38 Special Treasury Load – RevolverGuy.Com, accessed December 25, 2025, https://revolverguy.com/ammo-evolution-38-special-treasury-load/

- SAMMI pressure specs – RangeHot – Expert Firearms Reviews & Guides, accessed December 25, 2025, https://rangehot.com/sammi-pressure-specs/

- 9×19mm Parabellum – Wikipedia, accessed December 25, 2025, https://en.wikipedia.org/wiki/9%C3%9719mm_Parabellum

- Cartridge of the Century: A History of the 38 Special – Lucky Gunner, accessed December 25, 2025, https://www.luckygunner.com/lounge/history-38-smith-wesson-special/

- That Classic Old FBI .38 Special Load – The Mag Life – GunMag Warehouse, accessed December 25, 2025, https://gunmagwarehouse.com/blog/that-classic-old-fbi-38-special-load/

- 45 vs 38 Super – Handgun Caliber Comparison by Ammo.com, accessed December 25, 2025, https://ammo.com/comparison/45-vs-38-super

- Making the Case for .38 Super +P | An Official Journal Of The NRA – American Rifleman, accessed December 25, 2025, https://www.americanrifleman.org/content/making-the-case-for-38-super-p/

- .257 Roberts – Wikipedia, accessed December 25, 2025, https://en.wikipedia.org/wiki/.257_Roberts

- .257 Roberts +P | Shooters’ Forum, accessed December 25, 2025, https://forum.accurateshooter.com/threads/257-roberts-p.3953571/

- Rise and Fall of the 9mm Subsonic Hollowpoint | Office of Justice Programs, accessed December 25, 2025, https://ojp.gov/ncjrs/virtual-library/abstracts/rise-and-fall-9mm-subsonic-hollowpoint

- 9mm +P and +P+ Cartridges: Winchester & Remington Win – Gun Tests, accessed December 25, 2025, https://www.gun-tests.com/ammo/9mm-p-and-p-cartridges-winchester-remington-win-2/

- Why Are 9mm Pistols Dominant in Law Enforcement? – American Handgunner, accessed December 25, 2025, https://americanhandgunner.com/our-experts/why-are-9mm-pistols-dominant-in-law-enforcement/

- Understanding Common Cartridge Malfunctions – Ammo Safety, accessed December 25, 2025, https://kirammo.com/understanding-common-cartridge-malfunctions-ammo-safety/

- Firearm malfunction – Wikipedia, accessed December 25, 2025, https://en.wikipedia.org/wiki/Firearm_malfunction

- What is +P Ammunition? – True Shot Ammo, accessed December 25, 2025, https://trueshotammo.com/blogs/true-shot-academy/what-is-p-ammunition-is-overpressure-ammo-safe

- 9mm NATO vs. 9mm Luger | thefirearmblog.com, accessed December 25, 2025, https://www.thefirearmblog.com/blog/2009/05/03/9mm-nato-vs-9mm-luger/

- Public Introduction – 30 Super Carry – 2022-06-30 – SAAMI, accessed December 25, 2025, https://saami.org/wp-content/uploads/2022/10/Public-Introduction-30-Super-Carry-2022-06-30.pdf

- SAAMI Publishes 30 Super Carry Cartridge Specs – The Firearm Blog, accessed December 25, 2025, https://www.thefirearmblog.com/blog/2022/07/06/30-super-carry-saami-specs/

- SAAMI Rifle Cartridge Catalog – The Ballistic Assistant, accessed December 25, 2025, https://www.theballisticassistant.com/saami-rifle-cartridge-catalog/

- 4140 vs 4150 Steel | Sorting, Differences & More – Verichek Technical Services, accessed December 25, 2025, https://verichek.net/4140-vs-4150-steel.html

- Steel for Firearms: Alloys and Key Characteristics, accessed December 25, 2025, https://www.jadesterling.com/ask-the-metallurgist/steel-for-firearms-alloys-and-key-characteristics

- Carpenter 158 – Specialty Alloys, accessed December 25, 2025, https://www.carpentertechnology.com/alloy-finder/carpenter-158

- What to Look for When Buying a Bolt Carrier Group | BUYER’S GUIDE – Wing Tactical, accessed December 25, 2025, https://www.wingtactical.com/what-to-look-for-when-buying-a-bolt-carrier-group/

- 9mm 1911 – 11lb Wolff spring vs. stock 14lb spring – 1911-style Pistols – Brian Enos’s Forums, accessed December 25, 2025, https://forums.brianenos.com/topic/208247-9mm-1911-11lb-wolff-spring-vs-stock-14lb-spring/

- Is +P Ammunition Safe? – The Armory Life, accessed December 25, 2025, https://www.thearmorylife.com/is-p-ammunition-safe/

- Life or Death: Best 9mm Defense Ammo – Expert Buyer Guide – Target Sports USA, accessed December 25, 2025, https://blog.targetsportsusa.com/best-9mm-defense-ammo-expert-buyer-guide/

- Best 9mm Ammo of 2025, Tested and Reviewed – Outdoor Life, accessed December 25, 2025, https://www.outdoorlife.com/gear/best-9mm-ammo/