The first thing I like to do when building is to install the trigger guard assembly. In this particular case I had paid extra for an extended paddle mag from a

Arms of America (AoA) and I would not do it again to be completely honest. I’m very familiar and comfortable with the standard AK controls and not only did I find the extended magazine release awkward but it would not fit into my ak-builder jig so I wound up having to trim it off anyways.

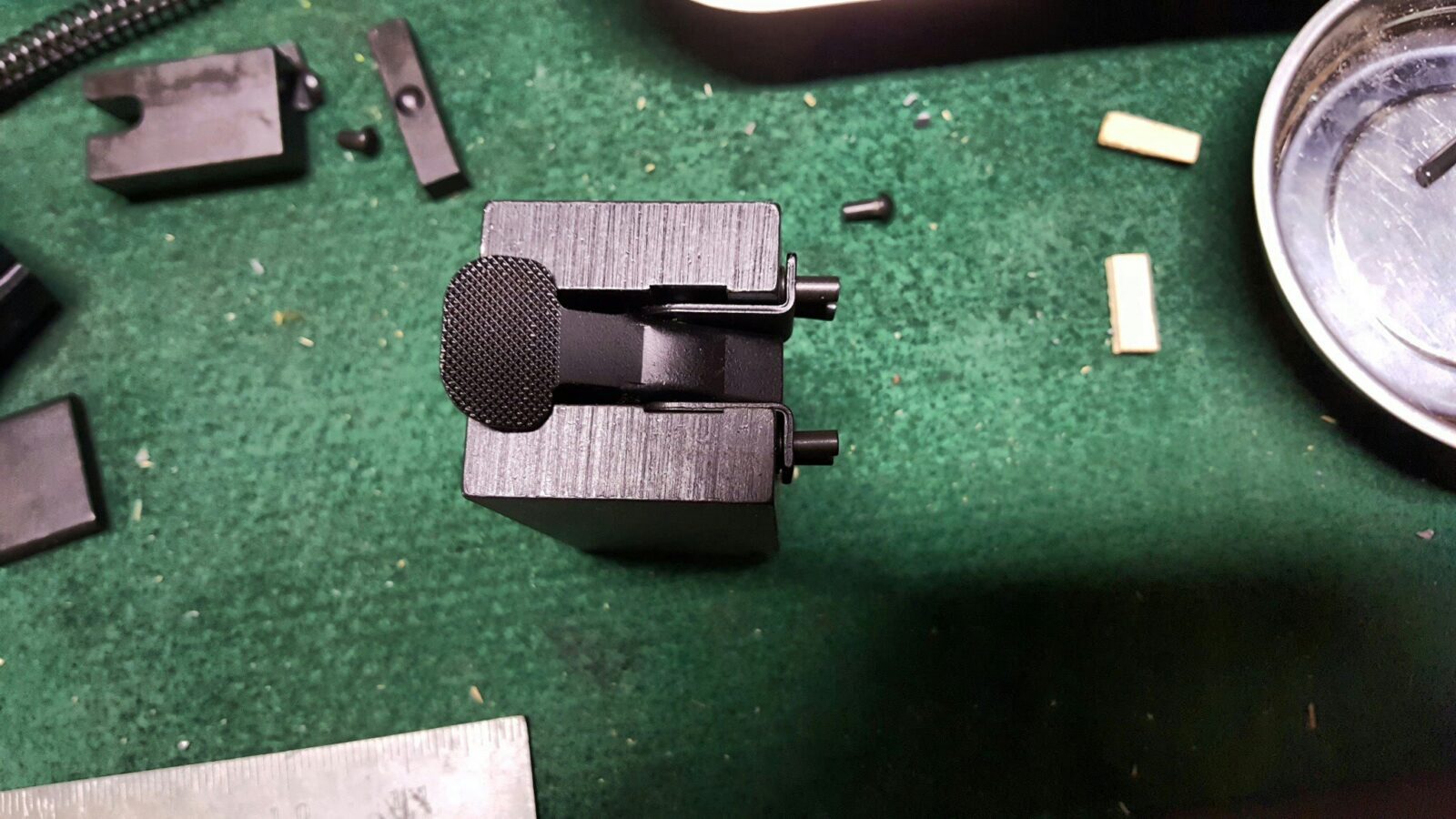

As you can see in this next photo, the paddle hits the front of the ak-builder jig and will not allow the trigger assembly to sit properly. Sure, I could have taken the trigger guard assembly apart and done the frame first but that defeated the purpose of it already being assembled so I simply sanded down the magazine release paddle using the rivet jig as a gauge. Once it fit in, I was good to go. I just did a little bit of cleanup sanding to make everything level and smooth. It was still a little bit bigger than normal but that was fine by me.

One thing you’ll notice in this next photo is that I have the selector stop plate and rivets already in place in The Jig. It is way easier to get them set and then put the receiver down on top of everything then to try and put the rivets in one at a time with the receiver ID place. Be very careful to orient the selector plate with the stop on the correct side. Years ago I did one backwards and it taught me a lesson.

