Velocity Arms finishes their VMAC9 uppers using a “manganese phosphate finished IAW 5.3.1.2 of Mil-STD-171” which is a fancy way of saying maganese park, heavy coating, class 2, oil coated. Of course the military gets into a lot of details further specifying it in MIL-DTL-16232. At any rate, Velocity Arms’ uppers are a nice rich dark black manganese park finish and I had a pretty good idea of how to duplicate it based on past experience.

I’m not going to get into all of the chemistry details – if you want that, click here for Wikipedia. I am going to point out, there are two types of park – zinc and maganese. Zinc is more of a grey or grey/green. Manganese is dark grey to black. What I have found purely based on experience is that an abrasive blasted clean steel surface will turn black in a fresh park solution and it approaching boiling and left in for 30-45 minutes.

Surface Prep is Critical

One thing I have found is that you just can’t take steel and drop it in park solution. You may get little to no reaction plus if there is oil or grease on the steel, you may contaminate your park solution so bad you have to discard it.

What I do is put on nitrile gloves, clean the part with brake cleabner thoroughly. If it’s bad, use an ultrasonic cleaner with a good cleaning solution. When the part is dry, then abrasive blast it. I use Black Diamond blast media from my local Tractor Supply (TSC) store. Never use sand – the dust from that is incredibly bad – really, really bad – for your lungs because it goes in and doesn’t come out. With Black Diamond, it does a wear out so I watch my parts and when the blasting starts taking too long, I replace it.

When I am done blasting, I clean it again with brake cleaner, let it dry and it’s time to go into the Manganese park solution.

I usually brew my solution and let it start heating up and aging while I get my parts ready.

A Manganese Home Park Formula That Really Works

I have used this formula for years. One ingredient though, Prep & Etch , is getting hard to find so you will either need to find an alternate or make your own mix.

This recipe generates about two gallons of mix so figure out your ratios if you want to make more:

- 2 gallons of distilled water (it gives more consistent results because impurities have been removed – sold at supermarkets and drug stores).

- 2 “biscuits” of clean plain 0000 steel wool (thinner steel wool dissolves faster hence the use of 0000 grade) – Click here for them on Amazon or here for eBay

- 1 cup of Klean Strip brand Phosphoric Prep & Etch (or other phosphoric acid etching solution around 35-45% concentrate per the Prep & Etch MSDS sheet. Dilute the acid if higher. For example, if 100% pure then go 60 water:40 acid to make the diluted acid solution that you add to the mix. This is not the ratio in the park solution itself – you can always experiment with the ratio that works for you). I can’t find Prep & Etch at any local stores but my local Ace Hardware is carrying something similar called “Ospho” and the SDS sheet identifies it as 45% phosphoric acid and it ought to work but haven’t tried it yet. I had two gallons of Prep & Etch and that amount has lasted me a number of years because I don’t do a lot of parking but you get the idea. Click here for Phosphoric Acid on Amazon or here for eBay.

- 6 very rounded tablespoons of manganese dioxide (available at pottery supply stores, Amazon or eBay). Do NOT mess with batteries. You may read about guys who open up batteries to get the manganese – don’t do it. Just buy the actual manganese in bulk. It’s cheap and you know what you are getting.

Heat Source & Vessel

Some years ago, I bought a Camp Chef Explorer two burner stove off Amazon and I really like it. It’s sturdy and can run off any of the common propane tanks. Also, there are many different sizes of stoves out there but I wanted a beefy two burner to be able to also heat my stainless tank when I park long parts.

I use 20 pound tanks because they are easy for me to move. I just swap cylinders when they pass their inspection date but otherwise get them refilled at my local Ace Hardware. Surprisingly, they tend to have the best prices in the area for propane.

In terms of what I use to hold the parts, the receivers were short so I just used a 12 quart stainless pot I have for that purpose. Note, do not use cookware for this. I’m not joking. I can just imagine some guy thinking “Oh – I’ll just use a pot from the kitchen.” This stuff leaves residues that you should never eat. I have a couple places on the bottom of my pot where I can’t scrape some kind of crust off. My best guess is that the alloy wasn’t consistent but regardlss, do not use pots or other containers from the kitchen. Buy and use dedicated pots, tongs, stainless wire, etc.

By the way, good long stiff BBQ tons are definitely worth it. I have one with plastic jaws and another that is completely stainless. While I was worried at first about scratching the parts, I really haven’t had a problem with that. Amazon has tons of affordable tongs with decent reviews.

18-20 gauge stainless wire also is really handy. I use it to suspend smaller parts and keep them together vs. losing track and trying to find them – been there and done that.

In cases where I can’t run a wire through the small parts, I use the strainer/steamer section of my boiler pot or a small kitchen stainless strainer in my big tank if I am using that.

Speaking of long tanks – there are good deal on eBay. That is where I bought mine.

On that point, I use

Steps to Follow

Add acid to water in a stainless pan/pot and heat to 190F – don’t boil and waste it – if it does boil or simmer, it’s not the end of the world and a lid can help reduce evaporative loss. I use a baking thermometer clipped to the side of the pan or my Fluke infrared thermometer.

