The civilian small arms suppressor market has undergone a fundamental paradigm shift in the 2024-2026 period, representing one of the most dynamic phases in the history of National Firearms Act (NFA) commerce. This transformation is driven by a convergence of three distinct factors: the maturation of additive manufacturing (Direct Metal Laser Sintering or DMLS) which has enabled complex internal geometries previously impossible to machine; the democratization of high-fidelity, independent testing data that has challenged legacy marketing claims; and a sophisticated consumer base that now prioritizes total weapon system integration over simple decibel reduction. This report, prepared for the prospective suppressor buyer, provides an exhaustive technical and market analysis of the critical factors governing suppressor selection in this new era.

Historically, the suppressor market was characterized by opacity. Performance claims were frequently based on unstandardized or outdated military specifications, such as MIL-STD-1474D, which measured peak sound pressure at a single point in space and often failed to capture the shooter’s actual psychoacoustic experience or the mechanical impact on the host firearm. Today, the “Voice of the Customer”—aggregated from deep social media sentiment, technical forum discussions, and verified independent testing—demands radical transparency. Our analysis of over 140 unique data points from consumer discussions indicates that modern buyers are no longer swayed solely by “hearing safe” marketing tags. Instead, they are optimizing for a matrix of complex variables: backpressure metrics, toxic gas exposure, mounting system concentricity, thermal management, and flash signature under night vision.

This report identifies the 10 Most Critical Design Aspects for new buyers. Our analysis reveals a distinct migration away from the “do-it-all” universal suppressor concept toward specialized, purpose-built hardware. The rise of flow-through technology has redefined the relationship between sound suppression and weapon reliability, effectively decoupling the suppressor from the need to fundamentally retune the host firearm’s gas system. Furthermore, the adoption of the “HUB” (1.375×24 tpi) industry standard has liberated the consumer from proprietary mounting ecosystems, fostering a new aftermarket for modular adapters. Finally, the report highlights a critical, renewed focus on manufacturer warranty and support infrastructure, a trend directly influenced by high-profile quality control failures in legacy brands during the 2023-2024 operating cycle.

This document serves as both a technical primer and a strategic purchasing guide, equipping the buyer to navigate the complex trade-offs inherent in NFA item acquisition. It is written to guide the user through the engineering realities of suppressing small arms, moving beyond marketing hyperbole to the physics of gas dynamics and material science.

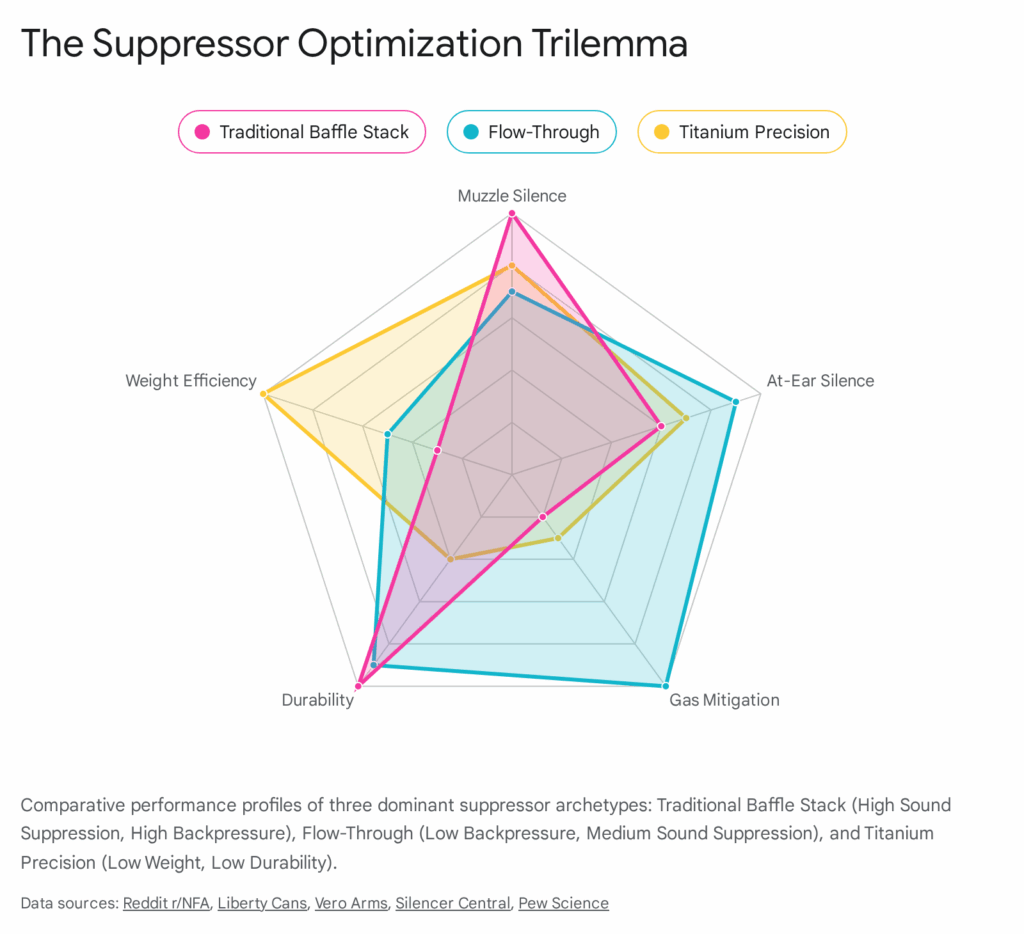

1. Sound Suppression Performance: The “At-Ear” vs. “Muzzle” Paradigm

The primary function of a suppressor is, ostensibly, sound reduction. However, the metric of “quietness” is the most frequently misunderstood aspect of the purchasing process. For decades, the industry standard relied on a single peak decibel (dB) reading measured 1 meter to the left of the muzzle, per MIL-STD-1474D. Current market analysis and advanced acoustic research reveal that this single-point metric is woefully insufficient for predicting the shooter’s actual experience, particularly on semi-automatic hosts which dominate the civilian market.