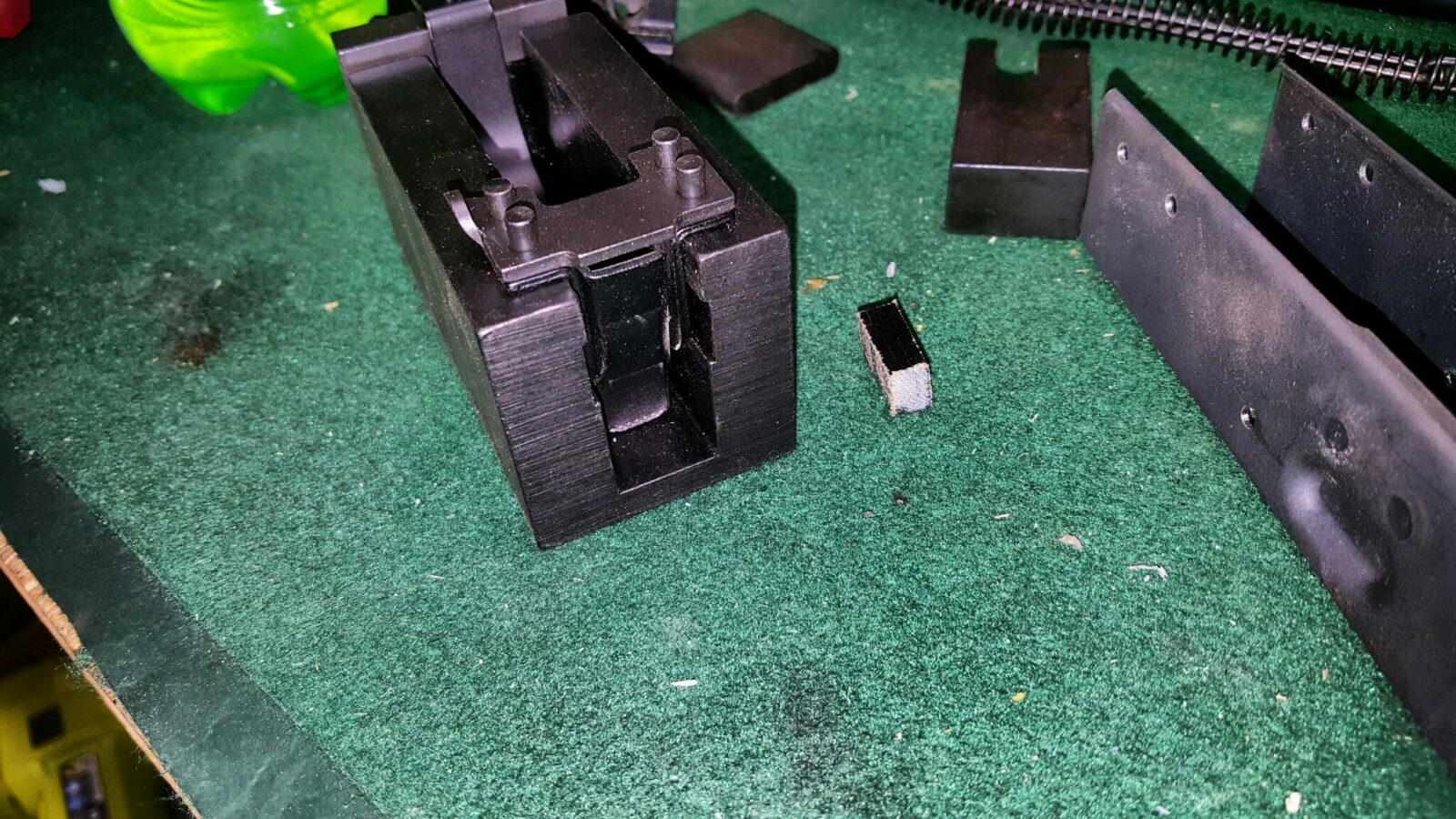

In the above photo you’ll notice a small square plate just above the trigger guard jig and the block with the u-shaped cut out just to the right of the jig and just touching the receiver. Those are what you will use to squish down the rivets.

I use a big H frame hydraulic press to do a lot of my rivet work. I have also used rivet sets and bucking bars for this as well. But for this step I did use the press and my ak-builder jig .Of course, I did not take a photo of this step and I don’t know why 🙂

If you buy a hydraulic press to build AK rifles, I would recommend at least getting a 12 ton unit. I have a 20 ton unit and it works great.

In the below photo you can see two of the four forward rivet sticking up. The square plate goes on that and then you use the bar to apply the pressure from the ram of the press. Keep checking things carefully. It doesn’t take a great deal of pressure to squish the rivets down and you’re looking for them to be flat.

When you get done, the trigger guard will be secured against the receiver, the inside rivets will be flat and the outside rivets will have nice round domes. I am jumping ahead of bit but with the below photo but you can see some of the squished rivets slightly.

And here are the domes that were protected by the dimples cut in the jig.

So that is it for the trigger guard. Next up are the trunnions.

If you find this post useful, please share the link on Facebook, with your friends, etc. Your support is much appreciated and if you have any feedback, please email me at in**@*********ps.com. Please note that for links to other websites, we are only paid if there is an affiliate program such as Avantlink, Impact, Amazon and eBay and only if you purchase something. If you’d like to directly contribute towards our continued reporting, please visit our funding page.