In the domain of small arms precision instrumentation, the optical sighting system represents a critical path component where performance failure is non-negotiable. For industry stakeholders, agency procurement officers, and individual end-users, the acquisition of “Tier 1” optics—specifically those manufactured by Nightforce Optics—often constitutes a significant capital expenditure, with flagship units such as the Advanced Tactical Riflescope (ATACR) series commanding retail prices between $2,800 and $4,000. This report provides an exhaustive engineering and market analysis of the viability of purchasing “blemished” (blem), “demonstration” (demo), and refurbished Nightforce optics as a cost-mitigation strategy.

The central thesis of this analysis is that purchasing blemished Nightforce optics represents a highly efficient procurement strategy for users prioritizing functional performance over aesthetic perfection. Data aggregated from major authorized distributors, including EuroOptic and Mile High Shooting Accessories, indicates that “blemished” inventory typically provides a price reduction of 14% to 27% off the Minimum Advertised Price (MAP). For a flagship model like the ATACR 7-35×56 F1, this translates to absolute savings exceeding $1,000 per unit.

From an engineering perspective, the risks associated with these units are minimal, provided they are sourced from authorized channels. The robust 6061-T6 aluminum chassis construction of Nightforce optics means that the most common defects—superficial Type III anodizing flaws or “ring marks” from display mounting—do not compromise the structural integrity or the hermetic sealing of the system. Furthermore, Nightforce’s rigorous Quality Assurance (QA) protocols dictate that every unit, regardless of cosmetic status, must pass identical impact (1,250 G-force) and tracking tests before leaving the facility.

However, the landscape is not without nuance. A distinction must be made between “Factory Blems” (cosmetic defects from the production line) and “Used/Demo” inventory (units with mounting history). While the former carries zero mechanical risk, the latter requires careful inspection of the main tube for deformation caused by improper torque application. Additionally, while the commercial Limited Lifetime Warranty is generally applicable, specific “Mil-Spec” contract overruns may carry restricted warranty terms, necessitating diligent verification of Stock Keeping Units (SKUs).

Key Strategic Findings:

- Economic Arbitrage: The secondary market for blems offers a high “performance-per-dollar” ratio, effectively allowing users to acquire ATACR-grade glass for the price of mid-tier NX8 models.

- Mechanical Integrity: The vast majority of blems utilize the same internal erector systems and optical glass as full-price units; defects are overwhelmingly cosmetic.

- Warranty Continuity: Authorized “Like New” and “Demo” units retain full manufacturer warranty support, mitigating long-term ownership risks.

- Operational Suitability: For field applications where the optic will inevitably be subjected to environmental wear, the initial cosmetic condition is functionally irrelevant.

| For blemished Nightforce, and other name brand scopes, check out EuroOptic. This link will take you to their blemished Nightforce scopes but you can select other brands as well such as Leupold, etc. Click here. |

1. Industry Context: The Economics of Precision Manufacturing

To understand the value proposition of a “blemished” optic, one must first deconstruct the manufacturing philosophy that drives the pricing of “factory new” units. The precision optics market operates on a curve of diminishing returns where incremental improvements in optical clarity, mechanical repeatability, and durability command exponential price increases. Nightforce Optics has established itself as a benchmark in this sector, not merely through marketing, but through a manufacturing process defined by obsession with tolerance stack-up and material consistency.

1.1 The Cost of “Rugged, Reliable, Repeatable”

The Nightforce motto—”Rugged, Reliable, Repeatable”—is an engineering mandate that dictates their cost structure. Unlike consumer-grade optics that may rely on batch testing (checking one out of every 50 units), Nightforce employs a 100% inspection protocol for its professional lines.1 This involves distinct, capital-intensive processes:

- Hand-Bedded Lenses: Lenses are not merely dropped into machined seats; they are often hand-bedded with proprietary adhesives to ensure they do not shift under the massive G-forces of recoil (up to 1,250 Gs for.50 BMG applications).1 This labor-intensive process reduces the likelihood of “zero shift” but increases the unit cost significantly.

- Optical Indexing: Every lens element is matched and aligned by hand to its partners to optimize light transmission and resolution.1 This “optical indexing” yields high performance but means that a lens cannot simply be swapped out if a minor coating flaw is found late in assembly—the entire optical train is tuned.

- Mechanical Pre-Stressing: Springs and erector assemblies are often cycled and “polished” for weeks before installation to ensure that the “settling” happens at the factory, not on the user’s rifle.1

1.2 The Genesis of the “Blem”

In such a high-stakes manufacturing environment, the rejection rate for cosmetic non-conformities is stringent. A scope that tracks perfectly, holds zero under 1,200 Gs, and resolves 1951 USAF resolution targets to specification may still be rejected for a 0.5mm pit in the anodizing on the underside of the objective bell.