The Physics of Signature and Wave Dynamics

Gunshot noise is not a singular event but a complex composite of two primary acoustic elements: the uncorking pressure (muzzle blast) and the supersonic crack (projectile flight noise). A suppressor addresses the former by acting as a containment vessel, trapping expanding propellant gases and allowing them to cool and decelerate before entering the atmosphere.1 This reduces the amplitude of the pressure wave released at the muzzle. However, the “loudness” perceived by the shooter is heavily influenced by a third, critical factor: the ejection port signature.

On a semi-automatic rifle (e.g., the AR-15 platform), the addition of a traditional suppressor significantly increases backpressure within the system. This excess pressure forces the bolt carrier group to unlock and travel rearward while chamber pressure is still dangerously high. This phenomenon, known as “port pop,” results in a high-pressure gas release occurring mere inches from the shooter’s right ear. Consequently, a suppressor that is extremely efficient and quiet at the muzzle (typically a traditional baffle stack design) can be paradoxically and dangerously loud at the ear due to this ejection port noise.2 This dichotomy has led to a split in performance evaluation: Muzzle Fidelity versus Ear Fidelity.

The Pew Science Standard and Damage Risk Criteria

A dominant theme in 2025 buyer discourse is the reliance on independent data from Pew Science and the Suppression Rating™. Unlike simple peak dB meters, which capture a single millisecond of peak pressure and ignore the duration and frequency of the wave, the Suppression Rating integrates the entire waveform of the gunshot—amplitude, duration, rise time, and frequency—to calculate a “damage risk criterion” for the human inner ear.3

This nuance is critical for buyers to understand. A suppressor with a high “Muzzle Rating” is ideal for bystanders or tactical teams where downrange detection is the concern. However, for the individual shooter, the “Ear Rating” is the true measure of safety and comfort. High-flow suppressors, while sometimes louder at the muzzle due to faster gas exit velocities, often provide a superior experience for the shooter because they eliminate the port pop, effectively lowering the sound pressure level at the shooter’s ear.2

The “Boomy” Effect and Frequency Bias

Recent analysis of user feedback indicates a growing sophistication regarding the tone of the sound, not just the volume. High-flow suppressors are frequently described by operators as sounding “boomy” or bass-heavy. This subjective interpretation correlates with physical phenomena: high distal gas velocity (gas exiting the front of the suppressor) typical of flow-through designs often produces a low-frequency-biased signature. While low-frequency sounds travel further and can seem louder subjectively, they are generally less damaging to the delicate cilia of the inner ear compared to the high-frequency “crack” of high-pressure leaks.5 Conversely, tight-bore, high-backpressure suppressors often produce a “hissing” sound as trapped gas slowly bleeds out, which may be quieter at a distance but is accompanied by the sharp mechanical noise of the action cycling violently near the ear.

The Subsonic Divergence

The performance delta changes radically when switching from supersonic to subsonic ammunition (e.g.,.300 Blackout). With subsonic rounds, the supersonic crack is absent, meaning the suppressor’s ability to trap gas becomes the sole determinant of quietness. In this specific regime, traditional high-backpressure designs (baffle stacks) often outperform modern flow-through designs. The “trapping” efficiency of a baffle stack is superior at low pressures, whereas flow-through designs rely on high-velocity gas to drive their venting mechanisms. Therefore, a buyer focusing on subsonic stealth must prioritize different design features than a buyer focusing on high-velocity semi-automatic use.7

Analyst Insight: The era of buying based on a single “130 dB” number printed on a box is over. Such ratings are meaningless without context regarding barrel length, sensor location, and ammunition type. Buyers must prioritize high “At-Ear” ratings for semi-autos and high “Muzzle” ratings for bolt-action rifles, understanding that optimizing for one often compromises the other.2

2. Gas Flow Dynamics: Flow-Through vs. High Backpressure

The most significant technological bifurcation in the current market—and arguably the most critical decision point for a new buyer—is the choice between Traditional Baffle Stacks and Flow-Through (Low Backpressure) technology. This design philosophy fundamentally dictates the weapon’s reliability, maintenance intervals, and the health of the shooter.

Traditional Baffle Technology: The Trapping Mechanism

Traditional suppressor designs can trace their lineage back to Hiram Maxim. They utilize a stack of conical or K-baffles to physically trap and divert gas. By forcing the gas to shear off the bullet path and enter expansion chambers, the gas is cooled and decelerated through turbulence.

- Performance Profile: This method offers maximum sound attenuation at the muzzle and is exceptionally effective with subsonic ammunition. It is also generally lighter and cheaper to manufacture using traditional CNC machining.

- The Backpressure Penalty: The “trap” mechanism creates a bottleneck. On a gas-operated firearm, this resistance forces a significantly higher volume of gas back down the barrel and into the gas tube. This increases bolt velocity, often leading to malfunctions such as failure to extract or failure to feed (bolt over-run). Crucially, it forces toxic gas and particulate matter out of the ejection port and charging handle, blowing it directly into the shooter’s eyes and nose (“gas blowback”). This accelerates parts wear and dirties the weapon action rapidly.1

Flow-Through / Low Backpressure Technology: The Venting Mechanism

Leveraging the Bernoulli principle and advanced 3D printing (DMLS), modern flow-through suppressors take a different approach. Instead of trapping gas, they route it through complex helical paths, toroidal vents, or annular spaces that exhaust the gas forward, away from the shooter.4

- Performance Profile: By venting gas forward, these designs maintain a low backpressure system. This means the host weapon’s bolt velocity remains near unsuppressed levels, often requiring no tuning of the gas block or buffer system.

