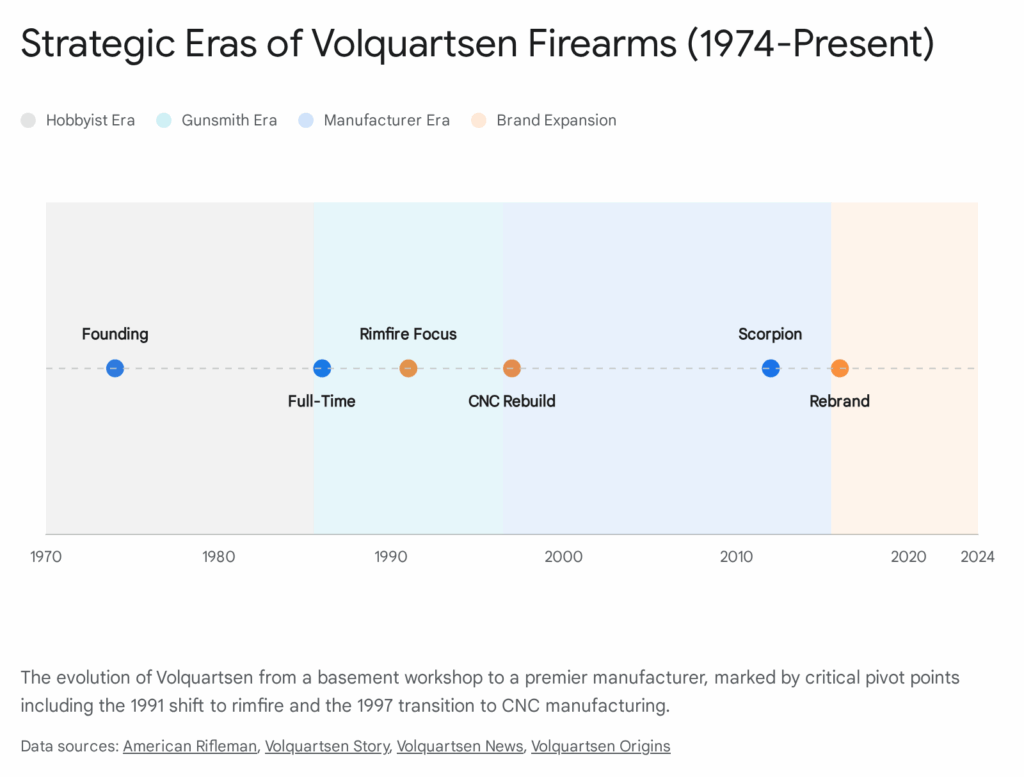

The trajectory of Volquartsen Firearms stands as a definitive case study in the American small arms industry, illustrating the successful evolution from a service-oriented artisan gunsmithing shop to a high-technology manufacturing firm that dominates a specific high-margin niche. Founded in 1974 by Tom Volquartsen in a basement in Carroll, Iowa, the entity originally operated as a generalist refinishing and repair service. Over the subsequent half-century, the firm has navigated critical inflection points—economic uncertainty in the 1980s, a counter-intuitive strategic pivot to the rimfire market in 1991, and a catastrophic facility loss in 1997—to emerge as the premier brand in the precision rimfire segment.

This report provides an exhaustive industry analysis of the company’s corporate history, manufacturing philosophy, and market positioning. Central to this analysis is the identification of the “Rimfire Renaissance,” a market phenomenon largely catalyzed by Volquartsen’s decision to apply aerospace-grade manufacturing tolerances to platforms previously regarded as recreational “plinkers,” specifically the Ruger 10/22 and MK series pistols. By validating the commercial viability of the “super-premium” rimfire category, Volquartsen effectively created the market segment it now leads.