For the manufacturer, scrapping such a unit is economically inefficient. The “sunk cost” in the glass, the internal mechanics, and the assembly labor is preserved by designating the unit as a “Blem” (Blemished) and selling it at a discount that recovers the material cost while sacrificing the profit margin associated with a pristine retail unit. For the consumer, this represents an opportunity to pay for the engineering while declining to pay for the aesthetics.

1.3 Market Positioning of the Secondary Stream

It is important to recognize that Nightforce carefully controls this secondary inventory. You will not find these units at big-box generalist stores. They are funneled through “authorized stocking dealers” who specialize in high-end precision shooting, primarily EuroOptic, Mile High Shooting Accessories, Sport Optics, and MidwayUSA.2 This controlled distribution ensures that the brand equity is protected—these scopes are clearly demarcated as “Demos” or “Blems” so they do not dilute the perceived value of the full-price inventory.

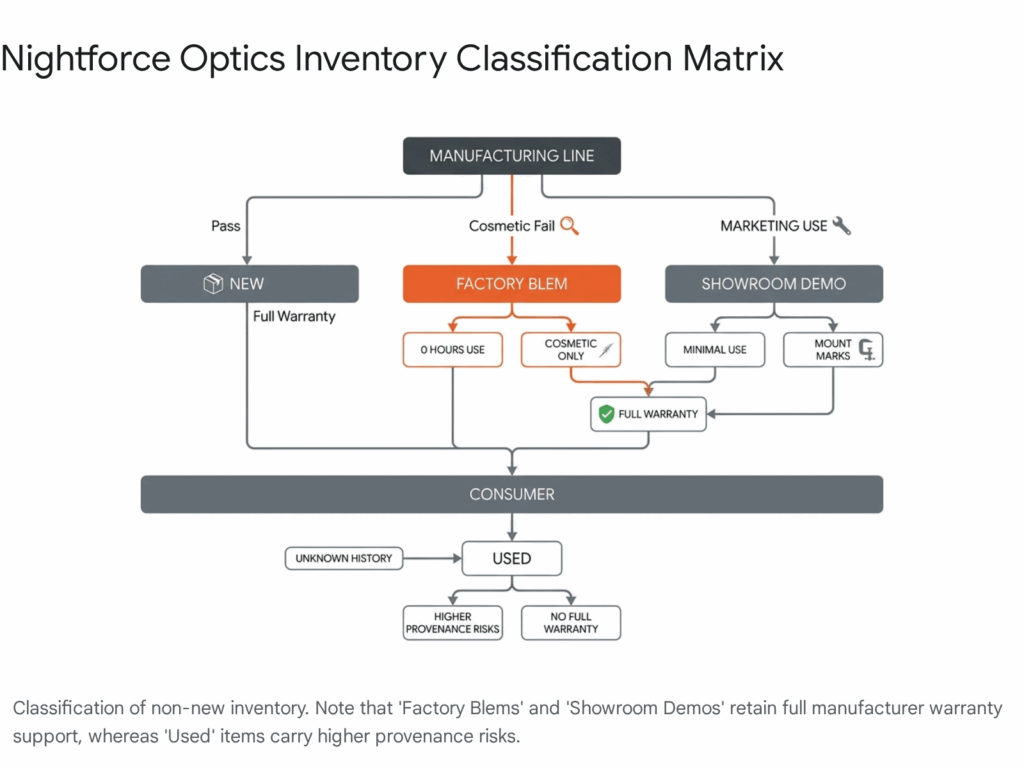

2. Taxonomy of Non-Standard Inventory

For the analyst and the engineer, precise terminology is required to assess risk. The consumer market often conflates “Blem,” “Demo,” and “Used,” but these terms represent distinct engineering states with different implications for longevity and performance. We must categorize these distinct streams of inventory to accurately assess the value proposition.

2.1 Factory Blems (Blemished)

A true “Factory Blem” is a unit that failed a specific cosmetic gate during the Quality Assurance (QA) process at the Nightforce facility. These units have never left the manufacturer’s control until sold to the distributor.

- Operational History: Zero hours. These units have never been mounted on a rifle by a user. They have only been mounted in factory test fixtures.5

- Defect Characteristics: The defects are strictly cosmetic anomalies incurred during production. Common examples include minor pits in the aluminum forging, uneven anodizing dye uptake (common in “Dark Earth” or FDE models where color consistency is chemically difficult to control), or laser engraving that is slightly off-center or double-etched.5

- Engineering Verdict: These are effectively new units. The defect is an aesthetic failure of the surface treatment, not a structural failure of the chassis.