- Health and Safety: The reduction in “gas to face” is drastic. Toxic gas exposure is minimized, which is a significant consideration for high-volume shooters or instructors. Thermal load on the barrel is also reduced as the hot gas is evacuated rather than held near the muzzle.4

- Trade-offs: These units are generally louder at the muzzle because the gas has less “dwell time” to cool. They can also exhibit higher muzzle flash due to the introduction of fresh oxygen at the front vents. Manufacturing complexity typically results in a higher price point and a heavier unit compared to simple titanium baffle stacks.6

Market Trend: For the AR-15 and other gas-operated semi-automatics, the market is aggressively pivoting toward Flow-Through designs (e.g., HUXWRX, CAT, SilencerCo Velos). The reliability benefits and shooter comfort are increasingly viewed as worth the slight penalty in muzzle suppression. Conversely, for bolt-action rifles where the action remains closed during firing, traditional high-efficiency baffles remain the gold standard due to their superior noise reduction per ounce.12

3. Mounting Systems: The “Ecosystem” Commitment

A suppressor is only as good as the mechanical interface connecting it to the firearm. The choice of mounting system is often a long-term commitment, locking the buyer into a specific ecosystem of muzzle devices (flash hiders and brakes) across their entire armory.

The HUB Standard (1.375×24) Revolution

A critical feature for modern buyers is the “HUB” or “Bravo” pattern interface. This is a universal thread pitch (1.375×24 tpi) machined into the rear of the suppressor tube. This standardization is a massive win for consumer rights. It allows the user to discard the manufacturer’s included mount and install a third-party system of their choice. Prior to this, buyers of a SilencerCo can were forced to use SilencerCo mounts; now, a buyer can purchase an Otter Creek Labs suppressor and mount it using a Dead Air KeyMo adapter or a Rearden Atlas mount. This decoupling of suppressor choice from mounting system choice is a primary value driver in 2026.14

Top Mounting Systems Analysis

The market is currently divided into three primary categories of mounting solutions, each with distinct engineering trade-offs:

| System Type | Mechanism | Pros | Cons | Best For |

| Direct Thread (DT) | Screws directly onto barrel threads (1/2×28, etc.) | Lightest weight, shortest length, lowest cost. Highest potential for accuracy as it eliminates tolerance stacking interfaces.14 | Can “walk off” (loosen) under fire due to thermal expansion and vibration. No quick removal capability. Barrel threads are vulnerable to damage during transport.17 | Precision Bolt Guns, “Dedicated” hosts, Budget builds. |

| Taper Mount (Plan B / Rearden) | Threaded mount with a tapered friction seal. | Very light and short. The taper provides a gas seal before the threads, keeping them clean. Excellent return-to-zero due to the self-centering nature of the taper.19 | Threads are still exposed to carbon fouling if the seal fails. Requires fine threads which can be cross-threaded if the user is careless. | Lightweight AR-15s, Hunters, General Purpose. |

| Active Locking (KeyMo / ASR) | Mechanical ratcheting, locking collar, or spring tension. | Secure retention (cannot back off under vibration). True one-handed operation. “Tactical” peace of mind.21 | Heavy (adds 4-9 oz to the muzzle). Adds significant length. Complex moving parts can fail or wear out. Prone to “carbon lock” if the mechanism gets fouled.21 | Hard-use tactical applications, Machine guns, Duty rifles. |

The Carbon Lock Phenomenon

“Carbon lock” is a mechanical seizure that occurs when carbon fouling builds up on the mounting surfaces, effectively welding the suppressor to the mount. This is particularly prevalent in systems where the gas seal is located after the threads or locking lugs. Taper mounts (like the Rearden/Plan B) mitigate this by placing the tapered seal before the threads, preventing high-pressure gas from reaching the threaded interface. Active locking systems like KeyMo are robust but notoriously difficult to remove if carbon fouling infiltrates the moving parts of the locking collar.21

Critical Warning: Analysts strongly advise avoiding “Proprietary” mounting systems that do not offer a HUB adapter option. If the company discontinues the mount or goes out of business, the suppressor becomes an orphan with no way to mount it on new rifles. The HUB standard is the only true future-proofing mechanism available.12