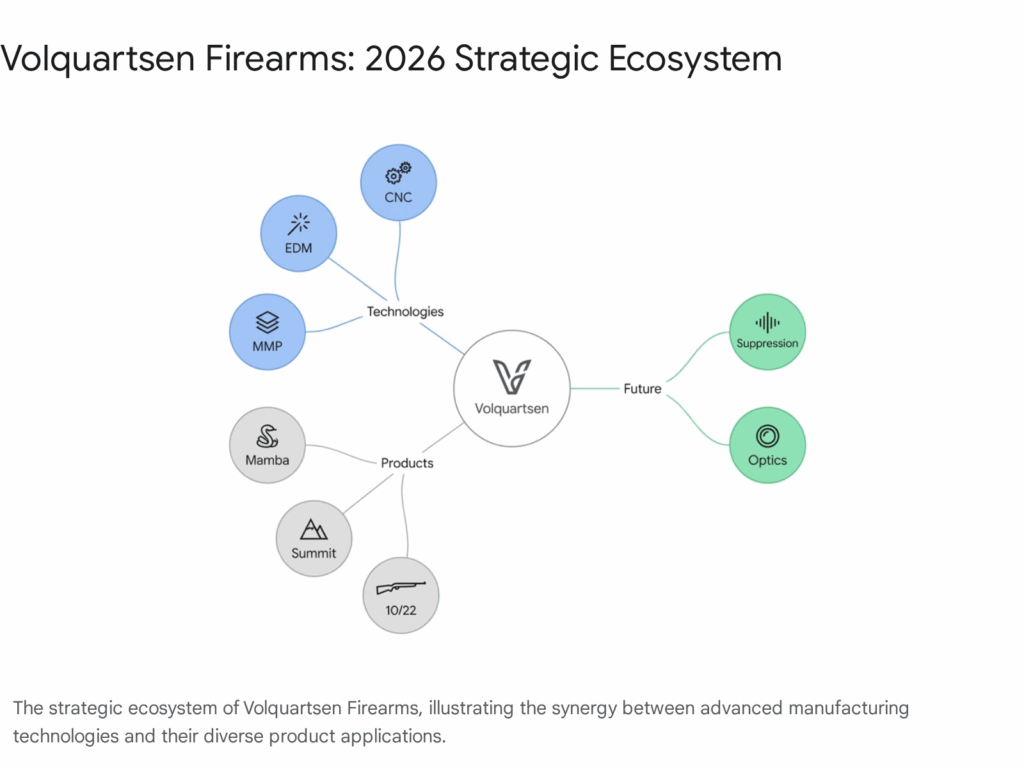

The analysis highlights the company’s operational shift from manual craftsmanship to Computer Numerical Control (CNC) and Wire Electrical Discharge Machining (EDM) in the late 1990s. This transition, forced by the destruction of the original workshop, allowed for the scalability of precision that defines the modern product line, including the Scorpion, Black Mamba, and Summit rifles. Today, under the second-generation leadership of President Scott Volquartsen and Vice President Nic Volquartsen, the firm has diversified beyond aftermarket parts into complete proprietary firearms systems.

Looking toward the operational horizon of 2026, Volquartsen is strategically positioned to capitalize on two converging industry trends: the normalization of acoustic suppression (silencers) and the integration of advanced optics into handgun platforms. Strategic partnerships, such as the 2025 collaboration with Angstadt Arms on integrally suppressed systems, signal a continued commitment to innovation within the National Firearms Act (NFA) space. However, the company faces inherent challenges, including the “commoditization of precision” by mass-market competitors and the distinct regulatory pressures of the U.S. firearms industry. This report concludes that Volquartsen’s enduring value proposition lies in its refusal to compromise on the “heirloom quality” ethos, securing its status not merely as a manufacturer, but as a legacy brand for the sophisticated shooter.

1. Introduction: The Rimfire Paradox and Industry Context

To fully appreciate the ascendancy of Volquartsen Firearms, one must first deconstruct the “Rimfire Paradox” that characterized the firearms industry for much of the 20th century. Historically, the.22 Long Rifle (LR) cartridge and the firearms chambered for it were relegated to the bottom tier of the manufacturing hierarchy. In the eyes of major manufacturers and consumers alike, rimfire was synonymous with “entry-level.” These were the rifles given to children to learn safety; they were tools for pest control on farms; they were tin-can plinkers.

Because the ammunition was inexpensive and the recoil negligible, the industry standard for rimfire firearm production was “acceptable functionality,” not “precision excellence.” Triggers were often heavy and gritty, barrels were mass-produced with loose tolerances, and receivers were cast from inexpensive alloys. The prevailing industry logic was circular: consumers wouldn’t pay a premium for a.22, so manufacturers didn’t build premium.22s.

Volquartsen Firearms challenged and eventually shattered this paradox. Their history is not just the story of a company, but the story of a fundamental shift in consumer psychology. They bet the existence of their family business on the hypothesis that adult shooters—competitive marksmen, discerning hunters, and gear enthusiasts—would indeed pay centerfire prices for rimfire performance, provided that the performance was genuinely superior. The success of that bet has reshaped the modern firearms landscape, spawning an entire ecosystem of high-end rimfire competitions (such as the NSSF Rimfire Challenge and NRL22) and aftermarket support industries.

2. The Genesis of Precision (1974–1990)

The origins of Volquartsen Firearms adhere to the classic archetype of American industrial entrepreneurship: the garage startup born of passion rather than profit maximization. However, the specific conditions of its founding in the mid-1970s provide critical context for its later obsession with quality.

2.1 The Basement Workshop and the Artisan Ethic (1974–1984)

In 1974, Tom Volquartsen established the nascent business in the basement of a rented home in Carroll, Iowa.1 At this juncture, the operation was strictly a part-time endeavor. Tom maintained a full-time position within the government sector, dedicating his nights and weekends to the trade.1

The 1970s were a transitional period for American gunsmithing. The market was dominated by generalists. A gunsmith in a town like Carroll was expected to be a jack-of-all-trades: capable of re-bluing a rusted duck gun, bedding a deer rifle, fixing a revolver timing issue, and refinishing a stock, all within the same week. Tom Volquartsen cut his teeth in this demanding environment. His initial scope of work focused heavily on aesthetics and restoration—refinishing old hunting rifles and bluing shotguns—but quickly expanded into performance enhancement, specifically trigger work on bullseye pistols.2

This period was foundational for the company’s culture. Working on “other enthusiasts’ firearms” 1 meant that every job was a custom commission. There was no assembly line; there was only the specific request of a specific customer. This instilled a service-oriented mindset that persists today. More importantly, it allowed Tom to reverse-engineer the failures of mass production. By seeing hundreds of guns come in for repair or improvement, he gained an intuitive understanding of where factory engineering fell short—knowledge that would later inform his own designs.