2.2 Showroom Demos / Sales Samples

This category encompasses units that have served a marketing function. They may have been displayed at trade shows like SHOT Show or IWA, or they may have sat in a glass cabinet at a premium retailer like EuroOptic or Mile High Shooting.6

- Operational History: These units have been handled. They may have been mounted in rings for display purposes. The turrets have likely been spun thousands of times by prospective customers.

- Defect Characteristics: The hallmark defect of this category is “ring marks”—faint circular abrasions on the main tube where the scope rings contacted the anodizing.5 Additionally, one might find fingerprint oils on the lenses (easily cleaned) or minor scuffs on the turret knurling from handling.

- Engineering Verdict: Risk is slightly higher than a Factory Blem due to potential handling mishaps (drops) or improper mounting torque by showroom staff (though unlikely at high-end dealers). However, the wear on the turret internals from hand-spinning is negligible compared to the lifecycle rating of the component.

2.3 “Like New” Open Box / Customer Returns

These are units that were sold to a customer and then returned within a short inspection window.

- Operational History: Variable. The unit may have been mounted and fired, or simply opened and inspected.

- Defect Characteristics: Retailers like EuroOptic are meticulous in grading these. “Like New” usually means no visible wear, but the factory seal is broken.3

- Engineering Verdict: This category relies heavily on the retailer’s inspection process. A reputable dealer acts as a firewall, ensuring that a scope returned because it “didn’t track” is sent for repair rather than resold as “Like New.”

2.4 Mil-Spec Contract Overruns

A niche but highly desirable category involves optics built for military contracts (e.g., SOCOM, NAVSPECWAR) that were either over-produced or rejected for minor non-conformities to the strict government contract specs.8

- Operational History: New, but built to a different standard.

- Defect Characteristics: Often nonexistent. The “defect” might simply be that the contract was filled, and these are surplus.

- Engineering Verdict: These units are often more robust than commercial units, having undergone batch testing for submersion up to 275 feet.8 However, they pose unique warranty challenges (discussed in Section 7).

3. Engineering Analysis of Cosmetic Defects

To validate the safety of purchasing a blemished optic, we must perform a root cause analysis of the common defects to ensure they do not propagate into structural failures.

3.1 Material Science: The 6061-T6 Aluminum Chassis

Nightforce utilizes 6061-T6 aluminum alloy for its main tubes.9 This material is precipitation-hardened, offering a yield strength of approximately 40,000 psi.

- Wall Thickness: Nightforce tubes are renowned for their thickness—often 2-3 times thicker than budget optics.10 This thickness provides the rigidity necessary to prevent the tube from flexing under the inertia of heavy objective lenses during recoil.

- Impact of Surface Scratches: From a fracture mechanics standpoint, a scratch acts as a stress riser—a point where stress concentrates. However, the scratches found on “blem” units are typically microns deep, penetrating only the anodizing layer (approx. 0.002″ depth) or barely scratching the substrate.11 Given the massive safety factor built into the tube’s wall thickness, a cosmetic scratch has a negligible effect on the tube’s hoop strength or resistance to bending.

3.2 Surface Treatment: Type III Hard Coat Anodizing

The “black” or “FDE” finish on these scopes is not paint; it is Mil-Spec Type III Hard Coat Anodizing.

- The Process: This electrochemical process converts the aluminum surface into aluminum oxide, a ceramic-like material almost as hard as diamond.12

- The “Silver” Scratch: When users see a silver mark, it indicates the anodizing has been breached, exposing the raw aluminum. While this technically reduces corrosion resistance at that specific point, aluminum creates its own protective oxide layer almost instantly upon exposure to oxygen (passivation). Unless the optic is used in a submerged saltwater environment for extended periods, this spot corrosion is unlikely to compromise the housing.13

- Blem Implications: Many factory blems are rejected for “color mismatch.” Anodizing is sensitive to alloy composition and temperature. A batch of FDE scopes might come out slightly greener or browner than the control sample. This is a purely aesthetic variance with zero functional impact.

3.3 The “Ring Mark” Phenomenon: A Critical Assessment

The most commonly cited defect in “Demo” optics is ring marks. This requires careful scrutiny.