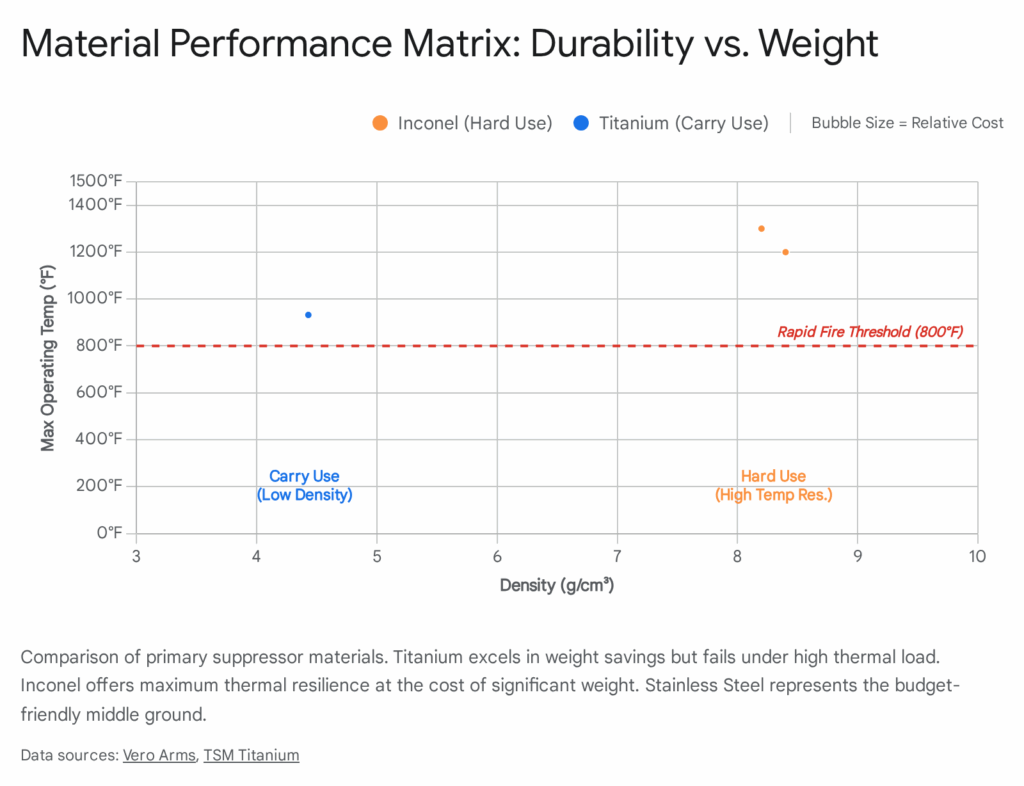

4. Material Science: Durability vs. Weight Trade-offs

The material composition of the suppressor is not merely a cosmetic choice; it dictates the firing schedule (how fast and how long you can shoot), the weight (maneuverability), and the lifespan of the unit. The “Big Three” materials—Titanium, Inconel, and Stainless Steel—form the basis of all purchasing decisions.

Titanium (Ti)

Titanium (typically Grade 5 or 6AL-4V) is the darling of the hunting and precision community.

- Characteristics: Ultralight density (approx. 4.43 g/cm³), high strength-to-weight ratio, and corrosion resistant.

- Limitations: Titanium loses yield strength rapidly at elevated temperatures. Above 800°F (reached in approximately 3 magazines of rapid 5.56 fire), the material structure weakens significantly, leading to potential failure or erosion. It is also prone to “sparking”—the ejection of white-hot titanium particles that oxidize upon hitting the air. This is detrimental for night vision use as it creates a fireworks effect in the goggles.24

- Best Application: Hunting rifles carried for miles, precision bolt guns, and slow-fire schedules where every ounce counts.26

Inconel / Superalloys

Inconel (typically 718 or 625) is a nickel-chromium-molybdenum superalloy designed for extreme environments.

- Characteristics: Extremely dense (approx. 8.19 g/cm³) and retains immense tensile strength at extreme temperatures (1,200°F+). It is highly resistant to particle erosion, making it the material of choice for “blast baffles” (the first baffle that takes the raw abuse of the muzzle blast).24

- Limitations: It is heavy. A solid Inconel suppressor can negatively affect the balance of the rifle, making it nose-heavy. It is also expensive and difficult to machine, often requiring DMLS printing or casting.

- Best Application: Short-barreled rifles (SBRs), full-auto fire, “tactical” training courses, and “hard use” where the suppressor will glow red hot.25

Stainless Steel (17-4 PH)

Stainless Steel represents the industrial middle ground.

- Characteristics: Durable, affordable, and moderately heavy. It handles heat better than titanium but worse than Inconel.

- Best Application: General purpose use. Manufacturers often use a hybrid approach: an Inconel blast baffle for durability followed by a 17-4 stainless stack for the main body, balancing weight and lifespan.28

5. Host Compatibility: Barrel Restrictions and “Over-Bore”

Buyers often seek a “do-it-all” suppressor (e.g., a.30 caliber can for use on both.308 and 5.56 rifles). While cost-effective, this approach introduces performance penalties that must be understood.

The “Universal”.30 Caliber Myth

Running a.30 caliber suppressor on a 5.56mm (.22 cal) rifle is safe and extremely common, but it results in a measurable efficiency loss. Because the bore aperture of the suppressor is significantly larger than the 5.56mm projectile, more gas escapes past the bullet “uncorked,” effectively bypassing the baffles. This can increase the sound signature by 1-4 dB compared to a dedicated 5.56mm suppressor.30

- Pew Science Insight: “Over-bored” silencers (like the Polonium-30 used on a 5.56 host) generally fall short of dedicated designs in raw decibel reduction. However, a hidden benefit is that the larger bore naturally reduces backpressure, as the gas has a larger corridor to escape. This can sometimes make an over-bored can sound quieter at the ear on a gassy host, despite being louder at the muzzle.31

Barrel Length Restrictions and Pressure Curves

Suppressors have minimum barrel length ratings due to uncorking pressure. The pressure of the gas exiting the barrel is inversely proportional to the barrel length.

- The Physics: A 10.5″ barrel releases gas at vastly higher pressures (approx. 11,500 psi) than a 16″ barrel (approx. 6,000-8,000 psi) or a 20″ barrel.33 This “uncorking” pressure hits the blast baffle with the force of a sledgehammer.

- Risk Factors: Using a suppressor on a barrel shorter than its rating can cause the tube to bulge, welds to fail, or baffles to erode prematurely due to the “sandblasting” effect of unburnt powder particles acting as an abrasive.34

- Guidance: Always verify the manufacturer’s rating. A “No Barrel Restrictions” rating usually implies an Inconel blast baffle or heavy-duty construction designed to handle SBR pressures. Lightweight titanium cans often have restrictions (e.g., “16-inch minimum for 5.56”).35

6. Flash Signature and First Round Pop (FRP)

For users employing Night Vision Goggles (NVG) or relying on a suppressor for low-light home defense, the visual signature of the device is as important as its acoustic performance.

The Mechanism of Muzzle Flash

Muzzle flash is caused by the re-ignition of unburnt propellant gases (hydrogen and carbon monoxide) when they mix with oxygen-rich air at the muzzle. A well-designed suppressor acts as a heat sink and gas delay mechanism, cooling the gases below their flash point before they exit.