2.2 The Leap of Faith: Full-Time Transition (1986)

By 1984, the Volquartsen family had relocated to a property with acreage, allowing for the construction of a dedicated shop detached from the residence.1 This physical expansion was the precursor to a professional metamorphosis. The demand for Tom’s services had steadily grown, fueled entirely by local reputation and word-of-mouth referrals. The “hobby” was now consuming all available bandwidth.

In 1986, facing the classic entrepreneur’s dilemma, Tom Volquartsen made the decisive leap to leave his secure government employment and pursue the business full-time.1 Historical context renders this decision particularly bold. The mid-1980s in the American Midwest were economically turbulent, often referred to as the “Farm Crisis.” Disposable income for luxury services like custom gunsmithing was not abundant. Furthermore, the Volquartsen family, consisting of Tom, his wife, and two children (Scott and Nic), relied entirely on this new venture. Anecdotal evidence underscores the financial precarity of this era: the family’s sole mode of transportation was a Volkswagen Beetle.1

This full-time transition marked the shift from “Tom Volquartsen, the guy who fixes guns” to “Volquartsen Custom,” a professional entity. It allowed for a drastic reduction in turnaround times and the capacity to take on more complex, labor-intensive projects that were impossible to complete during mere evenings and weekends.

2.3 The Media Catalyst (1989)

In the pre-digital era, the gatekeepers of success in the firearms industry were the editors of the major print publications: American Rifleman, Guns & Ammo, Shooting Times, and American Handgunner. A product or service effectively did not exist outside of one’s local zip code unless it appeared in these pages.

Volquartsen’s ascent from a regional Iowa secret to a national brand occurred in the late 1980s. The quality of Tom’s work caught the eye of industry writers, leading to a series of reviews. The inflection point arrived in 1989 when Tom Volquartsen and his work were featured on the cover of American Handgunner.2 The impact was immediate and transformative. In an industry driven by reputation, a cover feature serves as the ultimate validation. It signaled to the national market that this small Iowa shop was producing work on par with the legendary custom houses of the era.

The resulting influx of orders created a backlog that fundamentally changed the operational tempo of the business. It was no longer about finding work; it was about managing a deluge of it. This period also saw the increasing involvement of the family, with Tom’s wife managing the administrative chaos and a young Scott Volquartsen beginning to absorb the business operations, sweeping floors and cleaning machines.3

3. The Pivot and the Fire: Strategic Reorientation (1991–2000)

The 1990s represented the most tumultuous and defining decade in the company’s history. It was characterized by a radical strategic gamble that defied industry wisdom and a literal trial by fire that forced a technological rebirth.

3.1 The 1991 Strategic Pivot: The Bet on the 10/22

In early 1991, amidst the boom following the media exposure, Tom Volquartsen made a controversial strategic decision: he decided to narrow the company’s focus exclusively to the rimfire market, specifically targeting the Ruger 10/22 platform.1

To understand the audacity of this move, one must contextualize the Ruger 10/22 in 1991. It was a ubiquitous, utilitarian semi-automatic rifle found in hardware stores across America for under $100.4 It was iconic, but it was not “high-end.” The prevailing wisdom among distributors and barrel makers was that the 10/22 was a “throwaway” gun—economical enough that if it broke, one might just buy another.

When Tom approached barrel manufacturers to produce high-grade, match-chambered barrels for the 10/22, he was met with refusal and derision.4 The industry consensus was that “nobody is going to pay that to upgrade an inexpensive 22”.4 Distributors were equally skeptical. Why would a customer spend $200 on a trigger group for a $100 rifle?

Tom, however, identified a “Blue Ocean” opportunity. He recognized that the 10/22’s modular design was akin to the Small Block Chevrolet engine—capable of immense performance if the components were optimized. He saw that shooters wanted the low cost and low recoil of rimfire ammunition but were frustrated by the lack of accuracy in factory rifles. By offering match-grade barrels, precision extractors, and crisp trigger assemblies, Volquartsen created a new value proposition: the “Ultimate 10/22.”

This pivot was not just a product change; it was a business model change. It moved the company away from the high-labor, low-volume model of “one-off” custom gunsmithing toward a product-based model where standardized (albeit high-quality) parts could be manufactured and sold.

3.2 The Twin Infernos (1991 and 1997)

The company’s resilience was tested by two devastating fires. The first occurred in 1991, shortly after the strategic pivot. While damaging, the business recovered.1 However, in 1997, a second, far more catastrophic inferno struck. This fire burned the facility to the ground, resulting in a total loss of the physical plant, tooling, and inventory.1

For a family business, such an event is often an extinction-level crisis. The insurance settlements and the daunting prospect of rebuilding from ash often lead founders to retire or seek employment elsewhere. The Volquartsen family, however, chose to rebuild. This decision to reconstruct the business was the second critical inflection point of the decade.

