In doing this M92, I wanted to use tools that many guys already have or can get without spending a fortune. I could have used my mill or drill press but I wanted you to see that some simple hand tools are all you need. The follow are what I used and certainly you can use other tools that work for you.

Dremel Tool with cutoff wheel, abrasive wheel and sanding drum

If you do much gun work, you’ll find a rotary tool to be a huge time saver when used properly. I have an ancient corded Dremel tool made for Sears plus an 18volt cordless that I use all the time. You will need some thin cut off wheels for metal, a small abrasive wheel (if you want or do it all with the sanding drum) and a sanding drum. Because I use my Dremel a lot, I buy the discounted multibit packs when I find them.

Here are the tools at Amazon:

One thing I would recommend against is buying cheap no-name import bits – they often fall apart or dull real fast. For the last few years, I have been buying Dremel brand bits off Amazon. Everything you’ll need is in the below accessory pack:

The one thing I will say here is to practice before you try to actually work on your new pistol. I can’t stress this enough – please practice first!! A Dremel can scoot around and chew things up if your hands aren’t supported and you don’t know the “feel” of how to cut things. So please be sure to do some testing and practice before you go near your pistol. I’ve been using a Dremel for almost 30 years (literally) and I still get surprised from time to time but I know what to do to minimize bad things from resulting due to my experience.

Hand Drill

You just need a plain jane hand drill. It could be corded or cordless. Slower is better to avoid heat build up. You will need to drill a 3/8″ hole for the arm brace and a #21 hole for the picatinny rail screws. All the work I did was done with my Ryobi 1/2″ 18volt hand drill that I bought from Home Depot and have gotten a ton of use from over the years.

Tap Handle

If you do not have one already, go get a tap handle from your local hardware store. You will need it to get a good square grip on the #10 tap if you install the CNC Warrior picatinny rail. Some guys try to go cheap and use a small wrench but the problem is that you will have a very hard time starting the threading squarely. Spend a few bucks and get a tap handle.

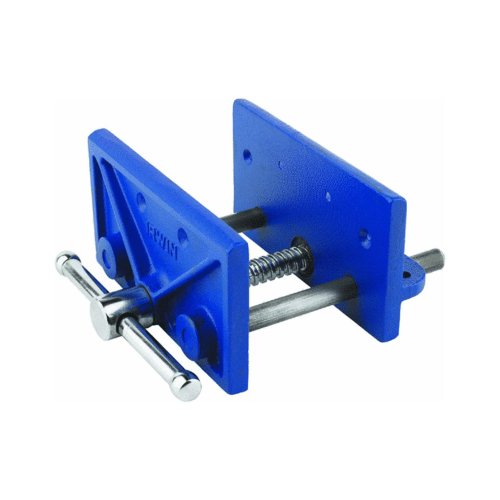

Good Vise

It really pays to have a good vise. There are so many options out there but make sure it is secure and that if it has steel jaws, that they are padded with leather, wood, plastic or something else that is relatively soft to protect the finish. It could be a tool vise or even one of the rifle cleaning and maintenance vises such as Tipton’s. Just make sure that whatever you use is firmly holding the rifle and can’t slide as you drill. You could drill it into your work bench or use some clamps on the corners.

I specifically used one of my woodworking vises that is permanently attached to my work bench for this project. It is like the following and you must add wood to make the actual jaws hence the screw holes in the side plates of the vise:

Roll Pin Punches

You could use any punch set but I like pin punches as they have a dimple in the face that goes into the roll spring to help center and drive it. Note, I have watched guys skip using a punch and just tap in the roll pin with a small hammer directly. The roll pin punches help but are not mandatory.

Hammer

I’ll skip the photo 🙂 You just need something to tap the pin punch with.

Cutting Oil

In a pinch you can use regular oil but I like to use Tap Magic for lubricating drill buts and also taps. This helps them run cooler and last longer

Cold Blue Solution and QTips

My favorite cold blue is Oxpho Blue liquid from Brownell’s. There are a lot of other brands out there and guys have told me they like the cold blue solution from Birchwood Casey as well.

Deburring tool or Sandpaper

The last tool I would recommend is a deburring tool. It is very handy for clearing drilled holes of burs. I used it after I drilled the rear of the receiver for example.

The next posts will be about doing the actual work – I promise 🙂