- Burnishing vs. Crushing: Most ring marks are simply “burnishing”—the smoothing of the microscopic peaks of the matte anodized surface. This changes the way light reflects off the tube (making it look shiny) but does not remove material or deform the tube.7

- The Danger of Crushing: The erector system (the internal tube holding the reticle and zoom lenses) floats inside the main tube. If the main tube is physically crushed (indented) by rings torqued beyond 25-30 inch-pounds, it can impinge on the erector tube.14 This causes “stiction”—the scope fails to track accurately or gets stuck at certain elevation ranges.

- Mitigation: Authorized dealers inspect for indentation. If a ring mark is purely visual (burnishing), the scope is functionally perfect. If there is a tactile indentation, the scope is structurally compromised. Nightforce’s thick tube walls make them more resistant to this than lighter competition, but it remains the primary risk factor for “Demo” units.15

3.4 Optical Defects: Why You Won’t Find Them

It is a common misconception that “blem” scopes have scratches on the glass.

- The Standard: Nightforce does not release scopes with scratched lenses or internal dust as “Blems”.5 Internal dust indicates a failure of the clean room process and potentially the nitrogen purging seal. Such units are reworked or scrapped, not sold.

- External Coatings: A scratch on the objective lens coating is often invisible to the user because it is so far out of the focal plane. However, even these are rare in the blem market. The “Blem” label is almost exclusively reserved for the metal chassis.

4. Optical Performance and Quality Assurance Protocols

The value of a Nightforce optic lies in its tracking capability. Does a blemished unit track? The answer lies in the testing sequence.

4.1 The “Box Test” and Collimator Verification

Every Nightforce scope—ATACR, NX8, and NXS—undergoes a tracking test before shipping. This is not a batch test; it is a 100% test.16

- The Process: The scope is mounted in a fixture and aimed at a collimator (an optical device that projects a reticle at infinity). The technician dials the turrets through their full range of travel. The reticle’s movement is measured against the collimator’s grid to ensure that 10 Mils of dial input equals exactly 10 Mils of reticle movement.17

- Return to Zero: The scope is dialed away from center and then back. It must return to the exact starting pixel.

4.2 Impact Testing

Following the tracking test, scopes are subjected to impact testing.

- The Force: The scope is mounted on a machine that simulates recoil forces up to 1,250 Gs on multiple axes (forward, backward, lateral).1

- Verification: After the beating, the scope is checked again on the collimator. If the zero has shifted or if the tracking is no longer true, the scope fails.

4.3 The “Blem” Sequence

Crucially, the cosmetic inspection often happens in parallel or before the final functional testing. A scope identified as having an anodizing flaw still proceeds through the impact and tracking stations. Therefore, a sold “Blem” has proven its ability to hold zero just as a “New” unit has. It is not a “second best” mechanical unit; it is a “first best” mechanical unit with a “second best” paint job.