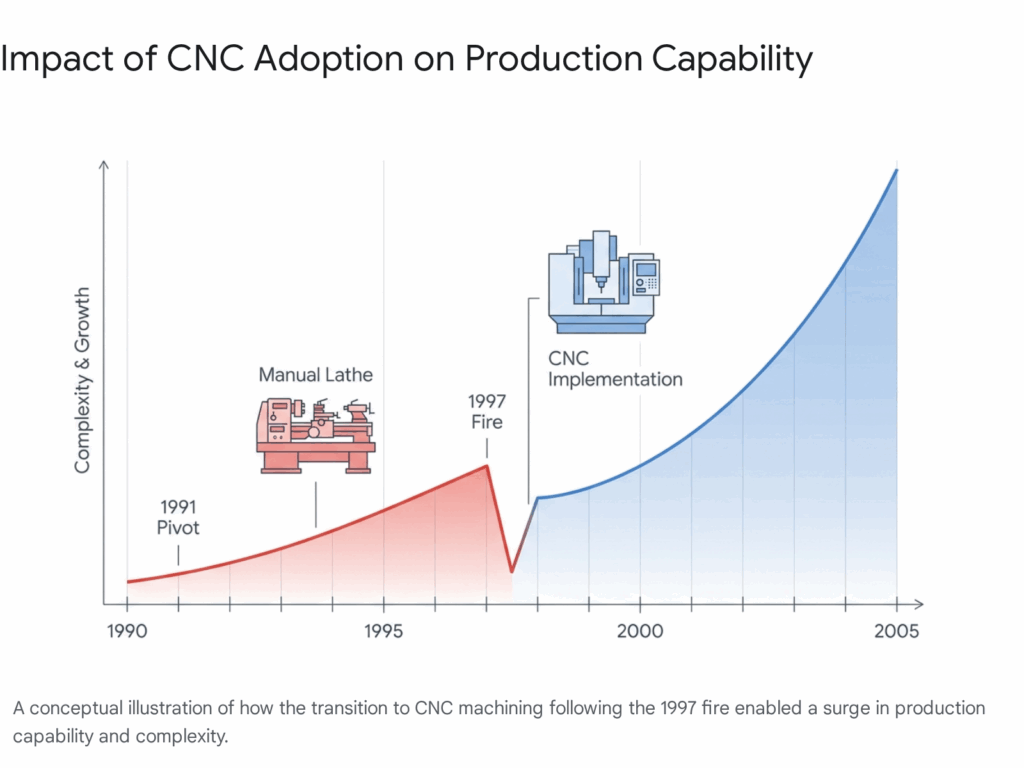

3.3 The Technological Renaissance: The CNC Revolution

The destruction of the facility had a paradoxical silver lining: it forced a modernization of the manufacturing floor. Prior to the fire, the shop relied heavily on manual lathes and mills—machines that required a skilled operator to guide every cut by hand.

When equipping the new facility in 1998, the Volquartsens did not replace the manual machines with identical units. Instead, they invested in Computer Numerical Control (CNC) machining centers.4 This shift was transformative for three reasons:

- Repeatability: A manual machinist, no matter how skilled, has variances between parts. A CNC machine can reproduce the same dimension to within ten-thousandths of an inch thousands of times in a row.

- Scalability: CNC allowed the company to produce parts in batches, satisfying the growing demand that manual machining could never keep up with.

- Complexity: CNC allowed for the design of complex geometries and internal cuts that were physically impossible or cost-prohibitive to execute by hand.

This transition marked the end of Volquartsen as a “shop” and its beginning as a “factory.”

3.4 The First Proprietary Firearm (1997)

Leveraging this new capability, Volquartsen moved from making parts for Ruger rifles to making their own rifles. In 1997, they released their first complete firearm: a semi-automatic rifle chambered in.22 WMR (Winchester Magnum Rimfire).6

This project was an engineering gauntlet. The.22 WMR is a significantly more powerful cartridge than the.22 LR, operating at higher pressures. Designing a blowback semi-automatic action that could handle these pressures without tearing the brass case apart or battering the receiver was considered nearly impossible by industry peers. “You are never going to get it to shoot accurately and furthermore you’ll never get it to function!” was the feedback Tom received at SHOT Show 1997.6

Undeterred, the team engineered a solution involving a heavy, tungsten-weighted bolt and a precisely tuned recoil spring system. The success of this rifle did more than generate revenue; it proved Volquartsen’s engineering chops. They were no longer just modifying existing designs; they were solving ballistic engineering problems that larger companies avoided.

4. Technical Mastery: The Engineering of Volquartsen

In the contemporary firearms market, “precision” is a marketing buzzword often applied loosely. For Volquartsen, however, precision is a measurable outcome of specific manufacturing technologies and material choices. The company’s reputation as the “Ferrari of Rimfire” 7 is built on a foundation of metallurgy and advanced machining processes that exceed standard industry practices.

4.1 The Role of Wire EDM

One of the most significant differentiators in Volquartsen’s manufacturing arsenal is the use of Wire Electrical Discharge Machining (EDM).8 Traditional machining involves a cutting tool physically carving metal, which creates heat and stress on the part. Wire EDM, conversely, uses an electrically charged brass wire to cut through conductive materials (like hardened tool steel) using electrical sparks.

This process is slow and expensive, but it offers two critical advantages for firearm components:

- Zero Stress: Because there is no physical contact between the cutter and the part, the metal is not warped or stressed during the cut. This is vital for trigger sears and hammers, where surface geometry must be perfect to ensure a crisp, safe trigger pull.

- Hardened Steel Cutting: EDM can cut steel that has already been heat-treated. This means Volquartsen can harden their trigger parts before cutting them to final dimensions, eliminating the risk of the part warping during the heat-treat process—a common issue in mass-produced triggers.