Spray each wool biscuit with brake cleaner to remove oils and allow each time to dry.

As the solution warms shred the steel wool into the liquid and add the manganese dioxide. When I did these Vmac9 receivers, I found all I had to do was unwind the steel wool rolls, place them in the solution and that was fine.

Let the mix simmer and dissolve the steel wool before adding parts. This is key. The solution needs to dissolve the steel to get the process started. I usually, get this started and then get my parts ready. Stir periodically to help things mix.

I always blast my parts before I parkerize them. I have used sanding mops and other approaches to expose the metal but just find blasting the best for a consistently colored surface. Blasting removes the oxides and exposes the bare steel. I always do that.

Make sure your parts are very, very clean and degreased — only handle with rubber gloves after they are cleaned or oils from your skin can mess things up.

Before you put your parts in, stir the solution to keep the manganese dioxide suspended. I do not stir once the parts are in the pot or tank.

You can suspend your parts in the liquid with stainless wire. Leave them until the fizzing stops or about 30-45 minutes. The time varies depending on many factors including the solution itself and the heat.

Rinse the parts with boiling water thoroughly to remove the acid. I have never found the need to do more than thoroughly hose down the parts. I literally use a garden hose.

Spray parts with WD40 to get the water away from the steel.

Wipe down with oil or apply whatever secondary finish you want – don’t do both 🙂 If you are going to apply a finish on top of the parkerized surface, use acetone or brake cleaner to remove any oils and then follow the vendor’s instructions.

Now, you have another option also – After the oil rub, I heated them up to about 125-150F, let them sit for a bit and then rubbed in Sno-Seal boot wax to just really seal things up but also keep the parkerizied look.

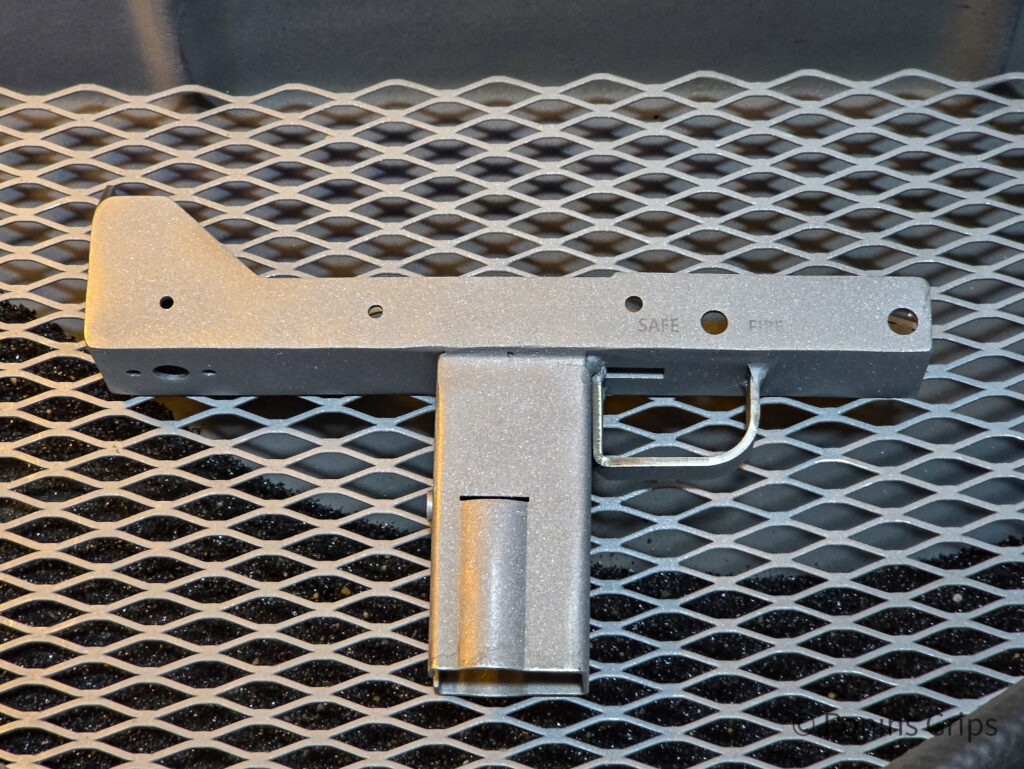

Here’s a view of them together:

Summary

You can definitely do a manganese park at home and make your own recipe that is just as dark as what Velocity does. The receipe and process above are affordable, easy and generate great results as evidenced above.

I hope this helps you out.

Note, I have to buy all of my parts – nothing here was paid for by sponsors, etc. I do make a small amount if you click on an ad and buy something but that is it. You’re getting my real opinion on stuff.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, we are only paid if there is an affiliate program such as Avantlink, Impact, Amazon and eBay and only if you purchase something. If you’d like to directly contribute towards our continued reporting, please visit our funding page.