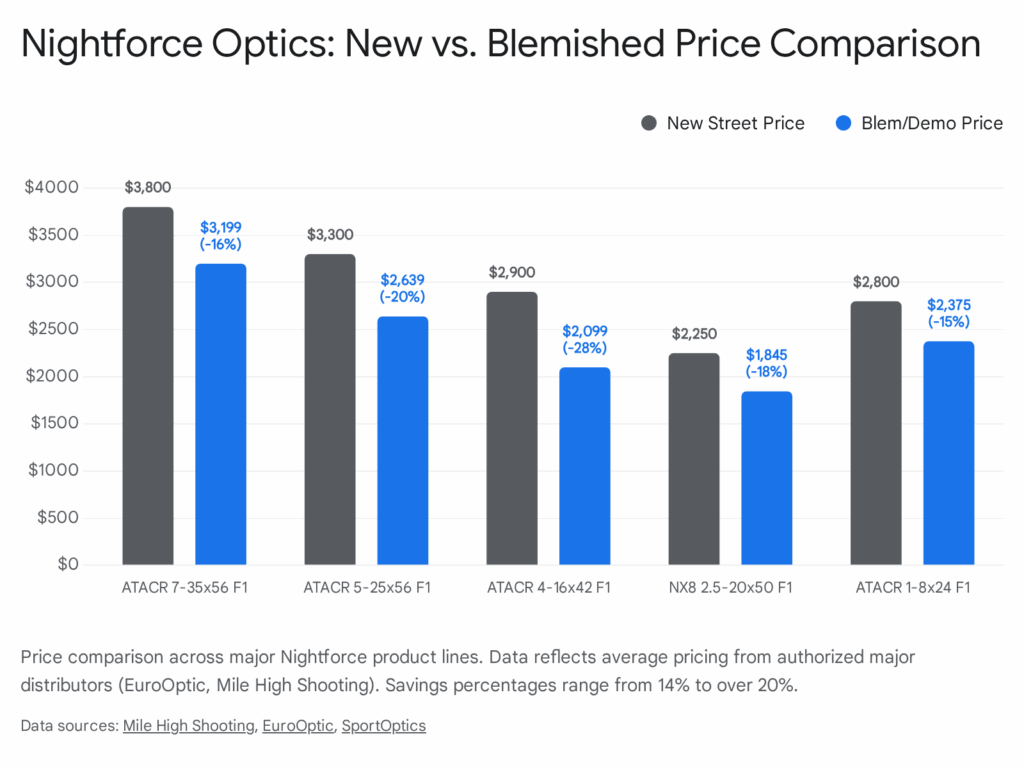

5. Financial Analysis: The Arbitrage Opportunity

The primary driver for purchasing blemished optics is the financial arbitrage. By accepting cosmetic imperfections, the user gains access to top-tier operational capabilities at mid-tier pricing. This section quantifies that value.

5.1 Price Disparity by Model Family

Analysis of current listings from EuroOptic and Mile High Shooting reveals significant price stratification.

5.1.1 The ATACR Series: The High-Yield Zone

The ATACR (Advanced Tactical Riflescope) line utilizes ED glass and 34mm tubes. It is the gold standard for long-range precision.

- ATACR 7-35×56 F1:

- New Price: ~$3,800.18

- Blem/Demo Price: ~$2,665 (Demo) to ~$3,200 (Like New).19

- Savings: $600 to $1,135 per unit.

- Analyst Insight: This is the highest absolute dollar saving. The 7-35x is a large, heavy optic used primarily in Precision Rifle Series (PRS) and Extreme Long Range (ELR) shooting. In these disciplines, gear is routinely braced against concrete barricades and rock faces. A brand-new 7-35x will likely incur user-induced blemishes within the first three matches. Therefore, paying an $1,100 premium for a pristine finish that will not last is economically irrational for the competitor.

- ATACR 4-16×42 F1:

- New Price: ~$2,900.21

- Blem Price: ~$2,099.21

- Savings: ~$800 (27%).

- Analyst Insight: This represents the “Best Buy” in the current market. The 4-16×42 is the quintessential Designated Marksman Rifle (DMR) optic—compact, robust, and capable. At a ~$2,100 price point, it competes directly with the lower-tier NX8 2.5-20x. An engineer would recommend the Blem ATACR over the New NX8 because the ATACR offers a superior optical prescription (larger objective relative to magnification, better eyebox) and better turret mechanics for roughly the same cost.

5.1.2 The NX8 Series: Diminishing Returns?

The NX8 line is designed for compactness with an 8x zoom ratio.

- NX8 2.5-20×50 F1:

- New Price: ~$2,250.22

- Blem/Demo Price: ~$1,845 – $1,950.23

- Savings: $300 – $400 (13-18%).

- Analyst Insight: The savings here are less compelling than the ATACR line. A 13% discount might not be sufficient to justify the risk of a “Demo” unit for some users, especially given the already lower entry price. However, finding a unit under $1,900 allows entry into the Nightforce ecosystem for a price comparable to mid-tier brands like Vortex Razor Gen II.

5.2 Summary of Savings Potential

| Model Family | Target Application | Typical New MAP | Typical Blem/Demo Price | Absolute Savings | % Savings |

| ATACR 7-35×56 F1 | ELR / PRS Competition | $3,800 | $2,665 – $3,200 | $600 – $1,135 | 16% – 30% |

| ATACR 5-25×56 F1 | Long Range / Sniper | $3,300 | $2,639 | $661 | 20% |

| ATACR 4-16×42 F1 | DMR / Recce | $2,900 | $2,099 | $801 | 27% |

| ATACR 1-8×24 F1 | CQB / LPVO | $2,800 | $2,375 | $425 | 15% |

| NX8 2.5-20×50 F1 | Crossover Hunting/Tac | $2,250 | $1,845 | $405 | 18% |

| NX8 4-32×50 F1 | Long Range Hunting | $2,450 | $1,835 | $615 | 25% |

Data aggregated from current inventory listings at EuroOptic and Mile High Shooting Accessories.3