4.2 CNC and 5-Axis Machining

The evolution from the manual machines of the pre-1997 era to modern CNC centers has allowed for “Digital Gunsmithing.” The company utilizes 5-axis CNC machines, which can rotate the part on multiple axes simultaneously. This allows for the machining of complex features, such as the integral Picatinny rails on their receivers, in a single setup. By not having to remove and re-fixture the part for different cuts, the concentricity and alignment of the receiver are maintained to a degree impossible with traditional 3-axis milling.

4.3 MMP Technology

To achieve the “glass rod” break their triggers are famous for, Volquartsen employs a proprietary Micro Machining Process (MMP Technology).8 This is a surface treatment technology that deburrs and polishes the internal surfaces of the sear and hammer to a mirror-like finish. While many gunsmiths polish triggers by hand using stones—a process prone to human inconsistency—MMP uses a fluid-based micro-abrasive process that uniformly treats the entire surface. This results in a friction coefficient that is drastically lower than standard machined steel, providing the tactile smoothness that defines the brand’s feel.

5. Defining the “Super-Premium” Rimfire: Product Ecosystem

Volquartsen’s product strategy has evolved from selling parts to improve other manufacturer’s guns to selling complete ecosystems that render the original platforms obsolete. Their current catalog is segmented into distinct families, each addressing a specific shooting discipline.

5.1 The Scorpion: Dominating the Competition

Launched in 2012, the Scorpion.22 LR target pistol was a watershed moment for the company.9 Before the Scorpion, competitive shooters in disciplines like the Steel Challenge Shooting Association (SCSA) typically used Ruger MKII or MKIII pistols that had been heavily modified by gunsmiths. These pistols were heavy, steel-framed, and difficult to balance.

The Scorpion disrupted this paradigm by introducing the LLV (Lightweight, Laser-hardened, Volquartsen) upper receiver. The LLV is constructed from aluminum alloy for lightness but features a stainless steel barrel liner for accuracy. This design significantly reduced the muzzle weight, allowing competitive shooters to transition between targets faster. The Scorpion became the dominant pistol in speed shooting sports, claiming the last three rimfire world championships.9 It proved that a dedicated race gun could be manufactured as a production item, rather than a one-off custom build.

5.2 The Black Mamba: The Hybrid Evolution

Following Ruger’s release of the MK IV platform—which featured a revolutionary push-button takedown system that solved the MK series’ notorious cleaning difficulty—Volquartsen acted quickly to integrate this convenience. In 2019, they released the Black Mamba.9

The Black Mamba is a hybrid design. It utilizes a Ruger MK IV polymer frame (for the takedown mechanics) but retrofits it with Volquartsen’s Accurizing Kit (trigger internals) and mates it to a Volquartsen LLV Competition Upper. This product exemplifies the company’s pragmatic approach: they are not afraid to use a competitor’s frame innovation (the Ruger button) if it serves the user, provided they can upgrade the rest of the system to their standards. The Mamba line has since expanded to include the Mamba-X, which features a specialized upper with direct-mounting points for red dot sights, reflecting the modern trend toward opto-electronic sighting systems.10

5.3 The Summit: The Bolt-Action Reinvented

In 2018, Volquartsen stepped out of their semi-automatic comfort zone to release the Summit Rifle.9 Developed in collaboration with Primary Weapons Systems (PWS), the Summit features a straight-pull toggle-bolt action inspired by the biathlon rifles of the Winter Olympics.

The strategic brilliance of the Summit lies in its appeal to the suppression market. Semi-automatic rimfires are inherently noisy because the action opens while pressure is still in the barrel, creating “port pop.” A bolt action keeps the breech sealed, forcing all gas out the muzzle. By combining the speed of a toggle action with the silence of a locked breech, the Summit became the ideal host for a suppressor—a “quiet professional’s” tool for discrete pest control or backyard practice.

5.4 The VM-22 and the Superlite Receiver

The VM-22 rifle demonstrates the company’s mastery of materials. It features a Superlite aluminum receiver and a carbon-fiber tensioned barrel. The tensioned barrel design is a key Volquartsen innovation: a thin steel barrel liner is placed under tension inside a carbon fiber or aluminum sleeve. This provides the rigidity of a heavy bull barrel without the weight, eliminating the harmonic vibration issues that plague standard thin barrels while keeping the rifle light enough for field carry.11

6. The Ballistic Frontier: Caliber Innovations

While many manufacturers stick to the ubiquitous.22 LR, Volquartsen has built a reputation for fearlessly adopting niche and emerging rimfire calibers.

6.1 The.22 WMR (Magnum) Legacy

As detailed in the history section, the.22 WMR semi-auto was Volquartsen’s first proprietary firearm. They have continued to refine this platform, which is now a staple for varmint hunters who need more energy than a.22 LR can provide but do not want the noise or expense of a centerfire cartridge.

6.2 The .17 HMR Explosion

When Hornady introduced the .17 Hornady Magnum Rimfire (HMR) in 2002, it revolutionized the rimfire world with its flat trajectory. Volquartsen was among the first to offer reliable semi-automatic rifles in this caliber. The .17 HMR operates at a pressure curve that is difficult to manage in a blowback action, but Volquartsen’s experience with the .22 WMR allowed them to adapt quickly, capturing the early adopter market for this high-speed cartridge.