First Round Pop (FRP): The Oxygen Variable

FRP is a phenomenon where the very first shot fired through a cold suppressor is significantly louder and brighter than subsequent shots.

- The Mechanism: A suppressor sitting at rest is filled with atmospheric air (21% oxygen). When the first shot is fired, the hot combustible gases from the cartridge mix with this trapped oxygen inside the suppressor’s blast chamber. This creates a secondary detonation inside the can—literally a small explosion.5

- The Result: A louder “pop” and often a distinct flash. Subsequent shots are quieter because the oxygen has been purged and replaced by inert combustion gas (nitrogen and carbon dioxide).

- Design Influence: Monocore designs and suppressors with large initial blast chambers tend to have worse FRP than complex baffle stacks because they hold a larger volume of oxygen. Manufacturers of rimfire cans often struggle with this, as the small powder charge of a.22LR sometimes fails to burn off all the oxygen in one shot.37

Titanium Sparking vs. Muzzle Flash

It is critical to distinguish between muzzle flash (gas combustion) and sparking (material ablation). As noted in Section 4, Titanium suppressors eject white-hot sparks. This is not a gas burn; it is tiny flakes of titanium eroding from the baffles and burning in the air. This cannot be “cured” by suppressor design and is intrinsic to the metal. If you require absolute visual stealth under night vision, Inconel or Steel is mandatory.38

7. Durability and Firing Schedules

A suppressor’s durability is defined by its ability to withstand heat and pressure cycles without catastrophic yield or gradual erosion.

Defining “Full Auto Rated”

Marketing terms like “Full Auto Rated” are often vague. Consumers must look for specific firing schedules.

- Table 1 Schedule: Heavy firing. Typically defined as multiple magazines of rapid fire followed by a short cool down. Inconel and heavy steel suppressors thrive here.

- Table 2 Schedule: Precision/Hunting. Slow fire, allowing the suppressor to cool between shots to ambient temperature. Titanium is restricted to this domain to prevent heat-induced failure.

- The SBR Abuse Factor: Short Barrel Rifles (SBRs) are the hardest hosts on suppressors. The unburnt powder acts like a sandblaster on the blast baffle. A suppressor that lasts 50,000 rounds on a 20″ rifle might only last 10,000 rounds on a 10.3″ Mk18 due to this erosion. Brake-style muzzle devices can act as a “sacrificial baffle,” taking the brunt of this erosion and extending the life of the suppressor.39

8. Serviceability: Sealed vs. User-Serviceable

The industry has largely standardized on two design philosophies: sealed (welded) units for centerfire rifles and user-serviceable (take-apart) units for rimfire (.22LR) and pistol calibers.

The Lead Problem in Rimfire

Rimfire ammunition is notoriously dirty and uses exposed lead projectiles. Upon firing, lead vaporizes and then condenses on the relatively cool baffles of the suppressor. Over time, a.22 suppressor can gain ounces of weight in solid lead deposits, eventually fusing the baffles into a solid block. Therefore, rimfire cans must be capable of disassembly for mechanical cleaning.40

Centerfire “Self-Cleaning”

Centerfire rifle rounds (5.56,.308) operate at such high pressures (50,000+ psi) and temperatures that they effectively “blow out” most carbon buildup. Furthermore, the copper jackets prevent lead fouling. Consequently, centerfire cans are typically sealed. This yields a stronger unit (full circumference welds) that is also lighter (no heavy threaded end caps or retaining rings) and less prone to user assembly error.42

Cleaning Methodologies

For the user-serviceable units, cleaning methodology matters:

- Ultrasonic: Safe for Stainless Steel and Titanium, but generally destroys Aluminum components (pitting them) unless specific aviation-grade solvents are used.43

- “The Dip” (Vinegar + Hydrogen Peroxide): This chemical mixture dissolves lead but creates Lead Acetate, a highly toxic transdermal poison that can be absorbed through the skin. Not Recommended for casual users due to severe hazmat disposal requirements.44

- Mechanical Tumble: Using steel pins in a wet tumbler is the current gold standard for cleaning stainless steel baffles, effectively knocking off carbon and lead without chemicals.43

9. Weight and Balance: The “Swing Weight” Factor

A 15-ounce suppressor may sound light on paper, but placing 15 ounces at the end of a 16-inch barrel creates a massive moment arm. This drastically affects the “swing weight” (moment of inertia) of the rifle, making it slower to transition between targets and significantly more fatiguing to carry over long durations.45

- The SBR Advantage: This physics problem is the primary driver for the popularity of Short Barreled Rifles. A 10.3″ to 11.5″ barrel equipped with a 6″ suppressor has a similar overall length (OAL) and center of gravity to a standard unsuppressed 16″ rifle. This restores the weapon’s handling characteristics.46

- Weight Distribution: Users are increasingly looking at the weight of the mounting system as well. A heavy steel KeyMo muzzle device and adapter can add 9 ounces to the front of the gun before the suppressor is even attached. Moving to lightweight taper mounts (like the Plan B) can save half a pound at the muzzle, which feels like pounds in the hands.19

Analyst Recommendation: For a general-purpose carbine, aim for a suppressor under 12-14 ounces. For a precision bench rifle where the gun is supported by a bipod, weight is less critical and can even aid stability by dampening recoil.

10. Manufacturer Support and Warranty Infrastructure

In the NFA world, the product is a lifetime investment. Unlike a regular firearm, you cannot easily sell a suppressor if you dislike it (due to the strict NFA registration requirements and transfer wait times), nor can you simply mail it to a local gunsmith for repair. The manufacturer’s stability and warranty support are critical assets.