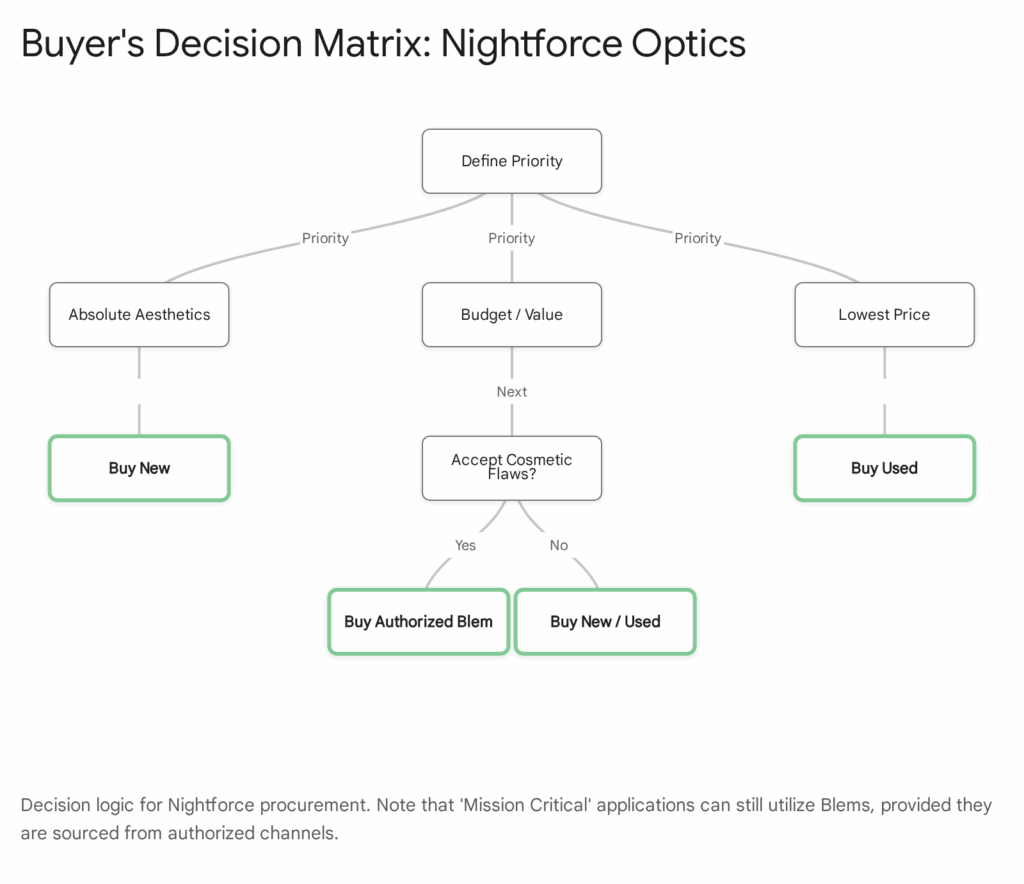

6. Strategic Recommendations by Use Case

Not all “blems” are created equal, and not all users should buy them. The decision depends heavily on the intended application.

6.1 The Competitive Shooter (PRS/NRL)

- Recommendation: Strong Buy.

- Reasoning: Competitive shooting is abusive to equipment. Rifles are jammed through portholes, balanced on tank traps, and exposed to dust and rain. The cosmetic condition of the scope is a rapidly depreciating asset.

- Target Model: ATACR 7-35×56 F1 Blem. The optical performance and mechanical reliability are paramount; the scratch on the tube is irrelevant.

6.2 The Law Enforcement / Agency Buyer

- Recommendation: Cautionary Buy / Authorized Sources Only.

- Reasoning: While agencies often face budget cuts, liability is a concern. Agencies should only purchase “Factory Blems” or “Like New Demos” from authorized dealers that provide a full paper trail and warranty guarantee. Avoid “used” or “no warranty” clearance items.

- Target Model: ATACR 4-16×42 F1. This fits the engagement profile of most urban/suburban police sniper operations perfectly. Securing these at ~$2,100 allows departments to outfit more rifles for the same budget.

6.3 The Collector / Safe Queen Enthusiast

- Recommendation: Avoid.

- Reasoning: For this user, the pristine condition of the equipment is part of the value proposition. A ring mark or anodizing pit will perpetually annoy a user who values aesthetics. Furthermore, the resale value of a “Blem” is permanently capped; you cannot resell it as “Like New” later without disclosing the blem status (which is usually recorded by serial number).

7. Warranty and Support Infrastructure

A critical component of the value proposition is the warranty. Does buying a blem void the safety net?

7.1 The Limited Lifetime Warranty

Nightforce offers a transferable Limited Lifetime Warranty that covers defects in materials and workmanship.27

- Commercial Blems: Factory Blems and Demos sold through authorized channels generally retain this full warranty regarding functional issues.5 If the reticle rotates or the tracking fails 5 years down the line, Nightforce will repair it.

- The Caveat: The warranty does not cover the cosmetic defect itself. You cannot buy a blemished scope and then send it in to have the tube replaced because you “found a scratch.”