6.3 The .17 WSM: Chasing Speed

In 2012, Winchester released the .17 Winchester Super Magnum (WSM), the fastest rimfire cartridge in existence, capable of 3,000 feet per second.13 This cartridge is based on a .27-caliber nail gun blank and operates at pressures far exceeding standard rimfire rounds. While most manufacturers shied away from making a semi-auto for such a high-pressure round, Volquartsen accepted the challenge.

Released in 2014, the Volquartsen .17 WSM Semi-Auto remains a marvel of rimfire engineering.9 It utilizes a delayed blowback system and a heavy bolt to ensure safe operation. By being the only company to successfully mass-produce a semi-auto in this caliber for years, Volquartsen cornered the market for hunters demanding the ultimate in rimfire velocity.

7. Market Dynamics and Competitive Landscape

Volquartsen occupies a unique “Super-Premium” tier in the rimfire market. To understand their success, one must analyze where they sit in the competitive matrix.

7.1 The “Ferrari of Rimfire” Positioning

The company’s pricing strategy is unapologetically premium. A standard Ruger 10/22 might retail for $300. A Volquartsen Superlite rifle retails for over $1,800.

- Target Demographics: The customer base is distinct. It includes competitive shooters who view the firearm as a tool of the trade; serious small-game hunters who require sub-MOA (Minute of Angle) accuracy; and affluent collectors who appreciate fine machining as an “heirloom” asset.

- Value Proposition: The core value proposition is the elimination of mechanical variables. As noted by reviewers, “my misses are normally caused by me… rarely is it the Volquartsen’s fault”.14 The customer pays a premium for the psychological assurance that their equipment is not the limiting factor in their performance.

7.2 The Competitive Field

- KIDD Innovative Design: Based in Texas, KIDD is the primary direct competitor in the high-end 10/22 market. Founded by Tony Kidd, they offer triggers and actions of comparable quality. The rivalry is akin to Mercedes vs. BMW; fans of each brand are fiercely loyal, with preferences often coming down to subjective feel (e.g., the shape of the trigger shoe or the aesthetic of the receiver).

- Tactical Solutions (Pac-Lite): This company competes in the lightweight barrel and receiver space. Their products are generally positioned at a slightly lower price point than Volquartsen’s flagship items, appealing to the “pro-sumer” rather than the elite competitor.

- The Custom Shop Ecosystem: The 10/22 market is flooded with small, one-man gunsmithing shops. While these artisans can produce exceptional work, they lack the manufacturing scale, warranty support, and brand equity of Volquartsen. Volquartsen competes with them by offering “off-the-shelf” custom quality—a rifle you can buy today without a 12-month waitlist.

8. Marketing and Brand Architecture

Volquartsen has successfully navigated the transition from “product-centric” marketing to “brand-centric” marketing.

8.1 Rebranding: From “Custom” to “Firearms”

In 2016, the company officially changed its trading name from “Volquartsen Custom” to “Volquartsen Firearms“.9 This semantic shift was strategic. “Custom” implies a service bureau that modifies other people’s products. “Firearms” implies a primary manufacturer. This change aligned the corporate identity with the operational reality that the vast majority of their revenue now came from selling complete, serialized weapons.

8.2 Content Marketing and The Podcast

Under the leadership of Scott Volquartsen, the company has embraced modern digital media. The launch of the “No Excuse to Miss” podcast is a prime example.15 Rather than just pushing product specs, the podcast features interviews with hunters, shooters, and motivational figures. It positions the brand not just as a seller of guns, but as a purveyor of a mindset—one of discipline, persistence, and excellence. This content strategy builds a community around the brand, fostering loyalty that transcends transactional sales.

8.3 Sponsorship and Social Proof

Volquartsen heavily leverages “social proof” by sponsoring top-tier shooters like Cheyenne Dalton and Kolby Pavlock.3 Seeing these juniors and professionals win world titles using Volquartsen hardware provides irrefutable evidence of the product’s performance. It creates an aspirational link: “If I want to shoot like a champion, I need the tool the champions use.”

9. Current Operations and Future Trajectory (2025–2030)

As of 2025, Volquartsen Firearms operates out of an expanded facility in Carroll, Iowa, having added 17,500 square feet of manufacturing space in 2015 to house their growing fleet of CNC machines.9 The workforce has tripled since 2010, reflecting sustained growth.9

9.1 Strategic Partnership: Angstadt Arms (2025)

A major indicator of the company’s future direction is the partnership announced at SHOT Show 2025 with Angstadt Arms.18 This collaboration aims to produce a line of integrally suppressed 10/22 rifles.

- Context: The U.S. market is seeing a normalization of suppressors (silencers). Wait times for NFA paperwork have decreased, and consumer awareness of hearing safety is at an all-time high.

- Implication: By partnering with Angstadt, known for their “Vanquish” porting technology, Volquartsen is positioning itself at the forefront of the “Quiet Rimfire” movement. This suggests a future product roadmap heavily focused on NFA-compliant integrated systems that offer hearing-safe shooting out of the box.