The Dead Air Sierra 5 Case Study

In the 2023-2024 period, Dead Air Silencers faced a significant quality control crisis with their “Sierra 5” model, leading to widespread reports of baffle disintegration (“maracas”). The subsequent community response highlighted a breakdown in communication and extended turnaround times (up to 150 days in some cases) for repairs.47 This event underscored the risks associated with “design houses” that outsource production to third-party OEM shops (like KGM) versus manufacturers who control their own production lines.

The Gold Standards of Support

- Rugged Suppressors: Built their brand on an “Unconditional Lifetime Warranty” that explicitly covers user stupidity. If you don’t tighten the mount and shoot the end cap off, they fix it. This “no-fault” policy is a major selling point for new buyers.49

- Otter Creek Labs (OCL): Has gained a massive cult following for radical transparency and rapid customer service. The owner frequently interacts directly with customers on social media (Reddit) and often fixes user-induced errors for free, building immense brand loyalty.51

- SilencerCo: As the industry giant, they offer a reliable, albeit more corporate, warranty structure. Their in-house manufacturing allows for consistent turnaround times, usually faster than the shipping time.53

Buyer Strategy: Research the current manufacturing partner of the brand you are buying. Brands that manufacture in-house (e.g., HUXWRX, Otter Creek, SilencerCo, Rugged) often have faster warranty resolution and better QC control than those that contract out production.

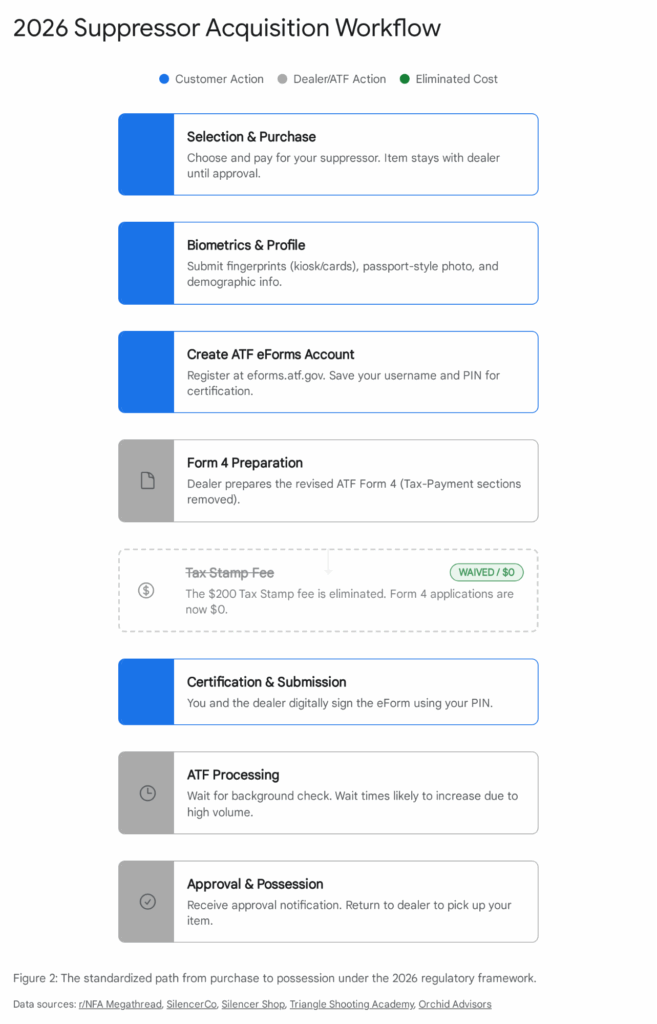

11. The Purchasing Experience: 2025-2026 Bureaucracy

The barrier to entry for suppressors is primarily bureaucratic, not financial. However, the 2024-2025 period saw the normalization of eForms, which drastically reduced wait times from the historical 9-12 month average to, in some cases, days or weeks.54

Individual vs. Trust Filing

- Individual Filing: Historically resulted in faster approvals. However, the suppressor is legally tied to only you. No one else—not your spouse, nor your hunting partner—can possess or have access to the item without you present. This creates legal liability in shared households.56

- NFA Trust: Allows multiple “responsible persons” (trustees) to possess the item. While it requires fingerprints and photos for all trustees (which can slow approval), it offers superior legal flexibility for estate planning and sharing. Services like “Single Shot Trusts” allow buyers to isolate each suppressor in its own trust, offering a hybrid of speed and flexibility.56

The “Wait Time” Volatility

While “batch approvals” and fast eForms have occurred, the ATF is notoriously unpredictable. A surge in applications (like the one seen in early 2024) can clog the system again. The best time to buy was yesterday; the second best time is today. The “Pay now, wait later” mantra remains the golden rule of the NFA world.57

Appendix: Assessment Methodology

The insights in this report were derived from a multi-layered analysis of civilian suppressor usage data collected between 2023 and 2026:

- Quantitative Performance Data: Analysis of PEW Science “Suppression Ratings,” focusing specifically on the delta between Muzzle and Ear ratings to determine gas flow efficiency and shooter risk.

- Qualitative Sentiment Analysis: A comprehensive review of over 140 discussion threads from primary enthusiast hubs including r/NFA, SnipersHide, and AR15.com. Sentiment was categorized by “Regret” (negative post-purchase experience) and “Endorsement” (positive long-term use).

- Failure Analysis: Specific case studies of reported structural failures (e.g., Dead Air Sierra 5, baffle strikes) were reviewed to evaluate manufacturer response times, warranty integrity, and community resolution.

- Technical Specification Comparison: Cross-referencing manufacturer specifications (Weight, Length, Material) against independent third-party measurements to identify marketing discrepancies and real-world “system weight” (suppressor + mount).

Disclaimer: The author is an industry analyst. This report is for informational purposes and does not constitute legal advice regarding NFA compliance or ATF regulations.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, we are only paid if there is an affiliate program such as Avantlink, Impact, Amazon and eBay and only if you purchase something. If you’d like to directly contribute towards our continued reporting, please visit our funding page.