7.2 The “No Warranty” / Mil-Spec Myth

There is significant confusion regarding “No Warranty” scopes.

- Mil-Spec Overruns: Occasionally, Nightforce releases batches of Mil-Spec scopes (e.g., those built for SOCOM contracts). These scopes, often marked with unique engravings, sometimes carry a restricted warranty (e.g., 10 years) or are sold “As-Is” with no warranty if they are contract rejects.8

- Identification: These units are typically clearly marked in dealer listings. The SKU often differs from the commercial version.

- Risk: If a listing says “No Warranty,” it means exactly that. If the scope fails, you are liable for the repair cost. These units are generally not recommended for professional use unless the user has an on-site armorer or spare units.

7.3 Dealer Support as a Buffer

Retailers like EuroOptic and Mile High provide an additional layer of security.

- Inspection Period: Most offer a return window (e.g., 15 days) for inspection.28 This allows the user to receive the scope, inspect the “blem,” and perform a tracking test. If the blem is too severe (e.g., a dented tube), it can be returned.

- Reputation: These dealers have a vested interest in not selling broken optics. User reports confirm that “Like New” items from these vendors are often indistinguishable from factory new stock.29

8. Buying Strategy: A Risk Mitigation Framework

To execute this strategy effectively, the buyer must follow a disciplined selection process.

8.1 Step 1: Verification of Vendor

Only purchase from authorized stocking dealers (EuroOptic, Mile High, Sport Optics, MidwayUSA). Avoid “Blem” listings on eBay or unknown third-party sites, as these could be gray market goods or damaged units masquerading as factory blems.

8.2 Step 2: SKU Analysis

Check the specific SKU.

- Reticle Choice: Blem inventory often consists of slow-moving reticles (e.g., MOAR in a world moving to Mil-XT). Ensure the reticle matches your system. A 20% discount is not worth 10 years of calculating angular conversions because you bought an MOA scope for a Mil-based team.24

- Turret Configuration: Verify the turret rotation (CW vs CCW). This is a common point of confusion that lands scopes in the “Return/Open Box” pile.

8.3 Step 3: Immediate Inspection Protocol

Upon receipt of the optic, perform the following checks:

- Visual Inspection: Locate the blemish. If it is a scratch in the anodizing, proceed. If it is a dent in the tube or a chip in the glass, initiate a return immediately.

- Mechanical Inspection (The “Feel” Test): Rotate the magnification ring and parallax adjustment. They should be smooth and consistent. Any “gritty” feel or binding indicates internal damage or tube deformation.

- Tracking Test: Mount the scope (properly torqued) and perform a tall target test or collimator check to verify return-to-zero.

9. Conclusion

The analysis leads to a definitive conclusion: Blemished Nightforce optics represent a superior value proposition for the pragmatic operator. The engineering margin of safety built into the Nightforce chassis ensures that cosmetic defects do not correlate with functional failure. The significant financial savings—ranging from $400 to over $1,100—allow for the reallocation of resources towards ammunition, training, or other critical system components.

While the “New” market offers the psychological comfort of perfection, the “Blem” market offers the professional advantage of efficiency. For those willing to accept a tool that looks like it has been used, in exchange for a tool that performs like it is new, the path is clear.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, we are only paid if there is an affiliate program such as Avantlink, Impact, Amazon and eBay and only if you purchase something. If you’d like to directly contribute towards our continued reporting, please visit our funding page.

| For blemished Nightforce, and other name brand scopes, check out EuroOptic. This link will take you to their blemished Nightforce scopes but you can select other brands as well such as Leupold, etc. Click here. |

Sources Used

- About Our Technology – Nightforce Optics, accessed December 31, 2025, https://www.nightforceoptics.com/technology/

- Find a Dealer – Nightforce Optics, accessed December 31, 2025, https://www.nightforceoptics.com/find-a-dealer/

- Nightforce Scopes Sale – Demo & Used Riflescopes for Precision – EuroOptic, accessed December 31, 2025, https://www.eurooptic.com/sale/nightforce-demo-sale

- Daily Deals – Blemished – Mile High Shooting Accessories, accessed December 31, 2025, https://www.milehighshooting.com/deals/blem/

- Nightforce Demo and Blem Sale | Sniper’s Hide Forum, accessed December 31, 2025, https://www.snipershide.com/shooting/threads/nightforce-demo-and-blem-sale.6891990/

- Nightforce Demos and Clearance – Scopelist.com, accessed December 31, 2025, https://www.scopelist.com/nightforce-demo-clearance.aspx