9.2 The Optics-First Paradigm

The release of the Mamba-X and Scorpion-X uppers signals a definitive shift toward optics-only firearms.10 These uppers lack iron sights entirely, featuring instead a system of drilled and tapped holes for direct-mounting red dot sights. This mirrors the broader industry trend where pistol-mounted optics are becoming the standard, not the exception. Volquartsen is betting that the future of rimfire competition is electronic, designing their receivers to lower the optic’s height-over-bore for a more natural point of aim.

9.3 50th Anniversary and the “Heirloom” Strategy

Having celebrated their 50th year in 2024, the company is leveraging its heritage as a key differentiator.5 In an era of disposable consumer goods and polymer-framed pistols that feel utilitarian, Volquartsen is doubling down on the “heirloom quality” narrative. They are positioning their steel and aluminum firearms as investments that will be passed down to the next generation. This strategy insulates them from the race-to-the-bottom pricing of mass manufacturers.

10. Conclusion

Volquartsen Firearms has successfully navigated the perilous journey from a basement hobby to a global industry leader by adhering to a counter-intuitive principle: in a market obsessed with cost-cutting, there is always a customer willing to pay for perfection.

The company’s history is defined by three pillars:

- Visionary Risk: The 1991 pivot to the 10/22 market created a category that did not previously exist.

- Technological Resilience: The 1997 fire forced a modernization that, while traumatic, provided the CNC capabilities necessary for today’s dominance.

- Generational Continuity: The successful transition of leadership to Scott and Nic Volquartsen has preserved the founder’s ethos while injecting modern marketing and R&D strategies.

As the industry moves toward 2030, Volquartsen faces the challenge of maintaining its premium status in a market increasingly crowded with imitators. However, their continued investment in difficult-to-master technologies like wire EDM, their agility in adopting new calibers like.17 WSM, and their strategic partnerships in the NFA space suggest that they will remain the benchmark against which all other rimfire firearms are measured. They have successfully transformed the humble.22 rifle from a child’s toy into a precision instrument, and in doing so, they have secured their legacy in the annals of American firearms history.

11. Milestones Summary

The following table summarizes the key milestones in the history of Volquartsen Firearms, sorted chronologically.

| Year | Milestone Event | Context/Significance |

| 1974 | Founding | Tom Volquartsen starts the business in a rented basement in Carroll, Iowa, as a part-time hobby focused on refinishing and basic repairs. 1 |

| 1984 | Facility Expansion | Family moves to a home with acreage; a dedicated shop is built to house the growing operation, moving work out of the basement. 1 |

| 1986 | Full-Time Operations | Tom Volquartsen leaves his government job to pursue gunsmithing full-time, a significant financial risk for the family. 1 |

| 1989 | Media Breakout | Tom Volquartsen featured on the cover of American Handgunner, sparking national demand and a backlog of orders. 1 |

| 1991 | Strategic Pivot | Decision made to specialize exclusively in the rimfire market (Ruger 10/22), abandoning general gunsmithing work. 1 |

| 1991 | First Fire | A fire strikes the business, causing setbacks but not total ruin. 1 |

| 1997 | The Great Fire | Operations burn to the ground. The rebuild catalyzes the switch from manual to CNC machines, transforming the company into a manufacturer. 1 |

| 1997 | First Firearm | Release of the first complete Volquartsen rifle: the semi-auto.22 WMR, proving their engineering independence. 6 |

| 2012 | Scorpion Launch | Launch of the Scorpion.22 LR Target Pistol, a major success in competitive shooting (Steel Challenge). 9 |

| 2012 | Facility Expansion | An addition is put onto the facility, which quickly fills up due to rapid growth. 20 |

| 2014 | .17 WSM Semi-Auto | Release of the first semi-automatic rifle for the new Winchester.17 WSM cartridge, beating major manufacturers to market. 13 |

| 2015 | New Facility | Acquisition of a second location adding 17,500 sq. ft. for machining and offices. 9 |

| 2016 | Rebranding | Company name changes from “Volquartsen Custom” to “Volquartsen Firearms,” signaling the shift to manufacturing. 9 |

| 2017 | Scorpion.22 WMR | Release of the “big brother” to the Scorpion pistol in.22 Magnum. 9 |

| 2018 | Summit Rifle | Launch of the straight-pull bolt action Summit Rifle, targeting the suppressor market. 9 |

| 2019 | Black Mamba | Launch of the Black Mamba pistol, utilizing the Ruger MK IV frame for easy takedown. 9 |

| 2024 | 50th Anniversary | Volquartsen celebrates 50 years in business, emphasizing their “heirloom” legacy. 5 |

| 2025 | Suppression Partnership | Collaboration with Angstadt Arms announced at SHOT Show for integrally suppressed rifles. 18 |

Appendix A: Methodology

This report was compiled using a qualitative meta-analysis of publicly available industry data, press releases, historical interviews with company leadership, and third-party media reviews.

Data Collection:

Research material was aggregated from a diverse set of sources to ensure a balanced perspective:

- Primary Sources: Official press releases from Volquartsen Firearms, “No Excuse to Miss” podcast transcripts featuring Scott and Nic Volquartsen, and direct email newsletters (Retail Mailers) from the company archives. These sources provided the internal narrative and specific dates for product launches.

- Secondary Sources: Articles from established firearms industry publications such as American Rifleman, Shooting Illustrated, Guns Magazine, and American Handgunner. These provided third-party validation of the company’s timeline and market impact.