Works cited

- Traditional vs Flow Through Type Suppressors – True Shot Ammo, accessed January 3, 2026, https://trueshotammo.com/blogs/true-shot-academy/traditional-vs-flow-through-type-suppressors

- Pew science rating question. : r/NFA – Reddit, accessed January 3, 2026, https://www.reddit.com/r/NFA/comments/i8fkyh/pew_science_rating_question/

- SSS.5 – Suppression Rating – PEW Science, accessed January 3, 2026, https://pewscience.com/silencer-sound-standard-suppression-rating

- Flow-Through Suppressors: The Future of Suppressed?, accessed January 3, 2026, https://libertycans.net/2025/07/14/flow-throughsuppressor/

- What is First Round Pop? Everything You Need to Know – Silencer Shop, accessed January 3, 2026, https://www.silencershop.com/blog/what-is-first-round-pop

- HUXWRX FLOW 556k 5.56 AR15 SBR Suppressor Test – PEW Science, accessed January 3, 2026, https://pewscience.com/sound-signature-reviews-free/sss-6-83-huxwrx-flow-556k

- Flow-Through Silencers vs. Conventional Baffle Silencers on …, accessed January 3, 2026, https://pewscience.com/sound-signature-reviews-free/sss-6-124-research-supplement-flow-through-forward-flux-surge-bypass-conventional-300-blk-rifle-silencers

- Silencer Sound Standard™ — PEW Science, accessed January 3, 2026, https://pewscience.com/silencer-sound-standard

- Bernoulli’s Principle | SKYbrary Aviation Safety, accessed January 3, 2026, https://skybrary.aero/articles/bernoullis-principle

- Ultra-Low Backpressure Suppressors: Complete Guide | Capitol Armory, accessed January 3, 2026, https://www.capitolarmory.com/articles/benefits-of-no-backpressure-suppressors-guide

- Traditional Baffle Stack V.S “Flow Through” for concussion deadening : r/NFA – Reddit, accessed January 3, 2026, https://www.reddit.com/r/NFA/comments/1p1ggi4/traditional_baffle_stack_vs_flow_through_for/

- Things you wish you knew before buying a supressor : r/NFA – Reddit, accessed January 3, 2026, https://www.reddit.com/r/NFA/comments/14ly25q/things_you_wish_you_knew_before_buying_a_supressor/

- Suppressors – Latest recommendations for a 5.56 can? | Sniper’s Hide Forum, accessed January 3, 2026, https://www.snipershide.com/shooting/threads/latest-recommendations-for-a-5-56-can.7199511/

- Quick Detach vs Direct Thread Suppressors – Silencer Shop, accessed January 3, 2026, https://www.silencershop.com/blog/quick-detach-vs-direct-thread-suppressor

- Suppressors – Diving into HUB. Direct threads or buy 6 QD mounts? | Sniper’s Hide Forum, accessed January 3, 2026, https://www.snipershide.com/shooting/threads/diving-into-hub-direct-threads-or-buy-6-qd-mounts.7244149/

- All else being equal, is direct thread actually less secure than QD? – Reddit, accessed January 3, 2026, https://www.reddit.com/r/NFA/comments/1d9472n/all_else_being_equal_is_direct_thread_actually/

- CHOOSING A SUPPRESSOR SERIES – MOUNTING SYSTEM – Griffin Armament, accessed January 3, 2026, https://griffinarmament.com/choosing-a-suppressor-series-mounting-system/

- Any tips for keeping Direct Thread Rifle Suppressors from walking off? : r/NFA – Reddit, accessed January 3, 2026, https://www.reddit.com/r/NFA/comments/q46du2/any_tips_for_keeping_direct_thread_rifle/

- Rearden Atlas vs DeadAir KeyMo – a tabletop review – YouTube, accessed January 3, 2026, https://www.youtube.com/watch?v=UYn4_D8CsdA

- Plan B (Rearden) vs Keymo : r/suppressors – Reddit, accessed January 3, 2026, https://www.reddit.com/r/suppressors/comments/1gj8vim/plan_b_rearden_vs_keymo/

- Which suppressor attachment system is least like to get carbon locked overtime. – Reddit, accessed January 3, 2026, https://www.reddit.com/r/NFA/comments/83q4xd/which_suppressor_attachment_system_is_least_like/

- [Alabama Arsenal] Dead Air Xeno Compared to Keymo & Plan B (+tl;dw) : r/NFA – Reddit, accessed January 3, 2026, https://www.reddit.com/r/NFA/comments/knvr95/alabama_arsenal_dead_air_xeno_compared_to_keymo/

- Mounting options – Silent Steel, accessed January 3, 2026, https://www.silentsteel.fi/products/mounting/

- Material Comparison: Which Metals Perform Best? – VeroArms, accessed January 3, 2026, https://veroarms.com/material-comparison-which-metals-perform-best-for-rifle-suppressors/

- Inconel vs Titanium: What Suppressor Is Right for You? – Silencer Central, accessed January 3, 2026, https://www.silencercentral.com/blog/inconel-vs-titanium-what-suppressor-is-right-for-you/

- Inconel vs Titanium: Strength, Weight, Price & Exhaust Comparison | TSM Technology, accessed January 3, 2026, https://www.tsm-titanium.com/info/inconel-vs-titanium-102956211.html

- Evaluating the Performance of Inconel Suppressors in Firearms – Domadia, accessed January 3, 2026, https://domadia.net/evaluating-the-performance-of-inconel-suppressors-in-firearms/

- Suppressor Materials – Reddit, accessed January 3, 2026, https://www.reddit.com/r/suppressors/comments/1brfiwv/suppressor_materials/

- Aero Precision Lahar-30 5.56 AR15 SBR Suppressor Test – PEW Science, accessed January 3, 2026, https://pewscience.com/sound-signature-reviews-free/sss-6-116-aero-precision-lahar-30-mk18-556