- Ring marks on scope | Shooters’ Forum, accessed December 31, 2025, https://forum.accurateshooter.com/threads/ring-marks-on-scope.3889955/

- Military, Government, and Law Enforcement Sales – Nightforce Optics, accessed December 31, 2025, https://www.nightforceoptics.com/mil-gov-le/

- Rifle Scopes – SCOPE TUBE MATERIAL | Sniper’s Hide Forum, accessed December 31, 2025, https://www.snipershide.com/shooting/threads/scope-tube-material.35440/

- Nightforce Optics Sale – SportOptics.com, accessed December 31, 2025, https://www.sportoptics.com/nightforce-optics.html

- Hard anodizing of aluminum alloys and its effect on Bal Seal® performance, accessed December 31, 2025, https://www.balseal.com/wp-content/uploads/2019/06/Effects_Of_Hard_Anodizing_Aluminum_Alloys_On_Bal_SealTR_17.pdf

- What materials and chemicals can damage anodized aluminum? – Linetec, accessed December 31, 2025, https://linetec.com/2022/06/10/what-materials-and-chemicals-can-damage-anodized-aluminum/

- Hard Coat Anodizing Services (Type III) – Light Metals Coloring, accessed December 31, 2025, https://www.lightmetalscoloring.com/hard-coat-anodizing-services

- Scope tube damage from over tightening rings? | Canadian Gun Nutz, accessed December 31, 2025, https://www.canadiangunnutz.com/forum/threads/scope-tube-damage-from-over-tightening-rings.1164528/

- bent scope tube? | Shooters’ Forum, accessed December 31, 2025, https://forum.accurateshooter.com/threads/bent-scope-tube.3330625/

- Nightforce Impact Test – SHOT Show 2023 | Sniper’s Hide Forum, accessed December 31, 2025, https://www.snipershide.com/shooting/threads/nightforce-impact-test-shot-show-2023.7159183/

- Nightforce Impact Test – YouTube, accessed December 31, 2025, https://www.youtube.com/watch?v=fDGIOQuIbdg

- Nightforce ATACR 7-35×56 Rifle Scopes, accessed December 31, 2025, https://www.sportoptics.com/nightforce-atacr-7-35×56-rifle-scopes.html

- Nightforce ATACR Riflescopes | Scope for Sale – EuroOptic.com, accessed December 31, 2025, https://www.eurooptic.com/nightforce-scopes-atacr

- Nightforce: Like New ATACR 7-35X56 F1, Mil-XT, accessed December 31, 2025, https://www.milehighshooting.com/nightforce-like-new-atacr-7-35×56-f1-mil-xt/

- Nightforce: ATACR 4-16×42 F1 – ZeroHold, Mil-C – Mile High Shooting Accessories, accessed December 31, 2025, https://www.milehighshooting.com/nightforce-atacr-4-16×42-f1-zerohold-mil-c/

- Nightforce NX8 2.5-20×50 Rifle Scopes, accessed December 31, 2025, https://www.sportoptics.com/nightforce-nx8-2-5-20×50-rifle-scopes.html

- Nightforce: Like New NX8 2.5-20×50 F1, MOAR – Mile High Shooting Accessories, accessed December 31, 2025, https://www.milehighshooting.com/nightforce-like-new-nx8-2-5-20×50-f1-zerostop-digillum-moar/

- BLEM Optics – Blem Models – Mile High Shooting, accessed December 31, 2025, https://www.milehighshooting.com/optics-mounts/blem-optics/

- Nightforce: BLEM ATACR 1-8×24 F1, DMx – Mile High Shooting Accessories, accessed December 31, 2025, https://www.milehighshooting.com/nightforce-blem-atacr-1-8×24-f1-dmx/

- Nightforce NX8 2.5-20×50 MOAR Riflescope C622 – EuroOptic.com, accessed December 31, 2025, https://www.eurooptic.com/nightforce-nx8-25-20×50-moar-c622

- Warranty Information – Nightforce Optics, accessed December 31, 2025, https://www.nightforceoptics.com/warranty/

- Return Policy – EuroOptic.com, accessed December 31, 2025, https://www.eurooptic.com/returnform

- Nightforce from Eurooptics | Rokslide Forum, accessed December 31, 2025, https://rokslide.com/forums/threads/nightforce-from-eurooptics.266500/

- Is it ever a good idea to buy used/demo scopes from online retailers? : r/longrange – Reddit, accessed December 31, 2025, https://www.reddit.com/r/longrange/comments/1lshruu/is_it_ever_a_good_idea_to_buy_useddemo_scopes/