- Multimedia Analysis: Review of video content from SHOT Show interviews (TFB TV, etc.) and product reviews to verify release dates, technical specifications, and the reception of specific products like the.17 WSM semi-auto.

- Government Data: Utilization of ATF AFMER (Annual Firearms Manufacturing and Export Report) data (where referenced in industry summaries) to contextualize the broader production trends in the U.S. firearms market.

Analytical Approach:

- Historical Reconstruction: The timeline was constructed by cross-referencing interview anecdotes (e.g., the “VW Beetle” story) with hard dates from business filings and magazine publication dates to create a definitive chronology.

- Market Positioning Analysis: The “Super-Premium” positioning was derived by comparing Volquartsen’s product features (EDM internals, stainless steel construction) and price points against known industry standards for the Ruger 10/22 and MK series platforms.

- Technological Contextualization: The analysis of manufacturing shifts (Manual to CNC) was informed by general industrial knowledge of machining processes applied to the specific claims made in Volquartsen’s technical literature.

Limitations:

Specific financial data (annual revenue, net profit, precise unit volume) for Volquartsen Firearms is private and not publicly disclosed. Therefore, financial health and growth analysis relies on proxy metrics such as facility square footage expansion, employee headcount growth (implied), and the rate of new product introduction.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, we are only paid if there is an affiliate program such as Avantlink, Impact, Amazon and eBay and only if you purchase something. If you’d like to directly contribute towards our continued reporting, please visit our funding page.

Sources Used

- Volquartsen Firearms: From Tinkering To Rimfire Specialization | An Official Journal Of The NRA – American Rifleman, accessed January 17, 2026, https://www.americanrifleman.org/content/volquartsen-firearms-from-tinkering-to-rimfire-specialization/

- Volquartsen Firearms Official Site, accessed January 17, 2026, https://volquartsen.com/media/story

- Scott Volquartsen: The Man Behind the VF Curtain – Women’s Outdoor News -, accessed January 17, 2026, https://www.womensoutdoornews.com/2017/11/scott-volquartsen-firearms/

- Here’s How It All Began – Part 2 – Volquartsen Firearms Official Site, accessed January 17, 2026, https://volquartsen.com/retail_mailers/2019-05-01-here-s-how-it-all-began-part-2

- 2024 | Our 50th Year In Business – Volquartsen Firearms Official Site, accessed January 17, 2026, https://volquartsen.com/retail_mailers/2023-12-29-2024-our-50th-year-in-business

- We had to prove him wrong. – Volquartsen Firearms Official Site, accessed January 17, 2026, https://volquartsen.com/retail_mailers/2019-06-05-we-had-to-prove-him-wrong

- Rimfire to the EXTREME w/ Scott Volquartsen and Volquartsen Firearms – YouTube, accessed January 17, 2026, https://www.youtube.com/watch?v=6w_bXfsr7ao

- The Evolution of Aftermarket Parts – Volquartsen Firearms Official Site, accessed January 17, 2026, https://volquartsen.com/retail_mailers/2022-03-11-the-evolution-of-aftermarket-parts

- A look back on the decade – Volquartsen Firearms Official Site, accessed January 17, 2026, https://volquartsen.com/retail_mailers/2019-12-30-a-look-back-on-the-decade

- Volquartsen Firearms Expands Pistol Line-Up – Outdoor Wire, accessed January 17, 2026, https://www.theoutdoorwire.com/releases/d604998d-d151-43af-8cef-133c57854045

- The VM-22 Semi-Auto 22 LR Rifle – Volquartsen Firearms Official Site, accessed January 17, 2026, https://volquartsen.com/videos/155

- VM-22 | Volquartsen Firearms, accessed January 17, 2026, https://volquartsen.com/departments/22_lr_rifles/families/vm-22-rifle

- Volquartsen Semi-Auto 17 WSM Debuts at 2014 SHOT Show, accessed January 17, 2026, https://bulletin.accurateshooter.com/2014/01/volquartsen-semi-auto-17-wsm-debuts-at-2014-shot-show/

- Volquartsen Custom Rugers | An Official Journal Of The NRA – Shooting Illustrated, accessed January 17, 2026, https://www.shootingillustrated.com/content/volquartsen-custom-rugers/

- No Excuse To Miss – 38. Evolution of Aftermarket Parts w/Scott Volquartsen [AUDIO ONLY], accessed January 17, 2026, https://www.youtube.com/watch?v=WfJ_31DhPqk

- 38. Evolution of Aftermarket Parts w/Scott Volquartsen, accessed January 17, 2026, https://volquartsen.com/podcast/38

- Team Volquartsen, accessed January 17, 2026, https://volquartsen.com/team

- Angstadt x Volquartsen Integrally Suppressed 10/22s | SHOT Show 2025 – YouTube, accessed January 17, 2026, https://www.youtube.com/watch?v=V7hgg_q3WHU

- Pistol Uppers: Understanding the Similarities & Differences – Volquartsen, accessed January 17, 2026, https://volquartsen.com/retail_mailers/2025-09-17-pistol-uppers-understanding-the-similarities-differences

- We are Expanding!! – Volquartsen Firearms Official Site, accessed January 17, 2026, https://volquartsen.com/retail_mailers/2015-04-29-we-are-expanding