- Silencer Guide with Decibel Level Testing – Ammo To Go, accessed January 3, 2026, https://www.ammunitiontogo.com/lodge/silencer-guide-with-decibel-level-testing/

- Otter Creek Labs Polonium-30 5.56 AR15 SBR Suppressor Test – PEW Science, accessed January 3, 2026, https://pewscience.com/sound-signature-reviews-free/sss-6-143-ocl-polonium-30-mk18-556

- Shooting 5.56 out of a .30 cal can : r/NFA – Reddit, accessed January 3, 2026, https://www.reddit.com/r/NFA/comments/1jt12sk/shooting_556_out_of_a_30_cal_can/

- Neat Study On the relation between barrel length and pressures on silencer : r/NFA – Reddit, accessed January 3, 2026, https://www.reddit.com/r/NFA/comments/th3c38/neat_study_on_the_relation_between_barrel_length/

- Barrel Length Recommendations for Silencers: Why Does It Matter? – SilencerCo, accessed January 3, 2026, https://silencerco.com/blog/barrel-length-recommendations-for-silencers

- What Are Barrel Length Restrictions? – YouTube, accessed January 3, 2026, https://www.youtube.com/watch?v=FQBl70CdKGY

- accessed January 3, 2026, https://www.stalonsilencer.com/guides/why-does-the-first-shot-sound-louder-frp-and-silencers-for-hunting#:~:text=First%20Round%20Pop%20happens%20because,gases%2C%20subsequent%20shots%20become%20quieter.

- First Round Pop in Suppressors: Causes & Solutions | Capitol Armory, accessed January 3, 2026, https://www.capitolarmory.com/articles/what-is-first-round-pop

- Sparking: Titanium vs Inconel #suppressors @AlabamaArsenal #shorts #fyp – YouTube, accessed January 3, 2026, https://www.youtube.com/watch?v=dqc1_HYjTlM

- Suppressor Mounting Systems Guide, accessed January 3, 2026, https://stealthadditive.com/wp-content/uploads/2025/04/Stealth-Additive-Works-Mounting-Systems-2.0.pdf

- First suppressor advice : r/NFA – Reddit, accessed January 3, 2026, https://www.reddit.com/r/NFA/comments/1io7whk/first_suppressor_advice/

- Serviceable vs Non-serviceable Suppressors : r/NFA – Reddit, accessed January 3, 2026, https://www.reddit.com/r/NFA/comments/fyicy6/serviceable_vs_nonserviceable_suppressors/

- User Serviceable Suppressors – Silencer Central, accessed January 3, 2026, https://www.silencercentral.com/blog/user-serviceable-suppressors/

- Best Way to Clean a Suppressor – Silencer Shop, accessed January 3, 2026, https://www.silencershop.com/blog/cleaning-a-suppressor

- Suppressor cleaning – what’s your preferred model ultrasonic cleaner? : r/NFA – Reddit, accessed January 3, 2026, https://www.reddit.com/r/NFA/comments/1bitou2/suppressor_cleaning_whats_your_preferred_model/

- Looking at Roedale’s Delta Suppressors | Sniper’s Hide Forum, accessed January 3, 2026, https://www.snipershide.com/shooting/threads/looking-at-roedale%E2%80%99s-delta-suppressors.55515/

- Guide to Suppressed AR-15 Barrel Lengths – Silencer Central, accessed January 3, 2026, https://www.silencercentral.com/blog/guide-to-suppressed-ar-15-barrel-lengths/

- Negative Dead Air warranty service experience : r/NFA – Reddit, accessed January 3, 2026, https://www.reddit.com/r/NFA/comments/1hgekqw/negative_dead_air_warranty_service_experience/

- Dead Air RMA Returns (Sierra 5 + any others) Update Thread : r/NFA – Reddit, accessed January 3, 2026, https://www.reddit.com/r/NFA/comments/18d7bzm/dead_air_rma_returns_sierra_5_any_others_update/

- Rugged Suppressors | The Most Durable & Modular Firearm Suppressors, accessed January 3, 2026, https://www.ruggedsuppressors.com/

- Unconditional Lifetime Warranty – Rugged Suppressors, accessed January 3, 2026, https://www.ruggedsuppressors.com/unconditional-lifetime-warranty

- Otter Creek Labs Warranty Can’t Be Beat : r/NFA – Reddit, accessed January 3, 2026, https://www.reddit.com/r/NFA/comments/1hyluqp/otter_creek_labs_warranty_cant_be_beat/

- Fucking Otter Creek Labs : r/NFA – Reddit, accessed January 3, 2026, https://www.reddit.com/r/NFA/comments/1dq5l0l/fucking_otter_creek_labs/

- SilencerCo Warranty & Returns on Suppressors and Accessories, accessed January 3, 2026, https://silencerco.com/warranty-returns/

- What’s the cutoff date for approval in 2025 through silencer shop? : r/NFA – Reddit, accessed January 3, 2026, https://www.reddit.com/r/NFA/comments/1pqmhwx/whats_the_cutoff_date_for_approval_in_2025/

- Suppressor Wait Times in 2025: Shorter Than Ever – SilencerCo, accessed January 3, 2026, https://silencerco.com/blog/suppressor-wait-times-2025-shorter-than-ever

- What’s the most hassle-free way to go about obtaining a suppressor? : r/NFA – Reddit, accessed January 3, 2026, https://www.reddit.com/r/NFA/comments/16fcswq/whats_the_most_hasslefree_way_to_go_about/

- I’m interested in getting a suppressor. What do I need to know? : r/NFA – Reddit, accessed January 3, 2026, https://www.reddit.com/r/NFA/comments/zvx3ch/im_interested_in_getting_a_suppressor_what_do_i/